SATO TG3 Series User manual

For printer model:

Operator Manual

TG3 Series

Read this Operator Manual before using this product.

Keep this document available for future reference.

NOTE:

The printer complies with the requirements in Part 15 of FCC Rules for a Class B Computing Device.

Operating the printer in a residential area may cause unacceptable interference to radio and TV reception. If

the interference is unacceptable, you can reposition the equipment, which may improve reception.

Be sure to ask your SATO representatives about our

maintenance contracts to ensure peace of mind during your

usage of SATO products.

Please refer to the back cover for SATO Group Member Company

closest to your location. You may also visit our home page at

www.satoworldwide.com for further updated details.

Copyrights

The contents of this document are proprietary information of SATO Corporation and/or its subsidiaries in

Japan, the U.S and other countries. No part of this document may be reproduced, copied, translated or

incorporated in any other material in any form or by any means, whether manual, graphic, electronic,

mechanical or otherwise, without the prior written consent of SATO Corporation.

Limitation of Liability

SATO Corporation and/or its subsidiaries in Japan, the U.S and other countries make no representations or

warranties of any kind regarding this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. SATO Corporation shall not be held responsible for errors

contained herein or any omissions from this material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or use of this material.

SATO Corporation reserves the right to make changes and/or improvements in this product and document

without notice at any time.

Trademarks

SATO is a registered trademark of SATO Corporation and/or its subsidiaries in Japan, the U.S and other

countries.

Version: GBS-TG3-01rA-25-01-10OM

© Copyright 2010 SATO Corporation.

All rights reserved.

Safety Precautions

TG3 Series Operator Manual Page i

Safety Precautions

Please read the following information carefully before installing and using the printer.

Pictographic Symbols

This instruction manual and the printer labels use a variety of pictographic symbols to facilitate safe and

correct use of the printer and to prevent injury to others and property damage. The symbols and meanings for

them are given below. Be sure to understand these symbols well before reading the main text.

Warning

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

in death or serious injury.

Caution

Ignoring the instructions marked

by this symbol and erroneously

operating the printer could result

in injury or property damage.

Warning

Do not set on an unstable area

• Do not set on an unstable

area, such as a wobbly table

or slanted area or an area

subject to strong vibration. If

the printer falls off or topples

over, it could injure someone.

Do not place containers full of water

or other liquid on the printer

• Do not place flower vases,

cups, or other containers

holding liquids, such as water

or chemicals, or small metal

objects near the printer. If they

are spilled and get inside the

printer, immediately turn off

the power switch, unplug the

power cord from the outlet,

and contact your SATO

reseller or technical support

center. Using the printer in this

condition could cause a fire or

electric shock.

Do not put objects inside the printer

• Do not insert or drop in metal

or burnable objects inside the

printer’s openings (cable

outlets, etc.). If foreign objects

do get inside the printer,

immediately turn off the power

switch, unplug the power cord

from the outlet, and contact

your SATO reseller or

technical support center.

Using the printer in this

condition could cause a fire or

electric shock.

Do not use other than the specified

voltage

• Do not use other than the

specified voltage. Doing so could

result in fire or electric shock.

Always ground the connections

• Always connect the printer’s

ground wire to a ground. Not

grounding the ground wire

could result in electric shock.

Handling of the power cord

• Do not damage, break, or

modify the power cord. Also,

do not place heavy objects on

the power cord, heat it, or pull

it because doing so could

damage the power cord and

cause a fire or electric shock.

• If the power cord becomes

damaged (core is exposed,

wires broken, etc.), contact

your SATO reseller or

technical support center.

Using the power cord in this

condition could cause a fire or

electric shock.

• Do not modify, excessively

bend, twist, or pull the power

cord. Using the power cord in

such a condition could cause a

fire or electric shock.

When the printer has been dropped or

broken

• If the printer is dropped or

broken, immediately turn off

the power switch, unplug the

power cord from the outlet,

and contact your SATO

reseller or technical support

center. Using the printer in this

condition could cause a fire or

electric shock.

