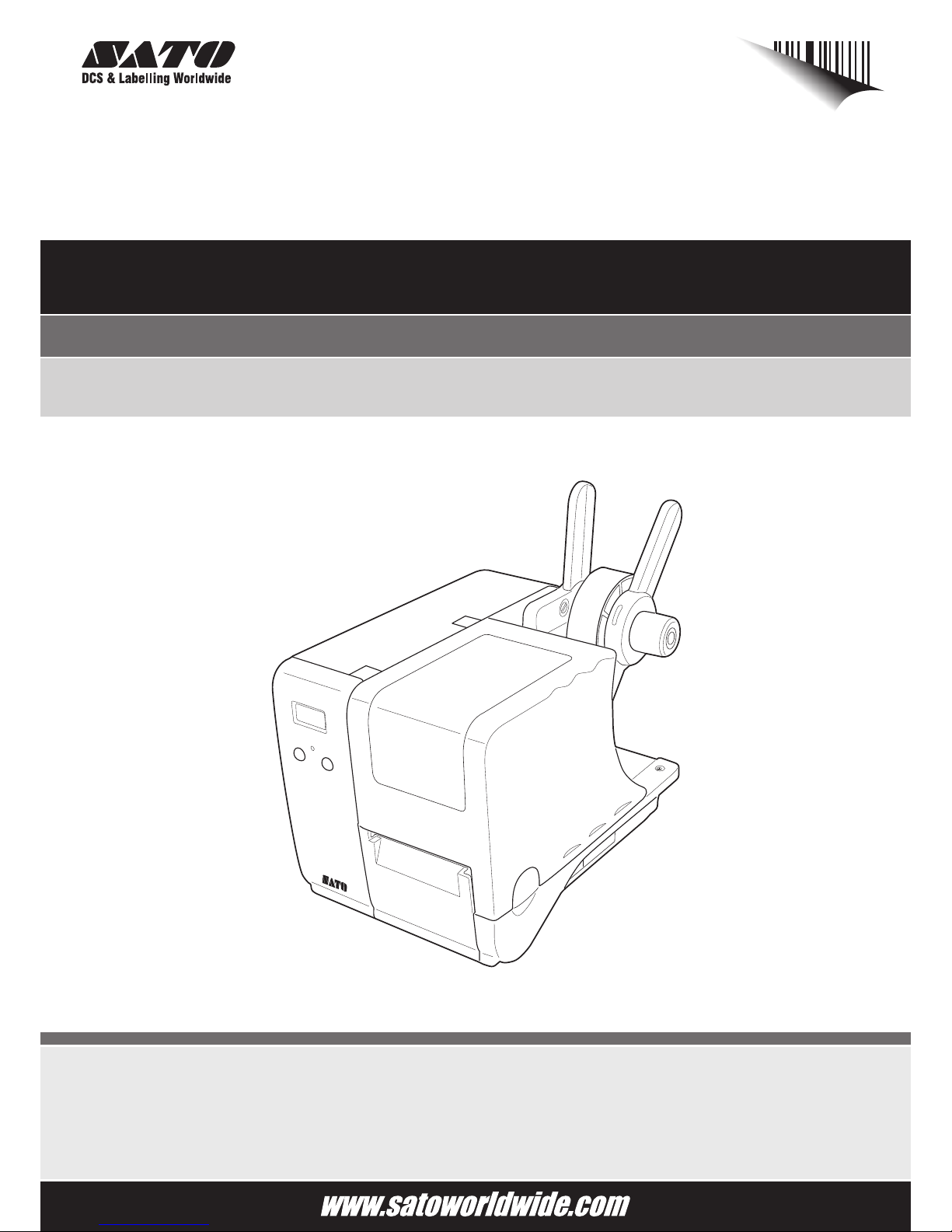

SATO DR308e User manual

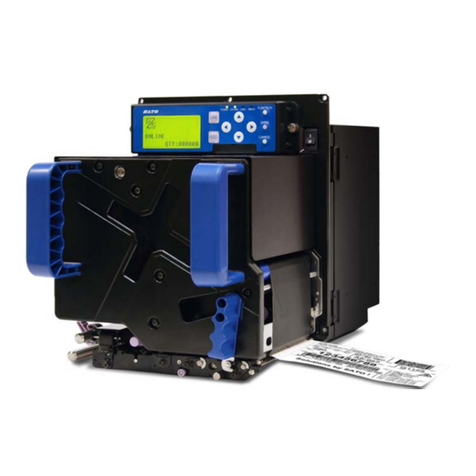

For printer model:

Operator Manual

DR308e

Read this Operator Manual before and during usage of the above product.

Keep this document handy for future reference.

STATUS

LINE

FEE D

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/ TV technician for help.

Be sure to ask your dealer about our maintenance contracts to

ensure a peace of mind during your usage of SATO products.

Please refer to the back cover for SATO Group Member Company

closest to your location. You may also visit our home page at

www.satoworldwide.com for further updated details.

All rights reserved. No part of this document may be reproduced or issued to third parties in any

form whatsoever without the express permission of SATO. The materials in this document are

provided for general information and are subject to change without notice. SATO assumes no

responsibilities for any errors that may appear.

Version: SI-DR308e-01rA-14-07-08OM

© Copyright 2008

SATO International Pte Ltd

Safety Precautions

DR308e Operator’s Manual Page i

Please read the following information carefully before installing and using the printer.

The Warning symbol

Whenever the triangular Warning symbol appears in this manual, pay special attention to the warning(s) cited

below it. Failure to abide by the warnings may create the danger of death or serious personal injury.

The Caution symbol

Whenever the triangular Caution symbol appears in this manual, pay special attention to the warning(s) cited

below it. Failure to abide by the warnings may result in injury or damage to property.

On Power Supply

Safety Precautions

• Do not use any other voltage except

the specified power voltage for the

printer that matches your domestic

power supply. Otherwise, it may

cause fires or electric shocks.

• Do not damage, break, or process the power

cable. Avoid placing heavy objects on, heating or

pulling the power cable. This may damage the

power cable and cause fires or electric shocks.

• When the power cable is damaged (cable conduc-

tors are exposed or cut, etc.), contact a sales out-

let, dealer, or service center. In this case,

continued use of the printer may cause fires or

electric shocks.

• Do not process, forcibly bend, twist, or pull the

power cable. Continued use of such a cable may

cause fires or electric shocks.

• If the printer emits any smoke or peculiar odors at

any time, stop using the printer immediately. Turn

off the power immediately, disconnect the power

cable from the power outlet, and contact a sales

outlet, dealer, or service center.

• Do not operate the power switch or handle the

power cable with a wet hand. Otherwise, it may

cause electric shocks.

• To reduce electrical risks, be sure

to connect the printer to ground

before use. Also, try not to share

the printer’s AC outlet with other

electrical equipment, especially

those that draw high amounts of

current or cause electrical interference.

STATUS

LINEFEED

STATUS

LINEFEED

Ground

• Place the printer on a solid, stable,

horizontal surface that is not sub-

ject to strong vibrations from adja-

cent mechanical devices. This

may cause malfunction and

shorten the life span of the printer.

• Avoid shaky or slanting tables, or

platforms that are liable to col-

lapse under a heavy weight. If the

printer is dropped or damaged,

immediately turn off the power,

pull out the power plug and con-

tact a service center. In this case, continued use of

the printer may cause a fire or electric shocks.

• Avoid installing the printer in direct

sunlight, or in dusty, very hot or

slippery areas. Also avoid place-

ment in damp, unventilated or

humid areas. If condensation

forms, immediately turn off the

power, and do not use the printer until the conden-

sation disappears. Otherwise the moisture may

cause electric shocks.

• Avoid placing the printer near large high-current

equipment, as such equipment can cause spikes

or under-voltages in the power supply.

LINEFEED

STATUS

LINEFEED

STA

TUS

LINEFEED

On Installation

Safety Precautions

Page ii DR308e Operator’s Manual

• Do not leave containers of liquid or chemicals

around the printer. If any liquid is spilled onto the

printer, immediately turn off the power, pull out the

power cable from the AC outlet, and contact a

sales outlet, dealer, or service center. In this case,

continued use of the printer may cause fires or

electric shocks.

