SATO XL400e User manual

XL400e/410e

OPERATOR’SMANUAL

Barcode SATO International Pte Ltd

438A Alexandra Road

#05-01/02

Alexandra Technopark

Singapore 119967

Tel: (65) 6271 2122

Fax: (65) 6271 2151

Email: customerservice@sato-int.com

© Copyright 1994 – 2004

Barcode SATO International

Warning: This equipment complies with the requirements in Part 15 of FCC rules for a Class A

computing device. Operation of this equipment in a residential area may cause unacceptable

interference to radio and TV reception requiring the operator to take whatever steps are

necessary to correct the interference.

All rights reserved. No part of this document may be reproduced or issued to third parties in any

form whatsoever without the express permission of SATO. The materials in this document is

provided for general information and is subject to change without notice. SATO assumes no

responsibilities for any errors that may appear.

i

TABLE OF CONTENTS

OVERVIEW

1.1 General Specifications.....................................................................................1-2

1.2 Character Fonts...............................................................................................1-4

1.3 Bar Codes........................................................................................................1-5

1.4 Physical Characteristics ..................................................................................1-6

1.5 Optional Accessories.......................................................................................1-7

INSTALLATION

2.1 Unpacking and Parts Identification..................................................................2-2

2.2 Setting Up The Printer.....................................................................................2-3

2.3 Printer Components.........................................................................................2-4

2.4 The Operator Panel.........................................................................................2-6

2.5 Tilting The Operation Panel.............................................................................2-7

2.6 Media Types Supported ..................................................................................2-8

2.7 Media Specifications........................................................................................2-10

2.8 Sensor Positions..............................................................................................2-11

2.9 Loading Tags and Labels................................................................................2-12

2.10 Loading THE RIBBON...................................................................................2-15

2.11 Cut Sensor Adjustment..................................................................................2-18

2.12 Turning the Printer ON/OFF..........................................................................2-21

CONFIGURATION

3.1 Printer dIp Switch Configuration......................................................................3-2

3.2 Default Settings...............................................................................................3-5

3.3 Printer Adjustments.........................................................................................3-6

3.4 User Mode.......................................................................................................3-8

3.5 Service Mode...................................................................................................3-11

3.6 User Test Print.................................................................................................3-17

3.7 Service Test Print............................................................................................3-17

3.8 Potentiometer Adjustments .............................................................................3-19

CLEANING AND MAINTENANCE

4.1 Introduction......................................................................................................4-1

4.2 Procedures......................................................................................................4-1

4.3 Cleaning the Print Head, Platen, Rollers and Sensors....................................4-3

INTERFACE SPECIFICATIONS

5.1 Introduction......................................................................................................5-1

5.2 Interface types.................................................................................................5-1

5.3 The Receive Buffer..........................................................................................5-2

5.4 RS232C Serial Interface..................................................................................5-3

5.5 Bidirectional Communications .........................................................................5-6

5.6 Centronics Parallel Interface ...........................................................................5-9

5.7 Accessory (Ext) Connector..............................................................................5-10

ii

TROUBLESHOOTING

6.1 Initial Checklist.................................................................................................6-1

6.2 Using the Centronics (Parallel) Interface.........................................................6-1

6.3 Using the RS232C (SERIAL) Interface............................................................6-3

OPTIONAL ACCESSORIES

7.1 Introduction......................................................................................................7-1

7.2 Label Rewinder................................................................................................7-1

7.3 PCMCIA Memory Cards..................................................................................7-2

7.4 Stacker ............................................................................................................7-4

7.5 Calendar..........................................................................................................7-6

Section 1: Introduction

XL400/410e Operator’s Manual Page 1-1

1

OVERVIEW

Thank you for your investment in this SATO printer product.

This Operator’s Manual contains basic information about the installation, setup,

configuration, operation and maintenance of the printer.

