TABLE OF CONTENTS

1 SAFETY INSTRUCTIONS.................................................................................................................................................4

1.1 Precautions...........................................................................................................................................................4

1.2 Symbo s................................................................................................................................................................4

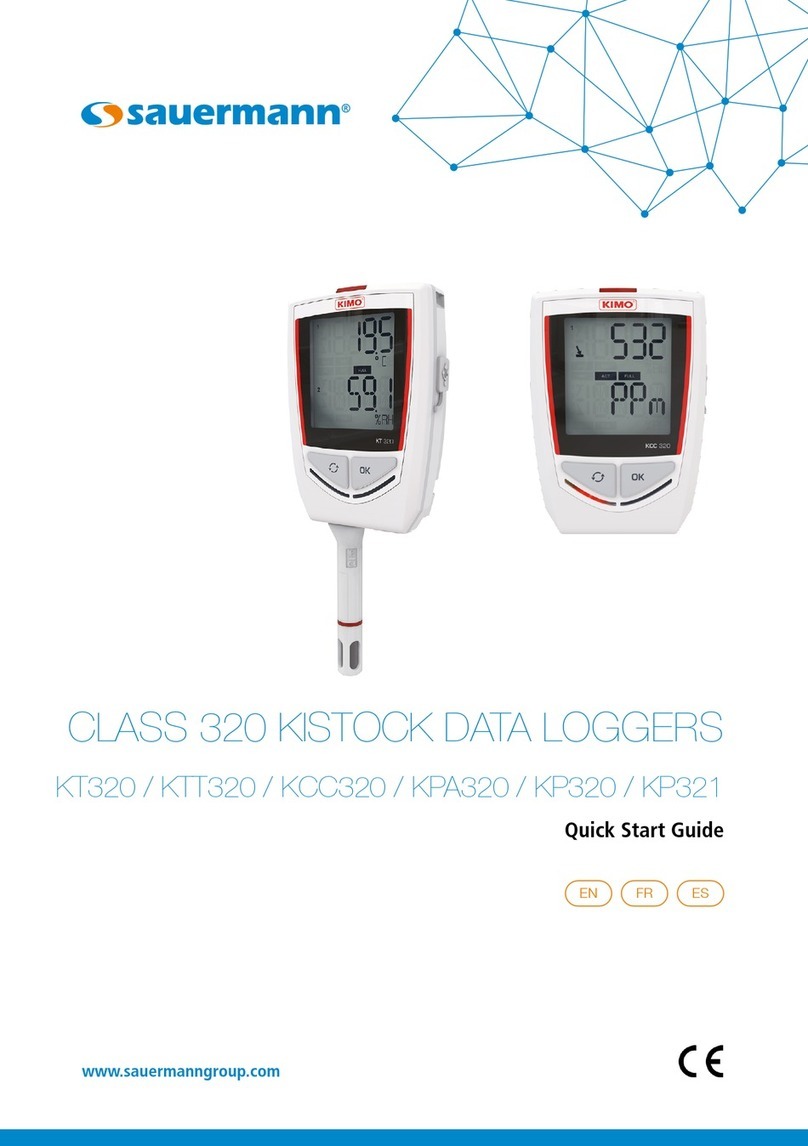

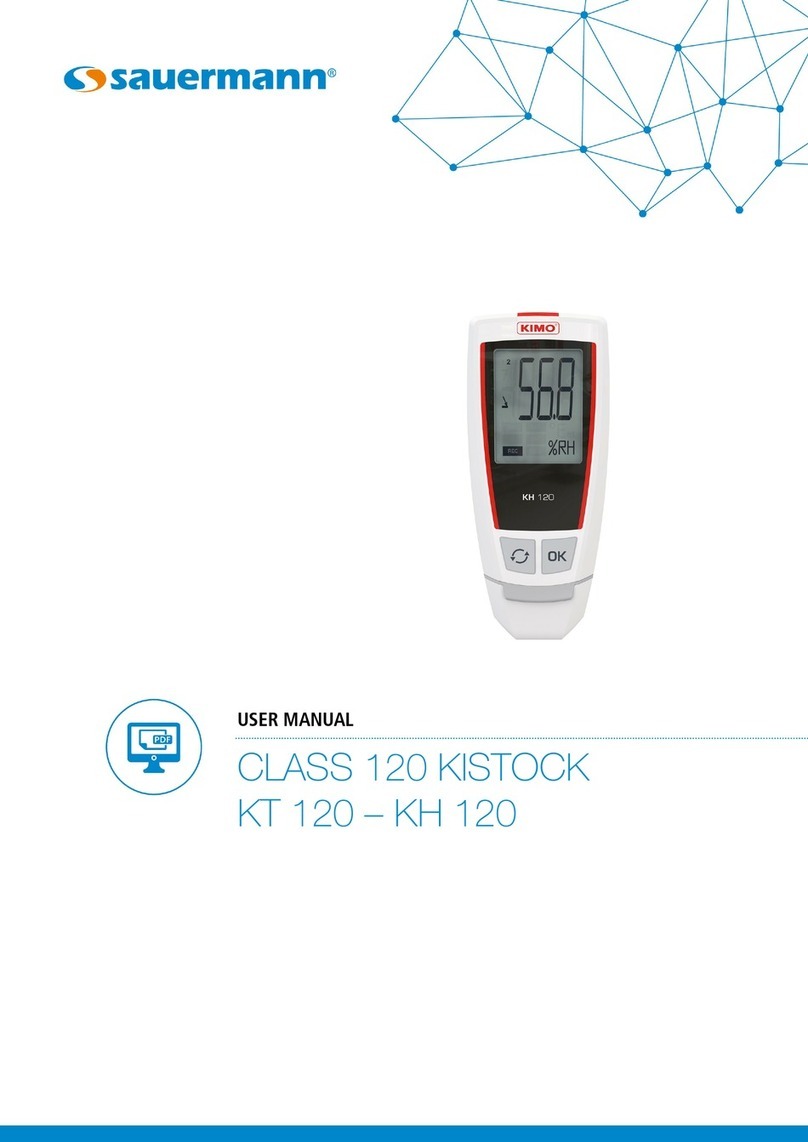

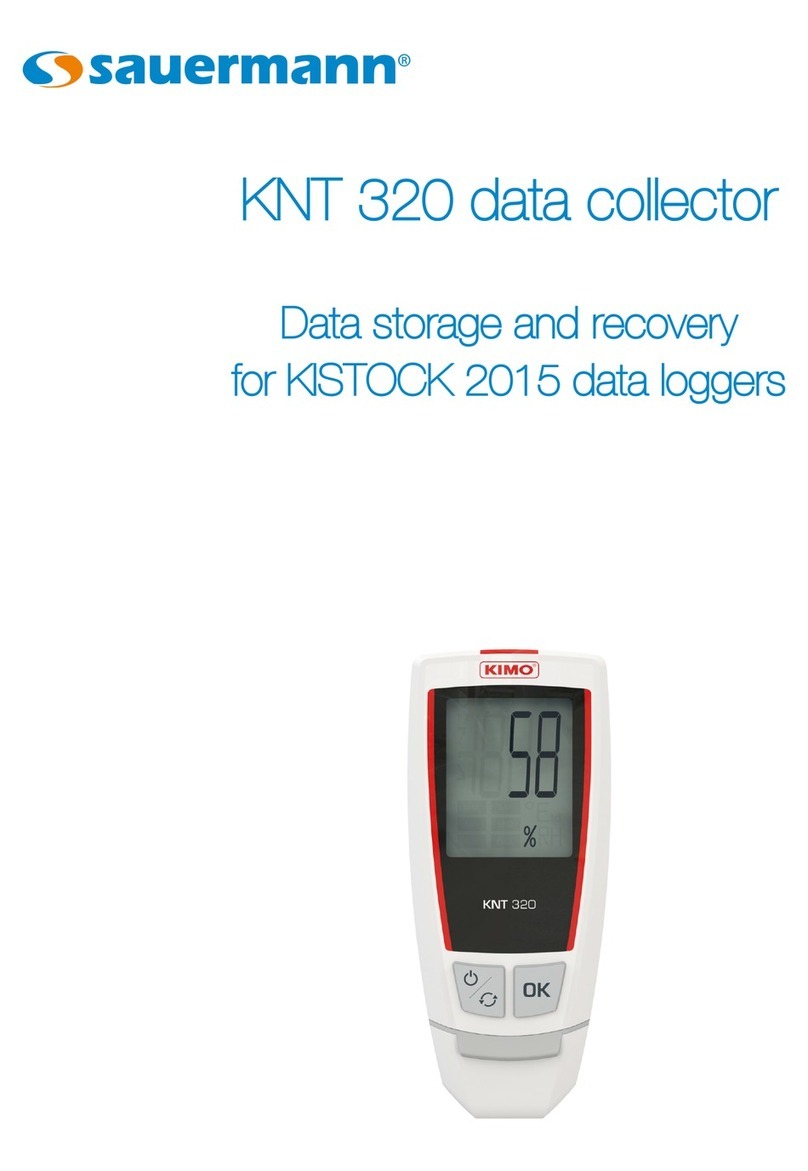

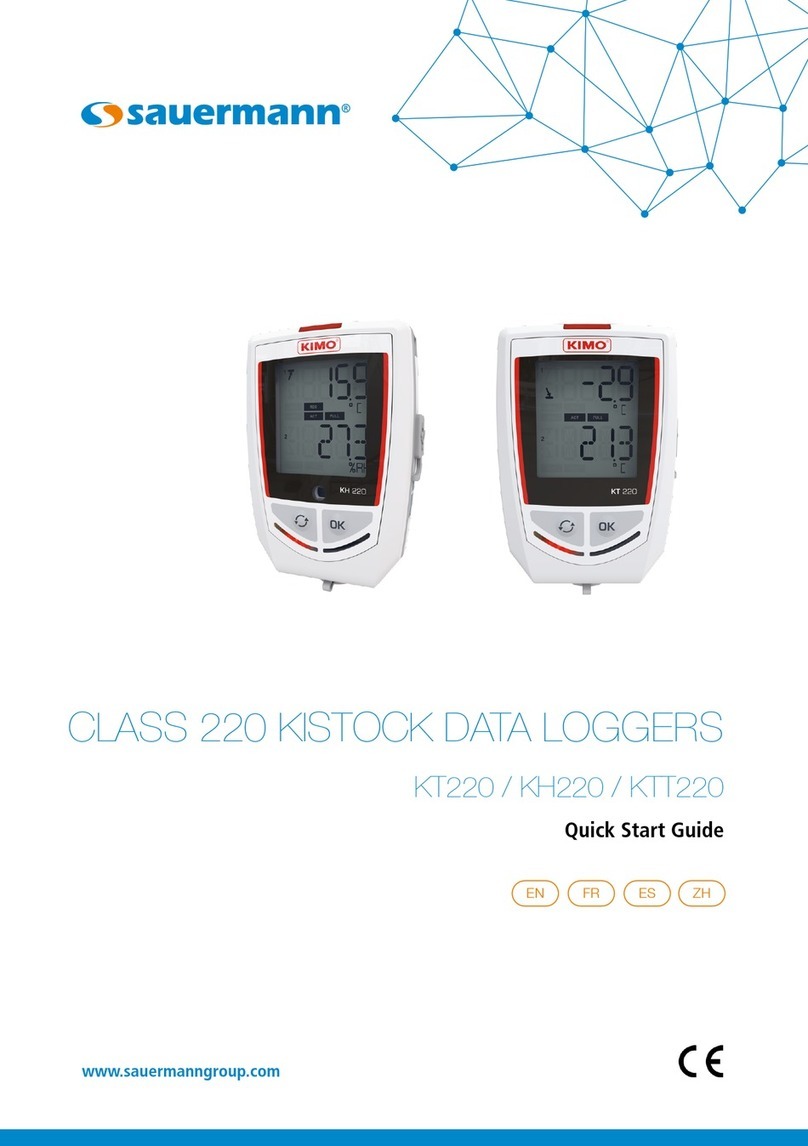

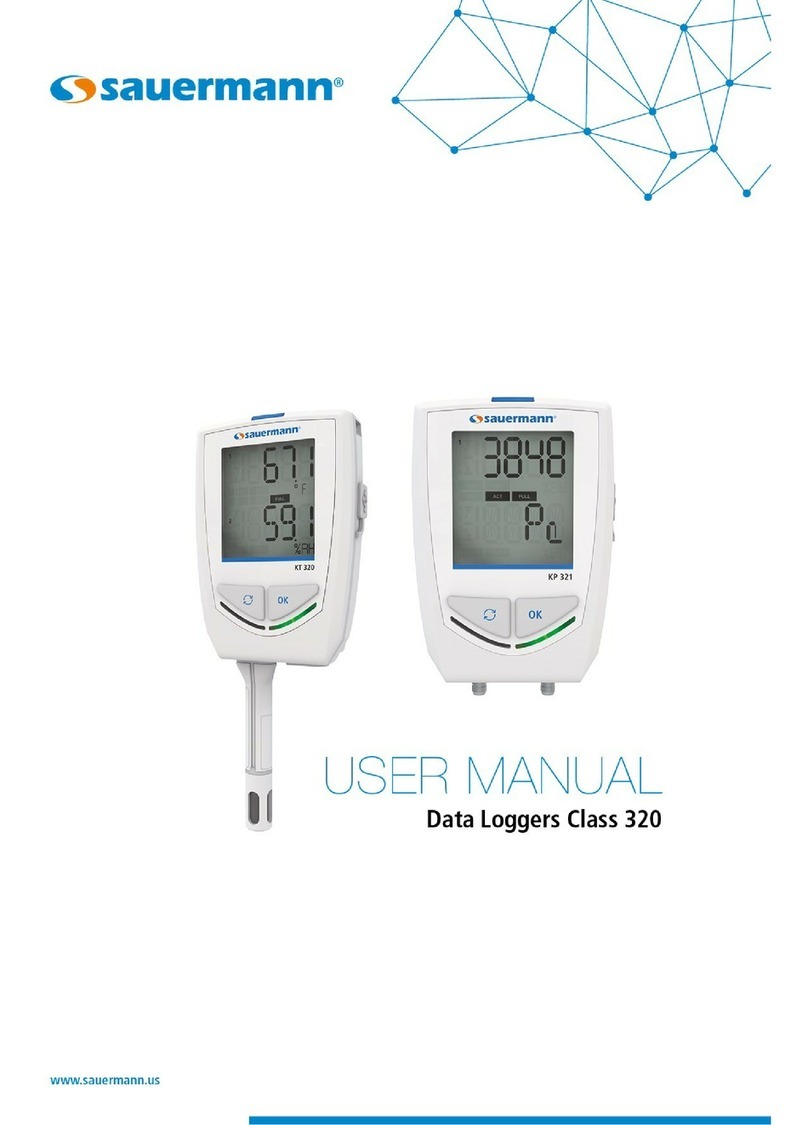

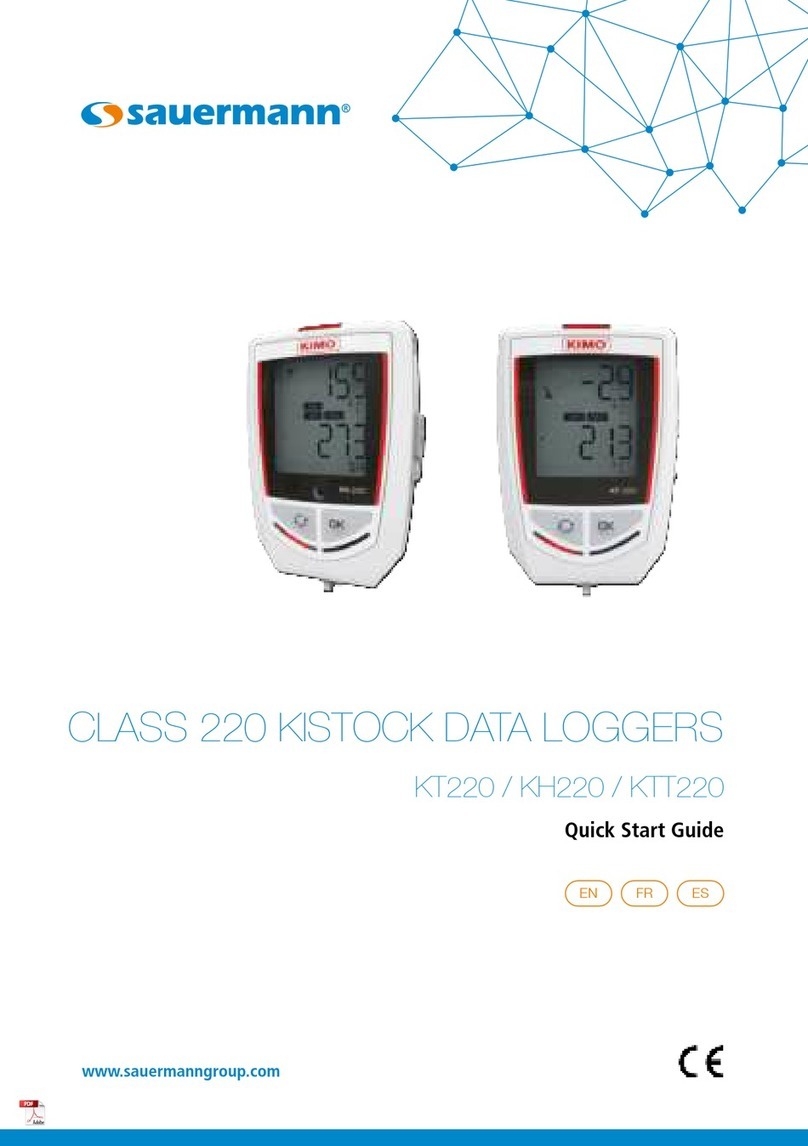

2 DEVICE COMPONENTS..................................................................................................................................................5

2.1 Use.......................................................................................................................................................................5

2.2 App ications..........................................................................................................................................................5

