B-Setup and Installation

C-Maintenance

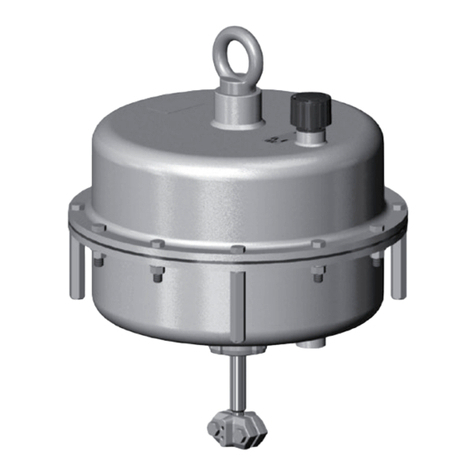

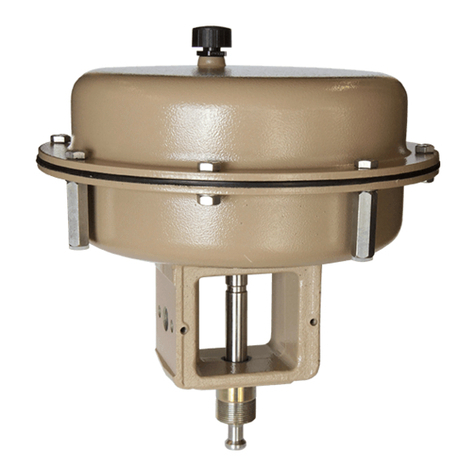

D-Device

Parts

Travel is not

achieved

.

Supply pressure is too low .Mounting incorrect.Recommended action : check supply air and

positioner mounting and setting .Re-initialize the

positioner

3.7mA

No supply air , mounting blocked

No input signal or input signal below 3.7mARecommended action: check supply air

,positioner mounting and mA input signal . Re-

initialize the position

Travel signal at

lower limit

Wrong pin position, wrong lever ,Wrong

attachment direction when NAMUR attachment

is used.

Recommended action: check positioner

mounting and re-initialize the positioner.

Travel signal at

upper limit

Wrong pin position, wrong lever, Wrong

attachment direction when NAMUR attachment

is used.

Recommended action: check positioner

mounting and re-initialize the positioner.