A total of seven topics are covered herein, and organized as follows:

Section 1: Overview

Section 2: Installation

Section 3: Configuration

Section 4: Cleaning and Maintenance

Section 5: Interface Specifications

Section 6: Basic Troubleshooting

Section 7: Optional Accessories

It is recommended that you become familiar with each section before installing and main-

taining the printer. Refer to the Table Of Contents at the front of this manual to search for

the relevant information needed. All page numbers in this manual consist of a section

number followed by the page number within the stated section.

For specialized programming, refer to the separate Programming Manual located on the

utility CD-ROM.

Section 1: Introduction

Page 1-2 XL400/410e Operator’s Manual

1.1 GENERAL SPECIFICATIONS

The SATO XL400/410 “e” series printers of Thermal Transfer Printers are complete,

high-performance labeling systems designed specifically for printing tags and labels.

All printer parameters are programmable using the front panel controls and DIP

switches. All popular bar codes, including 2-D codes, eight human-readable fonts with

two Care Symbol fonts and a fast and efficient vector font, are resident in memory, pro-

viding literally thousands of type styles and sizes.

All of the XL printers use the same command codes. The only differences are the allow-

able values representing print positions on the label. These values are specified in “dots”

and will vary depending upon the resolution of the printer and the amount of memory

available for imaging the label.

