Contents

EB2111/2121/2123 EN

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1-5

1.2 Notes on possible personal injury ................................................................1-5

1.3 Notes on possible property damage.............................................................1-7

2 Markings on the device ..............................................................................2-1

2.1 Valve nameplate .........................................................................................2-1

2.2 Nameplate of the control thermostat .............................................................2-2

2.3 Location of the nameplates ..........................................................................2-2

2.4 Materialidenticationnumber .....................................................................2-2

2.4.1 Type2111andType2422Valve .................................................................2-2

2.4.2 Types2231to2235ControlThermostat .......................................................2-2

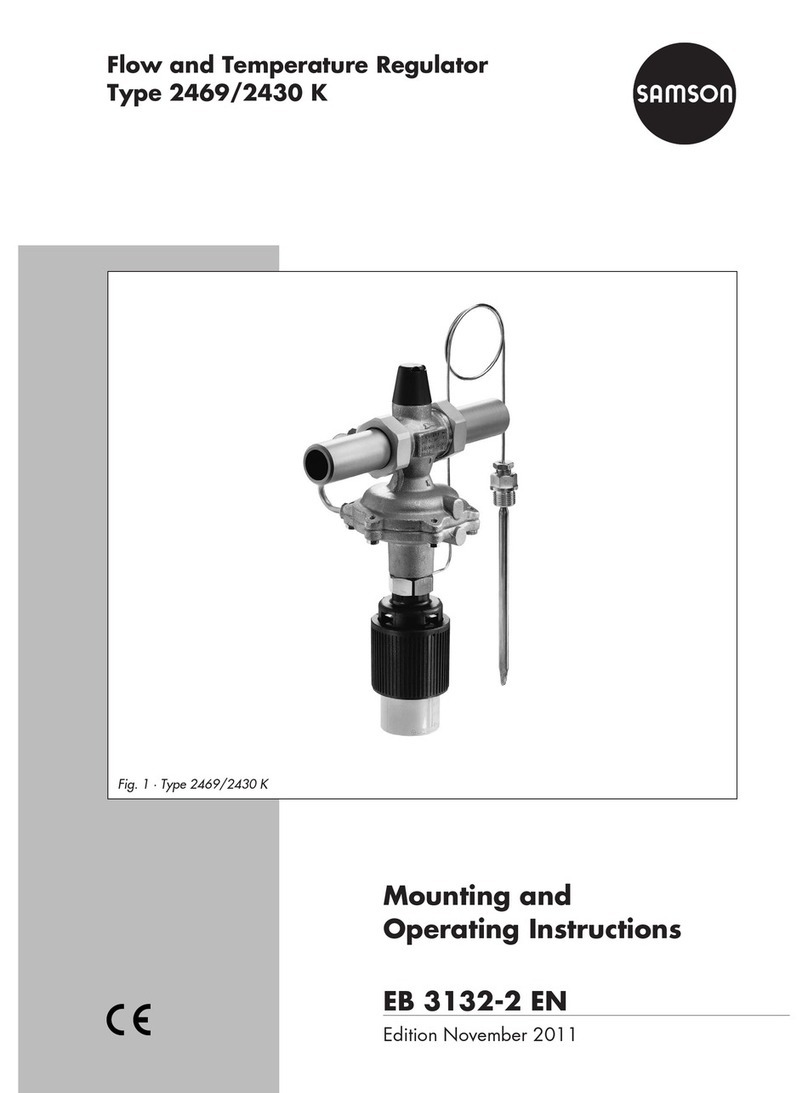

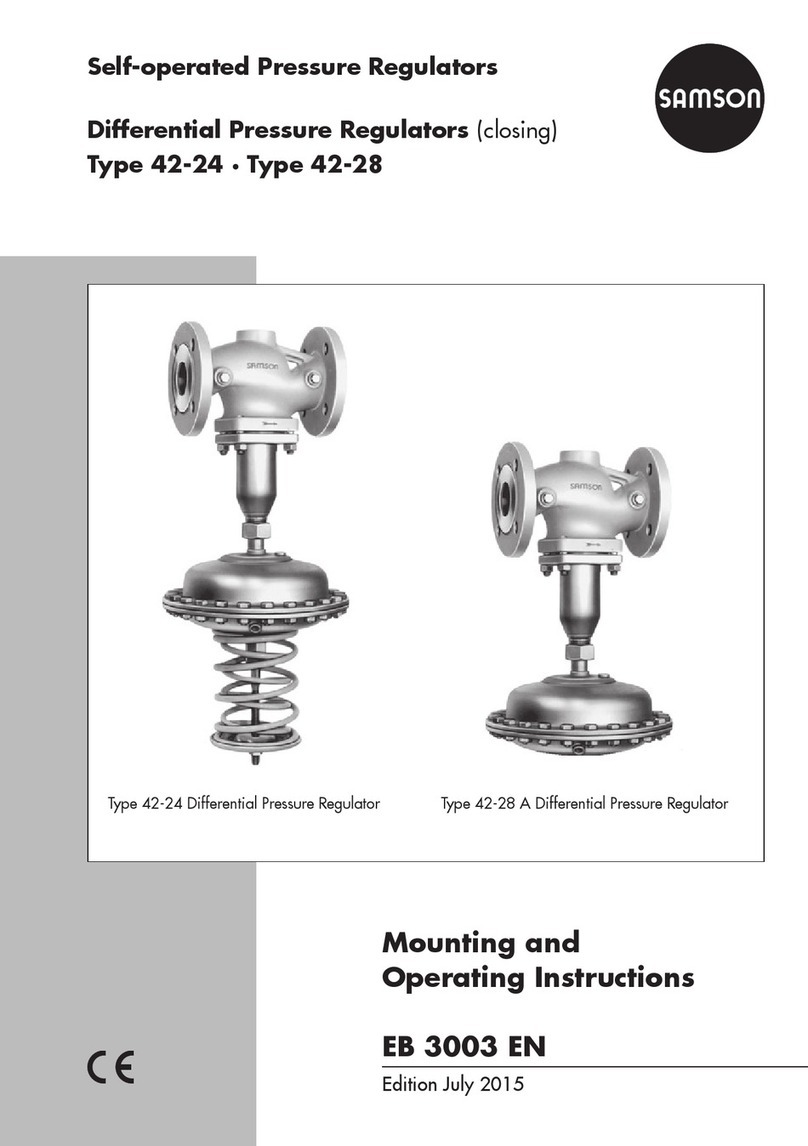

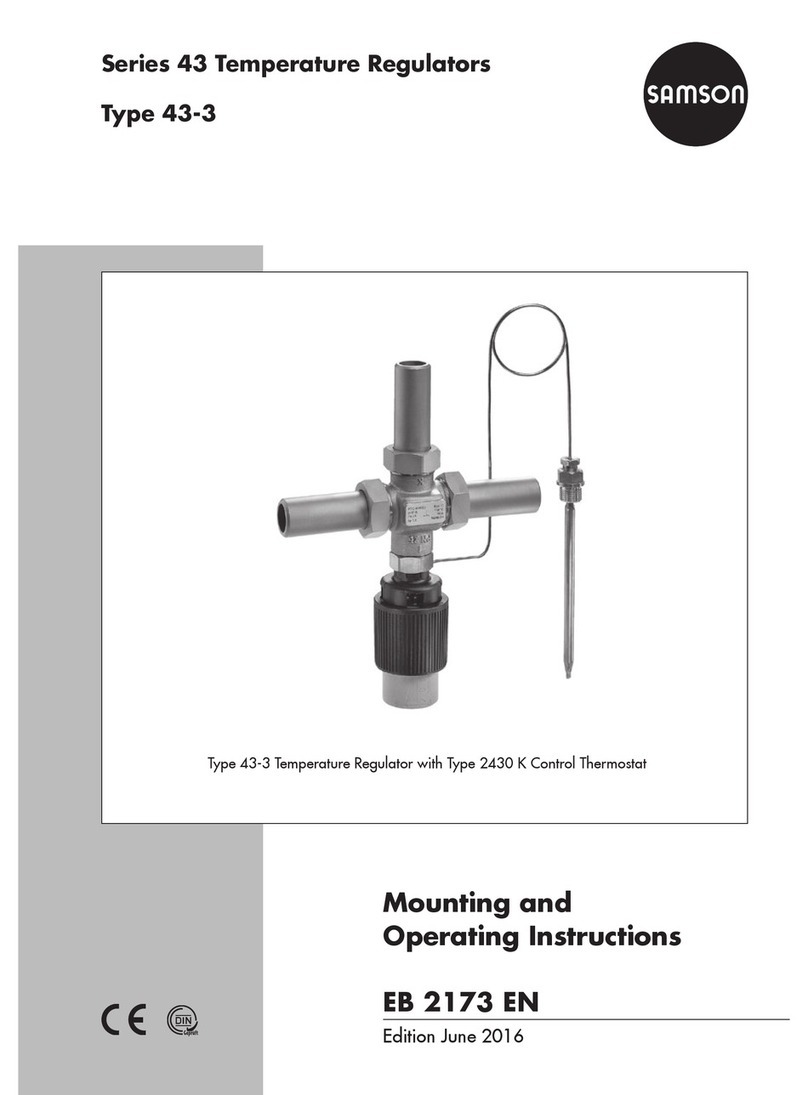

3 Design and principle of operation ...............................................................3-1

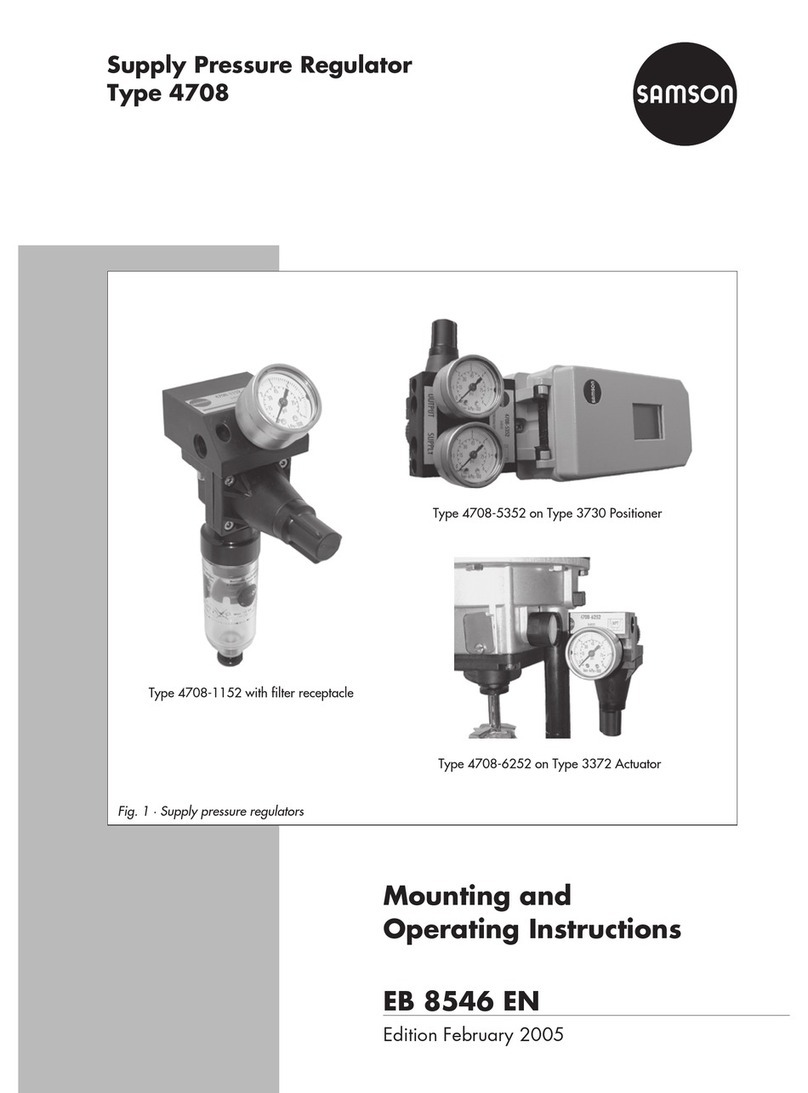

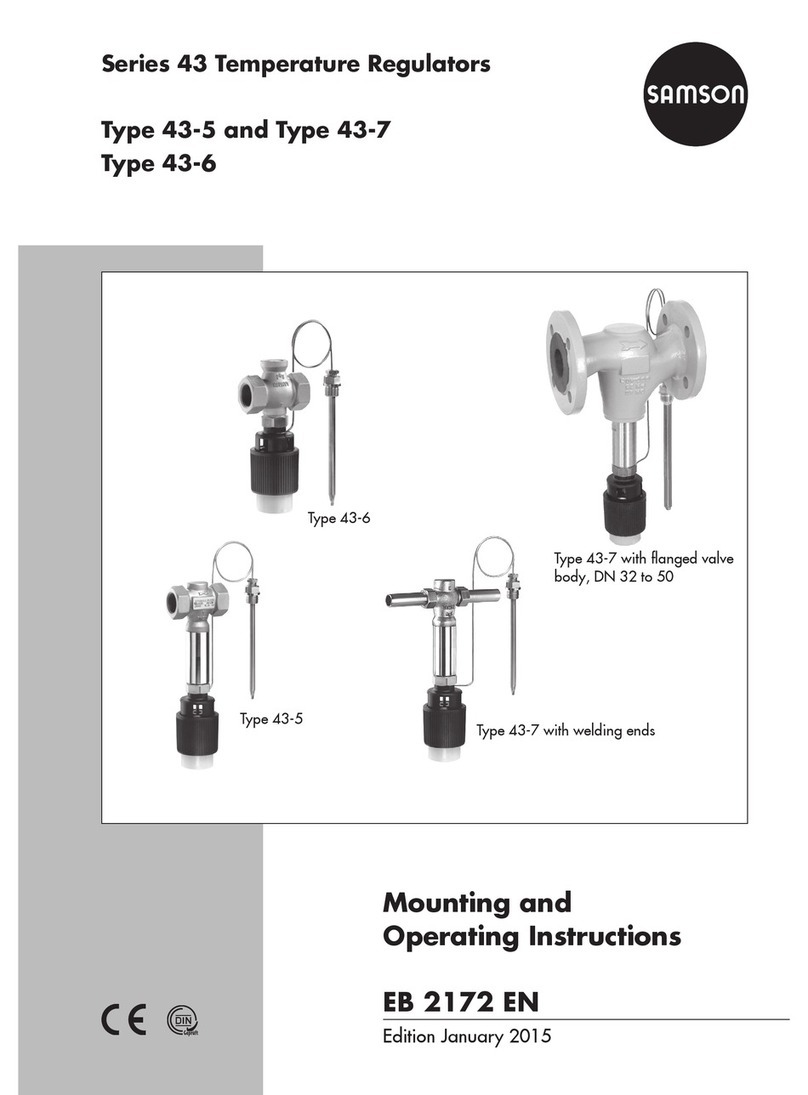

3.1 Accessories ................................................................................................3-3

3.2 Additionalttings........................................................................................3-5

3.3 Technical data ............................................................................................3-6

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removing the packaging from the regulator ..................................................4-1

4.3 Transporting and lifting the regulator............................................................4-2

4.3.1 Transporting the regulator............................................................................4-2

4.3.2 Lifting the regulator.....................................................................................4-3

4.4 Storing the regulator ...................................................................................4-4

5 Installation .................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-4

5.3 Installation..................................................................................................5-4

5.4 Installing the regulator.................................................................................5-6

5.4.1 Installing the valve.......................................................................................5-6

5.4.2 Installing the control thermostat ....................................................................5-7

5.4.3 Installing the reversing device.......................................................................5-7

5.5 Cleaningthepipeline ..................................................................................5-8

5.6 Testing the regulator....................................................................................5-8

5.6.1 Leak test.....................................................................................................5-9

5.6.2 Pressure test..............................................................................................5-10

5.6.3 Filling the plant.........................................................................................5-11

5.7 Insulation .................................................................................................5-11

5.8 Mounting accessories ................................................................................5-11