Contents

EB 8310-7 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible severe personal injury .........................................................7

1.2 Notes on possible personal injury ...................................................................8

1.3 Notes on possible property damage ................................................................9

2 Markings on the device ...............................................................................10

2.1 Actuator nameplate ......................................................................................10

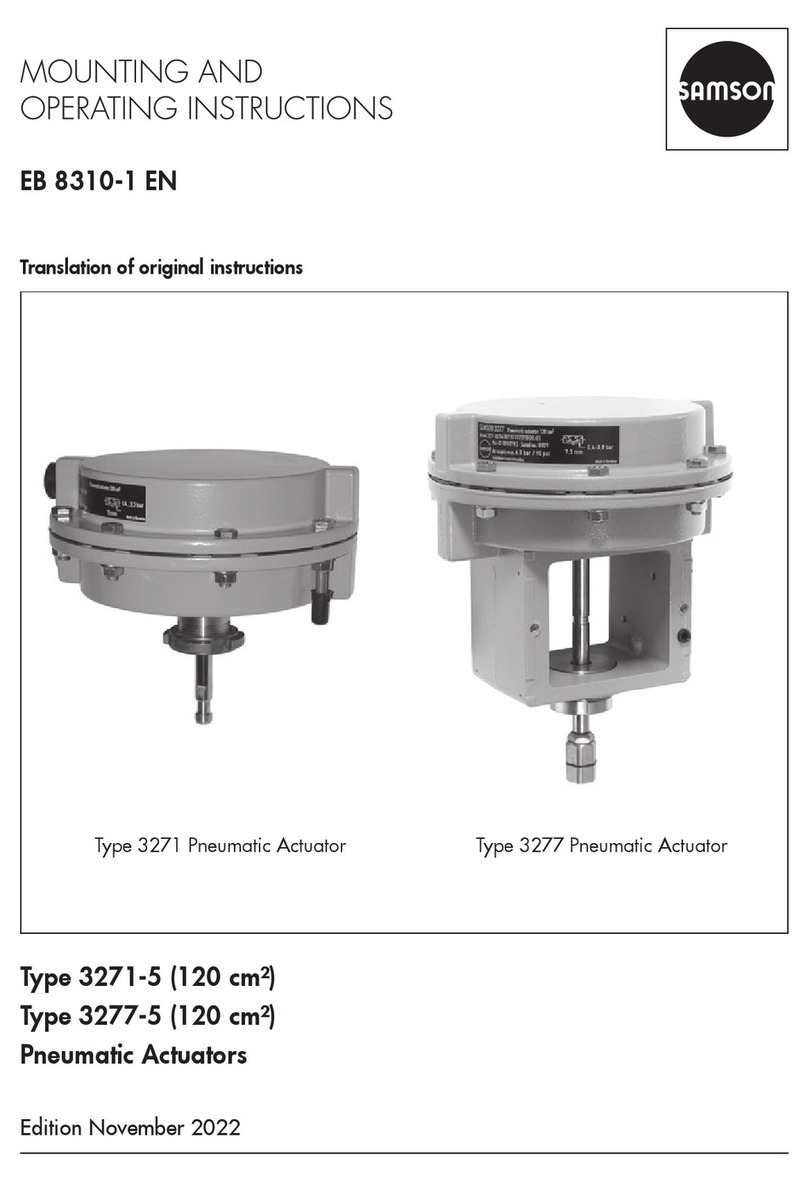

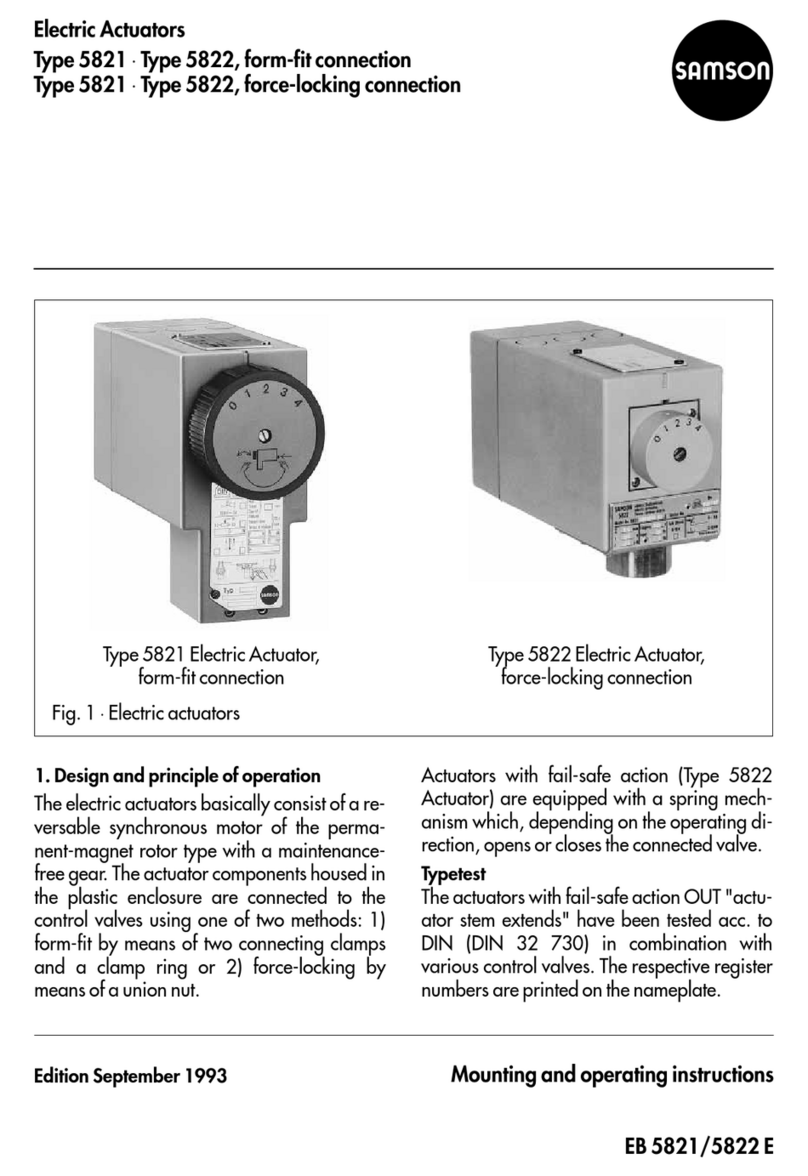

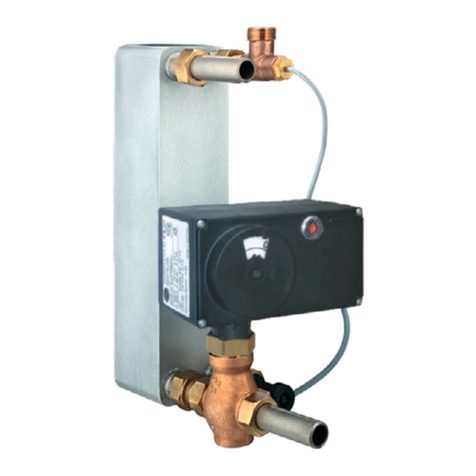

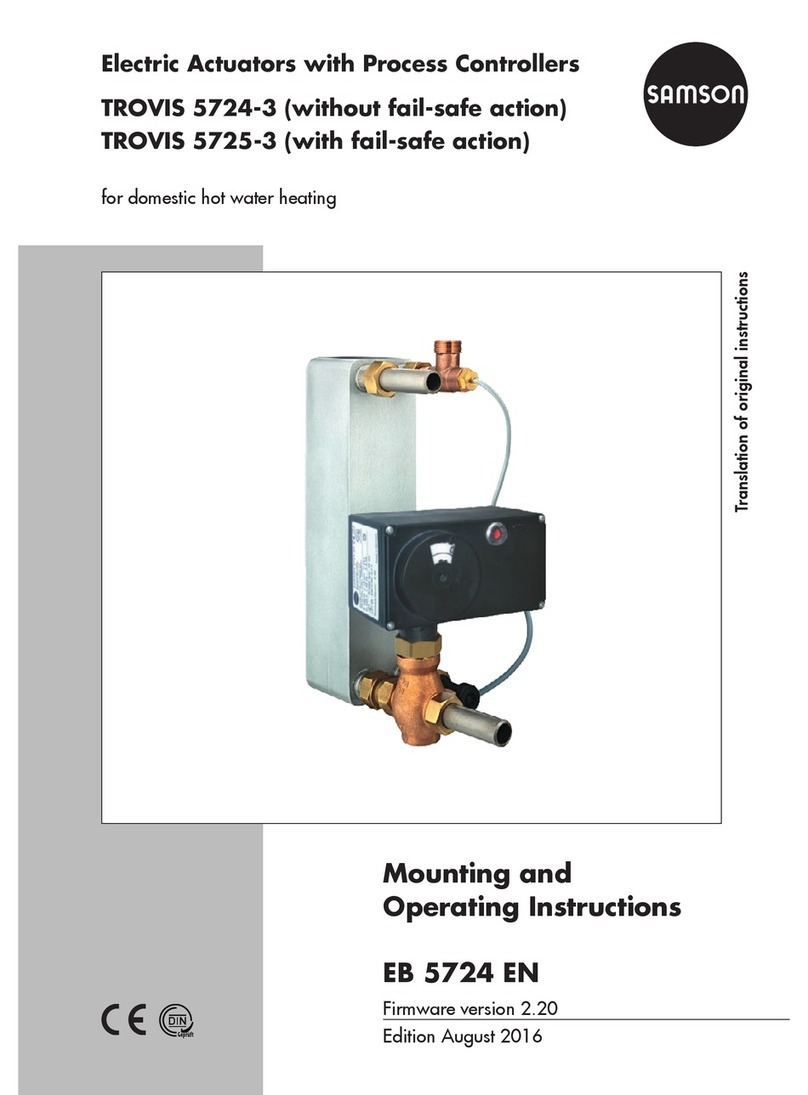

3 Design and principle of operation ................................................................12

3.1 Direction of action ........................................................................................12

3.2 Signal pressure routing .................................................................................12

3.3 Fail-safe action ............................................................................................14

3.3.1 Version with direction of action "actuator stem extends" (FA) ...........................14

3.3.2 Version with direction of action "actuator stem retracts" (FE) ............................14

3.4 Versions ......................................................................................................14

3.5 Technical data .............................................................................................14

4 Measures for preparation............................................................................18

4.1 Unpacking ..................................................................................................18

4.2 Transporting and lifting ................................................................................18

4.2.1 Transporting ................................................................................................19

4.2.2 Lifting ..........................................................................................................19

4.3 Storage .......................................................................................................22

4.4 Preparation for installation ............................................................................23

5 Mounting and start-up.................................................................................24

5.1 Mounting the actuator onto the valve .............................................................24

5.2 Preloading the springs ..................................................................................26

5.2.1 Tensioning the springs ..................................................................................26

5.2.2 Increasing the actuator thrust ........................................................................27

5.2.3 Adapting the travel range .............................................................................27

5.3 Additional ttings .........................................................................................28

6 Operation...................................................................................................29

6.1 Throttling service ..........................................................................................29

6.2 On/off service .............................................................................................29

6.3 Reversal of the direction of action ..................................................................30