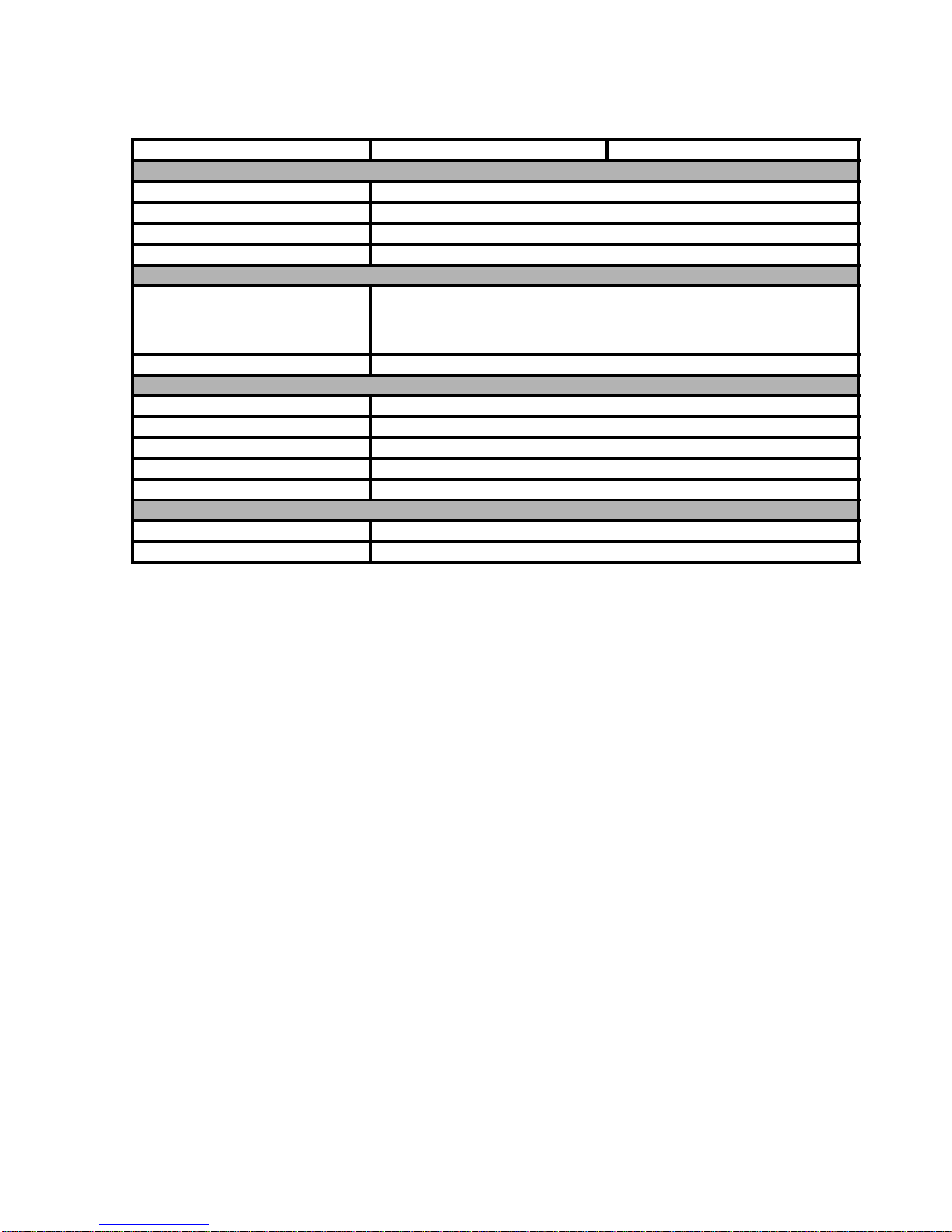

Features of SATO XL400e and XL 410

Feature XL400e XL410e

Print resolution 203dpi for economi-

cal labeling solution 305dpi for laser

quality printing and

graphic images

Print method Thermal Transfer

and Direct Thermal Thermal Transfer

and Direct Thermal

Label sizes sup-

ported (using

default internal

memory)

4 inches (W) by 9.4

inches 4 inches (W) by 9.4

inches

Label sizes sup-

ported (using

optional PCM-

CIA memory

card)

4 inches (W) by

49.2 inches at 203

dpi

4 inches (W) by

32.8 inches at 305

dpi

Integrated Cutter Built-in Built-in

Stacker option Up to 500 3.9 inch

(W) by 5.9 inch

labels

Up to 500 3.9 inch

(W) by 5.9 inch

labels

Interfaces avail-

able RS-232C (stan-

dard) and optional

LAN, USB, IEE

1284 or high speed

RS-232C

RS-232C (stan-

dard) and optional

LAN, USB, IEE

1284 or high speed

RS-232C

Section 1: Introduction

XL400/410e Operator’s Manual Page 1-3

1.1 GENERAL SPECIFICATIONS (CONT’D)

SPECIFICATION XL400e XL410e

CONTROLS AND SIGNALS

On-Line LED Green

Cutter Green

Error LED Red

LCD Panel 2 Line x 16 Character

Start/Stop Switch Rear

Feed Switch Front Panel

Cutter Front Panel

Eject Front Panel

Media Front Panel

Configuration 3 x 8 DIP, Inside Cover

Power On/Off Switch Rear Panel

POTENTIOMETER ADJUSTMENTS

Print Darkness Inside Cover

Pitch Inside Cover

Offset Inside Cover

Display Inside Cover

INTERFACE CONNECTIONS

Parallel (AMP 36 pin) Centronics Compatible

Serial (DB25S) RS232C (2400 to 19.2K bps)

Serial Protocol Hardware Flow Control (Ready/Busy)

Software Flow Control (X-On/X-Off)

Bi-directional (ENQ/Response)

Data Transmission ASCII Format

PROCESSING

CPU 32 Bit RISC

ROM 1 MByte

DRAM 2 MByte

Section 1: Introduction

Page 1-4 XL400/410e Operator’s Manual

1.2 CHARACTER FONTS

SPECIFICATION XL400e XL410e

MATRIX FONTS

XU Font (5 dots W x 9 dots H) Helvetica

XS Font (17 dots W x 17 dots H) Univers Condensed Bold

XM Font (24 dots W x 24 dots H) Univers Condensed Bold

OA Font (15 dots W x 22 dots H)

OCR-A (22 dots W x 33 dots H)

OCR A

OB Font (20 dots W x 24 dots H)

OCR-B (30 dots W x 36 dots H)

