<previous|home|next>

EZManual:M-8400RVe6

BarcodeSATOInternationalPteLtd

Excessiveribbonandrewindtensionwill resultinvariable

motionandcouldbethecauseofprintqualityproblems.

Ensuretheribbonrewindandunwindtensionsarewithin

specificationsoradjustmentofeitherclutchisnecessary.

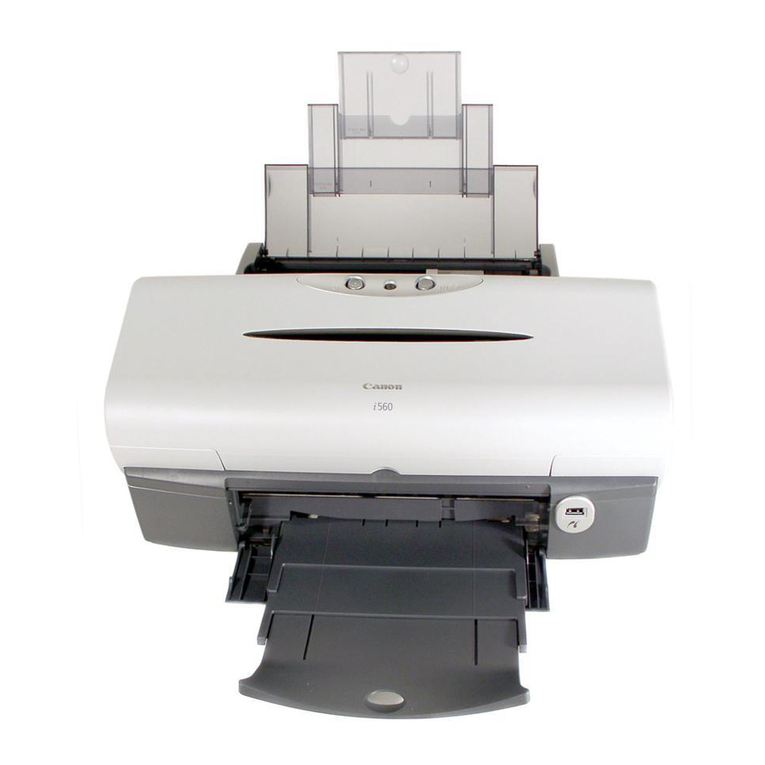

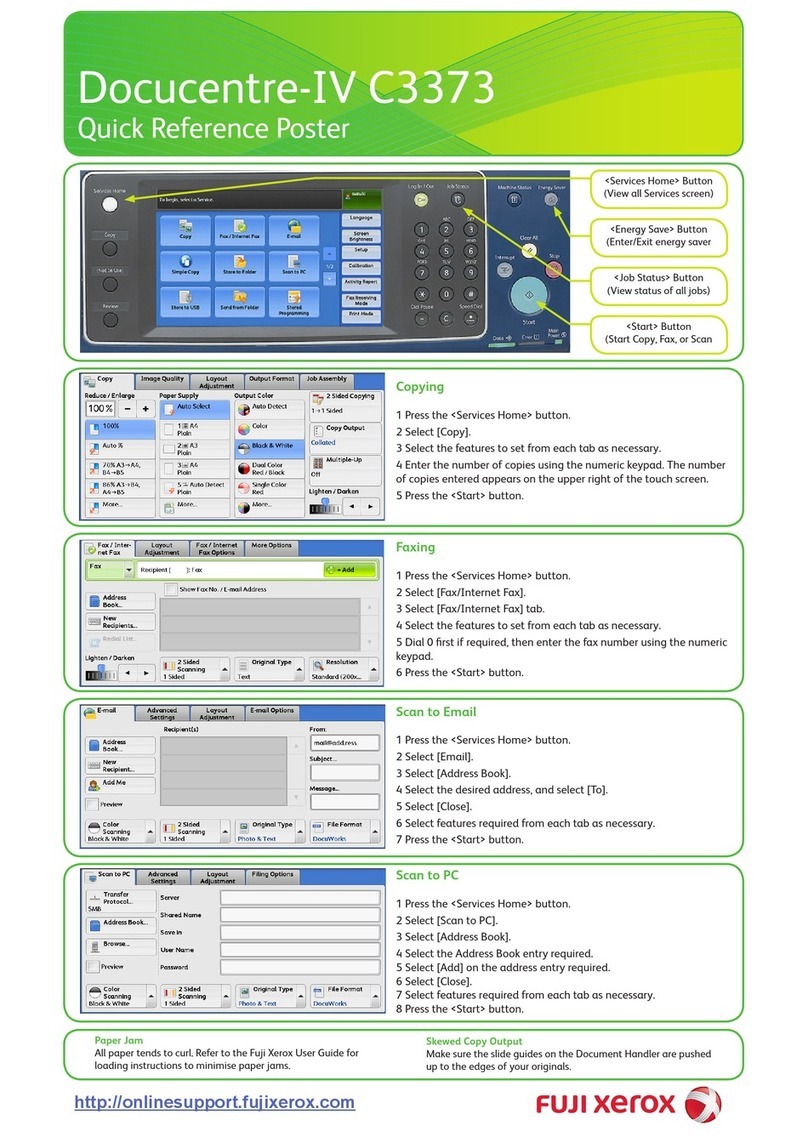

Requiredequipment

1EmptyRibbonCoreandString

212mm Wrench

31kgor2kgTensionGage

4#2 PozidrvScrewdriver

STEPS

1SwitchtheprinterOFF anddisconnectthepower

cable.

2Raisethetopaccess doorandopenthefrontaccess

door.Removetheribbonandlabelstockifinstalled.

3Attachstringtoanemptyribboncoreandplace on

