wnnenneneenennsessenseens

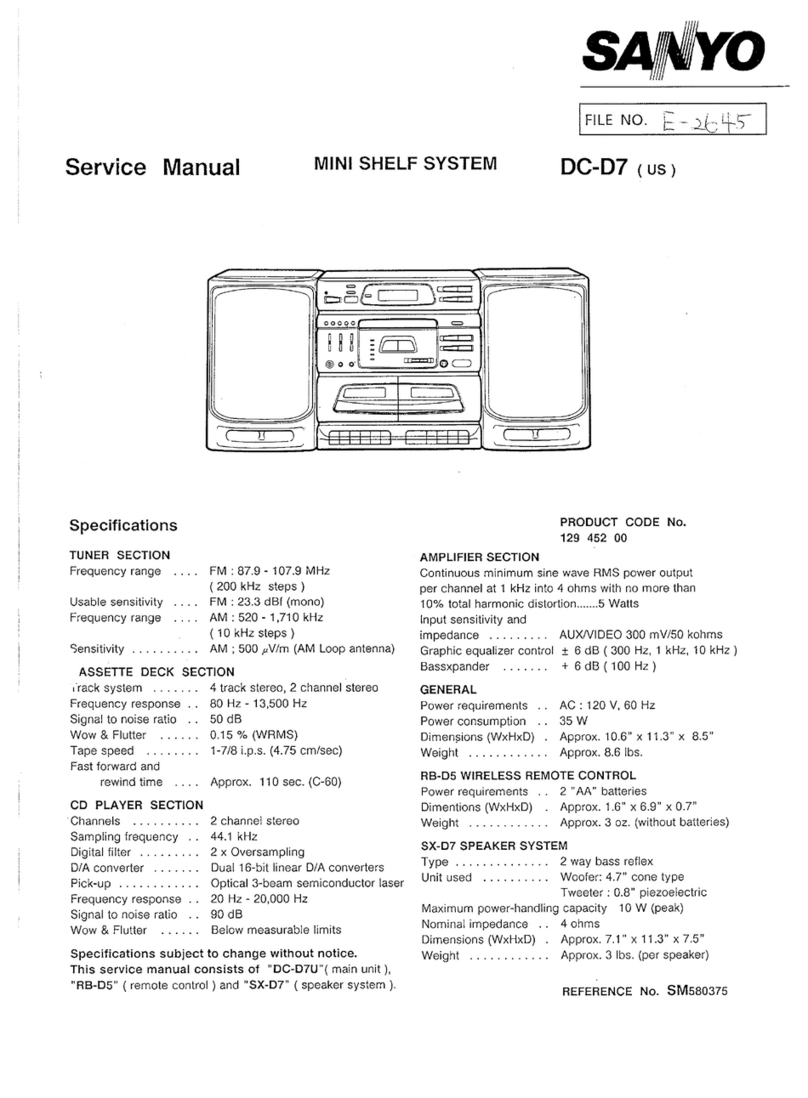

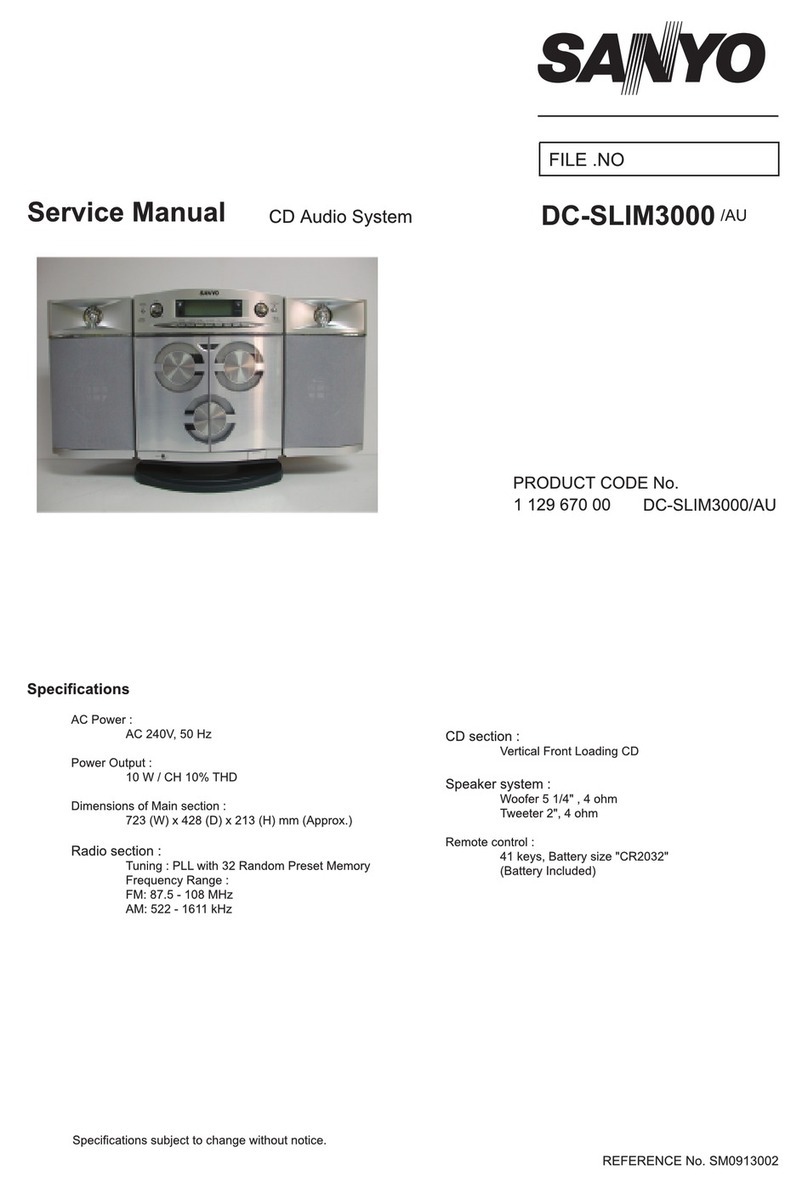

TUNER/CD

PLAYER

UNIT

--2220220022rennenneemenem

ADJUSTMENT

(TUNER)

@

Use

a

plastic

screwdriver

for

adjustment.

@

Adjust

the

intermediate

frequency

of

AM

and

FM

to

the

frequency

of

ceramic

filter.

SG

RF

Level

:

75

ohm

Open

voltage

dBuV

1.

FM

BAND

Antenna

:

75

ohm

Direct,

Modulation

:

1kHz,

Dev.

:

+75kHz

(mono)

-

+

40kHz

(main)

-

+6.75kHz(pilot)

TUNING

INPUT

CONDITION

OUTPUT

CONDITION

STEP

ITEMS

PARTS

STANDARDS

peered

ne

Sane

an

eae

fom

eee

1

ER

87.5MHz

‘aital

|

TP202(H)

Confirm

1.4~1.6V

cov

108.0MHz

Digital

Voltmeter

|

tp294(E)

Confirm

<8.5V

(about

7.8V)

FM

SG

TP211(H)

wa

TP203(H)

FM

SG

TP211(H)

Frequency

TP206(H)

##

seas

(6608)

___|rP212¢€)

E207)

nl

SRE

*

°

Tp204

is

no

earth

