EFA EFA 57 User manual

Pneumatically operated

breastbone saw EFA 57

Operating instructions EN

Schmid & Wezel GmbH

www.efa-germany.com

Part no. 110 885 700 – Rev. 00 – 01.2020

EFA breastbone saw

EFA 57

Pneumatically operated

breastbone saw EFA 57

Schmid & Wezel GmbH

www.efa-germany.com

Part no. 110 885 700 – Rev. 00 – 01.2020

Operating instructions

Schmid & Wezel GmbH. All rights reserved.

Printed in Germany.

These operating instructions must not be reproduced in whole or in part, used for competitive

purposes without our authorisation, or made available to third parties without our consent.

Any changes or amendments to these operating instructions are only allowed to be made by us;

otherwise any warranty claim against us will be void.

Schmid & Wezel GmbH

Maschinenfabrik

Maybachstrasse 2

75433 Maulbronn/Germany

Phone: +49 7043 1020

Fax: +49 7043 10278

E-mail: [email protected]

Internet: http://www.efa-germany.de

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 1 of 34

Table of contents

1. Introduction and general information ___________________________________________ 3

Information on the operating instructions ______________________________________________ 3

User group _____________________________________________________________________ 4

Scope of supply _________________________________________________________________ 4

Intended use ___________________________________________________________________ 4

Claims for defects, liability, warranty _________________________________________________ 5

2. Safety ______________________________________________________________________ 8

Safety instructions _______________________________________________________________ 8

2.1.1 Other safety signs _____________________________________________________________ 9

2.1.2 Warning sign _________________________________________________________________ 9

2.1.3 Mandatory instruction sign _______________________________________________________ 9

2.1.4 Prohibition sign _______________________________________________________________ 10

2.2 Personal protective equipment in the following lifecycle phases ___________________________ 10

2.3 Conduct at the workplace _________________________________________________________ 11

3. Technical description _______________________________________________________ 12

Machine overview_______________________________________________________________ 13

3.2 Dimensions ___________________________________________________________________ 14

3.3 Nameplate ____________________________________________________________________ 15

4. Transport and storage _______________________________________________________ 16

5. Connection and start-up _____________________________________________________ 16

Connecting the EFA pneumatically operated breastbone saw _____________________________ 17

5.1.1 Filter pressure reducer _________________________________________________________ 18

5.1.2 Spring balancer ______________________________________________________________ 18

5.2 Handling ______________________________________________________________________ 19

5.3 Switching on the EFA pneumatically operated breastbone saw ____________________________ 19

5.4 Switching off ___________________________________________________________________ 20

5.5 Working with the EFA pneumatically operated breastbone saw ____________________________ 20

Operational safety ____________________________________________________________ 20

5.6 Procedure for non-utilisation ______________________________________________________ 21

6. Assembly _________________________________________________________________ 21

Changing the saw blade __________________________________________________________ 21

6.1.1 Changing the saw blade ________________________________________________________ 21

6.2 Setting of the ledges/slider clearance________________________________________________ 23

6.3 Adjusting the saw blade guide _____________________________________________________ 24

6.4 Adjustment of the spring balancer __________________________________________________ 24

7. Service and maintenance ____________________________________________________ 25

Daily cleaning __________________________________________________________________ 25

7.1.1 Cleaning during operation ______________________________________________________ 25

7.1.2 Cleaning the EFA pneumatically operated breastbone saw _____________________________ 26

7.2 Daily maintenance ______________________________________________________________ 27

7.2.1 Tools and accessories _________________________________________________________ 27

7.2.2 Lubrication __________________________________________________________________ 27

7.2.3 Saw blade __________________________________________________________________ 27

7.3 Extended maintenance ___________________________________________________________ 28

7.3.1 Lubrication of the EFA pneumatically operated breastbone saw _________________________ 28

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 2 of 34

7.3.2 Extended maintenance after 400 operating hours ____________________________________ 28

7.3.3 Sharpening saw blade _________________________________________________________ 29

7.4 Oil mist lubricator _______________________________________________________________ 29

8. Maintenance _______________________________________________________________ 30

8.1 Repair by the customer service ____________________________________________________ 31

9. Waste disposal, recycling ____________________________________________________ 31

9.1 Disassembly and disposal ________________________________________________________ 31

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 3 of 34

1. Introduction and general information

Important! Operating instructions cannot prevent

misuse in every case!

Information on the operating instructions

These operating instructions are part of the technical documentation of the machine and comply with the

Machinery Directive.

The machine has been designed and built according to the selection of the harmonising standards to be

observed as well as other technical specifications.

The operating instructions are intended to describe the operation and handling of the EFA pneumatically

operated breastbone saw and provide the necessary safety instructions.

They contain details for the intended use as well as important information:

If the instructions are followed, the EFA pneumatically operated breastbone saw will be operated safely,

properly and economically and its operational capability will be maintained.

Observance of these instructions helps to avoid dangers, minimise repair costs and downtimes, and increase

the reliability and service life of the machine.