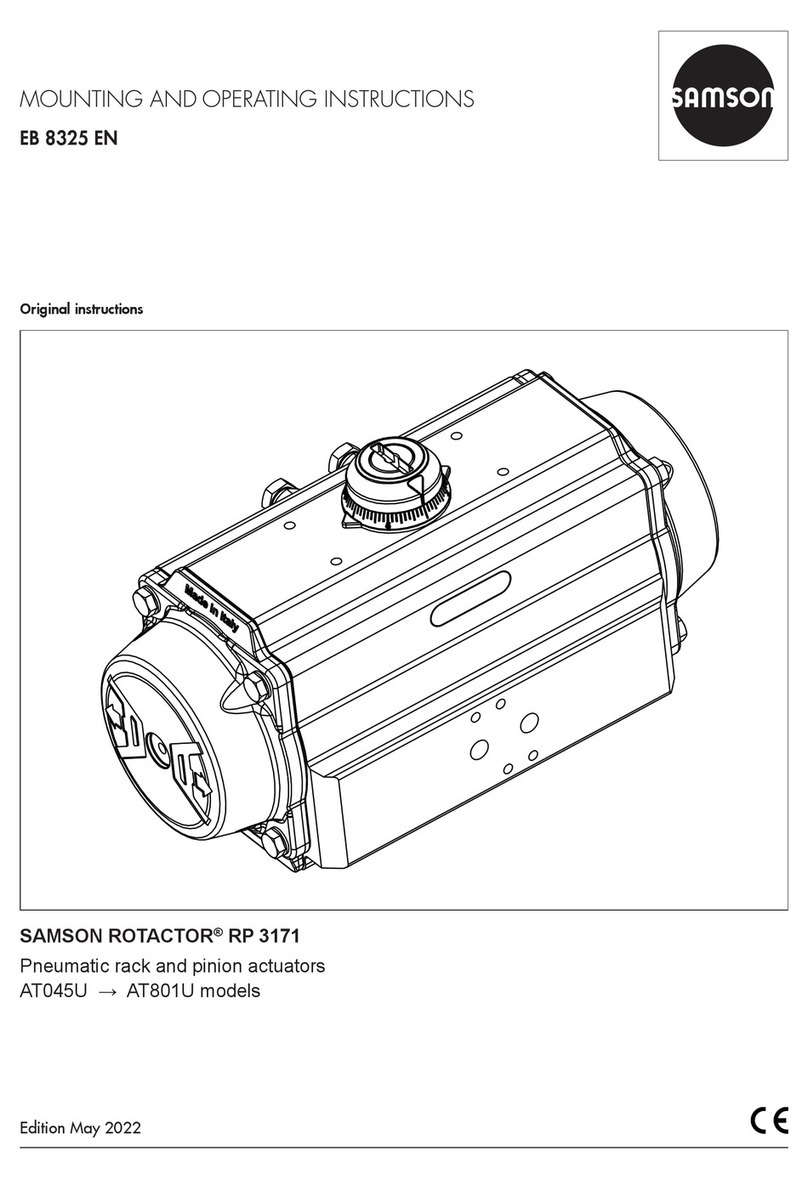

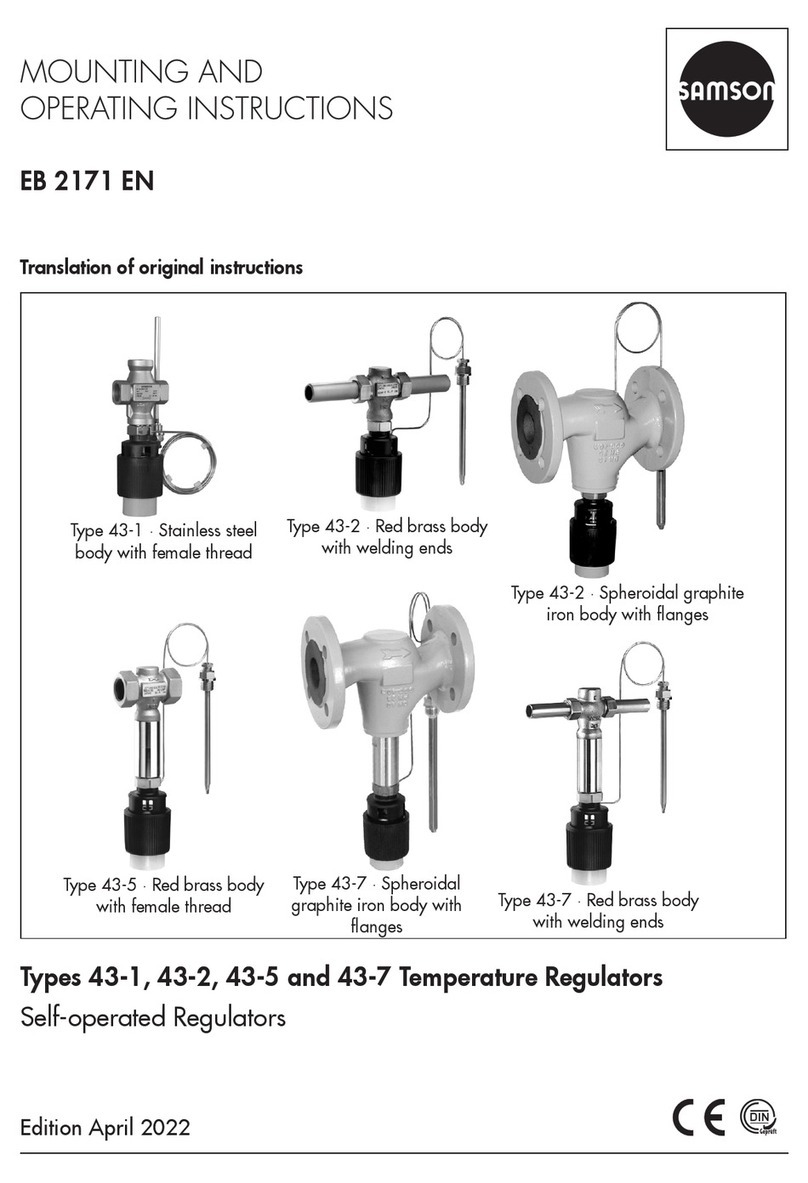

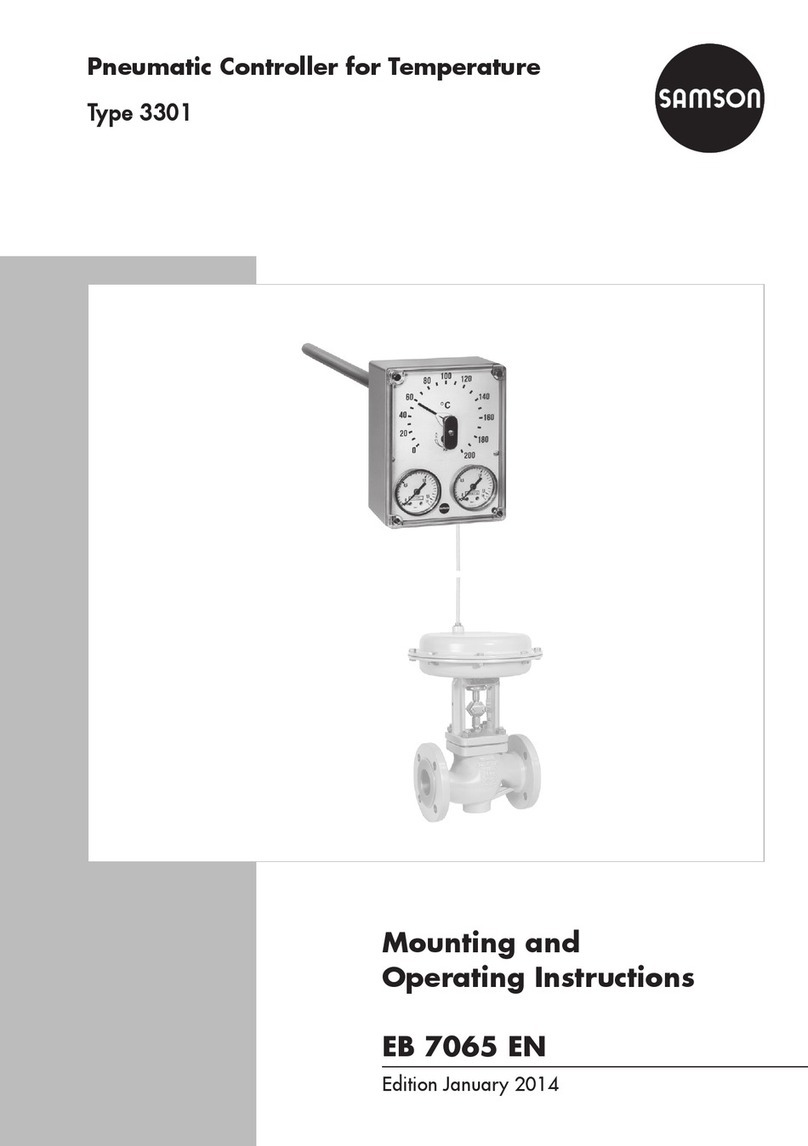

I-P3730-1Samson

I-P

4…20 mA

This manual is only for

installation of I-P type 3730-1 by

Samson. After mounting I- P to

control valve correctly, Please

read following notices

information before operating :

1-Lever and pin must be mounted

according to actuator size(1-1

table)

according to (2-1 table

2- Choose appropriate supply air

pressure to actuator range.

3-After, controlling wind system

and checking pressure and

connector pipe, please be sure

there is 4…20MA current

according to (2-1 table)

3730-1

A. Installation and Maintenance