• Do not insert or drop anything metallic or flamma-

ble into the openings of the printer (the cable out-

let). Otherwise, immediately turn off the power,

disconnect the power cable from the power outlet,

and contact a sales outlet, dealer, or service cen-

ter. In this case, continued use of the printer may

cause fires or electric shocks.

• When moving the printer, be sure to pull out the

power cable from the AC outlet, and check that

any other external interface cables have been dis-

connected. Otherwise, the connected cables may

be damaged, or may cause trips and falls, in addi-

tion to or a fire or electric shocks.

• This printer has a built-in optical sensor. Expose to

strong lighting will make the sensor less respon-

sive and may cause the label to be sensed incor-

rectly. Close the cover when printing.

• The optional head cleaning liquid is flammable.

Never heat it or throw it into a fire. Keep it out of

children’s reach to avoid accidental consumption.

Should this occur, consult a doctor immediately.

• When opening or closing the cover, beware of get-

ting your fingers caught. Also, hold the opening/

closing cover well so that it will not slip and fall on

your hand.

• After printing, the print head remains hot. When

replacing paper or cleaning the printer immedi-

ately after printing, be careful not to burn yourself.

• Touching even the edge of the printer head may

cause injuries. When replacing paper or cleaning

the printer, be careful not to hurt yourself.

• If the printer will not be used for extended periods

of time, disconnect the power cable for safety.

• When releasing and locking down the printer head,

be careful not to catch any other foreign matter in

it except loaded media.

• Do not disassemble or perform modifications to

the printer, as this renders the product unsafe. For

maintenance, troubleshooting and repairs, consult

a sales outlet, dealer, or service center for help,

instead of attempting to perform this yourself.

Renewable annual service contracts are available.

• When maintaining or cleaning the printer, always

disconnect the power cable for safety.

• Do not insert your hand or other objects into the

cutter when the option cutter is installed.

• When loading roll media, be careful not to catch

your fingers between the media and the feeder.

On Installation (cont’d)

On General Handling

Table of Contents

DR308e Operator’s Manual Page iii

TABLE OF CONTENTS

1 Introduction

1.1 Unpacking ..............................................................................................................1-2

1.2 Parts Identification .................................................................................................1-3

2 Installation

2.1 Site Location ..........................................................................................................2-2

2.2 Media Selection .....................................................................................................2-2

2.3 Loading Labels or Tags ........................................................................................2-3

2.4 Loading the Carbon Ribbon .................................................................................3-7

2.5 Remove the Carbon Ribbon .................................................................................3-9

2.6 Adjusting the Pitch Sensor ..................................................................................2-9

2.7 Connections ...........................................................................................................2-10

3 Operation and Configuration

3.1 Operation Panel .....................................................................................................3-2

3.2 Operating Modes ...................................................................................................3-3

3.3 ONLINE And OFFLINE Modes ..............................................................................3-5

3.4 Printer Setting Modes ...........................................................................................3-6

3.5 Paper (media) Mode ..............................................................................................3-6

3.6 User Mode ..............................................................................................................3-7

3.7 Interface Mode .......................................................................................................3-11

3.8 Advance Mode .......................................................................................................3-15

3.9 HEX Dump Mode ...................................................................................................3-22

3.10 Test Print Mode .....................................................................................................3-24

3.11 Default Setting Mode .............................................................................................3-26

4 Cleaning and Maintenance

4.1 Cleaning The Print Head, Platen and Rollers .....................................................4-2

4.2 How To Clean The Printer (Cleaning Kit) ............................................................4-2

4.3 How To Clean The Printer (Cleaning Sheet) .......................................................4-3

4.4 Adjusting Print Quality .........................................................................................4-4

5 Troubleshooting

5.1 Error signal troubleshooting ...............................................................................5-2

5.2 Troubleshooting table ...........................................................................................5-4

5.3 Interface troubleshooting .....................................................................................5-5

5.4 Test print troubleshooting ....................................................................................5-6

6 General Specifications

6.1 Printer Basic Specifications .................................................................................6-1

6.2 Optional Accessories Specifications ..................................................................6-5

Table of Contents

Page iv DR308e Operator’s Manual

7 Interface Specifications

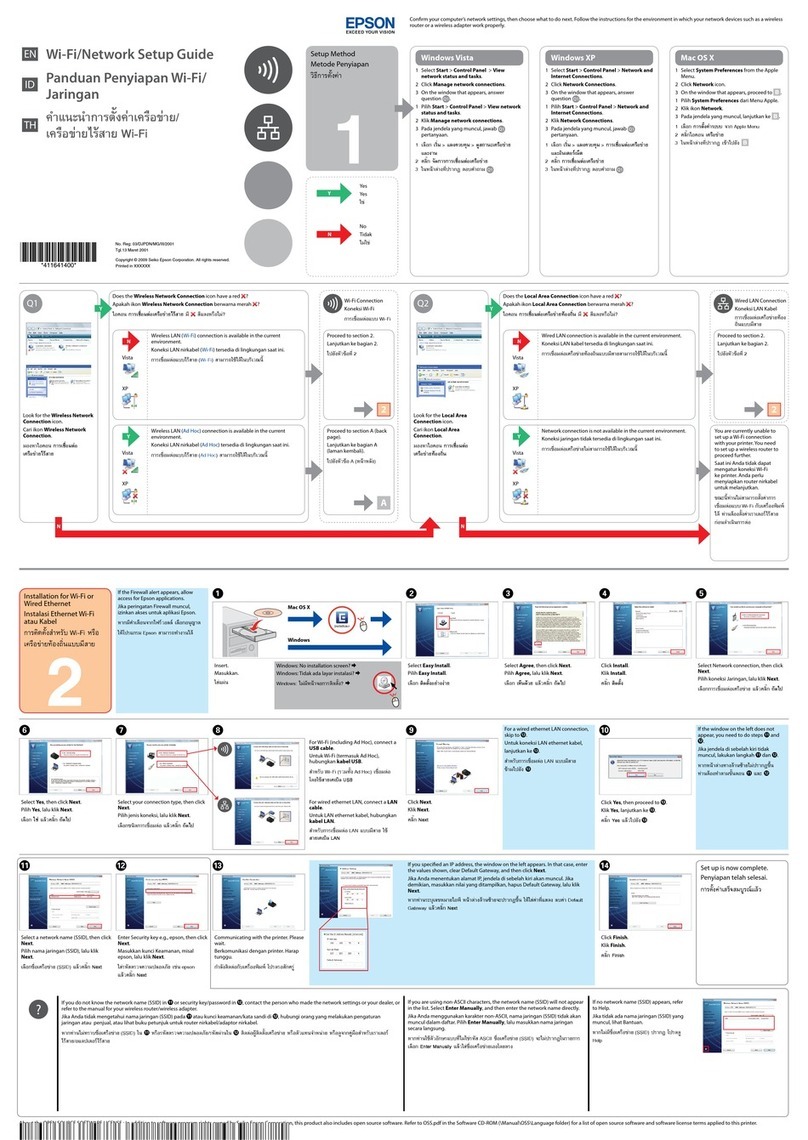

7.1 Interface types .......................................................................................................7-1

7.2 RS232C High Speed Serial Interface ...................................................................7-2

7.3 IEEE 1284 Parallel Interface .................................................................................7-6

7.4 Local Area Network (LAN) Ethernet ....................................................................7-8

7.5 Universal Serial Bus (USB) Interface ...................................................................7-9

7.6 External Signal Interface (EXT) ............................................................................7-9

8 Optional Accessories

8.1 Cutter ......................................................................................................................8-1

8.2 Stacker ...................................................................................................................8-2

8.3 Dispenser ...............................................................................................................8-4

8.4 External Rewinding Unit .......................................................................................8-5

8.5 Keypad ...................................................................................................................8-6

8.6 Calendar IC ............................................................................................................8-6

9 Sato Group of Companies ......................................................... Back cover

Section 1: Introduction

DR308e Operator’s Manual Page 1-1

INTRODUCTION

Thank you for your investment in this SATO printer product.

