5

4 –OPERATION

4.1 –TOOL PREPARATION BEFORE USING

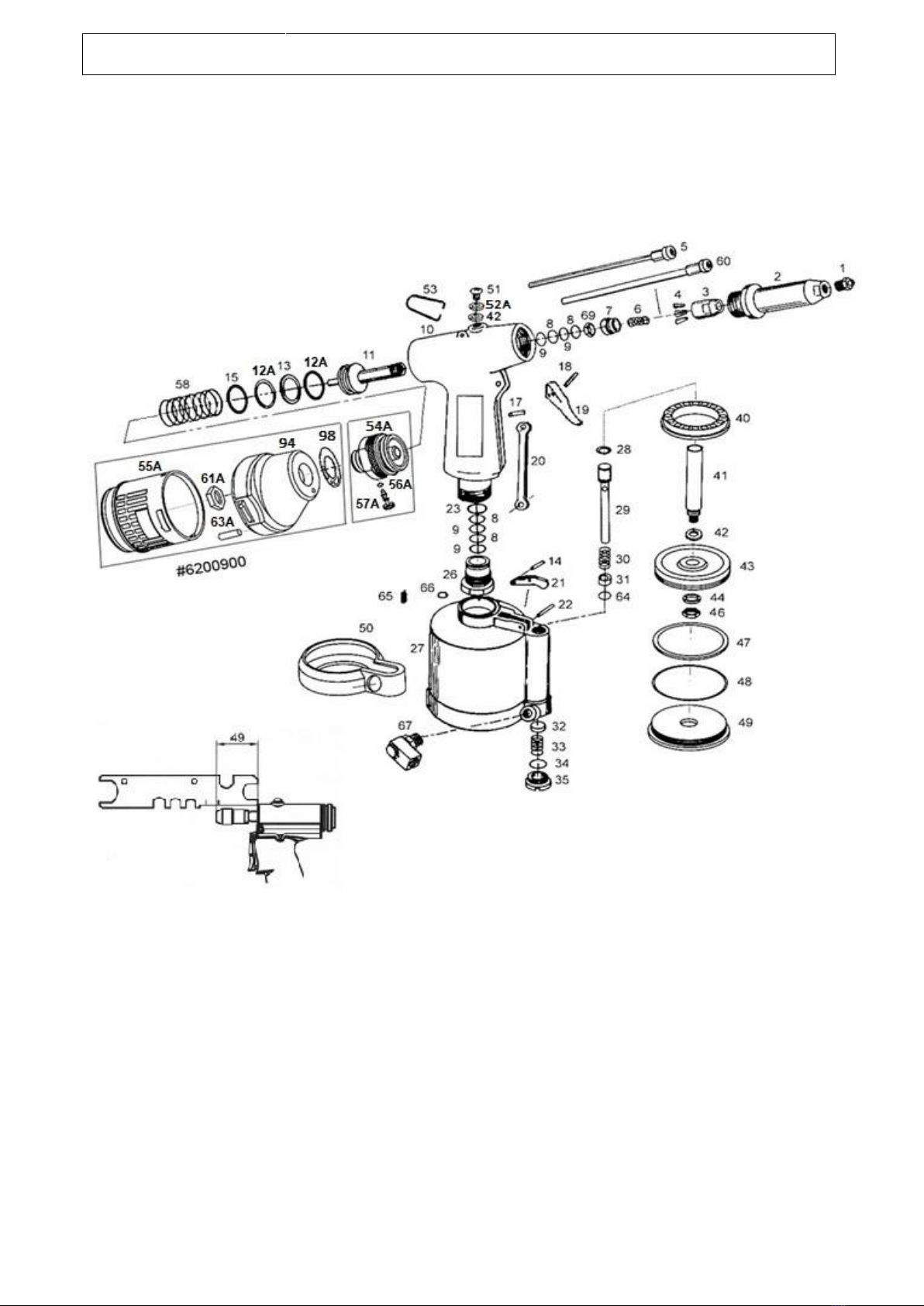

1. Prior to each operation of the riveter, you must choose the rivet size you are going to use. If you set

4.8mm rivets, no changes on the tool are necessary (4.8mm nosepiece is installed on the riveter).

2. If you set rivets with other diameters, you have to follow the instructions below:

A. If you set 4mm rivets: remove the nosepiece (#01), unscrewing it by turning counter-

clockwise, then take the 4mm nosepiece and screw it onto the riveter by turning clockwise.

Use the small wrench (included) to loosen and tighten the nosepiece.

B. If you set smaller rivets (2,4mm to 3,2mm) you have to change the pusher tube (insert part

#05 instead of #060).

To do it, unscrew firstly the head (#02) and then the jaw housing (#03), then change the tube

and insert part (#05) with the same spring (#06) put around the pusher tube originally

installed.

At the end re-screw the jaw housing and the head, and insert the nosepiece as written above

in point A.

3. Attach the mandrel collector tube (#55A) to the riveter by screwing it tightly onto the fitting in the

back of the tool.

4. Make the air circulate through the tool when the air connection is hooked up, to insure correct

alignment of jaws.

5. Adjust the air flow by screwing / unscrewing the regulator (#57): note that rivets of bigger diameter

need more air than the smaller.

4.2 –OPERATING INSTRUCTIONS

1. Attach a ¼” NPT (quick connect valve) to the brass air inlet fitting (#67) and then plug the air supply

(not over 100 PSI) into the quick connect valve.

2. Push the trigger (#19) to start the vacuum system.

3. Insert the mandrel of the rivet into the riveter and position the rivet into the previously drilled hole

(rivets will be held by the tool thanks to the vacuum system).

4. Squeeze the trigger to set the rivet (the trigger may need to be activated twice to set larger-size

rivets completely).

5. The mandrel will be ejected into the mandrel collector once the trigger is released.

6. To empty the mandrel collector, remove it from the tool unscrewing it or open the small windows

positioned in the back of the mandrel collector.