49-075D 2011-09 Warranty 49-071 7 Sapphire Scientific

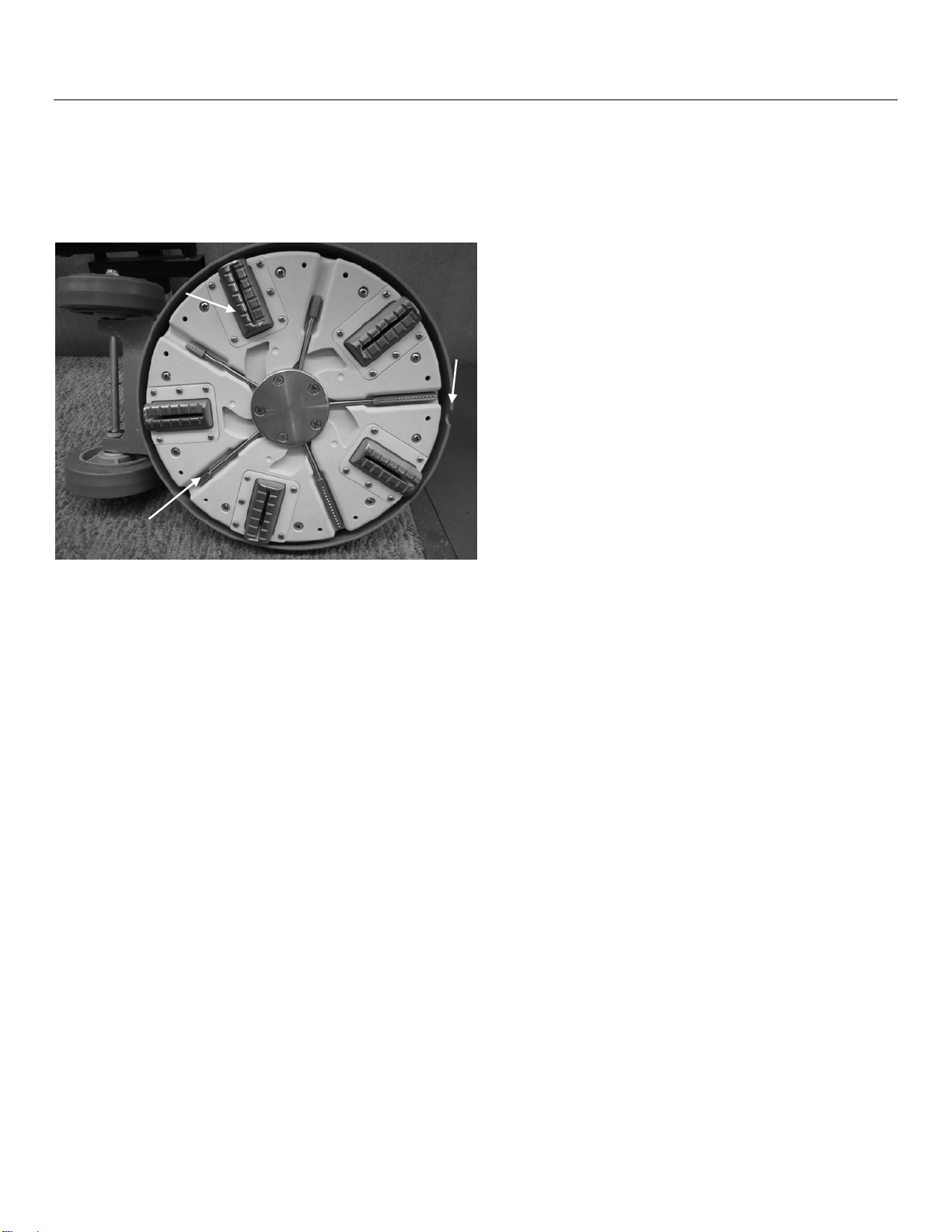

9. IMPORTANT: Replace temporary gear box plug (S)

with vent plug provided.