Do not use the printer when some-

thing is abnormal about it

• Continuing to use the printer in

the event something is

abnormal about it, such as

smoke or unusual smells

coming from it, could result in

fire or electric shock.

Immediately turn off the power

switch, unplug the power cord

from the outlet, and contact

your SATO reseller or

technical support center for

repairs. It is dangerous for the

customer to try to repair it, so

absolutely do not attempt

repairs on your own.

Do not disassemble the printer

• Do not disassemble or modify

the printer. Doing so could

result in fire or electric shock.

Contact your SATO reseller or

technical support center to

conduct internal inspections,

adjustments, and repairs.

Example Pictographs

The pictograph means “Caution is required.” A specific

warning symbol is contained inside this pictograph (The sym-

bol at left is for electric shock).

The pictograph means “Should not be done.” What is spe-

cifically prohibited is contained in or near the pictograph (The

symbol at left means “Disassembly prohibited”).

The pictograph means “Must be done.” What is specifically

to be done is contained in the pictograph (The symbol at left

means “Unplug the power cord from the outlet”).

Safety Precautions

Page ii TG3 Series Operator Manual

Warning

Regarding the cutter

• Do not touch the cutter with

your hands or do not put

something into the cutter.

Doing so could result in an

injury.

Using the head cleaning fluid

• Use of flame or heat around

the head cleaning fluid is

prohibited. Absolutely do not

heat it or subject it to flames.

• Keep the fluid out of reach of

children to prevent them from

accidentally drinking it. If the

fluid is drunk, immediately

consult with a physician.

Caution

Do not place in areas with high

humidity

• Do not place the printer in

areas with high humidity or

where condensation forms. If

condensation forms,

immediately turn off the power

switch and do not use the

printer until it dries. Using the

printer while condensation is

on it could result in electric

shock.

Carrying the Printer

• When moving the printer,

always unplug the power cord

from the outlet and check to

make sure all external wires

are disconnected before

moving it. Moving the printer

with the wires still connected

could damage the cords or

connecting wires and result in

a fire or electrical shock.

• Do not carry the printer with

paper loaded in it. The paper

could fall out and cause an

injury.

• When setting the printer on the

floor or a stand, make sure not

to get your fingers or hands

pinched under the printer feet.

Power supply

• Do not operate the power

switch or plug in/unplug the

power cord with wet hands.

Doing so could result in

electric shock.

Power cord

• Keep the power cord away

from hot devices. Getting the

power cord close to hot

devices could cause the cord’s

covering to melt and cause a

fire or electrical shock.

• When unplugging the power

cord from the outlet, be sure to

hold it by the plug. Pulling it by

the cord could expose or

break the core wires and

cause a fire or electric shock.

• The power cord set that

comes with the printer is

especially made for this

printer. Do not use it with any

other electrical devices.

Top cover

• Be careful not to get your

fingers pinched when opening

or closing the top cover. Also

be careful the top cover does

not slip off and drop.

Print head

• The print head is hot after

printing. Be careful not to get

burned when replacing paper

or cleaning immediately after

printing.

• Touching the edge of the print

head immediately after printing

could result in injury. Use

caution when replacing the

label or cleaning the print

head.

• You should not replace the

print head without having

received the proper training.

Loading paper

• When loading roll paper, be

careful not to get your fingers

pinched between the paper roll

and the supply unit.

When not using the printer for a long

time

• When not using the printer for

a long time, unplug the power

cord from the outlet to

maintain safety.

During maintenance and cleaning

• When maintaining and

cleaning the printer, unplug the

power cord from the outlet to

maintain safety

Safety Precautions

TG3 Series Operator Manual Page iii

Precautions for Installation and Handling

Printer operation can be affected by the printer environment.

Refer to the following instructions for installation and handling of TG3 Series printer.

Select a Safe Location

Power Supply

Place the printer on a surface that is flat and level.

If the surface is not flat and level, this may result in poor

print quality. This may also cause malfunction and

shorten the life span of the printer.

Do not place the printer on a location that

produces vibration.

Giving serious vibration or shock to the printer may

cause malfunction and shorten the life span of the

printer.