OCR B

XCS (24 dot W x 24 dot H) Care Symbol

XCL (36 dots W x 36 dots H) Care symbol

AUTO SMOOTHING FONTS

XB XB Font (48 dots W x 48 dots H) Univers

Condensed Bold

XL XL Font (48 dot W x 48 dots H) Sans Serif

VECTOR FONTS

Proportional or Fixed Spacing

Font Size 50 x 50 dots to 999 x 999 dots

10 Font Variations

DOWNLOADABLE FONTS

TrueType Fonts with Optional Memory Card

CHARACTER CONTROL

Expansion up to 12X in either the X or Y

coordinates

Character Pitch control

Line Space control

Journal Print facility

0×, 90×, 180× and 270× Rotation

Section 1: Introduction

XL400/410e Operator’s Manual Page 1-5

1.3 BAR CODES

SPECIFICATION XL400e XL410e

Symbologies Bookland (UPC/EAN Supplemental)

EAN-8, EAN-13

CODABAR

Code 39

Code 128

Interleaved 2 of 5

UCC/EAN-128

UPC-A and UPC-E

Data Matrix

Maxicode

PDF417

Ratios 1:2, 1:3, 2:5 User definable bar widths

Bar Height 4 to 600 dots, User programmable

Rotation 0×, 90×, 180× and 270×

OTHER FEATURES

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Graphics Full dot addressable graphics, SATO Hex/Binary or PCX

formats

Form Overlay Form overlay for high-speed editing of complex formats

Section 1: Introduction

Page 1-6 XL400/410e Operator’s Manual

1.4 PHYSICAL CHARACTERISTICS

SPECIFICATION XL400e XL410e

DIMENSIONS

Width 19.6 in. (302 mm)

Depth 11.8 in. (552 mm)

Height 11.5 in. (294 mm)

Weight 30.8 lbs (14 Kg)

POWER REQUIREMENTS

Voltage 100 - 115 V (+/- 10 %)

220 V (+/- 10 %)

50/60 Hz (+/- 1%)

Power Consumption 300 Watts Operating

ENVIRONMENT

Operating Temperature 41 deg to 104 deg F (5 to 40 deg C)

Storage Temperature 0 deg to 104 deg F (-20 to 40 deg C)

Operating Humidity 15–85% RH, non-condensing

Storage Humidity Max 90% RH, non-condensing

Electrostatic Discharge 8KV

REGULATORY APPROVALS

Safety UL, CSA

RFI/EMI FCC Class A

Section 1: Introduction

XL400/410e Operator’s Manual Page 1-7

1.5 OPTIONAL ACCESSORIES

Accessory Description

Memory Expansion Two slots for PCMCIA Memory Cards (up to 2MB each) that

can be used for Graphic File storage, print buffer expansion,

format storage and downloaded TrueType fonts.

Calendar An internally mounted Date/Time clock that can be used to

date/time stamp labels at the time of printing. Firmware

upgrade may be required.

Integrated Stacker Allows cut labels to be stacked. Interfaces to EXT Acces-

sory Port connector.

Label Rewinder External option rewinds labels onto a roll after they are

printed.

Section 1: Introduction

Page 1-8 XL400/410e Operator’s Manual

This page has been left blank intentionally.

Section 2: Installation

XL400/410e Operator’s Manual Page 2-1

2

INSTALLATION

This section assists you in unpacking and installing the printer from the shipping container.

You will also be guided through a familiarization tour of the main parts and controls.

The following information is provided:

• Unpacking and Parts Identification

• Setting up the Printer

• Loading Labels or Tags

• Loading the Ribbon

• Adjusting the Sensors

• Turning the Printer ON/OFF

SECTION 2: INSTALLATION

Page 2-2 XL400/410e Operator’s Manual

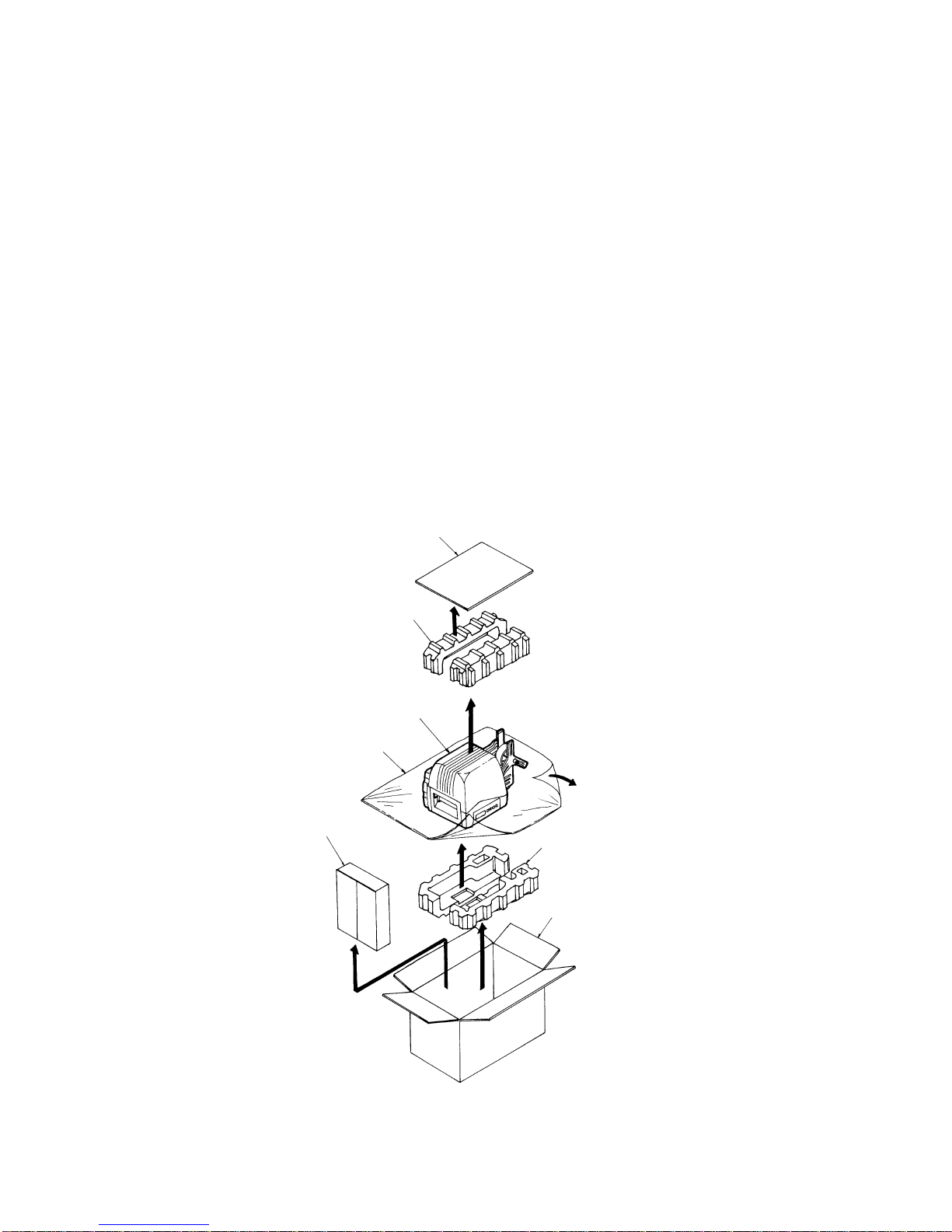

2.1 UNPACKING AND PARTS IDENTIFICATION

When unpacking the printer, take note of the following:

• The box should stay right-side up.

• Lift the printer out of the box carefully.

• Remove the plastic covering from the printer.

• Remove the accessory items from their protective containers.

• If the printer has been stored in a cold environment, allow it to reach room temperature

before powering it on.

• Set the printer on a solid, flat surface. Inspect the shipping container and printer for any

sign of damage that may have occurred during shipping.

Note

The following illustrations are representative only. Your printer may not be packed exactly as shown, but

the unpacking steps are similar.