This Operator’s Manual contains basic information about the installation, setup, configuration, operation and

maintenance of the printer.

A total of eight topics are covered herein, and they are organized as follows:

Section 1: Introduction

Section 2: Installation

Section 3: Operation and Configuration

Section 4: Cleaning and Maintenance

Section 5: Troubleshooting

Section 6: General Specifications

Section 7: Interface Specifications

Section 8: Optional Accessories

It is recommended that you become familiar with each section before installing and maintaining the printer.

Refer to the Table Of Contents at the front of this manual to search for the relevant information needed. All

page numbers in this manual consist of a section number followed by the page number within the stated

section.

For specialized programming, refer to the separate Programming Manual.

This section assists you in unpacking the printer from the shipping container. You will also be guided through

a familiarization tour of the main parts and controls.

The following information is provided herein:

• Unpacking

• Parts Identification

Section 1: Introduction

Page 1-2 DR308e Operator’s Manual

1.1 UNPACKING

When unpacking the printer, take note of the following:

1. The box should stay right-side up.

Lift the printer out of the box carefully.

2. Remove all the packaging covering from the printer.

3. Remove the accessory items from their protective containers.

4. Set the printer on a solid, flat surface. Inspect the shipping container and printer for any sign of damage

that may have occurred during shipping.

Notes

• If the printer was been stored in the cold, allow it to reach room temperature before turning it on.

• Please do not discard the original packaging box and cushioning material after installing the printer. They

may be needed in future, if the printer needs to be shipped for repairs.

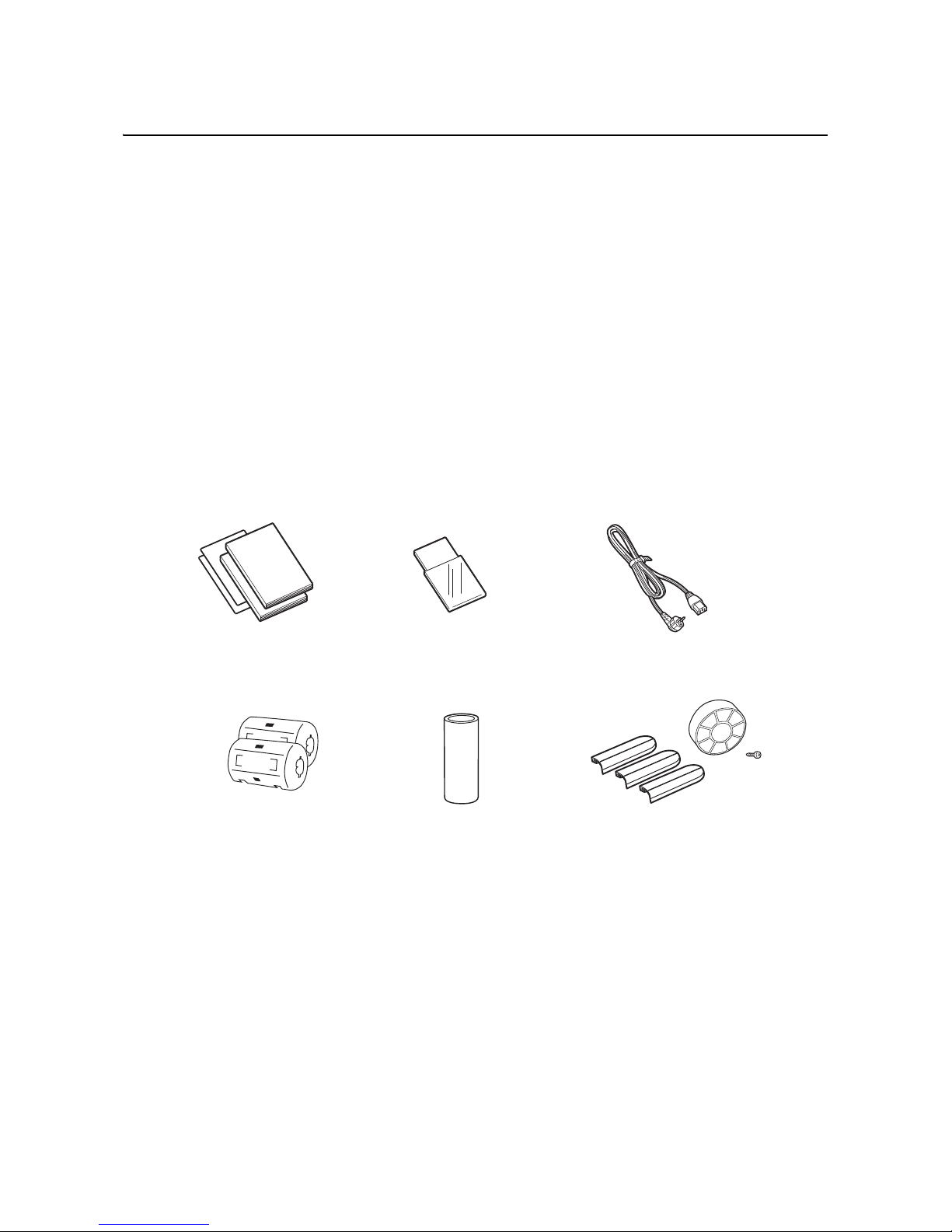

1.1.1 Included Accessories

After unpacking the printer, verify that the following materials are in the accessories or packaging:

kciuQ

ediuG

User Documentations

(Quick Guide, Warranty, etc.)

Head cleaning sheet Power cable*

Ferrite core (for attaching

to power cable)

Ribbon core (for winding) Extension guide plates,

core adaptor, screw to

secure the core adaptor

* The shape of the power plug may varied depending on the location of purchased.