SETUP

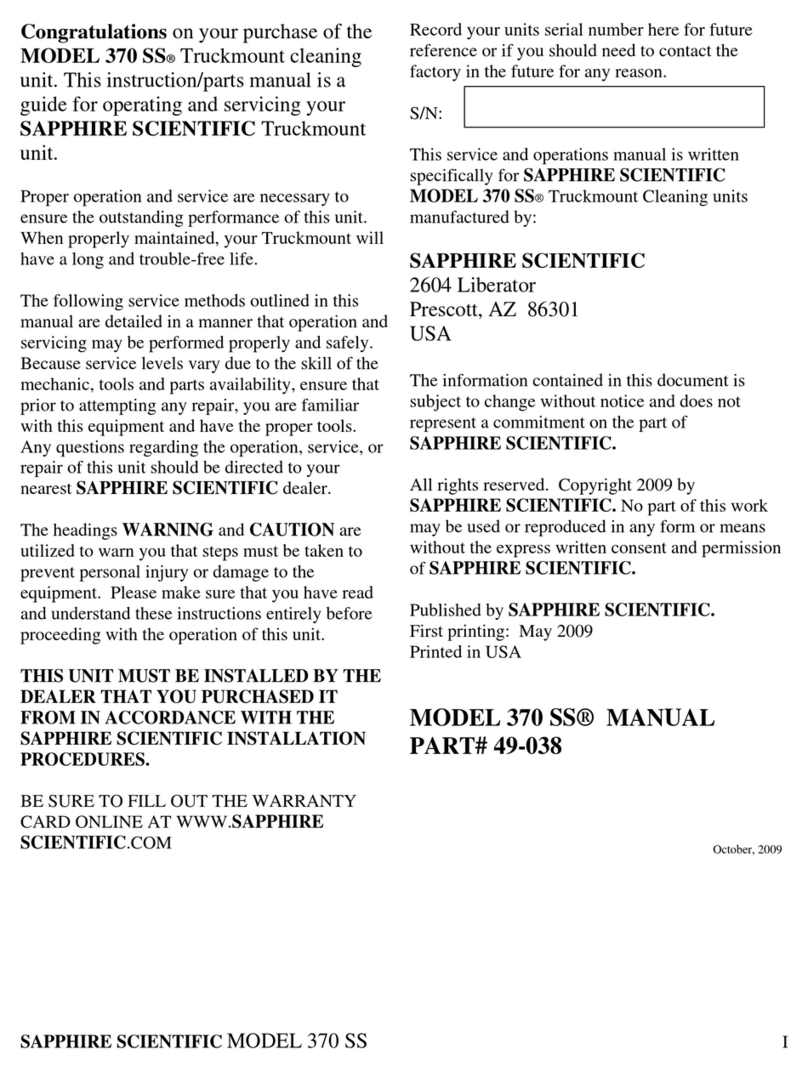

1. Adjust handle height for operator comfort. Loosen

black knob, move handle up or down to desired height,

and retighten. See Fig. 1.

TIP: To maximize control and operator comfort, position

the handles at hip height.

2. Attach vacuum hose to vacuum outlet. The HOSS 700

is fitted with a 2 in. O.D. vacuum outlet, Fig. 1, F.

3. Attach solution hose to quick-connect fitting, Fig. 1, D.

4. Connect to a 115V/15 amp supply power source (Fig.

1, G), using a suitable extension cord. Cords up to 50 ft.

long should be at least 14 gauge 3-wire; longer cords, up

to 100 ft. maximum, should be 12 gauge 3-wire..

WARNING: Electrical shock hazard. Unit must be prop-

erly grounded. Do not remove grounding prong or oth-

erwise alter the grounding system.

OPERATION

WARNING:Rotating parts. Keep hands, feet and all

cords and hoses clear. Make sure the area to be

cleaned is free from obstructions and place power cords

and hoses well away from the unit.

1. Turn on the carpet cleaning extractor vacuum and

solution pump.

2. Start the flow of solution first. Grasp handles firmly

and squeeze right trigger (Fig. 1, B).

3. Balance the unit with the head flat on the carpet. Then

squeeze left trigger (Fig. 1, C) to start rotary head.

WARNING:Rotary head starts abruptly. Be prepared to

raise or lower the handle to control the unit. Only slight

adjustments are required.

Controlling the unit

•To move to the right, LIFT the handle with both

hands slightly.

•To move to the left, LOWER the handle with both

hands slightly.

Tip: Only small adjustments in handle position are

needed to control the unit. If you are unfamiliar with ma-

neuvering this cleaning tool, practice first in an open and

unobstructed area.

Tip: Do not tip the unit to the left or right, as this will im-

pair vacuum performance and make the unit difficult to

control.

Cleaning and Operational Tips

Do not operate the HOSS 700 on dry carpets, as this

may damage carpet fibers.

Do not operate the HOSS 700 on hard surfaces, as

this may damage the vacuum heads and/or floor surfac-

es.

For best results, vacuum the carpet thoroughly before

using the HOSS 700.

Adjust solution flow. The flow of solution can be cus-

tomized to soiling conditions and type of cleaning

equipment used. To provide maximum solution flow, the

HOSS is shipped without a restrictor installed. The Hoss

700 is supplied with .048, .052, and .057 in. flow-

restricting orifices. Customers who wish to restrict flow

may add one of the restrictors provided to the inline filter

assembly (Fig. 1, H). To install a restrictor, disassemble

the in-line filter, place the restrictor in position between

the filter screen and the nut, and reassemble.

For best results, always groom the carpet after clean-

ing.

Always establish adequate drying conditions after

cleaning.