Ziegelei 1

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433-9933-199

Fax: +49-[0]7433-9933-149

Internet: www. sauter.eu

Instruction Manual

TB-BA-e-1212 2

4. Measuring procedure

4.1 The power- key is to be pressed to turn on the power.

`0` appears on the display 3-2.

Remark: The instrument will auto- calibrate, as soon

as it is switched on.

Please pay attention to the sensor. During the initial

calibration it should be neither in direct surroundings

of the base plate nor other magnetic materials.

4.2 The sensor is to be placed on the coating to be

measured.

The coating thickness is now shown on the display.

4.3 To perform the next measurement the sensor has to

be lifted for more than 1cm off the base material

and step 4.2 is to be repeated.

4.4 In case of inaccuracies to the measurement result, it

is recommended to calibrate the instrument before

measuring as described in 6.

4.5 The instrument can be switched off by the

Power- on/ Power- off key 3-6. The gauge

switches off automatically 2 minutes after the

last operation.

5. OFFSET-Accur

With this instrument the possibility is given to improve

the measurement result essentially by using the OFFSET-

Accur function. Therefore it is necessary to calibrate the

gauge with a reference coating in the typically measured

range. This adjustment can also be done with the

calibration foils, included in the delivery. Ideally this adjust-

ment should be done on the base material which is used

for the real measurement instead on the base plate

included in the delivery.

5.1 The result of the initially measurement is still shown on

the display (as performed in 4.2).

5.2 The sensor is to be removed from the test object. Then

the reading on the display shall be corrected by

pressing the Plus- key or the Minus- key.

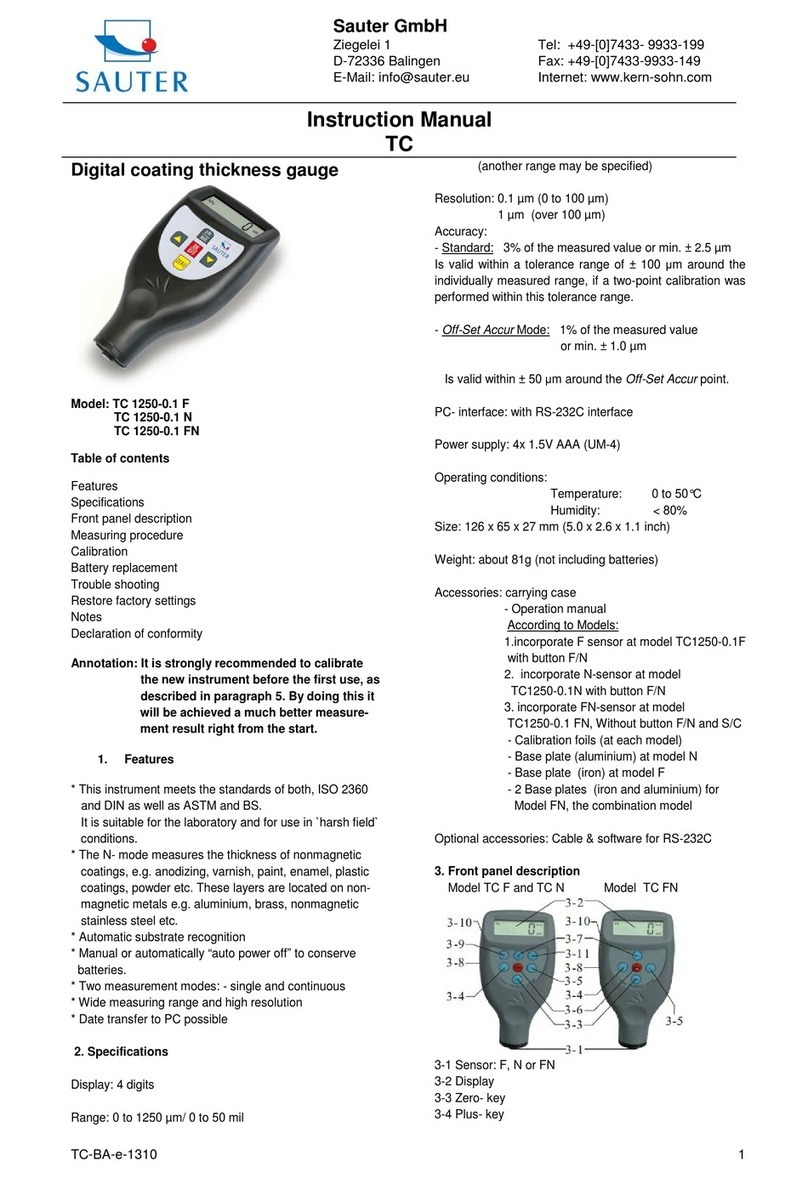

6. Calibration

6.1 Zero calibration: The sensor has to be placed on the

base plate or another uncoated nonmagnetic material.

On the display `0` is shown when pressing the

Zero- key.

The Zero- key may not be pressed if the sensor is not

placed on the base plate or on any other uncoated

base material.

6.2 An applicable calibration foil is to be chosen adequate

to the typical measurement range.

6.3 The chosen calibration foil has to be placed onto the

base plate or another uncoated base material.

6.4 The sensor 3-1 has to be placed carefully onto the

calibration foil and then it has to be lifted.

The result now appears on the display.

It shall be corrected by pressing the Plus- key 3-4 or

the Minus- key 3-5. For doing this, the sensor must be

removed from the base plate or the material to be

measured.

6.5 Step 6.4 is to be repeated until the measurement

accuracy has been realised.

7. Battery replacement

7.1 The batteries are to be replaced if the battery

voltage is less than 4.8V. In this case the battery

symbol ``+-`` appears on the display.

7.2 The battery cover is to be removed (Fig.1, 3-6) from

the instrument and the batteries are to be taken off.

7.3 The batteries (4×1.5V AA/UM-3) are to be installed

correctly into the case.

7.4 If the instrument is not to be used for an extended

period, batteries are to be extracted.

8. Calibration foils

As accessory the instrument includes a calibration foil

set and the base plate.

9. Correct handling of coating thickness measurement

with external sensors

The sensor has to be touched at the lower pole segment

and it has to be pressed slightly onto the test object.