2.3 Se ection...............................................................................................................................................................5

2.4 Layout.................................................................................................................................................................. 5

2.5 Buttons.................................................................................................................................................................6

2.6 LEDs..................................................................................................................................................................... 6

2.7 Connections..........................................................................................................................................................6

2.8 Mounting..............................................................................................................................................................6

3 TECHNICAL FEATURES..................................................................................................................................................7

3.1 Technica data.......................................................................................................................................................7

3.2 Housing................................................................................................................................................................8

3.3 Directive: FCC part 15........................................................................................................................................... 8

3.4 Optiona probes and cab es...................................................................................................................................9

3.4.1 KT 220 and KH 220 optiona probes, cab es and ammeter c amps...................................................................9

3.4.2 KTT 220 optiona thermocoup e probes........................................................................................................10

3.5 Connect a probe on the universa input................................................................................................................10

3.6 Connect a probe on the thermocoup e input.........................................................................................................10

3.7 Dimensions.........................................................................................................................................................11

3.7.1 Devices.......................................................................................................................................................11

3.7.2 Wa mount................................................................................................................................................. 11

3.8 Warranty period...................................................................................................................................................11

4 USE OF THE DEVICE....................................................................................................................................................12

4.1 Disp ay................................................................................................................................................................ 12

4.2 Functions of LEDs................................................................................................................................................12

4.3 Configuration, data ogger down oad and data processing with the KILOG software..............................................13

4.4 Functions of buttons............................................................................................................................................13

4.4.1 Groups organization....................................................................................................................................15

4.4.2 Measurements scro ....................................................................................................................................15

4.5 PC communication..............................................................................................................................................15

5 MAINTENANCE........................................................................................................................................................... 16

5.1 Rep ace the battery.............................................................................................................................................16

5.2 Device c eaning...................................................................................................................................................16

5.3 Safety ock wa mount with pad ock....................................................................................................................16

6 CALIBRATION............................................................................................................................................................. 17

7 ACCESSORIES.............................................................................................................................................................17

8 TROUBLESHOOTING.................................................................................................................................................... 17