point.

sae

Adjust

in

the

modulation

off

Tuner

Mode

:

AUTO

STEREO

2.

MW

BAND

STEP

|

ITEMS

TUNING

FREQUENCY

522kHz

we

1404kHz

3.

LW

BAND

step

|

ITEMS

TUNING

INPUT

CONDITION

OUTPUT

CONDITION

PARTS

STANDARDS

on

ee

[input

|

Measure

|

outPut

144kHz

ig

TP202(H)

|

12154

|

Confirm

1.3

~

1.8V

ea

COVER

|

290kHz

Se

a

Digits

VolsMmeter

Il

rezaq{e)

Confirm

<8.5V

(about

6.5V)

4.

PARTS

LOCATION

Antenna

:

IRE

Loop,

Modulation

:

1kHz

30%

SG

RF

Level

:

75

ohm

Open

voltage

dByV

INPUT

CONDITION

OUTPUT

CONDITION

PARTS

STANDARDS

INPUT

|

MEASURE

|

OUTPUT

Bad

=aRseGal

TP202(H)

|

12153

|

Confirm

1.0

~

1.4V

Digital

Voltmeter

|

tpagi(e)

|

-----

Confirm

<8.5V

(about

7.2V)

AM

SG

LOOP

VTVM

TP233(L)

Output

:

Maximum

:

TP234(R

Confirm

to

near

gid

Oscilloscope

sens

the

effective

sensitivity.