A prerequisite for safe handling and trouble-free operation of the machine is observance of the following . . .

These operating instructions must always be kept accessible at the machine for all work to be carried out.

Note!

If these operating instructions have been damaged or lost, you can request a new copy by

stating the part number "Art Nr.", year of construction "Bj." and serial number "S/N" see

paragraph 3.3 – Nameplate.

If you have any questions, or if you cannot solve a problem with the help of these operating instructions,

please contact our Service department.

for safe handling of the machine,

for maintenance,

for cleaning.

the operating instructions,

the company directives (safety signs and danger warnings),

the legal provisions on occupational safety,

the applicable laws and regulations.

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 4 of 34

User group

Only instructed and/or trained personnel over 16 years of age are allowed to set up or operate the EFA

pneumatically operated breastbone saw. Furthermore, it is imperative that everyone working with and on the

machine has read the operating instructions and observes them.

Instructed person

Persons over 16 years of age who have been instructed and trained by a qualified person (specialist) in the

tasks assigned to them and about possible dangers in the event of improper behaviour, as well as in the

handling of the necessary protective devices and protective measures, are considered to be instructed

persons.

Trained person (specialist personnel)

Persons who have obtained a professional qualification and have demonstrated this by checking the results or

passing an examination are considered to be trained persons.

Scope of supply

Pneumatically operated

breastbone saw EFA 57

Saw blade

Air-outlet hose with sound

absorber

Assembly tool: Socket wrench

EFA special grease (1 kg tin)

Grease gun

Operating instructions

Upon receipt of the delivery, check immediately whether the scope of supply corresponds to the

accompanying documents.

Submit a complaint in the event of:

These operating instructions describe the EFA pneumatically operated breastbone saw with all possible

options.

Options are not necessarily included in the scope of supply and can only be retrofitted to a limited extent.

Intended use

The EFA pneumatically operated breastbone saw is used for opening breastbones designed for on-the-rail

operation in medium sized and large plants.

EFA pneumatically operated breastbone saws are only allowed to be used:

apparent transport damage immediately to the supplier,

apparent defects/missing items, to Schmid & Wezel GmbH.

in fully functional condition,

with properly functioning safety devices,

with the equipment approved by the manufacturer.

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 5 of 34

Do not use materials harmful to health.

If, contrary to the intended use, materials harmful to health are to be processed then Schmid & Wezel GmbH

must be informed in writing about the planned use and the protective measures taken by the customer/

operating company.

The customer/operating company is solely responsible for suitable protective measures (e.g. extraction

devices, respiratory protection, protective suits, etc.) and company directives.

If the EFA pneumatically operated breastbone saw is not used as intended or is modified without the approval

of Schmid & Wezel GmbH, persons could be injured and the machine damaged.

The operating permit is invalidated.

The intended use includes in particular that you:

Claims for defects, liability, warranty

Warranty and liability claims for personal injury and damage to property are excluded in particular in the

following cases:

Liability

The manufacturer accepts no liability for accidents, machine damage and consequences of machine failure

resulting from failure to observe the operating instructions. In addition, the local accident prevention

regulations and general safety regulations for the area of application of the machine apply.

Limitation of liability

All technical information, data and instructions for the operation of the machine contained in the operating

instructions are up to date at the time of delivery. They are provided to the best of the manufacturer's

knowledge, taking into account previous experience and knowledge. The manufacturer reserves the right to

make technical modifications in the course of further development of the machine described in these operating

instructions. No claims can therefore be derived from the information, figures and descriptions in these

operating instructions. The manufacturer shall be liable for any errors or omissions within the scope of the

warranty obligations entered into in the contract, to the exclusion of further claims.

Claims for damages are excluded, irrespective of the legal basis on which such claims are derived. Only the

text of the operating instructions is authoritative.

The textual and graphical representation in the operating instructions does not necessarily correspond to the

scope of supply or a spare parts order. Illustrations in these instructions are not to scale.

Observe the operating instructions and company directives,

Observe maintenance instructions and intervals,

Immediately rectify any faults that impair safety,

Do not operate the EFA pneumatically operated breastbone saw if safe working with it is not possible,

Do not structurally modify the EFA pneumatically operated breastbone saw without authorisation.

Improper use or unsuitable use,

Improper transport or storage,

Improper assembly and/or initial start-up,

Improper operation (operating errors),

Disregarding of operating instructions/company directives,

Faulty or negligent handling,

Improper maintenance/repair,

Unsuitable equipment or spare parts that are not approved by Schmid & Wezel GmbH Maschinenfabrik,

Natural wear and tear,

Improper or unprofessional rectification of defects by the customer/operating company or third parties,

Unauthorised structural changes to the machine without written permission from Schmid & Wezel GmbH,

Chemical, electrochemical or electrical influences – unless they are the responsibility of Schmid & Wezel

GmbH.

