10 EB 8384-6 EN

Design and principle of operation

3 Design and principle of oper-

ation

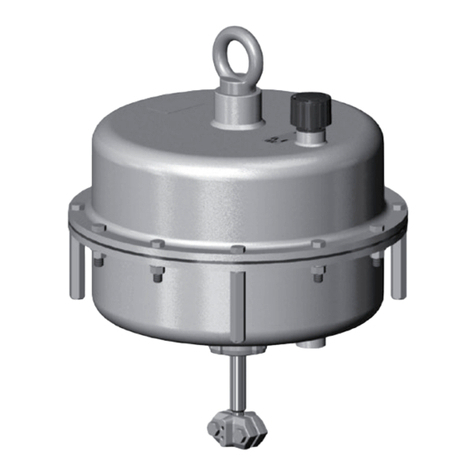

The electropneumatic positioner is mounted

on pneumatic control valves and is used to

assign the valve position (controlled vari-

ablex)tothecontrolsignal(referencevari-

ablew).Thepositionercomparestheelectric

control signal of a control system to the travel

or opening angle of the control valve and is-

suesasignalpressure(outputvariabley)for

the pneumatic actuator.

The positioner consists of a travel sensor sys-

tem (2) proportional to resistance, an analog

i/p converter (6) with a downstream air ca-

pacitybooster(7)andtheelectronicswith

microcontroller (5).

Thepositioneristtedwiththreebinarycon-

tacts as standard: A fault alarm output indi-

cates a fault to the control room and two

congurablesoftwarelimitcontactsareused

to indicate the end positions of the valve.

The valve position (x) is transmitted as a ei-

theranangleofrotationortraveltothepick-

up lever and to the travel sensor (2) and sup-

plied to an analog PD controller. An A/D

converter (4) transmits the position of the

valve to the microcontroller (5). The PD con-

troller (3) compares this actual position to the

4to20mADCcontrolsignal(reference

variable)afterithasbeenconvertedbythe

A/D converter (4). In case of a set point de-

viation, the activation of the i/p converter (6)

is changed so that the actuator of the control

valve (1) is pressurized or vented according-

lyoverthedownstreambooster(7).This

causes the valve plug to move to the position

determinedbythereferencevariable(w).

Thesupplyairissuppliedtothebooster(7)

andthepressureregulator(8).Anintermedi-

ateowregulator(9)withxedsettingsis

used to purge the positioner and, at the

sametime,guaranteestrouble-freeoperation

ofthebooster.Theoutputsignalpressure

suppliedbytheboostercanbelimitedby

software. Both pressure sensors (23 and 24)

monitors the supply pressure psand the sig-

nal pressure pout.

The volume restriction Q (10) is used to opti-

mize the positioner.

Thepositionerissuitableforthefollowing

types of attachment using the corresponding

accessories:

−DirectattachmenttoSAMSON

Type3277Actuator

−Attachment to actuators according to IEC

60534-6(NAMUR)

−AttachmentaccordingtoVDI/VDE3847

−AttachmenttoType3510Micro-ow

Valve

−Attachment to rotary actuators acc. to

VDI/VDE3845