1 Design and principle of

operation

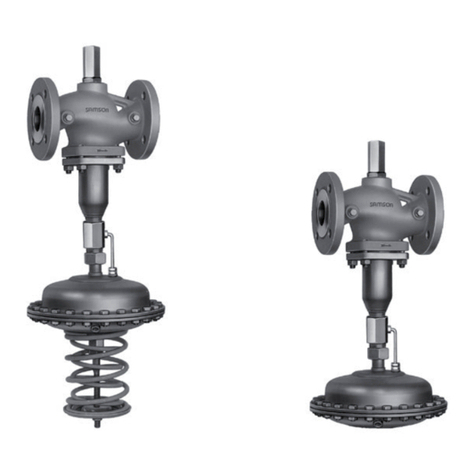

The differential pressure regulators are used

to maintain the differential pressure between

the high-pressure and the low-pressure pipe

at a set point which is either fixed (Type

42-38) or adjustable (Type 42-34). The re-

striction built into the valve body allows for

limitation of the flow rate.

The regulators basically consist of a valve

with a seat, plug and restriction as well as a

closing actuator with an operating dia-

phragm. The valve and actuator are deliv-

ered in separate packaging and need to be

connected on site using the coupling nut (11).

The process medium flows through the valve

in the direction indicated by the arrow. The

free areas of flow released by the orifice (1.4)

and the valve plug (3) determine the flow rate

V

.and the differential pressure Δpplant across

the plant.

Fully balanced valves ensure that the up-

stream and downstream forces acting on the

valve plug are eliminated by a balancing bel-

lows (5) or a balancing diaphragm (5.1). The

principle of operation of the regulators with

valves balanced by a bellows or by a dia-

phragm only differ concerning their pressure

balancing. Valves balanced by a diaphragm

(DN 125 to 250 only) have a balancing dia-

phragm instead of a balancing bellows (5).

The pressure downstream of the orifice (1.4)

acts on the outer surface of the metal bellows

or balancing diaphragm and the down-

stream pressure on the inside of the bellows

or diaphragm. As a result, the forces created

by the upstream and downstream pressures

acting on the valve plug are equally bal-

anced.

The regulators in sizes DN 15 to 100 are

equipped with a connecting piece (10) for the

low-pressure control line between the valve

and the actuator.

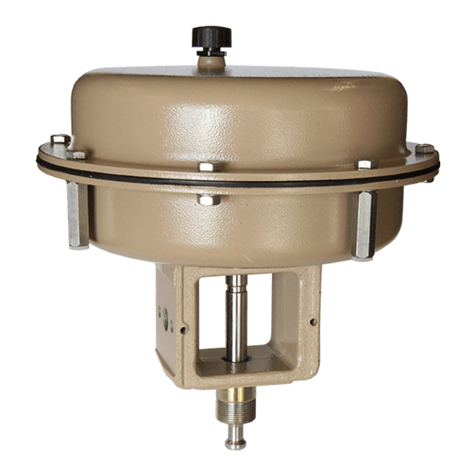

In differential pressure control, the high pres-

sure (flow) of the plant is transmitted to the

bottom diaphragm chamber of the actuator

over the high-pressure control line. The pres-

sure downstream of the orifice (1.4) acts on

the top diaphragm chamber over the hollow

plug stem and the connected low-pressure

control line. The differential pressure is con-

verted into a positioning force at the dia-

phragm (13) and is used to change the posi-

tion of the valve plug according to the force of

the set point springs (16). Depending on the

version of the actuator, the set point springs

are installed in the actuator to provide a fixed

set point (Type 42-38), or they are located

outside to allow the set point to be adjusted as

required (Type 42-34).

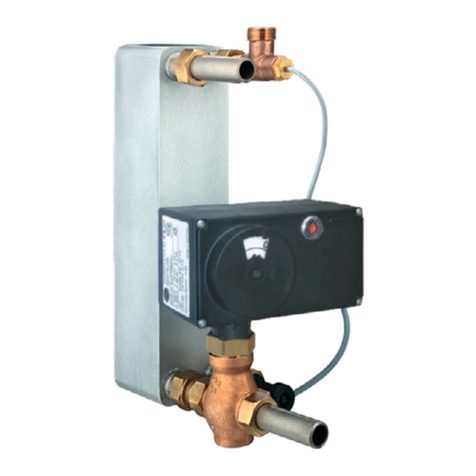

The restriction (1.1) is used to adjust the flow

limitation.

The force limiter (20) as well as the internal

excess pressure limiter (21) are designed to

protect the seat (2) and plug (3) against over-

load in case of extreme operating conditions.

4EB 3013 EN

Design and principle of operation

Table 1 · Regulator configuration

Controller = Valve + Actuator

Type 42-34 with connecting piece (for DN 15 to 100) Type 2423 Balanced Type 2424 Adjustable set point

Type 42-38 with connecting piece Type 2423 Balanced Type 2428 Fixed set point