Section 1: Introduction

DR308e Operator’s Manual Page 1-3

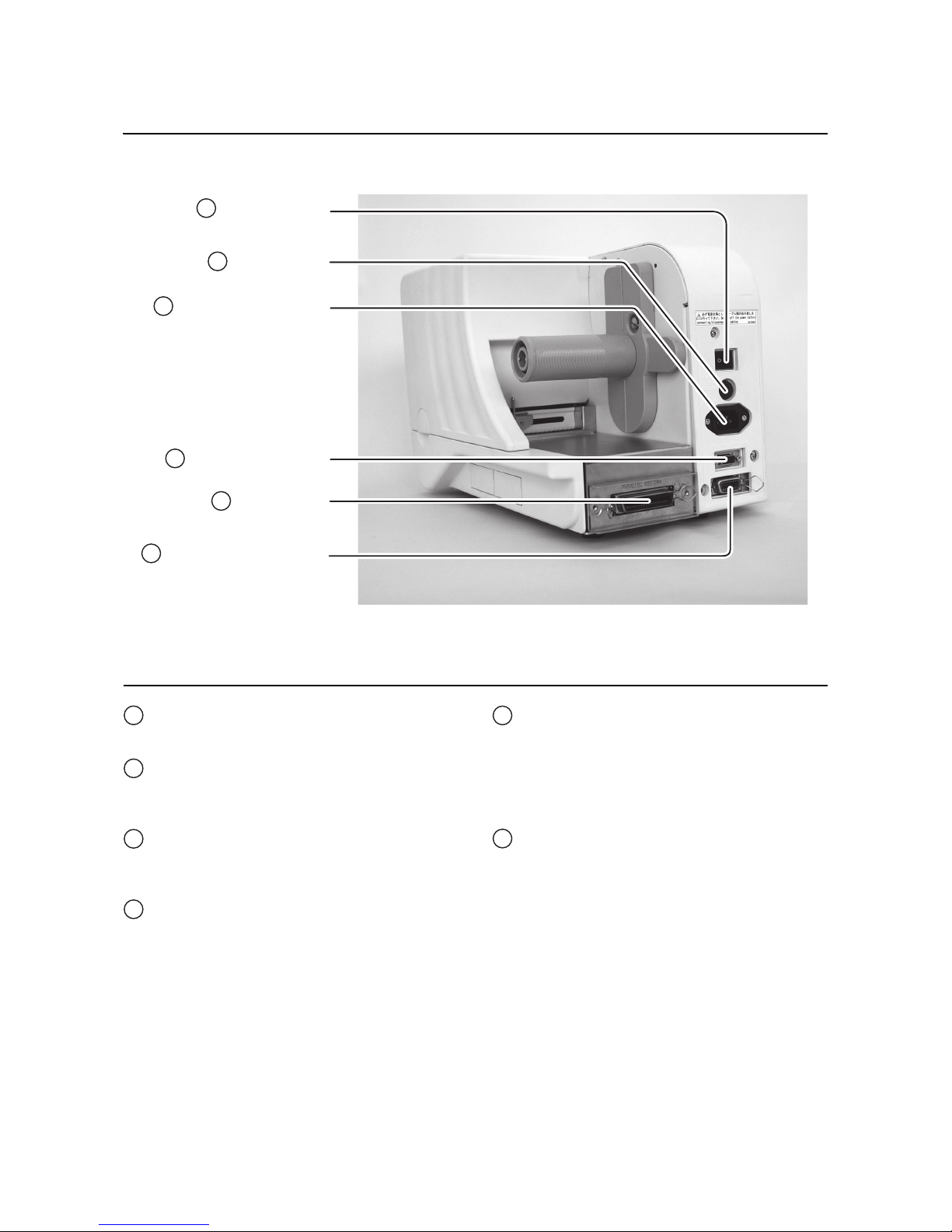

1.2 PARTS IDENTIFICATION

1 Main Cover

Front View of DR308e

2 Display panel

3STATUS (LED) indicator

4 LINE button

5 FEED button

6 Media ejection slot

8 Cover for potentiometer

and Dip switch compart-

ment

7 Optional device

compartment

Main cover

Open and close this cover to load the media

and ribbon.

Display panel

Displays an error and operation messages.

STATUS (LED)

Lights or flashes to indicate the printer status.

It turns red when error occurred, turns green

when printing and data communication are

enabled (ONLINE) and turns off when the

printer is in OFFLINE mode.

LINE button

Used to start or stop printing, and also to

toggle between the on/off settings for data

transmission and reception.

When the printer is in configuration setting

mode, it is pressed to select options or adjust

the settings.

FEED button

Press once to feed one blank label.

When the printer is in configuration setting

mode, it is pressed to enters to the selected

mode.

Media ejection slot

Opening for media output.

Optional device compartment

This printer comes with a tear-off cover. An

optional device can be installed on this

compartment, e.g. dispenser, cutter, stacker or

external rewinding unit.

Cover for potentiometers and Dip switch

compartment

Open the cover to access the potentiometers

and Dip switch for adjustment.

1

2

3

4

5

6

7

8

Section 1: Introduction

Page 1-4 DR308e Operator’s Manual

1.2 PARTS IDENTIFICATION (cont’d)

9 POWER switch

Back View of DR308e

10 FUSE holder

11 AC IN power terminal

13 Interface slot

14 EXT external connector

terminal

12 Keypad connection

terminal

POWER switch

Turns power On(-) or Off(O).

FUSE holder

Used to hold a fuse which protect the printer

from unstable power supply surge.

AC IN power terminal

Supplies power to the printer by inserting the

power cable.

Keypad connection terminal

Used to connect to the optional keypad.

Interface slot (option)

Optional interface slot for connection to a host

PC. An option of RS-232C (High-speed)

interface board, IEEE1284 interface board,

LAN interface board and USB interface board

are available for connection.

External connector terminal

Interface connector for external signals.

9

10

11

12

13

14

Section 1: Introduction

DR308e Operator’s Manual Page 1-5

1.2 PARTS IDENTIFICATION (cont’d)

18 Ribbon supply spindle

Side View of DR308e with main cover open

17 Roll media guide

25 Media guide shaft

22 Platen roller

15 Supplied yellow

screwdriver

19 Ribbon take-up spindle

20 Head lock lever

23 Pitch sensor

24 Pitch sensor guide

16 Roll media supply spindle

21 Print head

Supplied yellow screwdriver

Used to adjust the potentiometers and Dip

switches.

Roll media supply spindle

Used to load the roll media, tag or label.

Roll media guide

Set to meet the size of the media used.

Ribbon supply spindle

Used to load the ribbon.

Ribbon take-up spindle

Used to wind up the used ribbon.

Head lock lever

Used to open and close the print head.

Print head

This component is used to print on the paper.

Perform maintenance at regular intervals.

Platen roller

This roller feeds the paper. Perform

maintenance at regular intervals.

Pitch sensor

Detects the holes in the tag stock so that the

media can be cut off by the cutter.

Pitch sensor guide

Adjustment slide used to align the position of

the pitch sensor with the holes.

Media guide shaft

Set to meet the size of the media used.

15

16

17

18

19

20

21

22

23

24

25

Section 1: Introduction

Page 1-6 DR308e Operator’s Manual

1.2 PARTS IDENTIFICATION (cont’d)

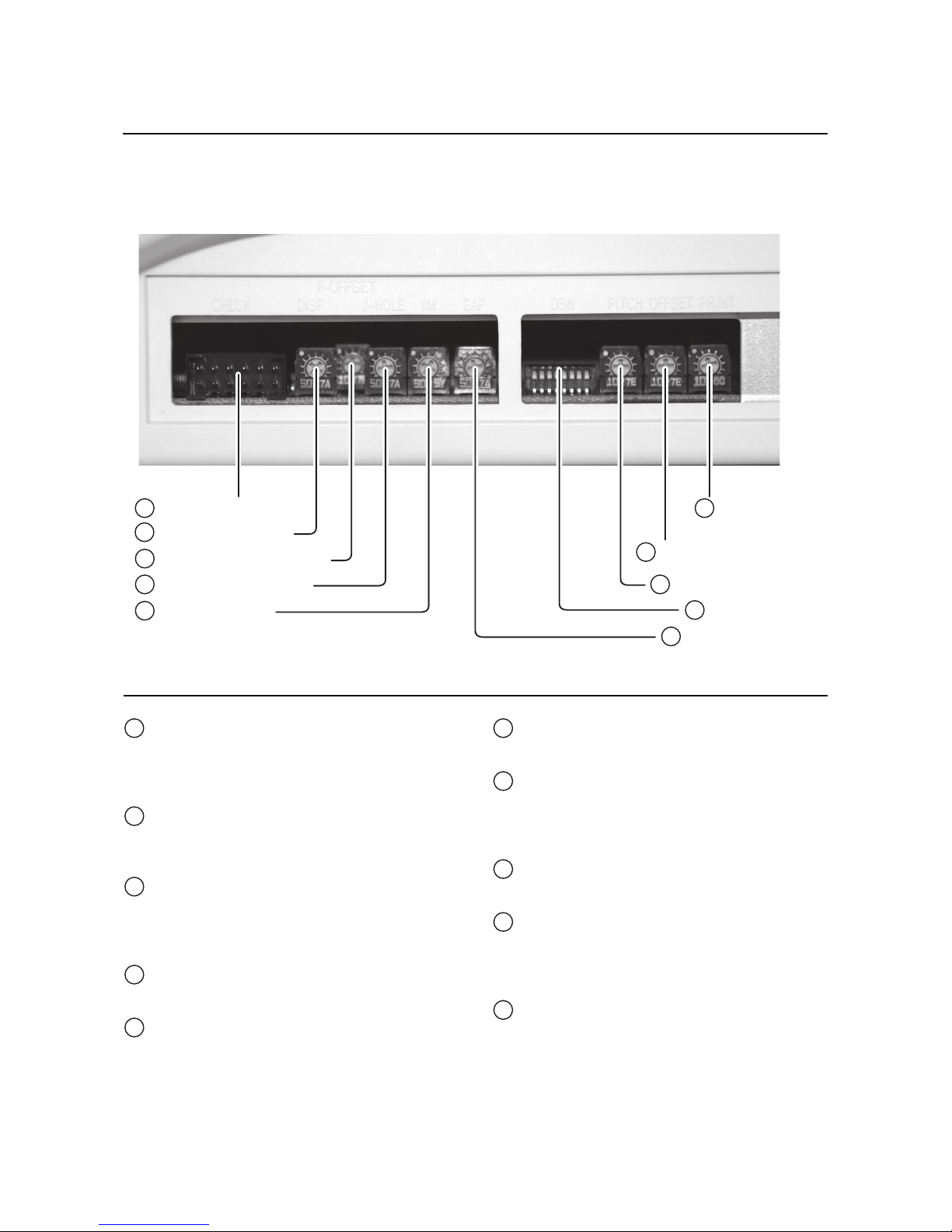

26 CHECK connector

Adjustment compartment at the right bottom side of DR308e

27 DISP potentiometer

31 PRINT

potentiometer

28 F-OFFSET potentiometer

29 J-HOLE potentiometer

30 IM potentiometer

32 OFFSET potentiometer

33 PITCH potentiometer

34 DSW dip switch

35 GAP potentiometer

CHECK connector

This is a connection terminal for sensor level

adjustment jig.This is only used by Sato

certified servicing personnel.

