GRAPHITE

DIGITAL PASSIVE INFRARED DETECTOR

graphite_e 11/06

The GRAPHITE digital motion detector is characterized by high sensitivity, as well

as high immunity to interference and false alarms. The detector construction is

based on an advanced signal processor with a high resolution transducer. A dual

pyroelectric element is used in the detector. An advanced digital temperature

compensation feature enables operation within a wide range of temperatures.

Other advantages of the detector include alarm memory and remote on/off

switching of the LED indicator.

NC TMP COM 12V

NC TMP LED MEM

JP1

LED ON/OFF

SENSIT.

1

23

4

5

7

8

6

9

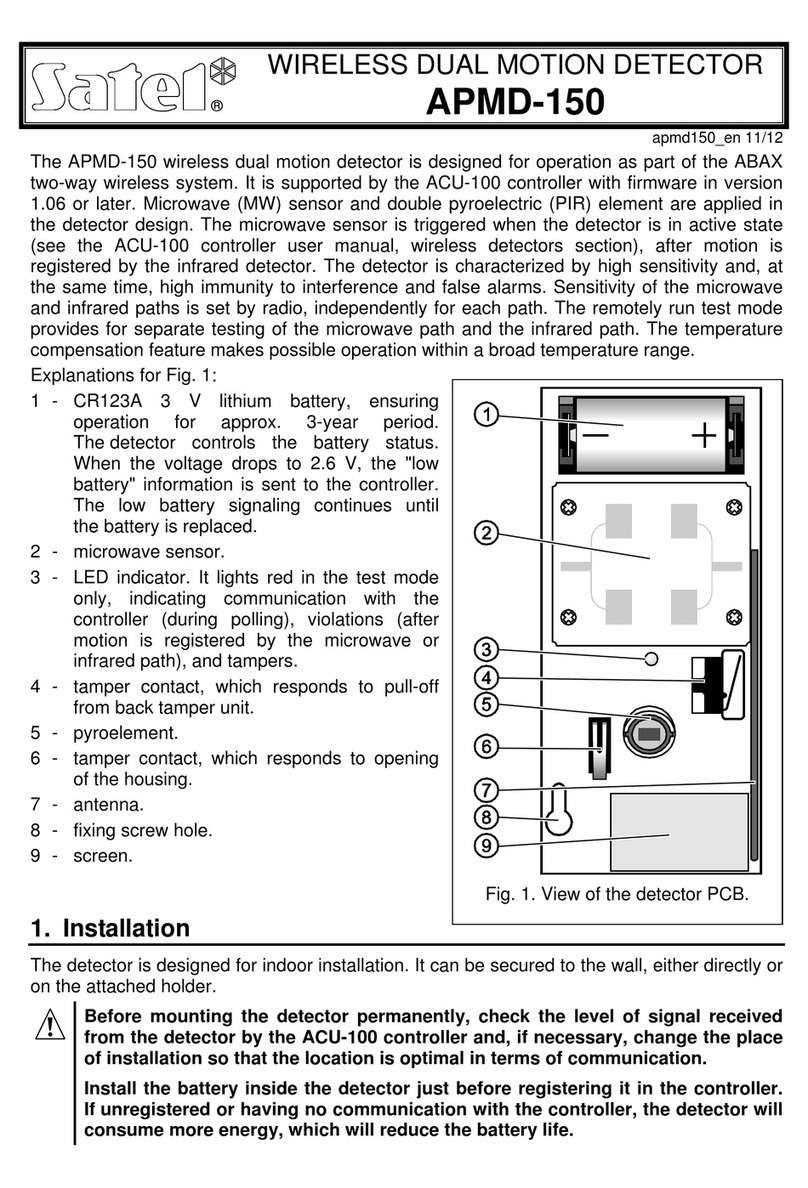

Figure 1. View of the detector electronics board.

Explanations for Figure 1:

1 – terminals:

NC – relay (NC).

TMP – tamper contact.

COM – common ground.

12V – power supply input.

LED – the input enables the LED indicator to be remotely switched

ON/OFF, if the jumper is removed from the LED ON/OFF pins. The

LED will signal violations, when the LED input is short-circuited to

the common ground. For control of the input, you can use the OC

type output of the control panel, programmed e.g. as SERVICE

MODE INDICATOR or BI SWITCH.

MEM – the alarm memory control input. It is required that the OC type

output of the alarm control panel, programmed as ARMED STATUS

INDICATOR be connected to the input. When the input is shorted to

the ground and the detector registers a motion, thus triggering the

alarm, the LED blinking will signal the alarm memory. The alarm

memory signaling will continue until the input is shorted to the

ground again. Cut-off of the input from the ground (disarming) will

not erase of the alarm memory.

2 – LED indicator. It lights red for approx. 2 seconds after registration of

movement by the detector and activation of the relay (opening of the NC

contacts). It allows the installer to check the detector performance and to

approximately determine the supervised area. Blinking of the LED indicates

alarm memory.

3 – LED ON/OFF pins. Setting the jumper will activate signaling by means of the

LED, irrespective of the LED input status.

4 – alarm relay.

5 – pyroelectric element.

6 – tamper contact.

7 – graduation for positioning the pyroelectric element against the lens (see

Table 1 and Figure 4).

8 – mounting screw hole.

9 – potentiometer for detector sensitivity adjustment.

For 30 seconds after power-up, the detector remains in the starting state, which

is signaled by short flashes of the LED indicator. Only after this time the detector

will enter the ready state.

The detector is monitoring power supply voltage and availability of the signal path.

In case of a voltage drop below 9V (±5%), lasting longer than 2 seconds, or

detection of a fault in the signal path, the detector will signal a trouble by activating

the alarm relay and steady lighting of the LED. The signaling continues as long as

the trouble exists.

Installation

The detector is designed for indoor installation. It can be mounted on the wall,

either directly or on the included holder (mounting on the holder is recommended

by the manufacturer).

It is advisable that you exercise particular care during installation

so as not to soil or damage the pyroelectric element.

Remember during installation that the detector should not be

directed towards heat sources or air-conditioning outlets, as well as

objects exposed to strong solar radiation.

1. Open the housing as shown in Figure 2.

Figure 2. The way to open the housing.

2. Remove the electronics board.

3. Make suitable holes for screws and cable in the rear housing panel.

4. Pass the cable through the prepared opening.

5. Secure the rear housing panel to the included holder or the wall.

Figure 3. Mounting the detector on holder.

6. Fasten the electronics board, taking into account the height at which the

detector is mounted (see Table 1 and Figure 4).

Mounting height Graduation position against housing index

above 2.4m middle graduation mark above the index

2.4m middle graduation mark aligned with the index

below 2.4m middle graduation mark below the index

Table 1. Positioning the pyroelctric element against the lens.

Note: If the detector is installed at a height above 2.4m, it is recommended that

the holder be used, and the detector be mounted in inclined position.

7. Connect the wires to corresponding terminals.

8. Using potentiometer, determine sensitivity of the detector.

9. Close the detector housing.