Keep the printer out of high temperature and hu-

midity.

Avoid locations subject to extreme or rapid changes

in temperature or humidity.

Do not place the printer in a location subject to

water or oil.

Do not place the printer in a location where it will be

splashed with water or oil. Water or oil entering

inside the printer may cause a fire, electric shock, or

malfunction.

Avoid dust.

Dust build up may result in poor print quality.

Keep out of direct sunlight.

This printer has a built-in optical sensor. Exposure to

direct sunlight will make the sensor less responsive

and may cause the label to be sensed incorrectly.

Close the top cover when printing.

This printer requires an AC power supply.

Be sure to connect the printer to an AC power supply.

Connect the power cord to a grounded power

outlet.

Make sure that the printer is plugged into a grounded

power outlet.

Provide a stable source of electricity to the

printer.

When using the printer, do not share its power outlet

with other electrical devices that could result in

power fluctuations and performance issues with your

printer.

Table of Contents

Page 1 TG3 Series Operator Manual

TABLE OF CONTENTS

Introduction 1 - 1

1.1 Features of the Printer................................................................................................. 1 - 2

1.2 Unpacking ................................................................................................................... 1-2

1.2.1 Included Accessories......................................................................................... 1 - 2

1.3 Parts Identification....................................................................................................... 1 - 3

Installation 2 - 1

2.1 Site Location................................................................................................................ 2 - 2

2.2 Media Selection........................................................................................................... 2 - 2

2.3 Loading Media............................................................................................................. 2 - 3

2.4 Media Type selection .................................................................................................. 2 - 6

2.5 Cutter Sensor Adjustment ........................................................................................... 2 - 7

2.6 Loading the Carbon Ribbon ........................................................................................ 2 - 8

2.7 Remove the Carbon Ribbon...................................................................................... 2 - 10

2.8 Basic Connections..................................................................................................... 2 - 11

2.8.1 Install and Connecting the Interface board ...................................................... 2 - 11

2.8.2 To Configure the Connected Interface............................................................. 2 - 12

2.8.3 Connecting the Power Cable ........................................................................... 2 - 13

2.8.4 Turning On the Power...................................................................................... 2 - 14

2.8.5 Turning Off the Power ..................................................................................... 2 - 14

2.9 LCD Power Saving Mode.......................................................................................... 2 - 15

2.9.1 Turning off the LCD Backlight.......................................................................... 2 - 15

2.9.2 Turning on the LCD Backlight.......................................................................... 2 - 15

Operation and Configuration 3 - 1

3.1 Operator Panel............................................................................................................ 3 - 2

3.2 Operating Modes......................................................................................................... 3 - 5

3.3 ONLINE And OFFLINE Modes.................................................................................... 3 - 8

3.3.1 Online Mode ...................................................................................................... 3 - 8

3.3.2 Offline Mode ..................................................................................................... 3 - 8

3.3.3 To Adjust the Screen Contrast........................................................................... 3 - 9

3.4 Adjustment Screen .................................................................................................... 3 - 10

3.5 Cancel Print Job Mode ............................................................................................. 3 - 11

3.6 User Mode................................................................................................................. 3 - 12

3.7 Interface Mode .......................................................................................................... 3 - 14

3.7.1 Overview of Interface Mode Configurations .................................................... 3 - 14

3.7.2 Enabling Interface Card Configuration............................................................. 3 - 16

3.8 SEMBL Mode ............................................................................................................ 3 - 24

3.9 Advanced Mode ........................................................................................................ 3 - 25

3.10 HEX Dump Mode .................................................................................................... 3 - 30

3.11 RFID USER Mode ................................................................................................... 3 - 31

3.12 Test Print Mode ...................................................................................................... 3 - 35

3.13 Default Setting Mode............................................................................................... 3 - 38

3.13.1 Table of Default Settings ............................................................................... 3 - 39

3.14 Maintenance Mode.................................................................................................. 3 - 41

Table of Contents

TG3 Series Operator Manual Page 2

3.15 Service Mode .......................................................................................................... 3 - 42

