3 Design and principle of

operation

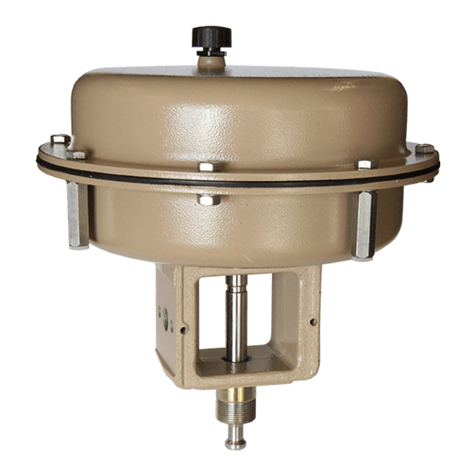

The electropneumatic positioner is attached

to pneumatic control valves. It is used to as-

sign the valve stem position (controlled vari-

able x) to the control signal (reference vari-

able w). The input signal received from a

control system is compared to the travel or

rotational angle of the control valve, and a

pneumatic signal pressure (output variable

y) is produced.

The positioner basically consists of an elec-

trical travel sensor system (2), an analog i/p

converter (6) with downstream air capacity

booster (7) and the electronics unit with a

microcontroller (5).

The standard positioner is fitted with three

binary contacts: A fault alarm output indi-

cates a fault to a control station and two

configurable software limit switches are

used to indicate the end positions of the

valve.

The valve position (x) is transmitted as a lin-

ear travel motion or an angle of rotation by

the pick-up lever and travel sensor (2) to an

analog PD controller (3). Simultaneously, an

A/D converter (4) transmits the position of

the valve to the microcontroller (5). The PD

controller compares this valve position to the

4 to 20 mA DC control signal supplied by

the controller after it has been converted by

the A/D converter (4). In case of a system

deviation, the actuator (1) is either vented or

filled with more air by changes to the i/p

converter (6). This causes the valve plug to

adopt the position corresponding to the ref-

erence variable (w).

The supply air is supplied to the air capacity

booster (7) and the pressure regulator (8).

An intermediate flow regulator (9) with fixed

settings is used to purge the positioner and

also guarantees trouble-free operation of the

air capacity booster. The output signal pres-

sure supplied by the booster can be limited

over the software. Both pressure sensors (23

and 24) monitors the supply pressure psand

the signal pressure pout.

The volume restriction Q (10) is used to opti-

mize the positioner.

The positioner is suitable for the following

types of attachment using the corresponding

accessories:

4Direct attachment to SAMSON

Type 3277 Actuator: Section 4.1

4Attachment to actuators acc. to

IEC 60534-6 (NAMUR): Section 4.2

4Attachment to Type 3510 Micro-flow

Valve: Section 4.3

4Attachment to rotary actuators acc. to

VDI/VDE 3845: Section 4.4

8EB 8384-6 EN

Design and principle of operation