5

US

Operating Instructions for SATA Breathing Protection Equipment Operating Instructions for SATA Breathing Protection Equipment

Table of Contents

[Original language: Ger-

man]

1. General Information.................5

2. Safety Instructions.................13

3. Safety Gear ...........................15

4. Intended Use.........................15

5. Technical Data.......................15

6. Breathing Protection Equipment

Scope of Delivery ..................15

7. System Overview ..................16

8. Description of Breathing

Protection Equipment............ 16

9. How to use the breathing

protection hood......................19

10. Maintenance and Repair to

Breathing Protection Hood ....22

11. Operation of Air Regulator..... 24

12. Maintenance and Repair to Air

Regulator...............................26

13. Operatingtheairhumidier ...26

14. Maintenance and Repair of Air

Humidier ..............................29

15. Operating the air warmer/

cooler.....................................30

16. Maintenance and Repair of Air

Warmer/Cooler ......................32

17. Use of Belt Unit .....................32

18. Maintenance and Repair to Belt

Unit........................................32

19. Service, Care and Storage ....32

20. Troubleshooting.....................32

21. Service and Parts ..................33

1. General Information

1.1. Introduction

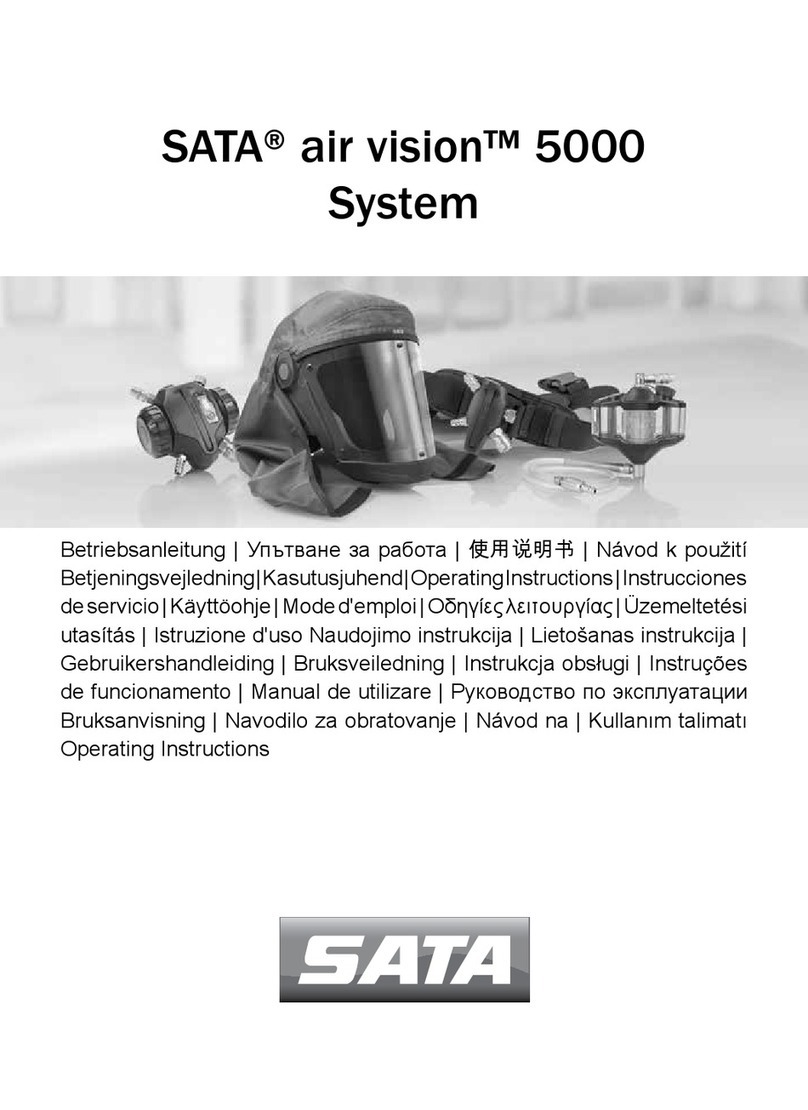

These User’s Instructions contain

important information on how to

use the breathing protection equip-

ment, which comprises the SATA

air vision 5000 breathing protection

hood, the SATA air regulator, the al-

ternative air regulator with activated

carbonlterSATAaircarbonregu-

lator with optional SATA air warmer

carbon,theSATAairhumidier,

the standalone SATA air warmer /

cooler and the SATA air regulator

belt. They also describe operation,

care, maintenance, cleaning, warn-

ings and error messages as well as

troubleshooting.

Read first!

Read these User’s Instructions

thoroughly and carefully before

using the breathing protection

equipment. Always observe

safety precautions and hazard

Always keep these operating in-

structions with the breathing pro-

tection equipment or at a location

accessible to everyone at any time.

1.2. Target group

These operating instructions are intend-

ed for

■Skilled personnel in the painting

trade.

■Personnel trained for painting work in

industrial and trade shops.

[US | CDN] Operating Instructions | US-english