162kHz

AM

SG

LOOP

VTVM

TP233(L)

|

(245,

|

Output

:

Maximum

TRACKING

(about

80dB)

i

TP234(R)

Confirm

to

near

279kHz

ais

ANT

Oscilloscope

the

effective

sensitivity.

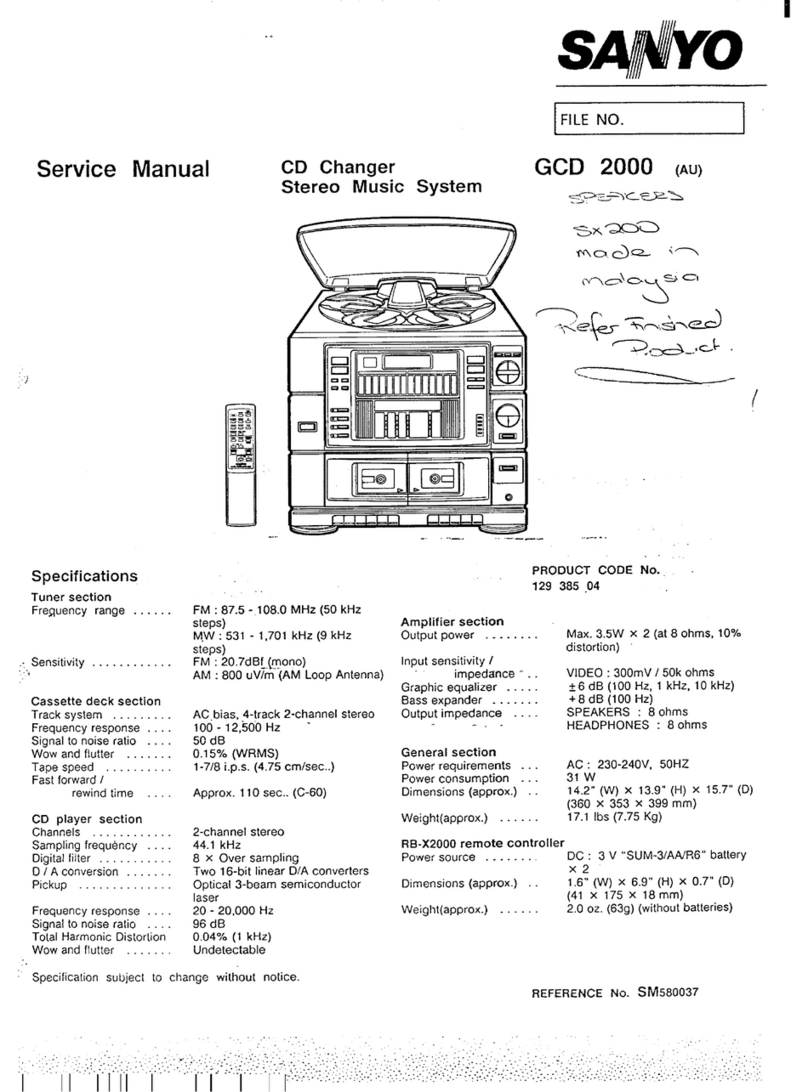