3.15.1 Overview of Sensor Level adjustment in Service Mode................................. 3 - 42

3.15.2 Pitch Offset adjustment in Service Mode ...................................................... 3 - 44

3.15.3 Cut Offset adjustment in Service Mode ........................................................ 3 - 45

3.15.4 Backfeed Offset adjustment in Service Mode ............................................... 3 - 46

3.15.5 Loading Offset adjustment in Service Mode ................................................. 3 - 47

3.15.6 Overview of Setting menu in Service Mode................................................... 3 - 48

3.16 RFID Mode .............................................................................................................. 3 - 50

3.17 Download Mode ...................................................................................................... 3 - 52

Cleaning and Maintenance 4 - 1

4.1 Cleaning The Print Head, Platen and Rollers.............................................................. 4 - 2

4.2 How To Clean The Printer (Cleaning Kit).................................................................... 4 - 2

4.3 How To Clean The Printer (Cleaning Sheet)............................................................... 4 - 3

4.4 Adjusting Print Quality ................................................................................................. 4 - 4

4.4.1 Adjusting Print Darkness ................................................................................... 4 - 4

4.4.2 Adjusting Print Speed ....................................................................................... 4 - 4

Troubleshooting 5 - 1

5.1 Error signal Troubleshooting ....................................................................................... 5 - 2

5.1.1 Error Message .................................................................................................. 5 - 2

5.1.2 More information about Command Error ........................................................... 5 - 6

5.1.3 Warning Message.............................................................................................. 5 - 7

5.2 Troubleshooting Table................................................................................................. 5 - 8

5.3 Interface Troubleshooting.......................................................................................... 5 - 10

5.4 Test Print Troubleshooting ........................................................................................ 5 - 11

5.4.1 Hex Dump........................................................................................................ 5 - 11

5.4.2 Test label printing ............................................................................................ 5 - 11

Basic Specifications 6 - 1

6.1 Printer Basic Specifications......................................................................................... 6 - 1

6.2 Optional Accessories Specifications ........................................................................... 6 - 8

Interface Specifications 7 - 1

7.1 Interface Types............................................................................................................ 7 - 1

7.2 RS232C High Speed Serial Interface.......................................................................... 7 - 2

7.2.1 RS-232C Serial Interface Card DIP SWITCH Settings...................................... 7 - 2

7.2.2 Basic Specifications .......................................................................................... 7 - 3

7.2.3 Ready/Busy ....................................................................................................... 7 - 4

7.2.4 X-ON/X-OFF ...................................................................................................... 7 - 5

7.3 IEEE 1284 Parallel Interface ....................................................................................... 7 - 6

7.3.1 Basic Specifications .......................................................................................... 7 - 6

7.3.2 Pin Assignments ................................................................................................ 7 - 7

7.3.3 Input and Output Signals ................................................................................... 7 - 8

7.4 Universal Serial Bus (USB) Interface .......................................................................... 7 - 9

7.4.1 Basic Specifications .......................................................................................... 7 - 9

7.4.2 Pin Assignments ................................................................................................ 7 - 9

7.5 Local Area Network (LAN) Ethernet .......................................................................... 7 - 10

7.5.1 Basic Specifications ........................................................................................ 7 - 10

7.6 Wireless LAN Ethernet.............................................................................................. 7 - 12

7.6.1 Basic Specifications ........................................................................................ 7 - 12

Table of Contents

Page 3 TG3 Series Operator Manual

7.7 LAN and Wireless LAN Ethernet Specifications........................................................ 7 - 15

7.7.1 Software Specifications ................................................................................... 7 - 15

7.7.2 TCP/IP Specifications ...................................................................................... 7 - 15

7.7.3 LPD Specifications........................................................................................... 7 - 15

7.7.4 FTP Specifications........................................................................................... 7 - 15

7.7.5 TELNET Specifications.................................................................................... 7 - 16

7.7.6 Setting/Displayed Items ................................................................................... 7 - 17

7.7.7 Wireless LAN Setting....................................................................................... 7 - 18

7.8 External Signal Interface (EXT)................................................................................. 7 - 18

7.8.1 Basic Specifications......................................................................................... 7 - 19