DISP potentiometer

To adjust the sensing level of the optional

dispenser.

F-OFFSET potentiometer

Factory offset adjustment. Adjust only when

instructed by Sato certified servicing

personnel.

J-HOLE potentiometer

Jump hole sensor adjustment.

IM potentiometer

I-mark sensor adjustment.

PRINT potentiometer

To adjust the darkness of the printing.

OFFSET potentiometer

To adjust the option stop positions (cutter

position, dispensing position and tear-off

position).

PITCH potentiometer

To adjust the beginning print position.

DSW dip switch

To set the printer to different modes when

servicing. This is only used by Sato certified

servicing personnel.

GAP potentiometer

Gap sensor adjustment.

15

26

16

27

17

28

18

29

19

30

20

31

21

32

22

33

23

34

24

35

Section 2: Installation

DR308e Operator’s Manual Page 2-1

INSTALLATION

This section assists you in installing consumable media to the printer, as well as adjustment instructions and

installing other optional attachment units.

The following information is provided:

• 2.1 Site Location

• 2.2 Media Selection

• 2.3 Loading Labels or Tags

• 2.4 Loading the Carbon Ribbon

• 2.5 Remove the Carbon Ribbon

• 2.6 Adjusting the Pitch Sensor

• 2.7 Connections

Section 2: Installation

Page 2-2 DR308e Operator’s Manual

2.1 SITE LOCATION

Consider the following when setting up the printer:

• Place the printer on a solid flat surface with adequate room. Make sure there is enough room at the

top and right-hand (facing the printer) side to provide clearance for the label access door to swing

open.

• Place it away from hazardous materials or dusty environments.

• Place it within operational distance of the host computer, within interface cable specifications

2.2 MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration before printer

purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that

does not cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also

wear a groove in the platen roller affecting print quality.

Note:

For optimal print performance and durability, please use SATO-certified label and ribbon supplies

on this printer. Using supplies not tested and approved for use by SATO can result in unnecessary

wear and damage to vital parts of the printer, and may void the warranty.

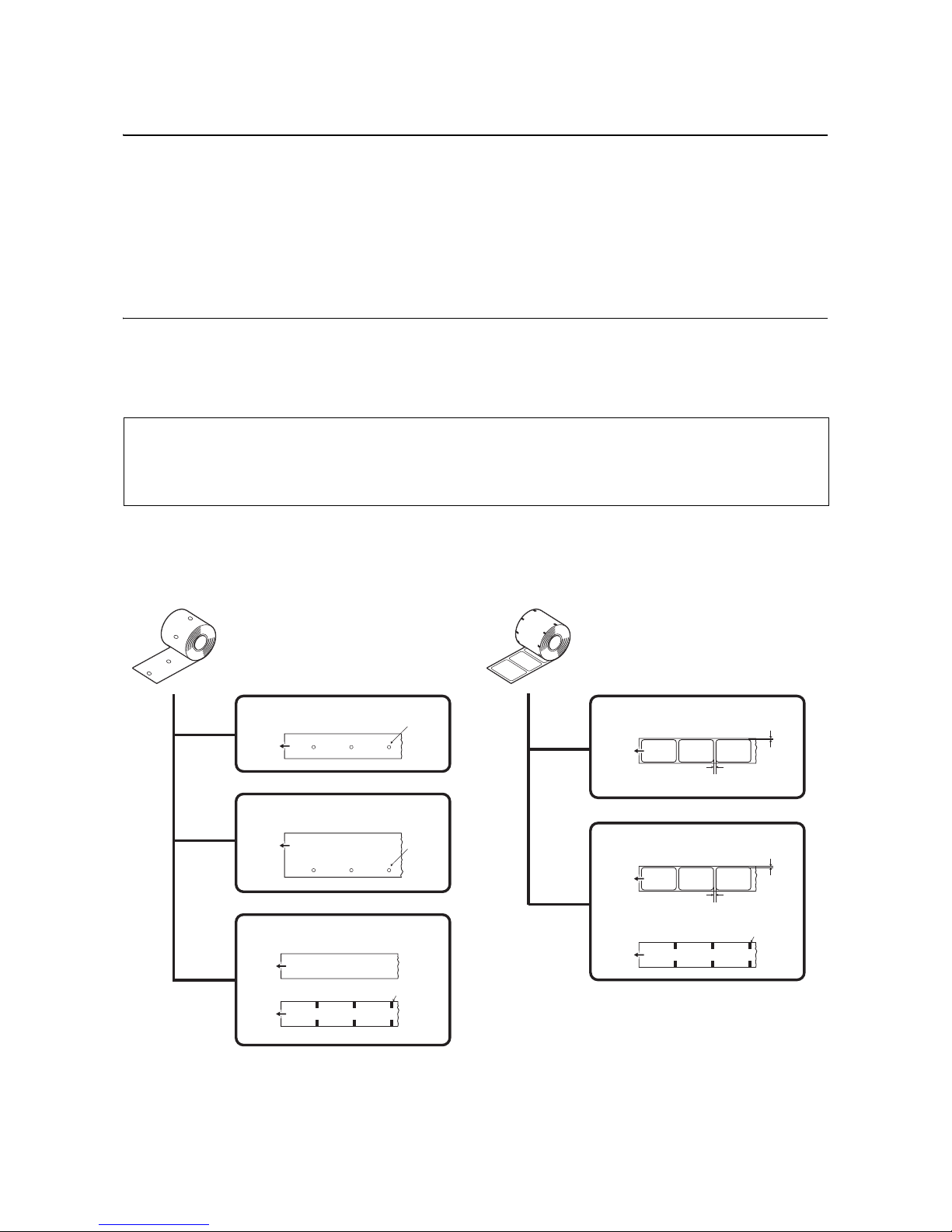

This printer can use five different types of media: three types of tag stock and two types of label media.

The methods used for loading tag stock and label media differ.

Tag stock

Center-hole

tag

Front side

Hole

Side-hole

tag

l-mark tag

Front side

Hole

Front side

l-mark

Reverse side

Front side

Front side

Fold perforation

I-mark

Reverse side

Label gap

Label

I-mark

1.5 mm

Label

3 mm

Gap (spacing)

3 mm

Gap (spacing)

Paper feed direction

Paper feed direction

Paper feed direction

Paper feed direction

Paper feed direction

Section 2: Installation

DR308e Operator’s Manual Page 2-3

2.2 MEDIA SELECTION (cont’d)

This printer accepts two types of media core sizes, φ40mm (1.5in.) and φ100mm (4in.). When using φ100mm

(4in.) core size media, the supplied core adaptor and guide plates need to be installed to the printer. Please

refer to Section 2.3.2 Loading Roll media with a large media core on page 2-5 for further instructions.

