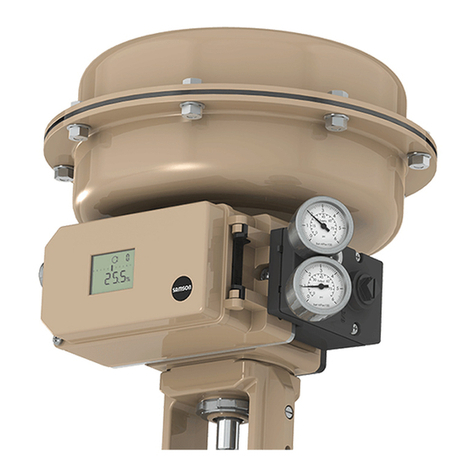

Samson 430 Series Service manual

Other Samson Controllers manuals

Samson

Samson EB 31a Service manual

Samson

Samson 3767 Service manual

Samson

Samson TROVIS 3730-1 Service manual

Samson

Samson 2357-11 Service manual

Samson

Samson TROVIS 5573 Service manual

Samson

Samson TROVIS 5400 Service manual

Samson

Samson 2488 N Service manual

Samson

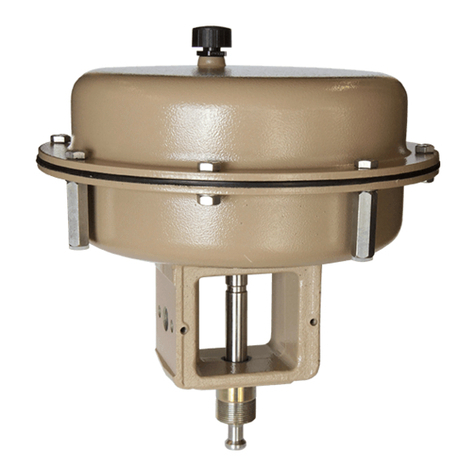

Samson 3271 Service manual

Samson

Samson 2357-3 Service manual

Samson

Samson Type 4708 Service manual

Samson

Samson Type 5824 Service manual

Samson

Samson 3274 Service manual

Samson

Samson Type 5824 Service manual

Samson

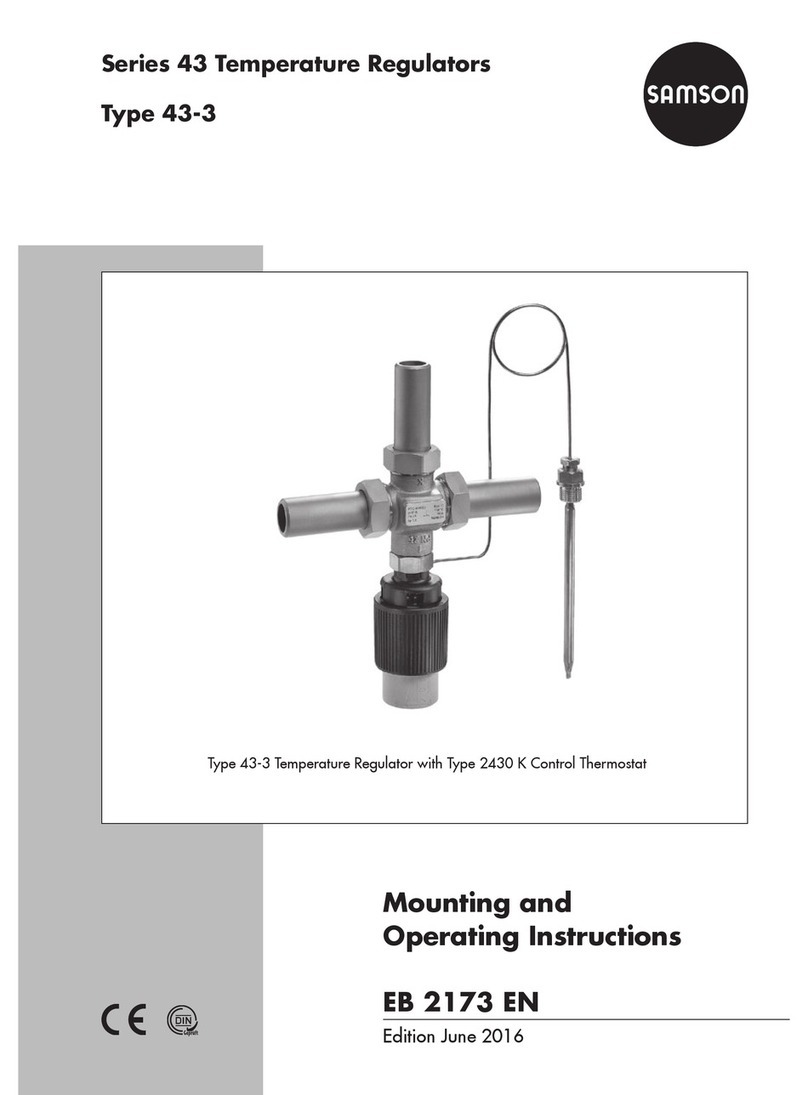

Samson series 43 Service manual