7.8.2 Pin Assignments .............................................................................................. 7 - 19

Appendix 8 - 1

8.1 Optional Accessories - Stacker ................................................................................... 8 - 2

8.1.1 Parts of Stacker Unit ......................................................................................... 8 - 2

8.1.2 To install the Stacker ......................................................................................... 8 - 3

8.2 Optional Accessories - Label Rewinder ...................................................................... 8 - 4

8.2.1 To install the Label Rewinder ........................................................................... 8 - 4

8.3 Optional Accessories - Keypad ................................................................................... 8 - 4

8.4 Positions of Sensors and Options ............................................................................... 8 - 5

8.5 Base Reference Point ................................................................................................. 8 - 6

8.6 Offset Position Adjustment.......................................................................................... 8 - 7

8.5.1 Adjustment of Print Position............................................................................... 8 - 7

8.5.2 Adjustment of Cut Position ................................................................................ 8 - 7

8.5.3 Adjustment of Backfeed Distance...................................................................... 8 - 9

8.5.4 Adjustment of Media Feeding Position ............................................................ 8 - 10

8.6 Shifting Motion of Base Reference Point................................................................... 8 - 11

8.7 Jump Hole ................................................................................................................. 8 - 12

8.8 Tag Sorting Method................................................................................................... 8 - 13

8.8.1 Batch Separator............................................................................................... 8 - 13

8.8.2 Separator ......................................................................................................... 8 - 14

8.9 Paper End ................................................................................................................. 8 - 15

8.9.1 End Mark ......................................................................................................... 8 - 15

8.9.2 Paper End Error Detection............................................................................... 8 - 16

8.10 Ribbon End.............................................................................................................. 8 - 17

8.11 Ribbon Near End..................................................................................................... 8 - 17

8.12 Media Size Check ................................................................................................... 8 - 17

8.13 Perforated Line........................................................................................................ 8 - 18

8.14 Information on Media when using Cutter................................................................. 8 - 19

8.14.1 Cutting of Labels............................................................................................ 8 - 19

8.14.2 Cutting Media with Perforation ...................................................................... 8 - 19

8.14.3 Cutter replacement ........................................................................................ 8 - 19

Sato Group of Companies 9 - 1

Sato Group of Companies................................................................................................. 9 - 2

Section 1: Introduction

TG3 Series Operator Manual Page 1-1

INTRODUCTION

Thank you for your investment in this SATO printer product.

This Operator Manual contains the basic information about the installation, setup, configuration, operation

and maintenance of the printer.

A total of eight topics are covered herein, and they are organized as follows:

Section 1: Introduction

Section 2: Installation

Section 3: Configuration and Operation

Section 4: Cleaning and Maintence

Section 5: Troubleshooting

Section 6: Basic Specifications

Section 7: Interface Specifications

Section 8: Appendix

It is recommended that you read carefully and become familiar with each section before installing and

maintaining the printer. Refer to the Table Of Contents at the front of this manual to search for the relevant

information needed. All page numbers in this manual consist of a section number followed by the page

number within the stated section.

This section assists you in unpacking the printer from the shipping container. You will also be guided through

a familiarization tour of the main parts and controls.

The following information is provided herein:

• Features of the printer

• Unpacking

• Parts Identification

Section 1: Introduction

Page 1-2 TG3 Series Operator Manual

1.1 FEATURES OF THE PRINTER

The SATO TG3 Series printers (Thermal Transfer or Direct Thermal) are complete, high-performance labeling

systems designed specifically for printing tags and labels.

