SCARAB M6 SWEEPER KIT

Amdt.1 - 03 November 2009 Operator’s Manual 2

TABLE OF CONTENTS

Para Title Page

GENERAL INFORMATION ................................................................................................. 1

TABLE OF CONTENTS (This Page).................................................................................... 2

HEALTH AND SAFETY ADVICE.......................................................................................... 3

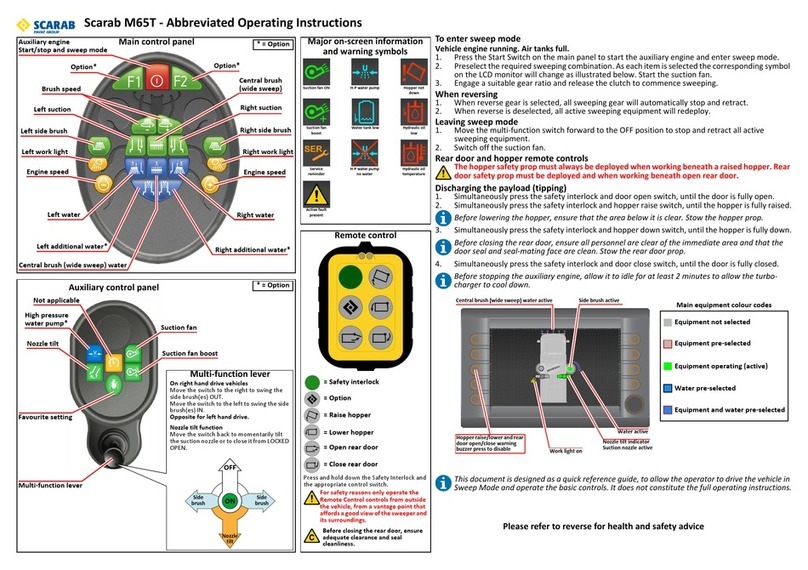

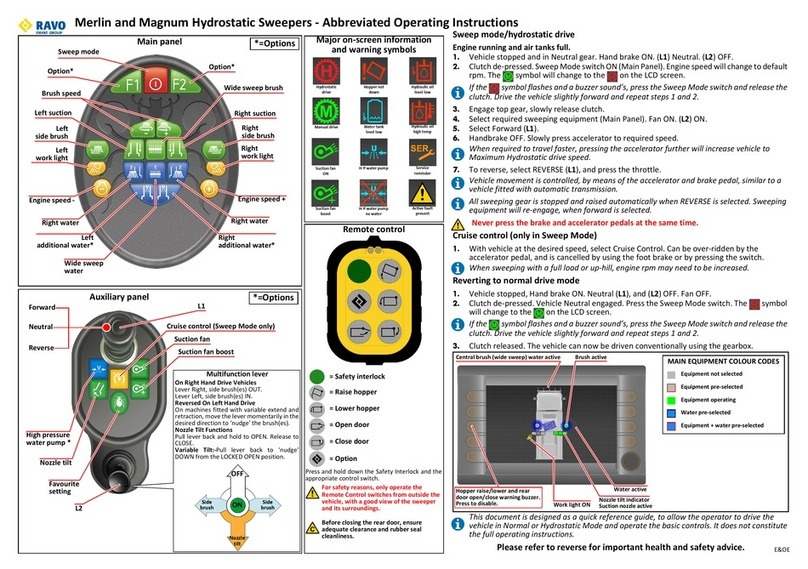