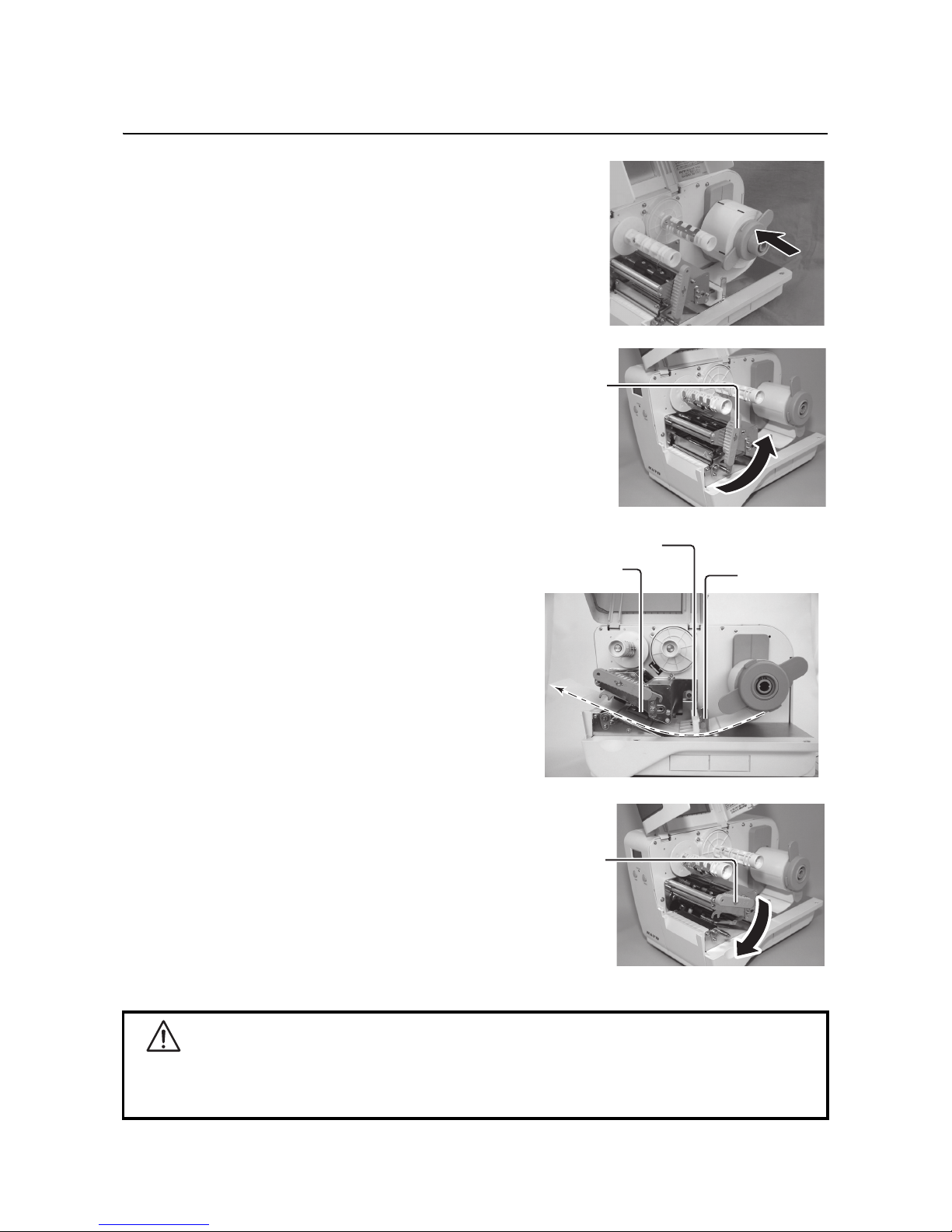

2.3 LOADING LABELS OR TAGS

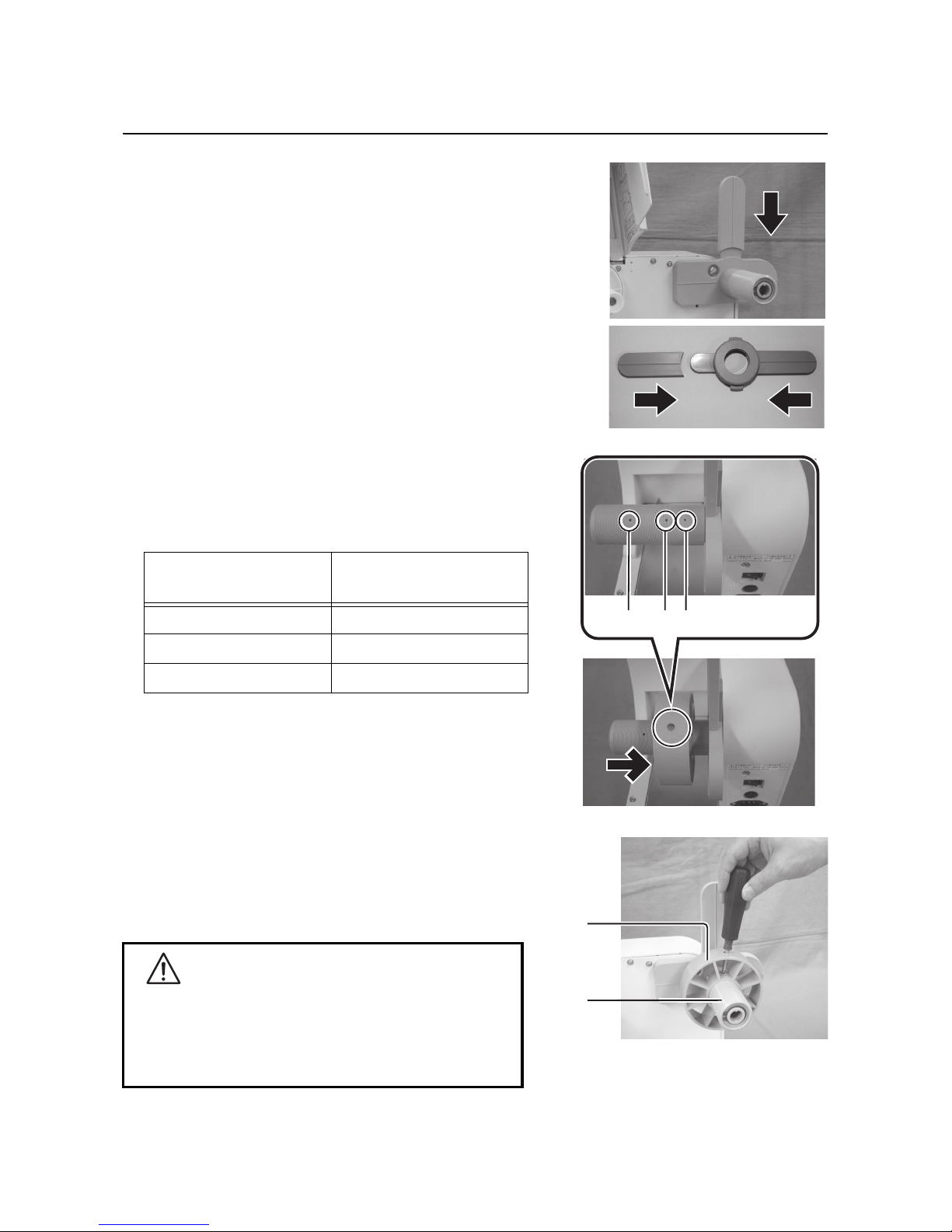

2.3.1 Loading Roll media with small media core

1. With the power supply is off, lift up the main cover.

Make sure that the cover rests firmly so that it will not fall

forward and injure your hands.

2. Remove the roll media guide by pressing the release

tab with your thumb and index finger and pulling it out.

3. Load the media to the roll media supply spindle.

Make sure the media leader is pull out from the bottom

and the printed side is facing upwards. Push the roll

firmly towards the end of the spindle.

φ 40mm (1.5”)

φ100mm (4”)

Main cover

Printed

side

should

face

upwards

Section 2: Installation

Page 2-4 DR308e Operator’s Manual

2.3 LOADING LABELS OR TAGS (cont’d)

4. Attach the roll media guide back and make sure that

the roll media guide pushes snugly against the media

roll to prevent media drift during printing.

5. Release the purple head lock lever by turning counter

clockwise.