The key features of the TG3 Series are:

• High Printing Speed and Throughput (32-bit RISC CPU (100MHz), Up to 10 ips print speed)

• Large Internal Memory Size (8MB Flash-ROM)

• Plug-in Interface Cards (Parallel IEEE1284, LAN, Wireless LAN, USB or the high speed RS-232C

interface can be selected)

• Thick Tags Supported (Up to 0.33mm thick)

• Print, Cut and Stack Operation

• Batch Separation Function

• Wide Range of Media Types Supported

• Large Media Roll Supported

• Large and Energy Efficient LCD Display

• Easy and More User-Friendly Operation

• HF and UHF RFID Support

• Coreless Ribbon Spindle

• Standalone Capability using SEMBL or SATO Keypad

• European and Asian Codepages

1.2 UNPACKING

When unpacking the printer, take note of the following:

1. The box should stay right-side up. Lift the printer out of the box carefully.

2. Remove all the packaging from the printer.

3. Remove the accessory items from their protective containers.

4. Set the printer on a solid, flat surface. Inspect the shipping container and printer for any sign of damage

that may have occurred during shipping. Please note that SATO shall hold no liability of any damage of any

kind sustained during shipping of the product.

Notes:

• If the printer has been stored in the cold, allow it to reach room temperature before turning it on.

• Please do not discard the original packaging box and cushioning material after installing the printer. They

may be needed in future, if the printer needs to be shipped for repairs.

1.2.1 Included Accessories

After unpacking the printer, verify that you have the following materials:

User Documents

(Quick Guide, Warranty, etc)

* The shape of the power plug may vary, depending on the location where it was purchased.

Power plug* Bosses and securing screws

Section 1: Introduction

TG3 Series Operator Manual Page 1-3

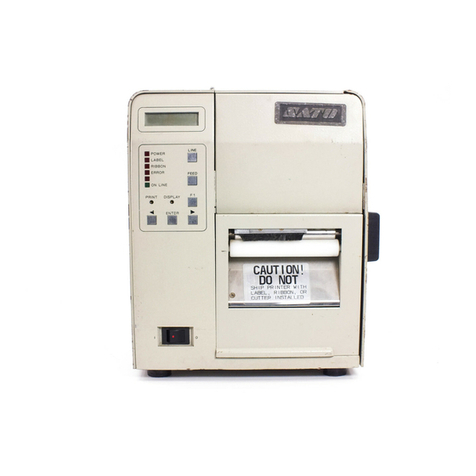

1.3 PARTS IDENTIFICATION

1

2

3

4

5

Front view

Main cover

Open this cover to load the media and ribbon.

Power (I/O) switch

Press this switch to turn the power on ( I ) or

off (O).

Keypad connection terminal

Used to connect to the optional keypad.

Media ejection slot

Opening for media output.

Operator panel

It consists of ten contact buttons and three

LED indicators. Please refer to Section 3.1

Operator Panel.

1

2

3

4

5

Section 1: Introduction

Page 1-4 TG3 Series Operator Manual

1.3 PARTS IDENTIFICATION (cont’d)

7

6

8

9

Back view

Interface slot

Optional interface slot for connection to a host

PC. An option of RS-232C (High-speed)

interface board, IEEE1284 interface board,

LAN interface board, Wireless LAN interface

board and USB interface board are available

for connection.

External connector terminal (EXT)

Interface connector for external signals.

Connect the optional stacker or rewinder to this

terminal.

FUSE (T5AH 250V) holder

Used to hold a fuse which protect the printer

from unstable power supply surge. Use fuse

with rating, T5AH 250V only.

AC IN power terminal

Supplies power to the printer by inserting the

power cable.

Before connection, ensure that the AC voltage

of your region is within the range of AC 100 to

240V, 50/60 Hz.

6

7

8

9

Section 1: Introduction

TG3 Series Operator Manual Page 1-5

1.3 PARTS IDENTIFICATION (cont’d)

15

13

14

10

11

12

Internal view when Main cover is opened (Front view)

Ribbon take-up spindle (coreless)

Used to wind up the used ribbon without using

core.

Print head assembly

This component is used to print on the media.

Perform maintenance at regular intervals.

Cutter assembly

This assembly consist of cutter as well as the

cutter sensor assembly.

Head balance adjustment knob

To adjust print head balance to obtain

consistent print out across media.

Head Alignment adjustment knob

To adjust print head alignment to obtain

consistent print out across media.

Head lock lever

Used to open and close the print head.