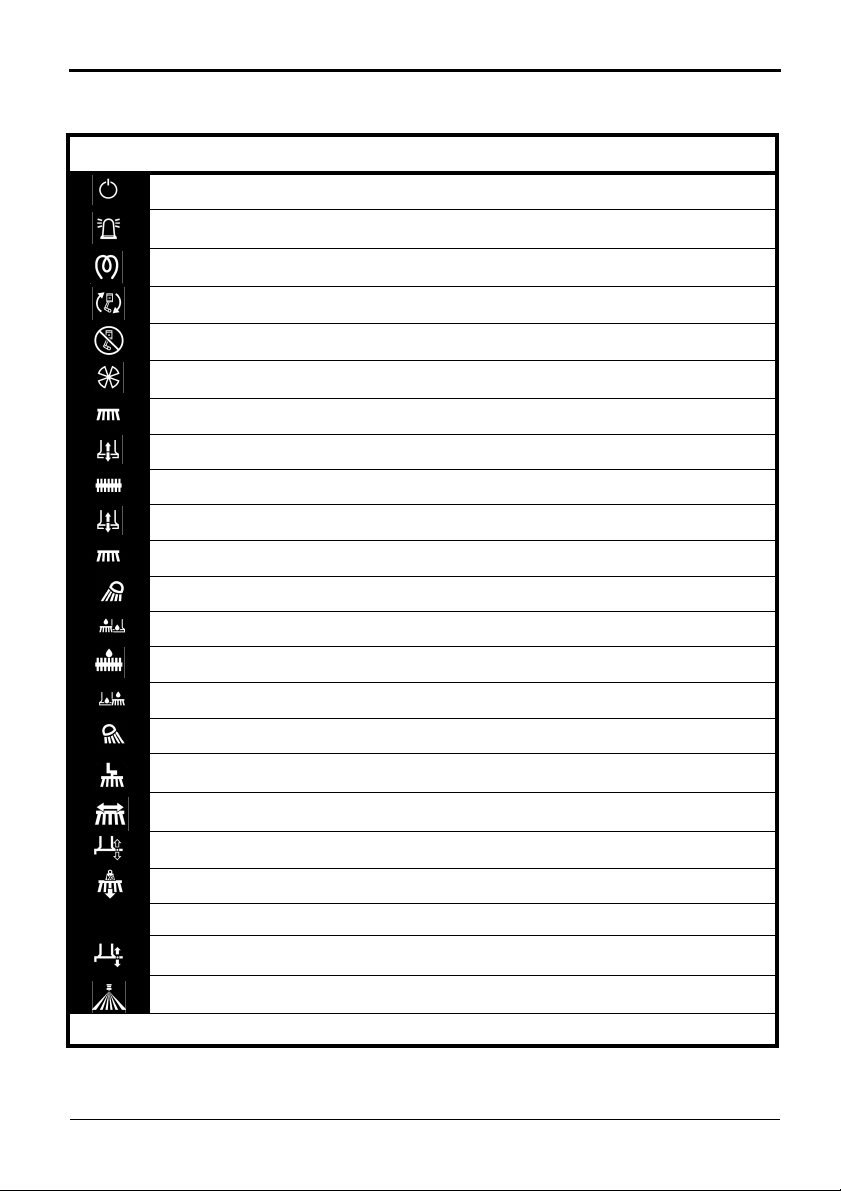

SWITCH SYMBOLS ............................................................................................................. 4

LCD SCREEN INFORMATION ........................................................................................... 5

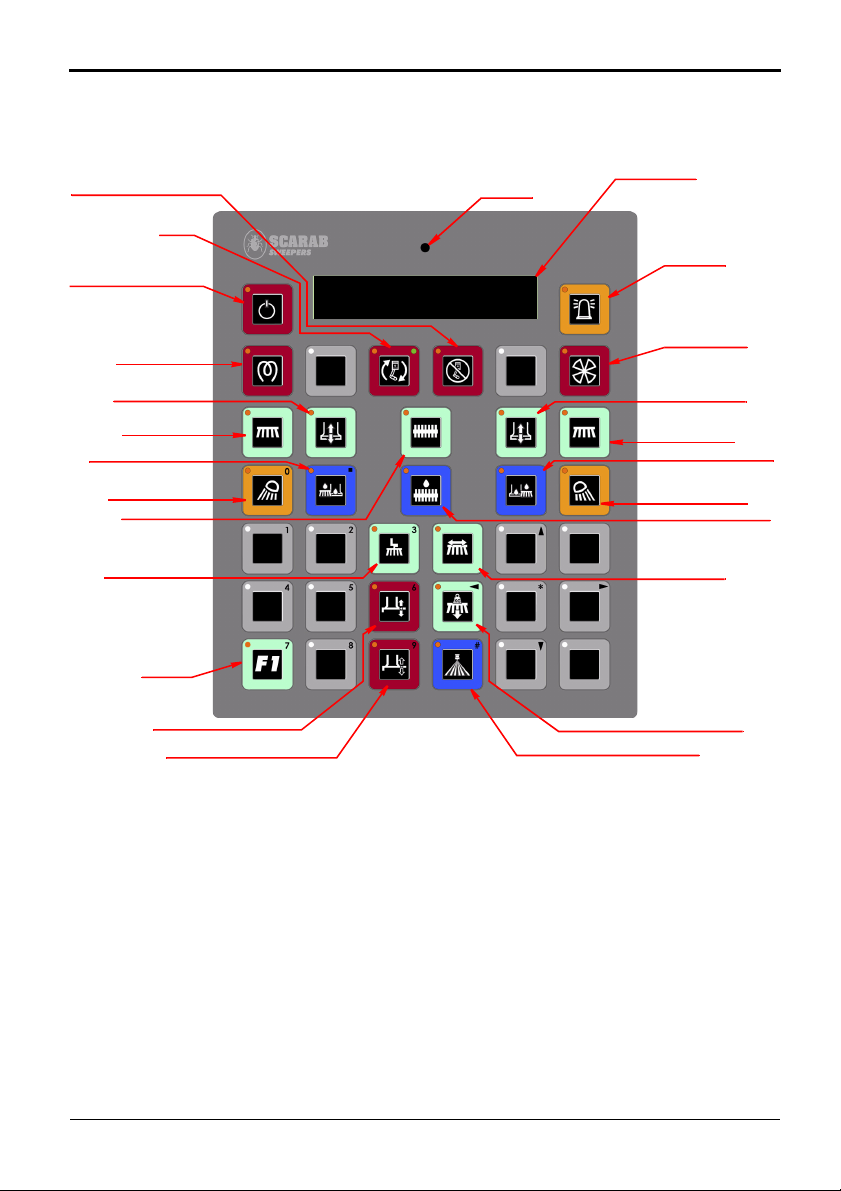

DESCRIPTION OF SWEEPING CONTROLS ....................................................................... 6

The CANbus System................................................................................................... 6