The print head assembly will be lifted up to allow media

loading.

6. Insert the media into the media guide from a sideways

angle, so that the media passes underneath the media

guide shaft and pitch sensor guide.

Inspect the media routing and verify that the path

matches that illustrated on the inner side of the main

cover.

7. Lightly push the entire media against the media guide

designated position. Adjust the sliding guide until it

lightly touches the edge of the label.

8. Now remount the print head by turning the head lock

lever clockwise until it latch on. The print head should

lock into place firmly.

9. After loading the media and the carbon ribbon, close the

main cover and do a test print to check that the media

roll has been loaded properly. See Section 3.10 Test

Print Mode on page3-24 for instructions on how to run

test print.

Notes:

• Be careful not to get your fingers caught at the bottom

ledge when you are closing the main cover.

• If the optional cutter or dispenser has been pur-

chased, see Section 8 Optional Accessories on

page 8-1 on how to route the media.

Caution

• When replacing media, bear in mind that the print head and its surrounding area remain hot. Keep

your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Head lock

lever

(purple)

Media guide shaft

Pitch sensor

guide Sliding guide

Head lock

lever

(purple)

Section 2: Installation

DR308e Operator’s Manual Page 2-5

2.3 LOADING LABELS OR TAGS (cont’d)

2.3.2 Loading Roll media with a large media core

1. With the power supply is off, lift up the main cover.

Make sure that the cover rests firmly so that it will not fall

forward and injure your hands.

2. Remove the roll media guide by pressing the release

tab with your thumb and index finger and pulling it out.

3. Unfasten the screw holding the roll media supply spin-

dle. Use a flat-blade screwdriver to unfasten the screw.

4. Rotate the spindle to 90 degree in the upper right (coun-

ter clockwise) direction.

5. Fasten the screw that you unfastened in step 3.

Main cover

Roll media

guide

Section 2: Installation

Page 2-6 DR308e Operator’s Manual

2.3 LOADING LABELS OR TAGS (cont’d)

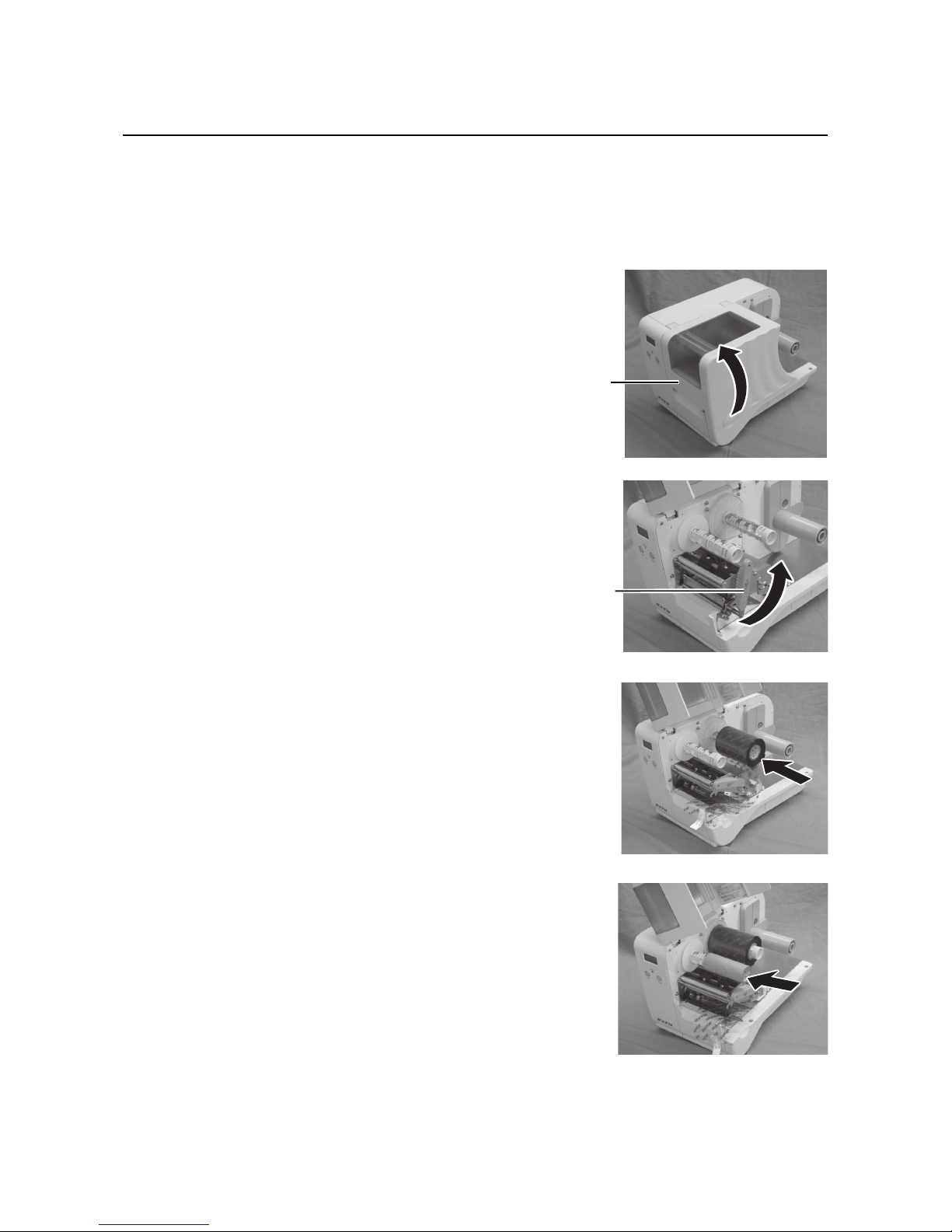

6. Attached a supplied extension guide plate to the side

of the roll media supply spindle. Attached the other

two extension guide plate to the roll media guide.

7. Insert the supplied core adaptor to the roll media

supply spindle. Align the screw hole of the core adap-

tor with the specific screw hole on the supply spindle

according to the width of media used as stated in the

table below.

8. Fasten the core adaptor in place with the supplied

screw.

9. Load the media.

Follow the instructions of Section 2.3.1 Loading Roll

media with small media core from step 3 onwards.

Caution

• When replacing media, bear in mind that the print

head and its surrounding area remain hot. Keep your

fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with

your bare hands.

Core adaptor attachment

position Media width

Attachment hole 1 Up to 50 mm (2in.)

Attachment hole 2 50 mm (2in.)to 80 mm (3in.)