10

11

12

13

14

15

Section 1: Introduction

Page 1-6 TG3 Series Operator Manual

1.3 PARTS IDENTIFICATION (cont’d)

22

19

21

16

17

18

20

Internal view when Main cover is opened (Back view)

Ribbon supply spindle

Used to load the ribbon.

Roll media guide

Set to meet the size of the media used.

Roll media supply spindle

Used to load the roll media, tag or label.

Pitch sensor guide

This plate guides the media passing through the

pitch sensor.

Lid Latch lever

Press the purple Lid Latch lever to open the

hinged Lid Latch.

Media feed-in guide

Feed in the media to the printer from this

guide.

Media guide knob

Set the media guide to meet the size of the

media used.

16

17

18

19

20

21

22

Section 2: Installation

TG3 Series Operator Manual Page 2-1

INSTALLATION

This section assists you in general printer set up and installing consumable media in the printer, as well as

interface connection with host computer and other optional attachment units.

The following information is provided:

• 2.1 Site Location

• 2.2 Media Selection

• 2.3 Loading Media

• 2.4 Media Type selection

• 2.5 Cutter Sensor Adjustment

• 2.6 Loading the Carbon Ribbon

• 2.7 Remove the Carbon Ribbon

• 2.8 Basic Connections

• 2.9 LCD Power Saving Mode

Section 2: Installation

Page 2-2 TG3 Series Operator Manual

2.1 SITE LOCATION

Consider the following when setting up the printer:

•Place the printer on a solid flat surface with adequate space. Make sure there is enough space above

the printer to provide clearance for the top cover to swing open.

•If a Stacker unit is to be used with the printer, make sure there is adequate room for the unit.

•Place it away from hazardous materials or dusty environments.

•Place it within operational distance of the host computer, within interface cable specifications.

2.2 MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration before printer

purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that

does not cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also

wear a groove in the platen roller, which can affect print quality.

This printer can use six different types of media, the figures below identifies the media types and their

specifications. The printer uses different sensors to detect the Center hole, Side hole, R-corner (Notch/Edge),

I-Marks or Gap on the media in order to precisely position the print content.

Note:

For optimal print performance and durability, please use SATO-certified media and ribbon supplies

on this printer. Using supplies not tested and approved for use by SATO can result in unnecessary

wear and damage to vital parts of the printer, and may void the warranty.

5mm

(0.2”)

ø 2.5mm

(0.1”)

10mm

(0.39”)

1.5mm (0.06”)

Center of Notch width

2.5mm (0.1”)

6mm (0.23”)

Center Hole Tag Side Hole Tag R-Corner (Notch/Edge) Tag

I-Mark Tag Gap Label I-Mark Label

ø 2.5mm (0.1”)

3mm (0.12”)

3mm

(0.12”)

3mm

(0.12”)

1.5mm (0.06”)

10mm

(0.39”)

3mm

(0.12”)

3.5±0.3mm

(0.14±0.01”)

1±0.3mm (0.04±0.01”)

5mm

(0.2”)

Section 2: Installation

TG3 Series Operator Manual Page 2-3

2.2 MEDIA SELECTION (cont’d)

This printer accepts two types of media core sizes, φ75mm (2.95”) and φ100mm (4”). When using φ100mm

(4“)

core size media, the supplied bosses need to be installed to the printer.

2.3 LOADING MEDIA

1. Lift up the main cover.

Note:

Make sure that the cover rests firmly so that it will not fall

forward and injure your hands.

2. Remove the roll media guide by pressing the release

tab with your thumb and index finger and pulling it out.

F75mm (2.95”)

F100mm (4”)

Section 2: Installation

Page 2-4 TG3 Series Operator Manual

2.3 LOADING MEDIA (cont’d)

3. If the inner diameter of the roll is 100 mm (4”), attach the

supplied boss at the roll media supply spindle. If the

inner diameter of the roll is 75 mm (2.95”), proceed to

Step 4.

Using the boss attachment positions given in the follow-

ing table as a guide, attach the boss and then fasten it in

place with the screws provided. Attached the screws on

both opposite side of the boss.

4. Load the media to the roll media supply spindle.

Make sure the media leader is pull out from the bottom

and the printed side is facing upwards. Push the roll

firmly towards the end of the spindle.