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 6 of 34

Technical changes

The manufacturer Schmid & Wezel GmbH reserves the right to make technical changes within the scope of

improving the usage properties and further development without prior notice. Figures are for basic

understanding and could differ from the actual design of the system.

Copyright

The manufacturer reserves the copyright to these operating instructions. These operating instructions are

intended for assembly, operating, maintenance and monitoring personnel.

Transferring the operating instructions to third parties without the written consent of the manufacturer Schmid

& Wezel GmbH is not permitted. Duplication in any kind and form – in whole or in part – as well as the use

and/or communication of the contents are not permitted without written declaration of the manufacturer.

Note! All content, texts, drawings, pictures and other representations are protected by copyright

and are subject to industrial property rights.

Any improper use may be punishable!

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 8 of 34

2. Safety

Everyone who is involved in the installation, start-up, operation, set-up, equipping and maintenance of the

machine in the operating company must have read and understood the operating instructions, in particular the

"Safety" chapter.

Safe operation of the machine is only guaranteed if:

Important! The operating instructions must be accessible at all times during the entire period of use of

the machine for the operating, maintenance and cleaning personnel.

Therefore, always keep these operating instructions close to the machine.

First aid

Important! In the event of an accident, provide FIRST AID.

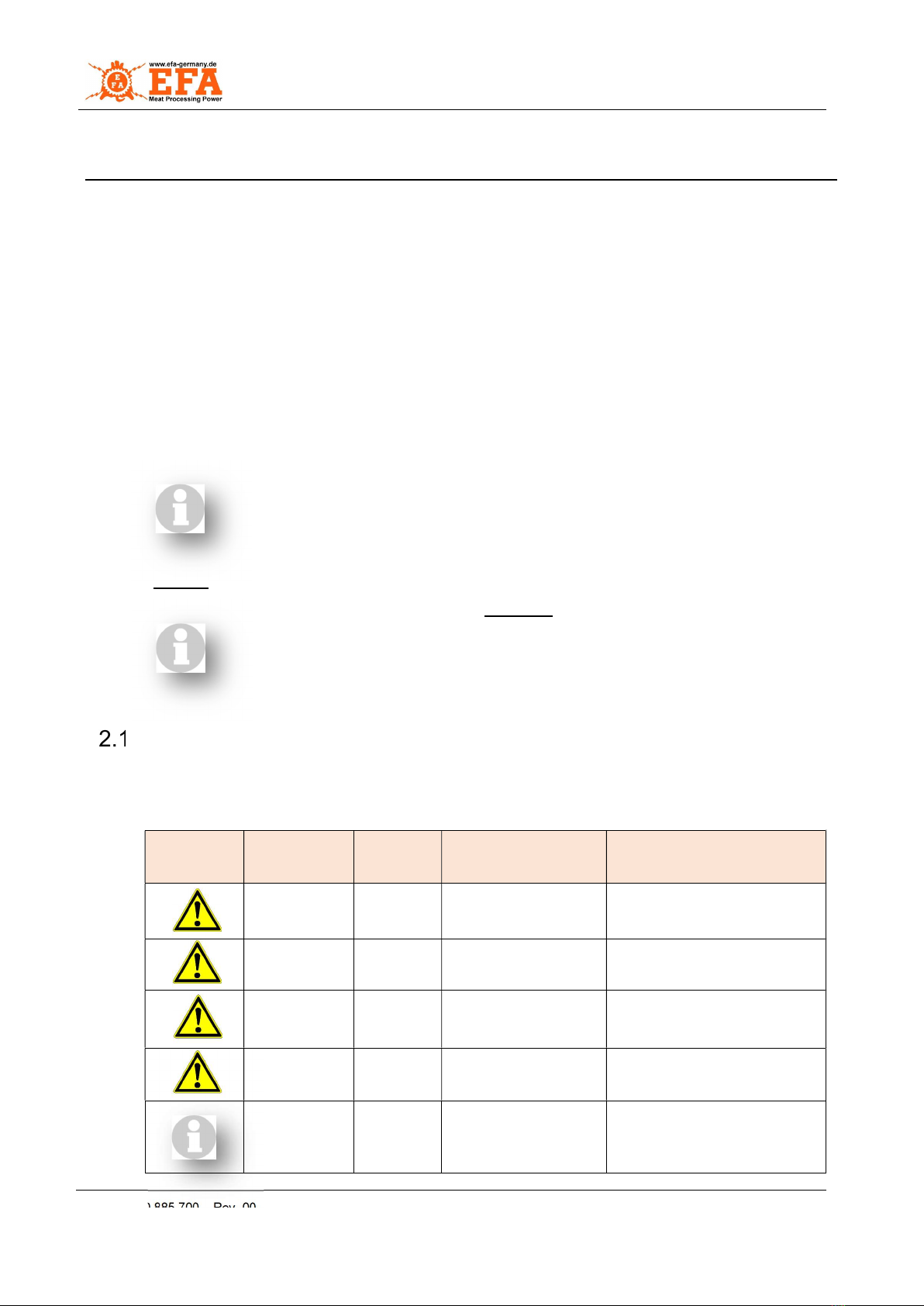

Safety instructions

During the use of the machine, dangers could arise in certain situations or through certain behaviour.

The measures described to protect against dangers must be observed.

The safety instructions are identified as shown in the following tables (pictograms).

Symbol /

pictogram Signal word Damage /

injury to . . . Definition

Possible consequences of

disregarding the safety

instructions

Danger Persons Imminent danger Death, serious bodily injury or

substantial damage to property

Warning Persons Potentially dangerous

situation

Death or serious bodily injury could

occur

Caution Persons Less dangerous situation Slight or minor injuries

Attention Property Potentially harmful

situation

Damage to the product or its

environment

Information -

Application tips and other

important/useful

information

No dangerous/harmful situation

Unauthorised persons are kept away from the working area of the machine,

Safe working with awareness of the dangers involved is regularly checked in accordance with the

operating instructions,

No working methods are employed that could compromise safety,

Malfunctions in the machine are eliminated immediately,

Maintenance work is carried out regularly.

• Keep calm!

• Remove injured persons from the danger area without endangering yourself!

• Inform other employees (first-aiders, paramedics) or request help!

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 9 of 34

2.1.1 Other safety signs

Symbol Meaning

Mark of conformity

The machine complies with the applicable regulations of the EC Machinery Directive

Recyclable materials!

Ensure that the materials are recycled properly!

2.1.2 Warning sign

Warnings and symbols used in the operating instructions and documentation are intended to help you to

recognise and assess the dangers more easily.

Symbol Meaning

Warning! Sharp cutting tool!

Contact with the running cutting tool/saw blade will lead to extremely severe cutting injuries involving

permanent or even fatal injury. Ensure that a sufficient safety distance is maintained. Contact with the

stationary cutting tool/saw blade could lead to severe cutting injuries involving permanent injury. Wear

safety gloves. Ensure that a safety distance is maintained.

Warning of hand injuries

There is a danger of hands being pinched, pulled in or otherwise injured. Keep your hands away from

places that bear this warning sign!

Warning of noise with high sound pressure level

If the sound pressure level at the workplace exceeds 85 dB(A). Remaining for a relatively long period

can cause permanent hearing damage. Only enter the area if wearing the correct hearing protection.

Warning of hot surface!

It is not always possible to notice the presence of hot machine parts, containers or materials, as well as

hot liquids. If such a safety sign is affixed to a component, care must be taken. Do not touch hot

surfaces without protective gloves.

2.1.3 Mandatory instruction sign

Symbol Meaning

General mandatory instruction sign!

Observe company directive, notes in operating instructions and generally applicable safety regulations.

Wear cut-resistant gloves!

Cutting injuries possible. Provide information about suitable cut-resistant gloves.

Use safety shoes

Safety shoes form part of the personal protective equipment and provide protection for the health of the

worker. They prevent accidents and injuries such as crushing by heavy objects.

Wear a protective helmet!

Head injuries are possible due to objects falling, tipping over or being thrown out, or due to swinging

loads; bumping into obstacles also represents a danger. A suitable protective helmet must always be worn

on the head when in the indicated area.

Wear protective goggles!

Eye injuries (loss of vision) possible when working due to flying solid objects.

Wear hearing protection!

If the continuous sound pressure level of the machine/system is above 85 dB(A), hearing protection must

be worn to prevent permanent hearing damage.

Wear protective clothing!

Protection against contact with auxiliary or working equipment. Find out about suitable protective clothing.

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 10 of 34

2.1.4 Prohibition sign

Symbol Meaning

General prohibition sign!

The red signal border/prohibition stripe indicates an immediate danger and is overlaid diagonally over

the self-explanatory symbol. The general prohibition sign must always be used in conjunction with

another sign.

2.2 Personal protective equipment in the following lifecycle phases

Some work requires protective equipment. This protective equipment must be made available to you.

Lifecycle phase Protective equipment

Transport Cut-resistant gloves

Safety shoes

Assembly, start-up &

maintenance

Cut-resistant gloves

Safety shoes

Protective goggles

Hairnet for long hair

Operation

Hairnet for long hair

Cut-resistant gloves

Protective goggles

Hearing protection

Safety shoes

Storage Cut-resistant gloves

Safety shoes

Disposal Cut-resistant gloves

Safety shoes

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2020 11 of 34

2.3 Conduct at the workplace

The workplaces must be designed in such a way that each employee has at least 1.5 m² of freedom of

movement.

The floor must minimise the danger of slipping on wet, greasy or dirty surfaces.

The workplace must comply with local hygiene and workplace regulations.

Keep your workplace tidy and in good working condition. A cluttered or messy workplace can lead to

accidents.

Take environmental influences into account. Ensure proper lighting (at least 500 lux).

Keep other persons away from your workplace. Focus on the job in hand when working.

Do not use the EFA pneumatically operated breastbone saw when you are tired and/or unfocused.

Avoid wearing loosely fitting items of clothing and jewellery that can be caught by moving parts. Wear

sturdy shoes during your work. Always wear a hairnet!

Ensure that your workplace has a correct, ergonomic set-up and make sure that you are standing

securely.

Store the EFA pneumatically operated breastbone saw safely. Store unused devices in a dry place.

When the EFA pneumatically operated breastbone saw is not in use, it must be stored in such a way that

unintentional contact with the sharp saw blade is avoided.

Look after your equipment with care. Use only sharp and undamaged saw blades for safe work.

Only use genuine EFA accessories/spare parts.

Non-compliance will void the warranty.

The use of other equipment, accessories or spare parts can endanger you and other persons.

Pneumatically operated breastbone saw EFA 57 Operating instructions EN

Part. no. 110 885 700 – Rev. 00 – 01.2019 12 of 34

3. Technical description

Tab. 1 – Technical data

Name

Type

Power

Operating pressure

Air consumption at full

load

Length of saw blade

Stroke rate

Cutting performance

per breastbone

Weight

Connection of the oil

mist lubricator

Vibration emission

(measurement

inaccuracy)

Sound pressure level

(measurement

inaccuracy)

Sound power level

(measurement

inaccuracy)

Peak sound pressure

level

Cross-section

watt bar m³/min mm min sec kg inch m/s² dB (A) dB (A) dB (C) mm

EFA 57 1150 6 – 8 1.5 312 3200 3 – 5 17 1/2" 16.6

(0.275) 89 (3) 100 (3) 107.3 (3)

ID OD

16 22

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev.00 – 01.2020 13 of 34

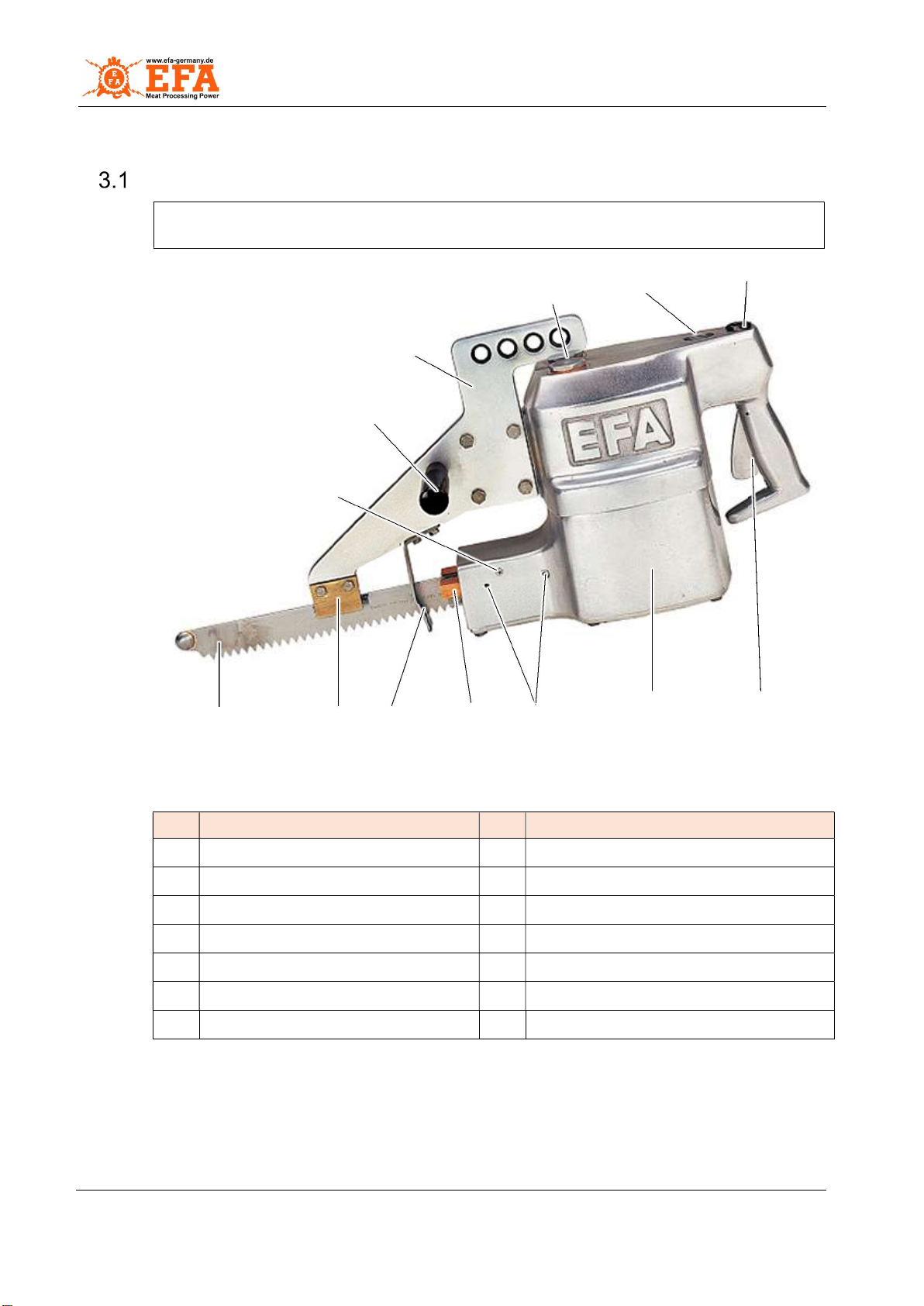

Machine overview

No. Part description No. Part description

1 Saw blade (78 teeth) 8 Supply air connection

2 Guide plate 9 Exhaust air connection

3 Keep-off rail 10 Sound absorber

4 Slider edge (2x) 11 Guide with holes for spring balancer

5 Threaded pin for slider adjustment 12 Tapered handle

6 Housing complete 13 Grease nipple

7 Handle with valve lever

Pneumatically operated breastbone saw EFA 57

10

1

2

3

4

7

6

5

9

8

11

12

13

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 14 of 34

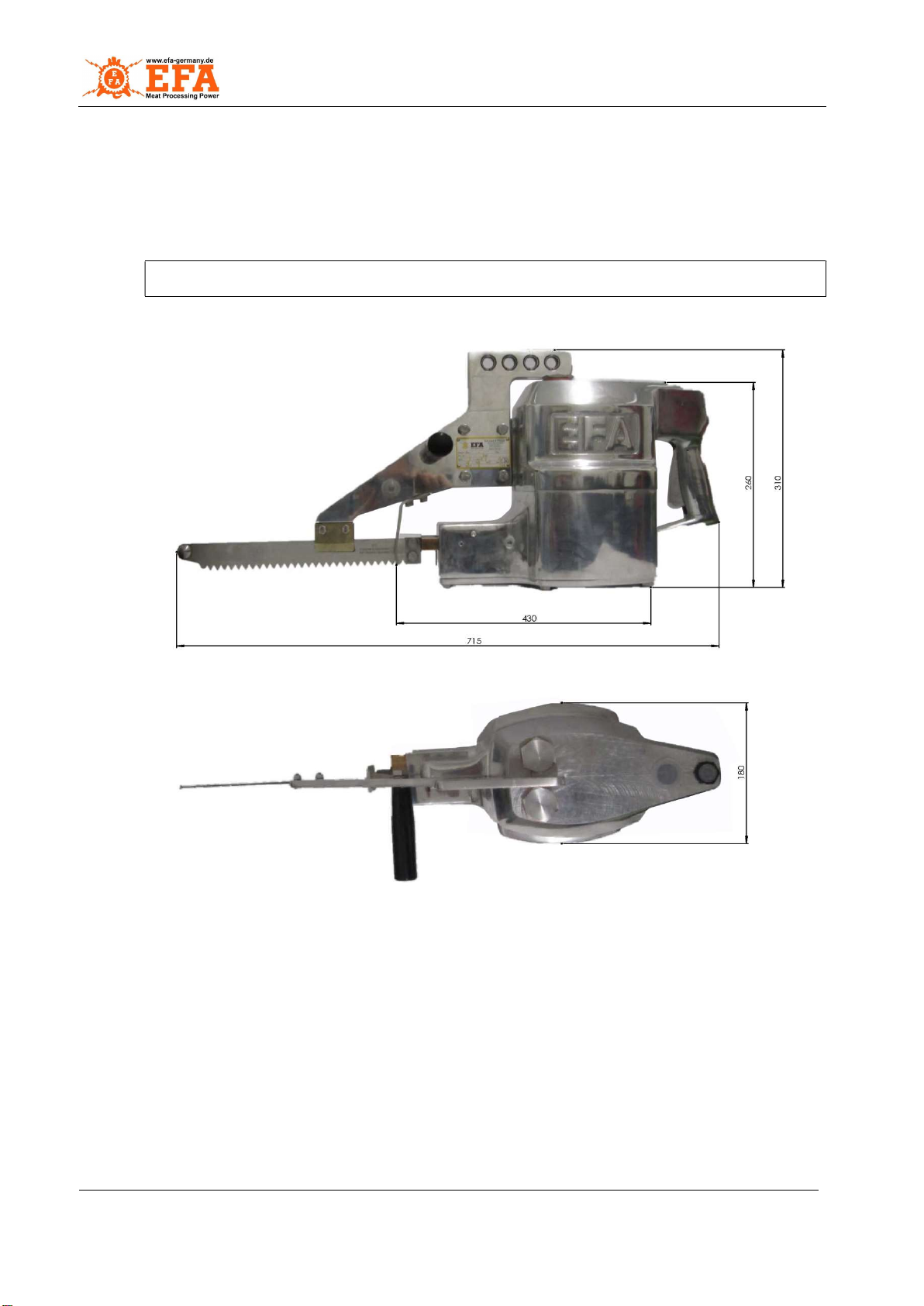

3.2 Dimensions

The following figure gives you an overview of the dimensions of the machine.

Pneumatically operated breastbone saw EFA 57 – part no. 110 885 700

Pneumatically operated breastbone saw EFA 57

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 15 of 34

3.3 Nameplate

The nameplate is attached to the guide and contains information on the machine performance.

The following figure shows an example of the nameplate for the pneumatically operated breastbone saw EFA 57.

Part number

Serial number

Year of manufacture

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 16 of 34

4. Transport and storage

The machine has been tested and carefully checked in our factory before shipment.

The test ensures that the machine is working properly.

Despite all care taken, there is a possibility that the machine could be damaged during transport.

Therefore, check the machine for possible transport damage when unpacking it.

Unpacking the machine

The machine is ready for use immediately after unpacking.

Storage of the machine

For safe storage of the machine, it is essential to observe the following instructions:

– Only store the machine in dry rooms.

– Only store the machine in a dry condition.

– Protect the machine from corrosion.

5. Connection and start-up

The working area for the operator should be at least 1.5 square meters in size.

No other workplace should protrude into this area, otherwise there is a danger of injury due to the actions

carried out with the EFA pneumatically operated breastbone saw.

The lighting of the workplace must be at least 500 lux.

The EFA pneumatically operated breastbone saw is delivered from the factory ready for use.

Caution! Danger from unintentional switch-on!

Connect the EFA pneumatically operated breastbone saw to the compressed air supply only

when switched off!

Caution! Tripping hazard!

Lay compressed air lines outside the traffic area.

Caution! Danger of malfunctions and injuries!

Installation work is only allowed to be carried out by authorised specialist personnel.

Remove all packaging materials and dispose of them in a professional and environmentally friendly

manner.

Check the machine for possible transport damage.

Information on disposal and recycling can be found in chapter 9.

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 17 of 34

3

Connecting the EFA pneumatically operated breastbone saw

Attention!

Device damage!

Operate the EFA pneumatically operated breastbone saw only with clean, water-free and oiled

air!

Insert the air hose (1) as far as it will go into the screw-in fitting (2) on the valve housing (3) of the EFA

pneumatically operated breastbone saw.

Screw the air-outlet hose (4) onto the valve housing (3) of the EFA pneumatically operated breastbone

saw.

Connect the EFA pneumatically operated breastbone saw to the oil mist lubricator (6) with the thread

nipple of the air hose (5) (with filter pressure reducer).

Make sure that the oil mist lubricator is assembled in the following sequence: water separator (7), pressure

gauge (8), oil mist unit (9).

The oil mist lubricator and the air hose are not included in the scope of supply but can be

purchased on request from our Sales department at Schmid & Wezel GmbH.

Air hose: Part no. 311 366 811

Oil mist lubricator: Part no. 311 367 043

To ensure lubrication of the pneumatic motor, the oil mist lubricator must be set to 2 – 3 drops of oil per minute

(or one drop of oil for approx. 15 cuts).

If the compressed air connection is faulty and there is a high water content in the compressed air, water can

escape at the connection point.

Therefore, make sure that the hose connection is correct and that compressed air with a low water content is

used (the water separator must be emptied regularly).

If no dried air is available, a water absorber must be installed by the customer.

1

2

4

5

6

7

8

9

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 18 of 34

5.1.1 Filter pressure reducer

The air from pneumatic systems is usually contaminated and enriched with moisture.

A filter pressure reducer with water separator must therefore be installed between the pneumatic system and

the tool. This not only regulates the operating pressure, but also cleans and dries the compressed air. The

utility and service life of the EFA pneumatically operated breastbone saw are thus considerably increased.

The filter pressure reducer should be installed as close as possible to the EFA pneumatically operated

breastbone saw.

You can purchase a suitable filter pressure reducer from Schmid & Wezel GmbH on request, through our

Sales department.

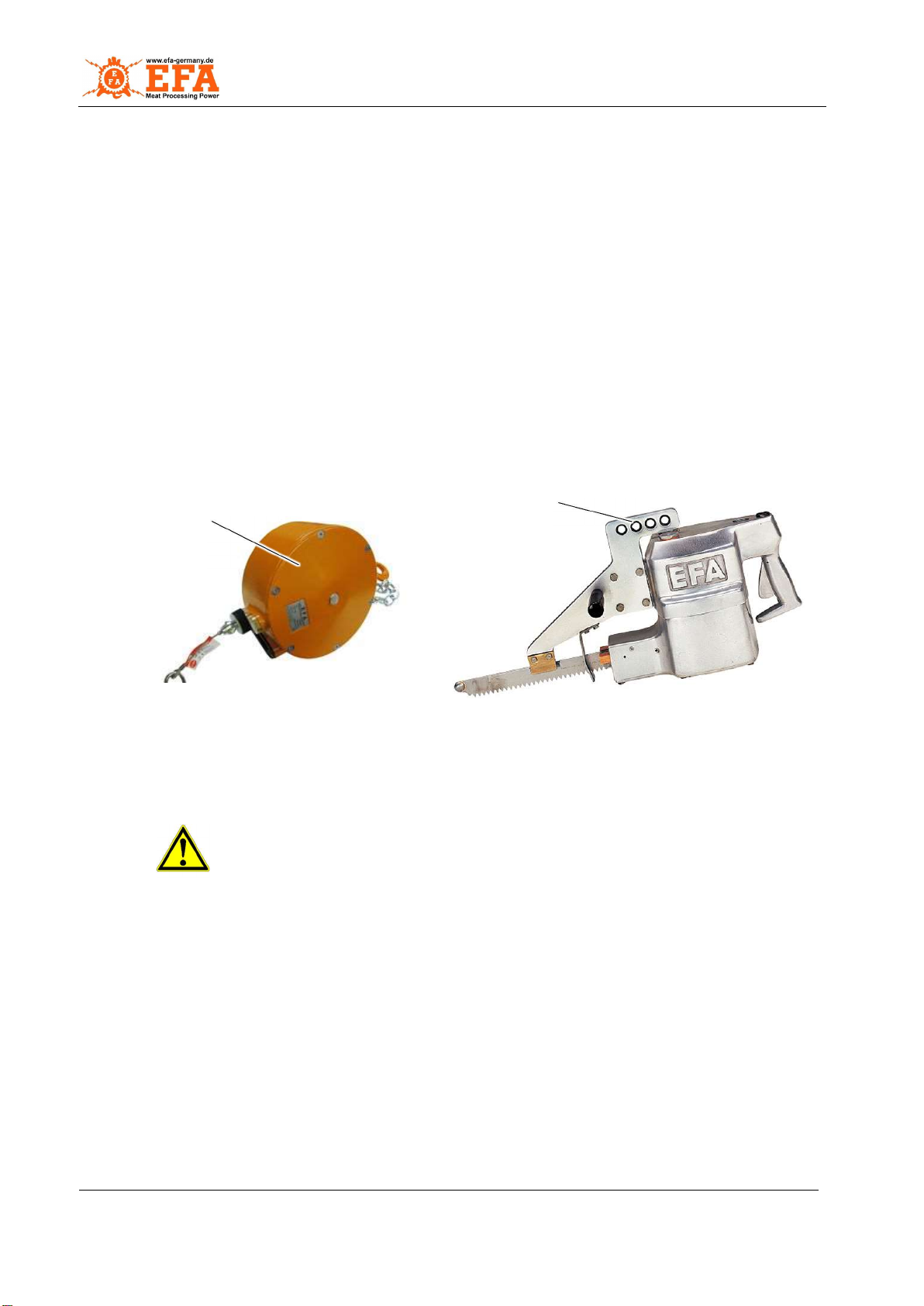

5.1.2 Spring balancer

The machine must always be operated in combination with a weight relief device (spring balancer (1)). Use a

trolley to attach it to a higher element above the workplace or to the ceiling.

Information on fine-tuning of the spring balancer can be found in chapter 6.4.

Suspend the EFA pneumatically operated breastbone saw so it is top-heavy if possible (2). The vertical can be

readjusted if necessary (by selecting a different hole on the guide (2)).

Due to the weight (17 kg), there could be a hazard due to the machine slipping or falling when the weight relief

device is attached or detached. Also make sure that the machine does not jam on the snap hook. Be careful!

Caution! Danger of injury when adjusting the spring balancer with an attached pneumatically

operated breastbone saw!

Before adjusting the spring balancer, remove the EFA pneumatically operated breastbone

saw!

Set an operating pressure of max. 8 bar at the filter pressure reducer.

1

2

Pneumatically operated breastbone saw EFA 57

Operating instructions EN

Part no. 110 885 700 – Rev. 00 – 01.2020 19 of 34

5.2 Handling

The EFA pneumatically operated breastbone saw is held with both hands while the saw is suspended from the

spring balancer and is guided to the breastbone of the suspended carcass.

The EFA pneumatically operated breastbone saw must not be switched on before the operator has read these

operating instructions and the saw has been connected correctly, see chapter 2 – Safety.

Caution! Machine damage and hazard to third parties due to improper use!

Use the machine properly.

Warning! Cutting hazard: Limbs can be severed!

Never reach into the area of the running saw blade.

Attention!

Wear eye protection or protective goggles when working!

5.3 Switching on the EFA pneumatically operated breastbone saw

The EFA pneumatically operated breastbone saw is equipped with a valve lever (1) for switching on the

compressed air flow.

Make sure that the EFA pneumatically operated breastbone saw is connected to the local compressed air

network (supply pressure 7 bar).

Perform a function test before starting work.

Hold the device firmly by its handles (2, 3).

To switch on, use your index and middle fingers to operate the operating lever.

Attention!

Device damage!

Improper handling will lead to increased wear!

The machine must not be switched on unless the saw blade has been correctly mounted and

is firmly seated.

1

3

2

Table of contents

Other EFA Saw manuals