CARDBOARD COVER

TOP FOAM INSERTS

XL PRINTER

PLASTIC SHEET

ACCESSORY BOX BOTTOM FOAM INSERTS

SHIPPING CONTAINER

Verify that the following

materials are in the

packaging:

• Printer

•PowerCord

•ExtraRib-

bon Core

• Operator’s

BOTTOM FOAM INSERTS

Section 2: Installation

XL400/410e Operator’s Manual Page 2-3

2.2 SETTING UP THE PRINTER

Consider the following when setting up the printer:

• Locate a solid, flat surface with adequate room to set the printer. If a Cutter/Stacker is to

be used with the printer, make sure there is adequate room for the unit. The printer cover

swings upward and back, so make sure there is enough clearance for the cover to swing

open.

• The location should be near the host computer or terminal. The maximum distance for

RS232 cables is 50 feet and six feet for Centronics parallel cables. Cables can be pur-

chased locally and their configuration will depend upon the host system.

• For information on interfacing the printer to a host system, see Section 5: Interface Spec-

ifications.

The procedures for setting up the printer and adjusting the sensors are outlined in the following

pages. • Loading the Ribbon (see page 2-15)

• Loading the Media (see page 2-12).

• Setting up the printer for the media type (see page 2-8). You must use the LCD panel to

select the proper media type (see page 2-14). The selections are:

Center Hole Tag

I-Mark Tag

Side Hole Tag

R-Corner Tag

Label Gap

I-Mark Label

• Adjusting the Cutter Sensor (see page 2-18). Note: The Cutter Sensor must be set up

even if the Cutter is disabled.

Procedures for setting up the operating parameters (Print Speed, Pitch Offset, etc.) are outlined in

Section 3 as follows:

• Adjusting the Cutter Offset to correctly locate the cut position. This can generally be done

with the Cut Position potentiometer on the Control Panel (see page 3-20) which has a +/-

3.75mm range. If this is insufficient, the Cut Offset can be moved +/- 99 dots using the

LCD panel (see page 3-15).

• Setting the Pitch, Cut and Backfeed Offset using the LCD panel (see page 3-14).

SECTION 2: INSTALLATION

Page 2-4 XL400/410e Operator’s Manual

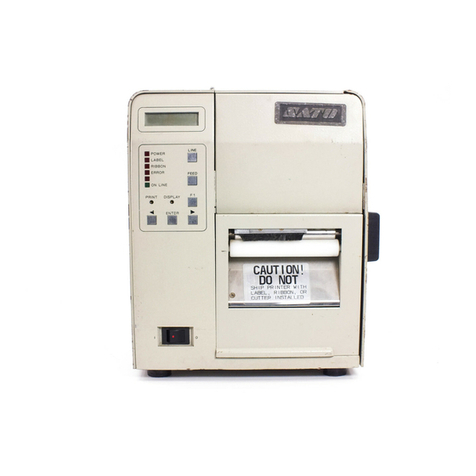

2.3 PRINTER COMPONENTS

Ribbon unwind MEDIA SUPPLY

SPINDLE

MEDIA RETAINInG

PLATE

head lock lever

operator panel

cutter

p

rint head

cover

ribbon

rewind

Section 2: Installation

XL400/410e Operator’s Manual Page 2-5

2.3 PRINTER COMPONENTS

DIP SWITCH AND

POTENTIOMETER COVER

FUSE

POWER SWITCHAC CONNECTORMEDIA HOLD-DOWN

INTERFACE

CONNECTORS:

CENTRONICS

PARALLEL, SERIAL

RS232, EXT

ACCESSORY

SECTION 2: INSTALLATION

Page 2-6 XL400/410e Operator’s Manual

2.4 THE OPERATOR PANEL

The XL Operator Panel consists of three LED indicators and five key switches. The switches are

used to set the printer operating parameters. The indicators display the status of the printer.

On Line : LED. Illuminated when the printer is ready to receive data.

Cutter On/Off : LED. Illuminated when the Cutter is enabled.

Error : LED. Illuminated when there is a system fault such as an open print head.

LCD Display : 2 Line, 16-character LCD display. Used for setting operational parameters

of the printer.

Start/Stop : Toggles the printer On and Off Line.

Feed : Momentary Switch. Feed one tag or label each time it is pressed. Effective

only when printer is Off Line.