5. Attach the roll media guide back and make sure that

the roll media guide pushes snugly against the media

roll to prevent media drift during printing.

Boss attachment position Media width

Attachment hole 1, 2 Up to 40 mm (1.6”)

Attachment hole 2 Up to 50 mm (2”)

Attachment hole 3 50 mm (2”) to 80 mm (3.1”)

2

31

boss

Roll media

supply spindle

Printed side should

face upward when

feed in to printer.

Section 2: Installation

TG3 Series Operator Manual Page 2-5

2.3 LOADING MEDIA (cont’d)

6. Press the purple Lid Latch lever to open the hinged Lid

Latch. Then, release the purple head lock lever by

turning counter clockwise.

The print head assembly will be lifted up to allow media

loading.

7. Load the media from the rear, so that the media passes

through the media guide and underneath the pitch

sensor guide,until the leading edge of the first media is on

the platen roller.

Inspect the media routing and verify that the path matches

that illustrated on the inner side of the main cover.

8. Loosen the Media guide adjustment knob and manually

adjust the media guide inward so the media is prevented

from moving horizontally. Retighten knob.

9. Lower and lock the Lid latch, remount the print head by

turning the head lock lever clockwise until it latch on. The

print head should lock into place firmly.

10.After loading the media, close the main cover.

You may need to set the Media type selection and set the

Cutter sensor adjustment. Refer to Section 2.4 Media Type

selection and Section 2.5 Cutter Sensor Adjustment for

more details.

Note:

Be careful not to get your fingers caught at the bottom edge

when you are closing the main cover.

Caution

• When replacing media, bear in mind that the print

head and its surrounding area remain hot. Keep your

fingers away from these areas to prevent injury.

• Avoid touching even the edge of the print head with

your bare hands.

Head lock

lever

(purple)

Lid Latch

lever

(purple)

Pitch sensor guide

Media guide

adjustment knob

Media guide

Media

Platen roller

Head lock

lever

(purple)

Lid Latch

lever

Main cover

Section 2: Installation

Page 2-6 TG3 Series Operator Manual

2.3 LOADING MEDIA (cont’d)

Automatic Feeding Function

The automatic feeding function automatically transports media detected with the Jump hole sensor to the

Print head position when media is feed in from the Media feed-in guide of the printer.

When leading edge of the media is inserted to the lid latch part while the printer is in the Offline state after the

head and lid latch are opened/closed, this function uses the jump hole sensor to detect the media and then

performs the automatic feed operation.

Due to different types of media available, it is recommended to load the media manually as mentioned in the

prior section for more precise motion of the media.

Overview of the media and ribbon loading path

2.4 MEDIA TYPE SELECTION

After first loading of the media or you have changed the media type, you need to set the Media selection of

the printer. Media selection is to select the media used and enable the appropriate sensor.

1. Turn the power On.

Error message is displayed on the LCD screen.

2. Release the purple head lock lever by turning counter clockwise and

then clockwise to latch the head lock lever back to position.

The printer enters Offline mode and the media type is displayed on the

screen.

3. In Offline mode, press the PAPER button repeatedly, the media selection

will advance cyclically.

Center Hole, I-Mark Tag, Side hole Tag, Edge Tag, Label Gap, Label I-

Mark and Not Sensor can be selected. Select the paper type according to

the loaded media and the paper sensor is to be used. Please refer to

Media (PAPER) selection in Section 3.3.2 Offline Mode for details.

Media roll Face out

Media roll Face in

Media type

Other manuals for TG3 Series

3

This manual suits for next models

2

Table of contents

Other SATO Printer manuals

SATO

SATO CX400 User manual

SATO

SATO HR2 Series User manual

SATO

SATO CL4NX RIDF User manual

SATO

SATO M-8459Se Series User manual

SATO

SATO MB2i Series User manual

SATO

SATO M-8400RVe Series User manual

SATO

SATO M-8465Se User manual

SATO

SATO M10e Series User manual

SATO

SATO FX3-LX User manual

SATO

SATO M-8400 User manual