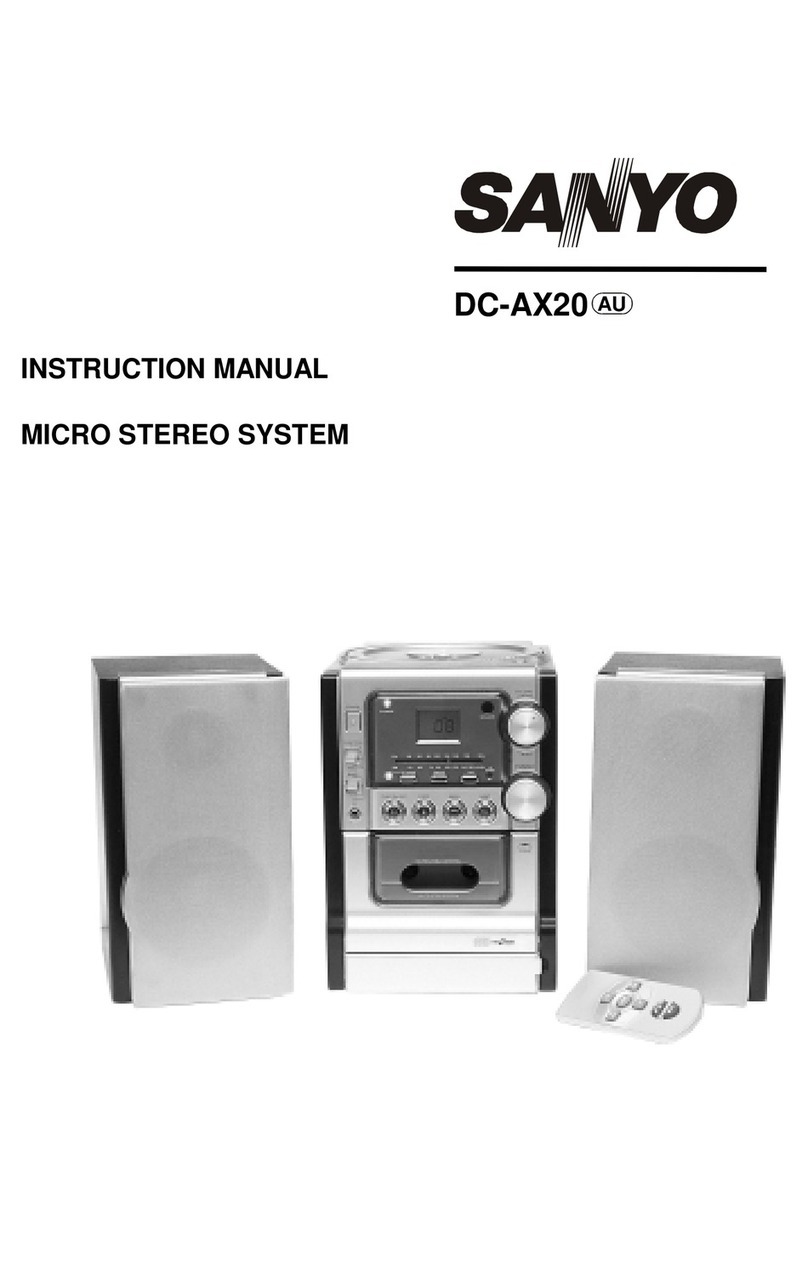

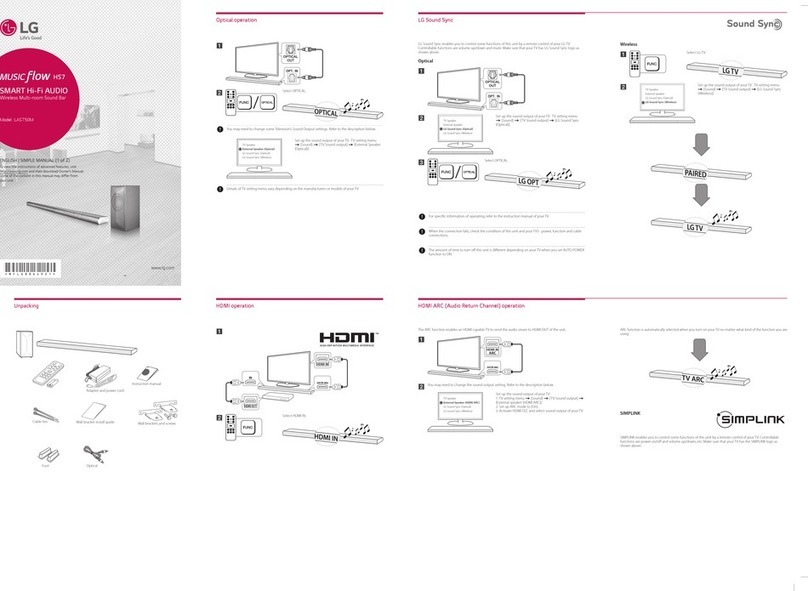

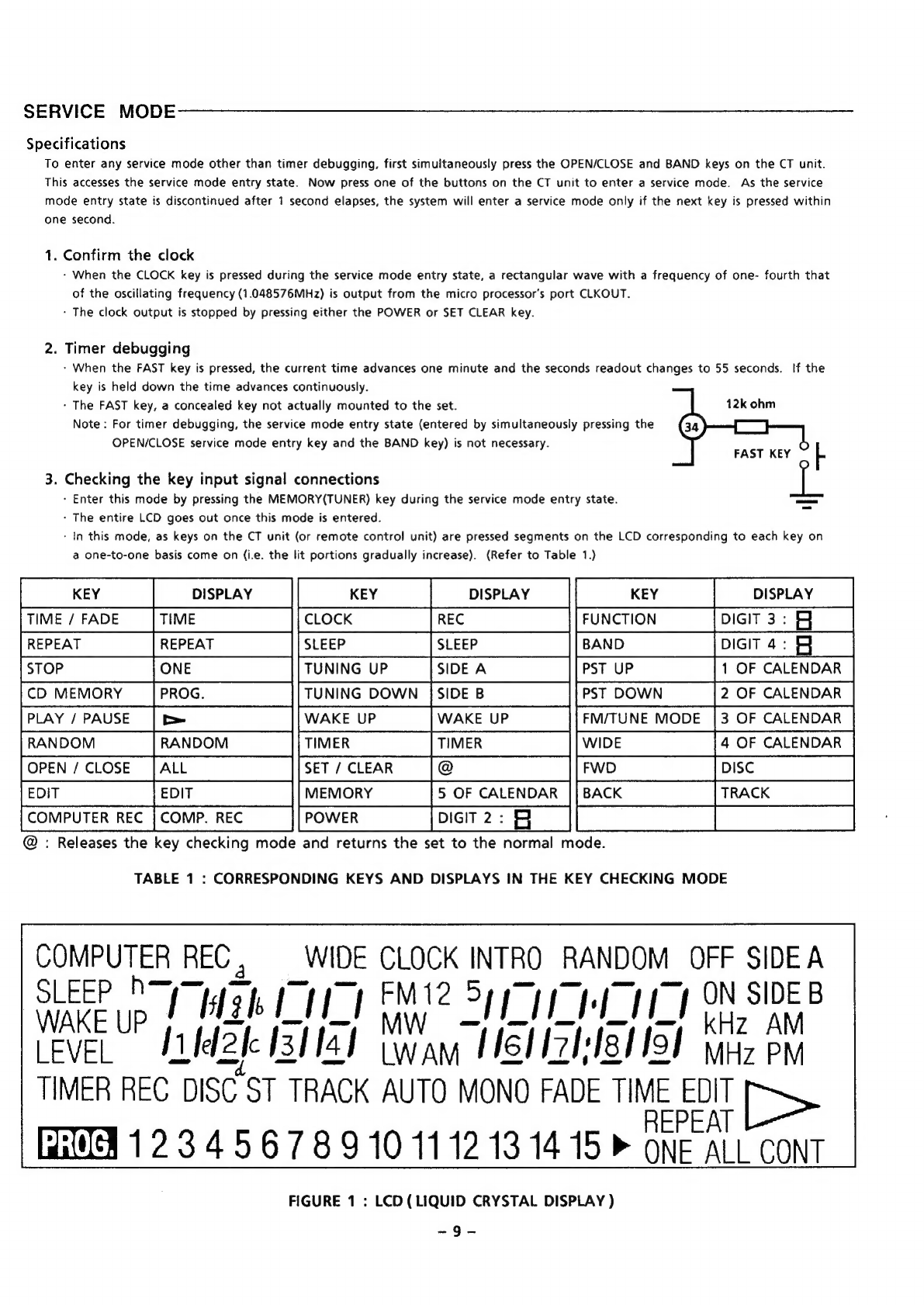

FM

EXT.

TP212

TP202(COVER)

TP201(E)

TP207(E)

ANT.(75)

C2133

5449

C2132

5422

1

TP212

P

[RAS

=e

©

ae

SVR23

NT

GND

+B

OSC

oa

oa

a

o

aoa

none

vt

Oa

>|

TU201

TP224

TP223

cae

R2227

CT251

CT252

a

qo.

@Q

6)

A

A

/TP203

[|

[

|

12154

L213

x

:

2202

tte

2151

L

2152

‘

1!

TP234(R-CH)

TP204

/

po

TP235

e

frolic)

J423(E)

4420

4

Z_

AM

LOOP

ANT.