theRibbonSpindle.Windthestringtightlyaroundthe

ribboncoreinsinglelayerandinclockwisedirection.

Attachtheendofthestringtothetensiongauge.

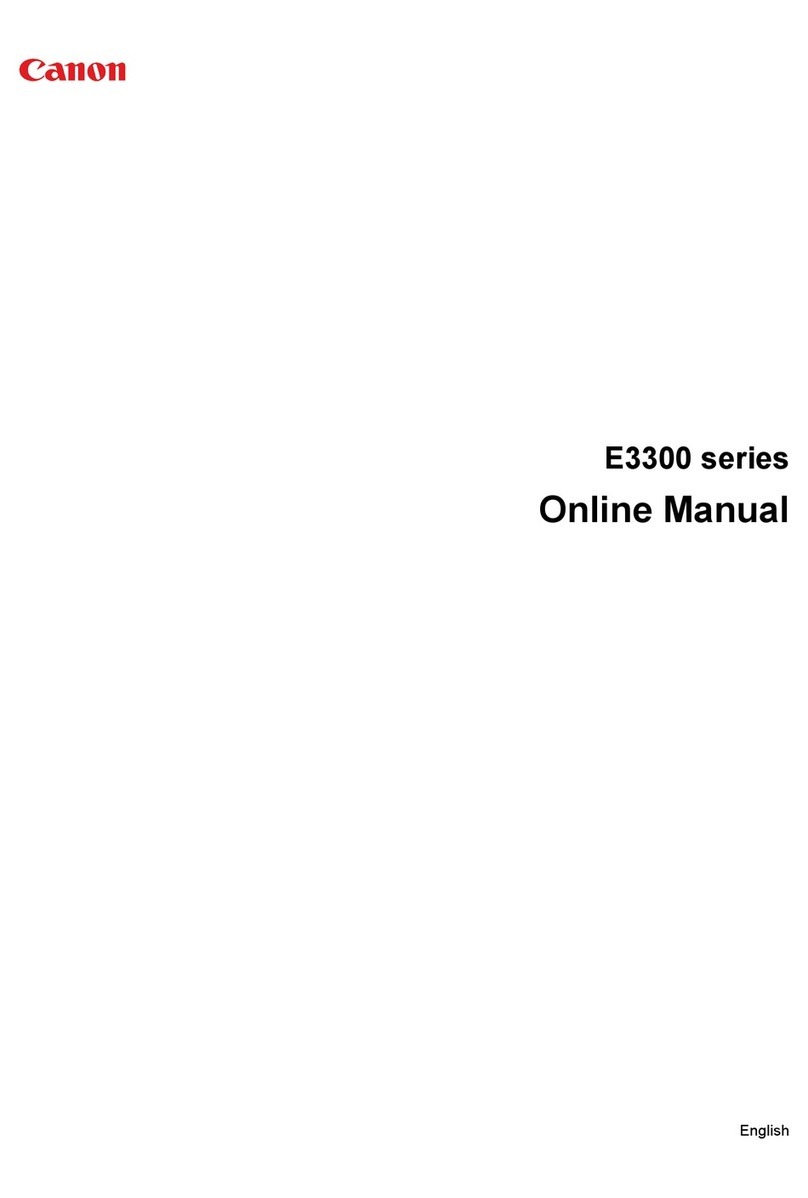

4Graduallyliftthetensiongauge,pullingthestringunwind

itfromthecore.Once thespindlestartstomove,the

gaugeshouldbeindicate950 to1050 gramsoftension

forribbonrewind,and550 to650 gramsoftension

forribbonunwind.Refertopicturesinnextpage.

5To adjusttheclutch,loosenthelockingscrewand

movetheadjustnutCWformoretensionandCCW

forless tension.Tightenthelockingscrewandrepeat

steps3and4until thecorrecttensionisachieved.

RibbonClutch

Adjustment

3

1

2

4