10 EB 3131-1 EN

Design and principle of operation

3 Design and principle of oper-

ation

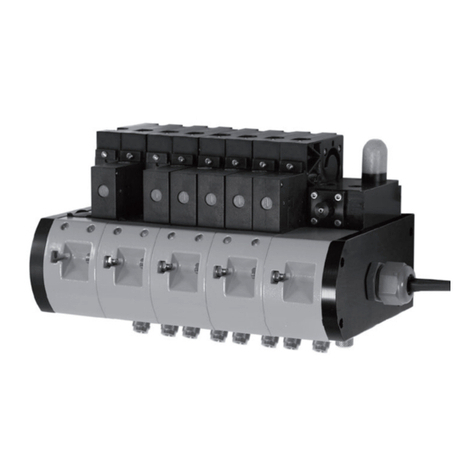

The combined regulators mainly consist of

the valve (1), closing actuator (6) with two

operating diaphragms (6.1, 6.3) and an ad-

justable restriction (9), on which an addition-

al pressure control actuator (15) with dia-

phragm chamber E is mounted. Its purpose

is to close the restriction (9) when the return

owpressureistoohightopreventdamage

to the consumers.

The regulator is used to limit the differential

pressureandowratetothesetpointsad-

justed at the actuator. The valve closes when

thedifferentialpressureorowrateincreas-

es. The additional pressure actuator closes

thevalvewhenthereturnowpressureistoo

high.

Themediumowsthroughthevalveinthe

direction indicated by the arrow. The areas

released by the restriction (9) and the plug

(3)determinetheowrate.Theinstalled

spring (5) determines the differential pres-

sureacrosstherestrictionof0.2bar.

Tocontroltheowrate,thelowpressure

downstream of the restriction is transmitted

through a hole in the plug to the top dia-

phragm chamber A. The high pressure of V

is transmitted through the attached control

line to the diaphragm chamber B and C,

which are connected to each other.

To control the differential pressure, the high

pressureof∆pmustbetransmittedthrough

the external control line (13), which is at-

tached on the site of installation, to the bot-

tom diaphragm chamber D. The low pres-

sureof∆pisequaltothehighpressureof

the Vandistransmittedoverthecontrolline

(11) to the diaphragm chambers B and C,

which are connected to each other.

Tosafeguardthereturnowpipe,thereturn

owpressuredownstreamofthevalveis

transmitted over the attached control line

(15.2) to diaphragm chamber E of the addi-

tional pressure control actuator (15) and

compared with the adjusted pressure set

point. If the resulting pressure force is higher

than the set point force adjusted at the set

point adjuster (15.1), the restriction closes,

causing the valve to close as well.

˙

˙

1Valvebody

2 Seat

3 Guide nipple with plug section

4 Plug stem

5Valvespring

6 Actuator

6.1 First operating diaphragm

6.2 First actuator stem

6.3 Second operating diaphragm

6.4 Second actuator stem

8 Set point spring (differential pressure)

9Restriction(owrate)

9.1 Setpointscrew(owrate,SW4)

10 Set point adjuster (differential pressure)

11 Control line (+) V

13 Externalcontrolline(+)Δp

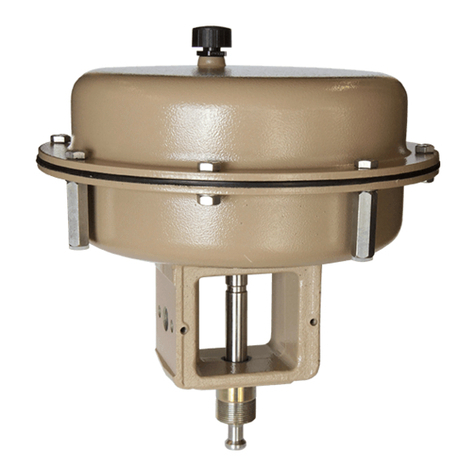

15 Pressure control actuator

15.1 Set point adjuster (pressure)

15.2 Control line (pressure)

15.3 G

1

/

8

blanking plug

15.4 Set point spring (pressure)

AtoE=Diaphragmchambers

˙