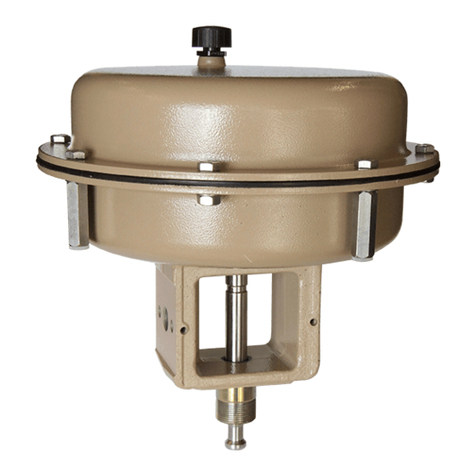

1.2 Principle of operation

The pressure-tight actuator housing (1, Fig.

2 on page 7) also serves as an oil reservoir

and incorporates the c linder housing (2),

c linder (5.1) and piston (5.2), motor (6.1),

pump (6.2) and solenoid pilot valves (6.4).

The motor (6.1) driven b the oil pump

(6.2) feeds compressed oil to the corre-

sponding c linder chamber via the check

valve (6.3) and pilot valve (6.4). In the de-

energized state, the solenoid valves are

closed. The open when the controller issues

a signal. When reaching final positions, or

external forces cause the nominal force of

the actuator to be exceeded, the motor is

deactivated.

Depending on the version, the actuators are

equipped with or without one or two com-

pression springs (5.7, 5.8). With T pes

3274-11, -12, -15, -16 and -21 to -23, the

motor moves the actuator stem in onl one

direction. The stem is then retracted b the

tension of the compression spring. Actua-

tors with electric override have two pushbut-

tons to open or close the valve.

Actuators with mechanical override are ad-

ditionall equipped with a gear case. An ex-

ternall mounted hexagon nut is used to

operate the mechanical override. The re-

lease button on the top of the actuator

serves to either open or close the control

valve.

Versions with fail-safe action are equipped

with a spring return mechanism and an ad-

ditional safet solenoid valve which opens

when the power suppl is interrupted, thus

reducing the oil pressure in the c linder

chamber. This mechanism moves the valve

plug to the fail-safe position. The operating

direction "Actuator stem extends or re-

tracts", depends on the spring arrangement

in the actuator.

1.3 dditional electric equipment

All additional electric equipment is located

in the terminal box (3). A rack-and-pinion

gear converts the linear travel of the actua-

tor stem into a rotar motion which is

picked off at the shaft to operate the switch-

ing and signaling elements. This additional

electric equipment can be retrofitted. The

maximum equipment configuration is

shown in the table "Additional equipment"

in section 4.2.

Electric positioners

Electric positioners compare the output sig-

nal of either 4(0) to 20 mA or 0(2) to 10 V

from an electric controller with the position

of a potentiometer (proportional to the

travel of the control valve) and produce a

three-point stepping signal.

Electric position transmitters

In the version with three-point stepping sig-

nal, an 0(4) to 20 mA or 0(2) to 10 V out-

put signal is generated proportional to the

travel of the valve using a 0 to 1000 Ω

potentiometer.

Potentiometers

The actuators can be equipped with two

potentiometers. A gear segment is driven b

a shaft. An easil adjustable transmission

mechanism including a twin pinion ensures

that the angle of rotation of 260° remains

the same for rated travels of 15 and 30 mm.

6EB 8340 EN

Design and rinci le of o eration