Attachment hole 3 Not used

2

31

Core

adaptor

Roll

media

supply

spindle

Section 2: Installation

DR308e Operator’s Manual Page 2-7

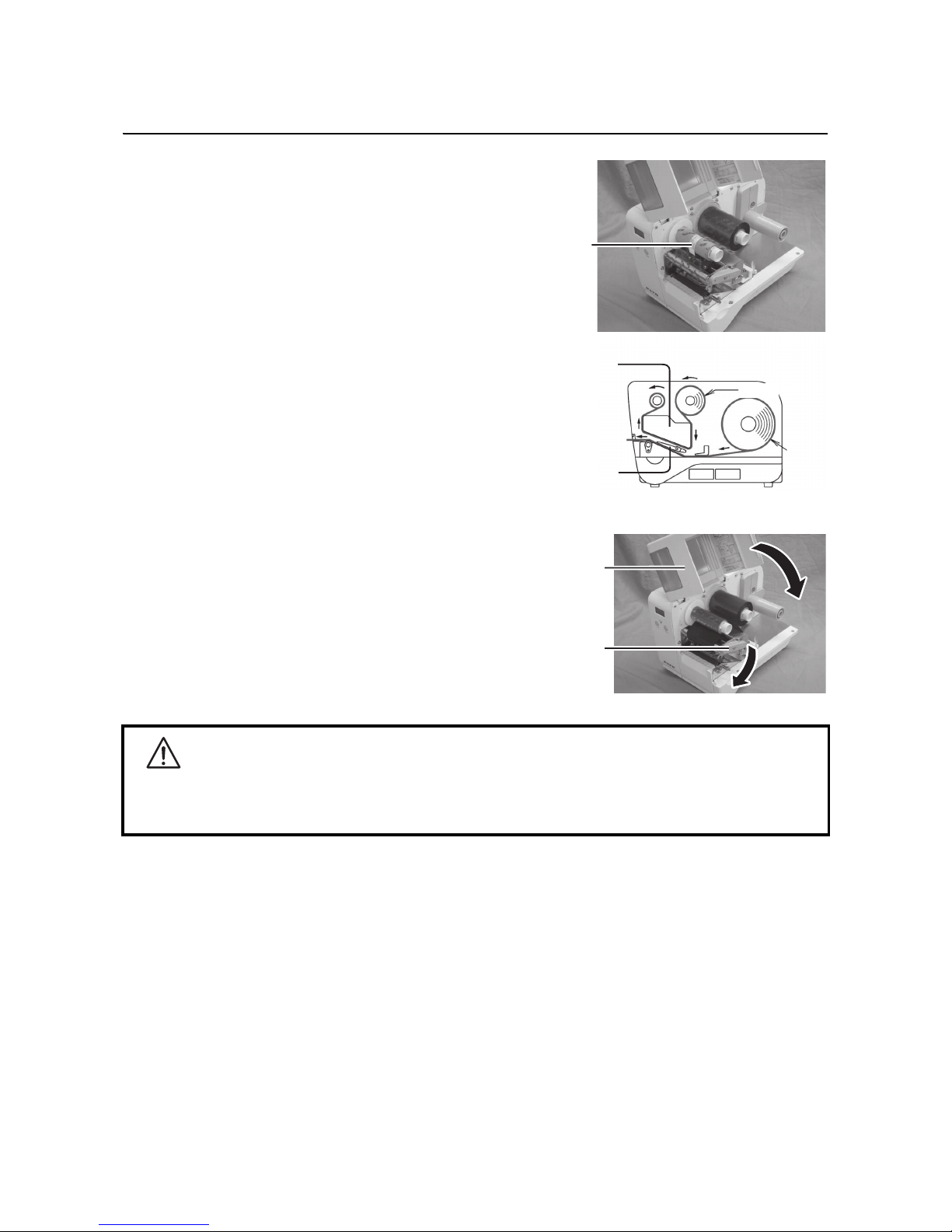

2.4 LOADING THE CARBON RIBBON

This printer enable two types of printing application, Thermal transfer and Direct thermal. Thermal transfer

paper media requires the use of carbon ribbon for print application. In such a scenario, it is the carbon ribbon

that contains the ink that will be transferred to the media. Direct thermal paper media has a coating on the

surface that is made visible through the application of heat from the print head. In this case, there is no need

of loading the carbon ribbon.

1. With the power supply is off, lift up the main cover.

Make sure that the cover rests firmly so that it will not fall

forward and injure your hands.

2. Release the purple head lock lever by turning counter

clockwise.

The print head assembly will be lifted up.

3. Open the carbon ribbon package, and then load the

ribbon on the ribbon supply spindle.

Push it inwards all the way, with the ribbon winding in a

counter-clockwise direction. The dull side of the ribbon

should be facing down as it travels through the print

head assembly.

Note:

Use only genuine SATO carbon ribbons for maximum

print quality and printer durability.

4. Mount the empty ribbon core on the ribbon take-up

spindle.

When loading the carbon ribbon for the first time, an

empty ribbon core is supplied with the printer. However,

the subsequent ribbon core can be obtained from the

last used up ribbon roll.

Main cover

Purple head

head lever

Section 2: Installation

Page 2-8 DR308e Operator’s Manual

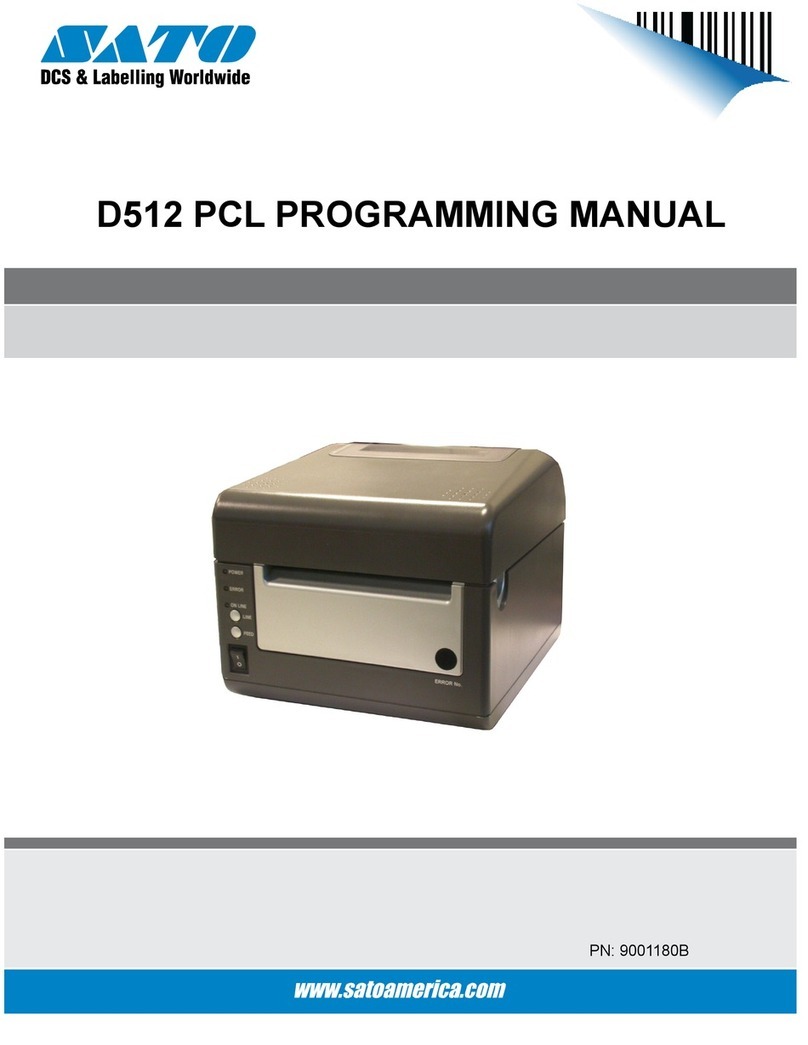

2.4 LOADING THE CARBON RIBBON (cont’d)

5. From the ribbon supply spindle, pass the carbon

ribbon underneath the print head assembly to the

ribbon take-up spindle. Route the ribbon behind and

over the top of the ribbon take-up spindle and tape the

leader portion of the carbon ribbon to the ribbon core.

Then turn the take-up spindle several times in the

direction of counter-clockwise to wind the ribbon around

the core. Confirm that the ribbon has been loaded as

shown in the figure on the right or as illustrated on the

inner side of the main cover.

Note:

Do not pass the carbon ribbon underneath the pitch sen-

sor unit.

6. Now remount the print head by turning the head lock

lever clockwise until it latch on. The print head should

lock into place firmly.

7. After loading the media and the carbon ribbon, close the

main cover and do a test print to check that the media

roll has been loaded properly. See Section 3.10 Test

Print Mode on page3-24 for instructions on how to run

test print.

Caution

• When replacing carbon ribbon, bear in mind that the print head and its surrounding area remain hot.

Keep your fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with your bare hands.

Media

Ribbon

Print head

assembly

Pitch

sensor

Tape

Figure showing carbon ribbon and media path

Head lock

lever

Main

cover

Other manuals for DR308e

1

Table of contents

Other SATO Printer manuals

SATO

SATO D512 PCL Owner's manual

SATO

SATO WS408DT User manual

SATO

SATO M-84Pro Series User manual

SATO

SATO CT 400 User manual

SATO

SATO S8412 Standard User manual

SATO

SATO M-5900RV Use and care manual

SATO

SATO TG3 Series User manual

SATO

SATO M-8400RVe Series Use and care manual

SATO

SATO CLe RFID Smart User manual

SATO

SATO HT200e User manual