Cutter On/Off : Momentary Switch. Enables or disables the cutter. Effective only when

printer is Off Line.

Eject : Momentary Switch. When pressed, feeds out any printed labels. If the

cutter is enabled, it feeds and cuts the label or tag.

Media Type : Momentary Switch. Steps through the media types.

ERROR LED

CUTTER ON/OFF INDICATOR

ON LINE INDICATOR

LCD DISPLAY START/

STOP FEED

CUTTER

OF/OFFEJECT MEDIA

TYPE

Section 2: Installation

XL400/410e Operator’s Manual Page 2-7

2.5 TILTING THE OPERATION PANEL

The panel can be used at two angles. The normal angle is flush with the surface of the printer.

Pushing the panel causes it to tilt backwards to allow better viewing under certain situations. To

release the panel from the tilted angle, press the release button above the panel, inside the printer.

OPERATOR PANEL

PUSH THE PANEL TO

TILT AND LOCK THE

POSITION

PUSH THIS BUTTON TO RELEASE

THE PANEL FROM TILT

OPERATOR PANEL

SECTION 2: INSTALLATION

Page 2-8 XL400/410e Operator’s Manual

2.6 MEDIA TYPES SUPPORTED

TAG CUT LINE SIDE NOTCH

OUTSIDE EDGE OUTSIDE EDGE

Side-Hole Tag without notch

(set printer for Side Hole) Side-Hole Tag with Side Notch

(set printer for Side Hole)

Center-Hole Tag without notch

(set printer for Center Hole) Center-Hole Tag with Side Notch

(set printer for Center Hole)

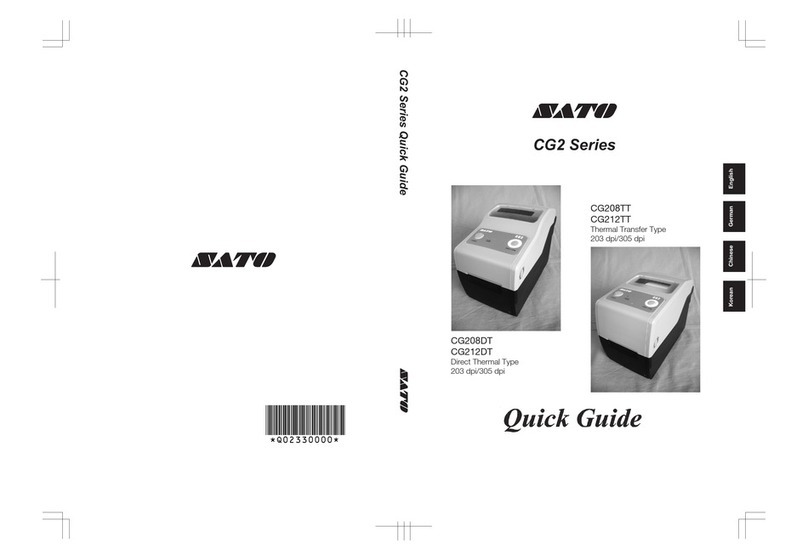

Other manuals for XL400e

2

This manual suits for next models

1

Table of contents

Other SATO Printer manuals

SATO

SATO CL-408 Owner's manual

SATO

SATO CG2 Series User manual

SATO

SATO ARGOX AME-3230W User manual

SATO

SATO Argox XM4 Series User manual

SATO

SATO MB2i Series User manual

SATO

SATO M-8400 User manual

SATO

SATO CX400 User manual

SATO

SATO XL400 User manual

SATO

SATO S8408 Standard User manual

SATO

SATO CX400 User manual

SATO

SATO M-5900RVe Series User manual

SATO

SATO GL 4xxe Series Quick guide

SATO

SATO CL412e Use and care manual

SATO

SATO HT200e User manual

SATO

SATO GL408e User manual

SATO

SATO M-8460Se Series User manual

SATO

SATO TG3 Series User manual

SATO

SATO M-8400 Guide

SATO

SATO FX3-LX User manual

SATO

SATO M-5900RVe Series User manual