Samson

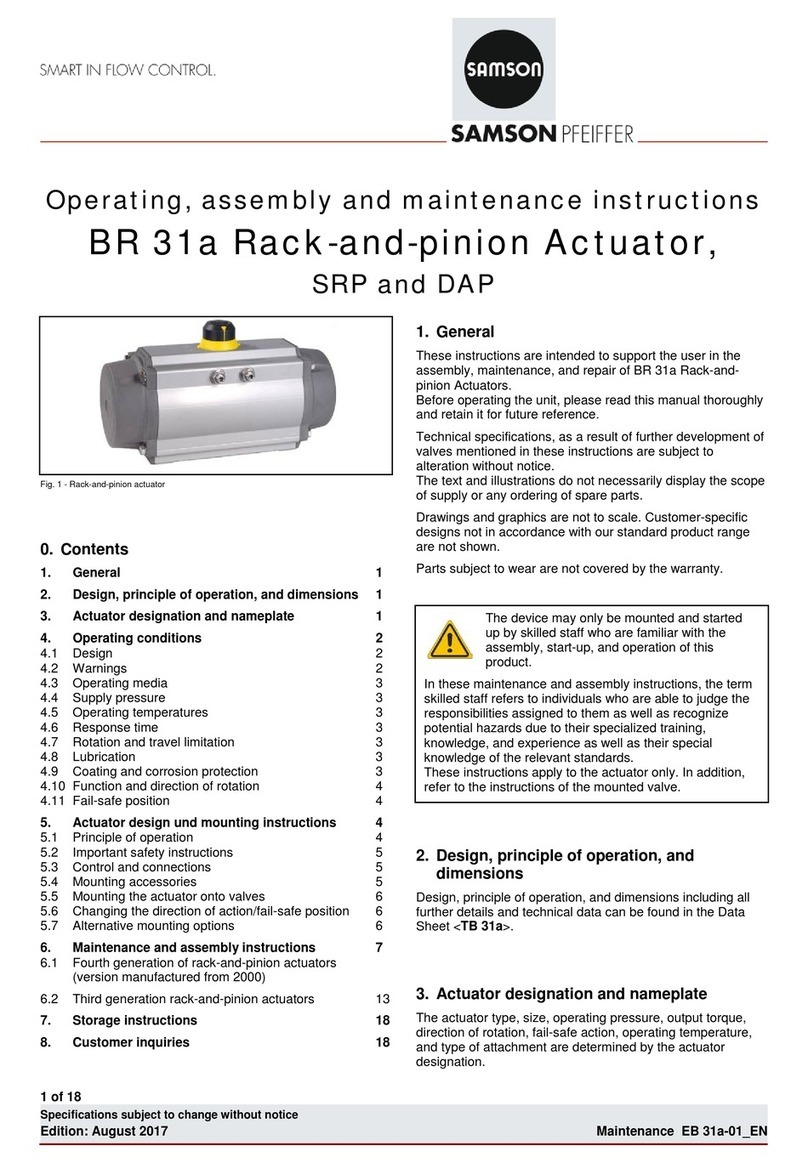

Samson BR 31a Series Quick guide

Samson

Samson 3372 Service manual

Samson

Samson 3371 Series Service manual

Samson

Samson TROVIS 5757-7 Service manual

Samson

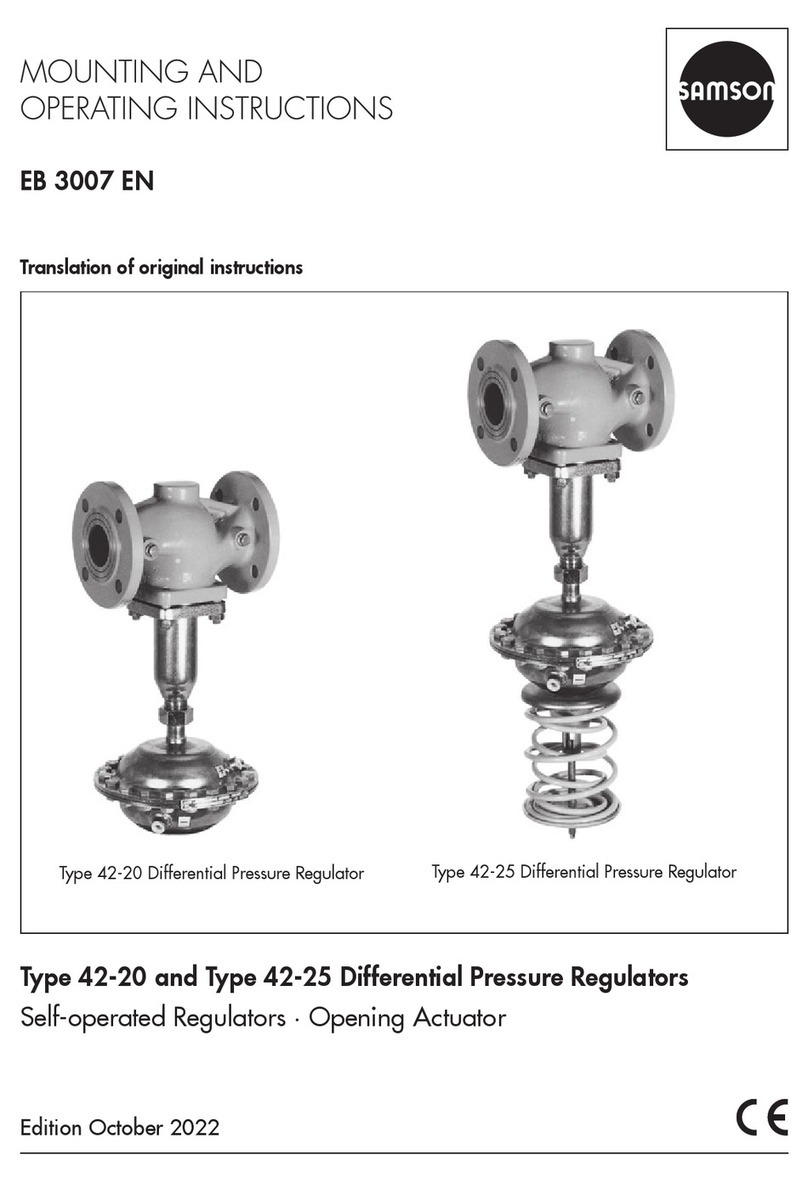

Samson 42-20 Service manual

Samson

Samson EB 2111 Setup guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions