Version 0.8 21/10/2004 Page 6 of 44

WHAT IS RFID?

RFID is best described as a wireless memory chip, or “smart tag”, that is attached to both

the product and transport packaging.

Q: How does an RFID system work?

RFID offers higher data storage capacities, higher identification speeds, and greater

immediacy and accuracy of data collection. RFID readers control the wireless reading and

writing of information stored on an RFID tag by generating a radio frequency field around

the antenna. The RF field gives the tag power (if passive tag), and a way to transfer data

from the tag to the reader. The tag modulates the reader's RF field, and the reader can

detect this. Likewise, the reader turns the RF field on and off in the right sequence in order

to write the tag.

Q: Why are supply chain management companies embracing this technology?

An increasing number of supply chain management companies worldwide are embracing

RFID technology to identify multiple items in a single container in an expeditious manner—

a feat that is not always possible with bar-coding systems. The technology’s enhanced

accuracy and security in data collection makes it an ideal data collection platform for the

healthcare, pharmaceutical, manufacturing, warehousing, logistics and retail sectors.

Q: What was the first application of RFID?

RFID can be traced back to World War II days, when the British military needed to find a

way to identify whether an approaching aircraft was friend or foe. Even today, as more

sophisticated navigation technology becomes accessible, the United States military is

currently using various forms of RFID.

Q: When was RFID first used to track inventory or livestock?

In the 1980s, Compaq Computer had begun using RFID tags to trace components through

the production process. The railroad industry has also used RFID to track nearly every rail

car in North America, while the agricultural industry has used RFID tags to trace its

livestock.

Q: What was the first implementation of RFID towards consumer applications?

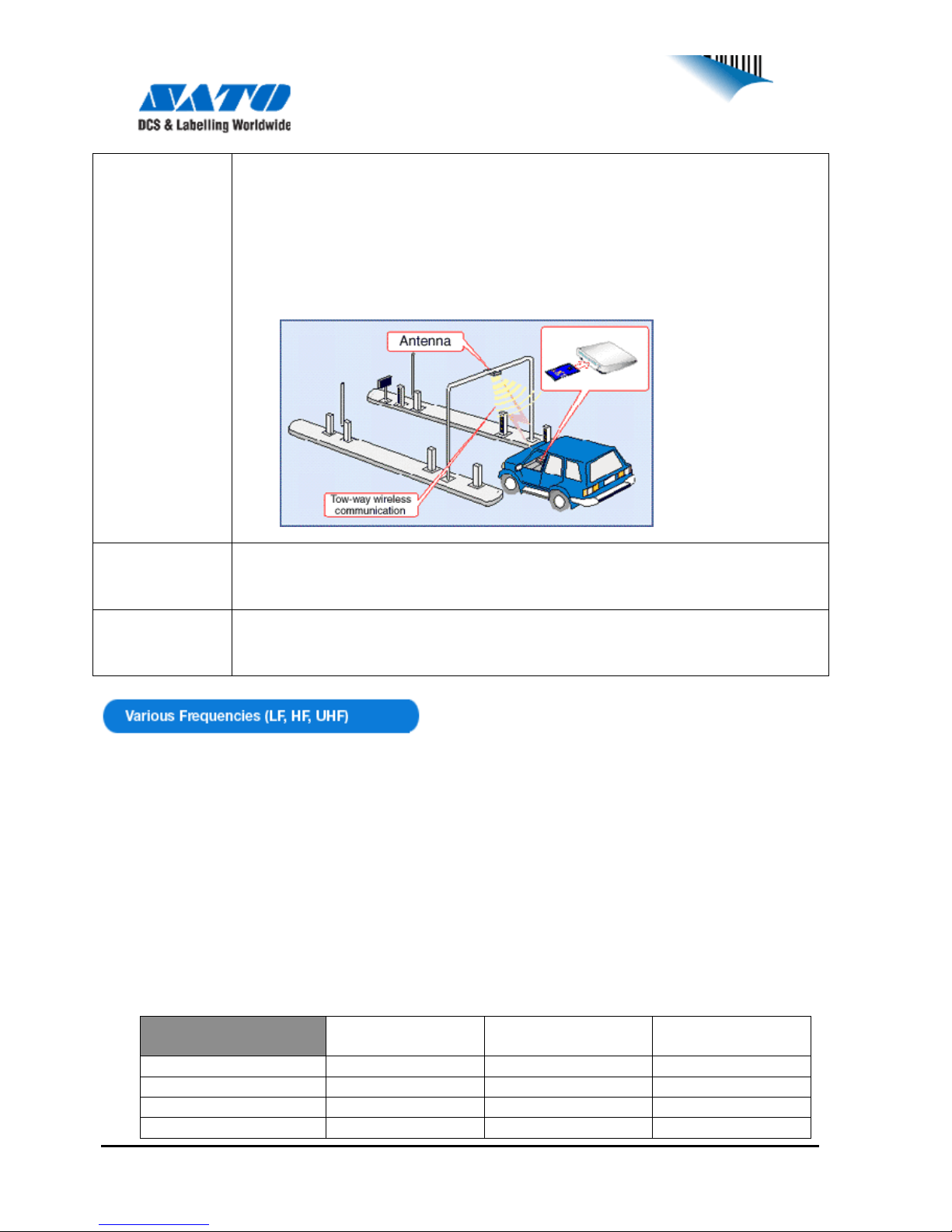

Additionally, RFID has also been used for various consumer applications. Vehicle

transponders use RFID to communicate with toll booths on bridges, expressways, or

special toll roads to automatically deduct funds from the account holder of the transponder.

Q: What is the driving force behind the initiative of so many companies to

implement RFID?

One of the major reasons is because a few major retailers, along with the U.S. Department

of Defense (DoD), have decided to utilise RFID technology within their supply chain

management. The major retailers are mandating that their top 100 suppliers utilise RFID

tags on all product deliveries by 2005.