Main Panel Switch Descriptions ............................................................................ 7

Additional Controls & Instruments....................................................................... 12

OPERATING IN SWEEP MODE........................................................................................ 12

Starting the Auxiliary Engine ................................................................................... 12

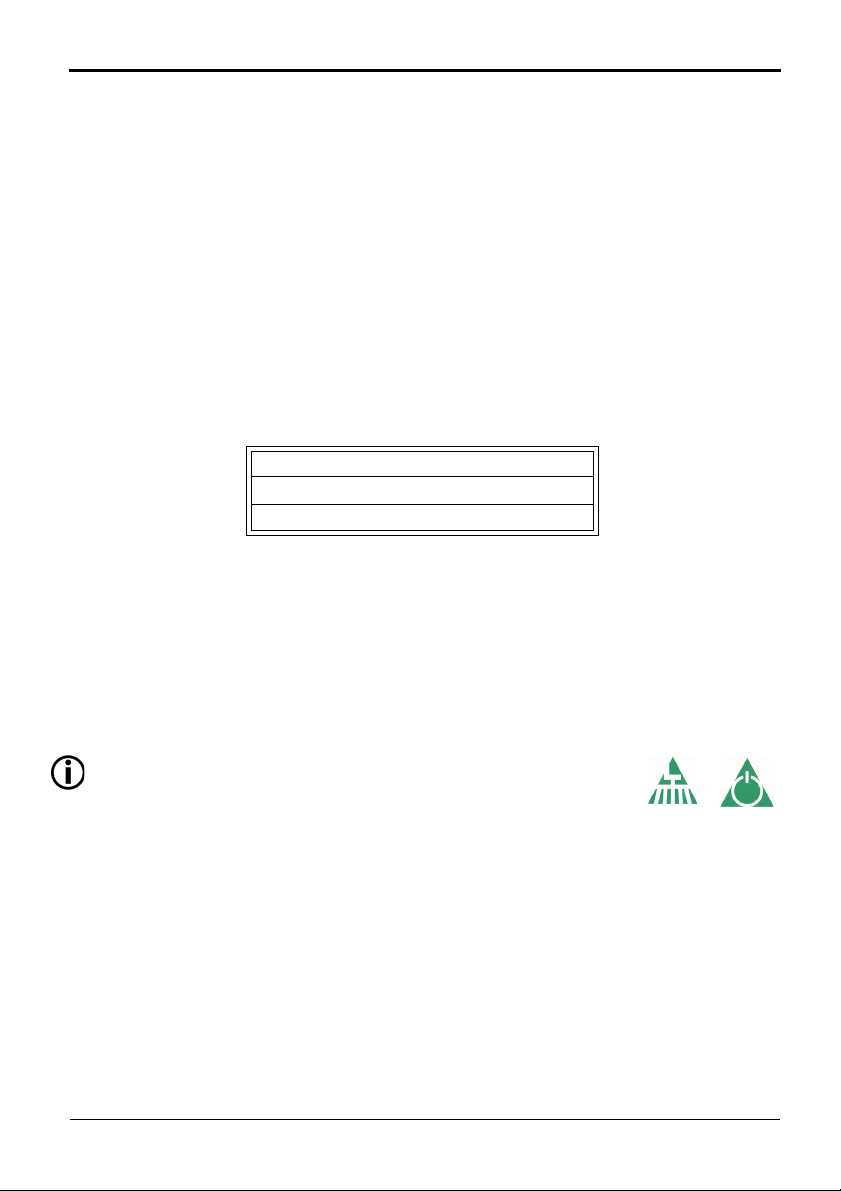

Activating the Control Panel.................................................................................. 13

Sweeping.................................................................................................................. 13

Reverting to Normal-Drive Mode........................................................................... 13

DISCHARGING THE HOPPER (TIPPING)......................................................................... 15

USING THE AUXILIARY HYDRAULIC PUMP..................................................................... 16

THE REAR-MOUNTED WANDER BOOM......................................................................... 17

USING THE LOW-PRESSURE WATER PUMP..................................................................... 18

Lubrication................................................................................................................ 18

Draining..................................................................................................................... 20

USING THE OPTIONAL HIGH-PRESSURE WATER PUMP ................................................. 19

Oil Level .................................................................................................................... 20

Draining..................................................................................................................... 20

Priming ...................................................................................................................... 20

RECOMMENDED OPERATOR’S ROUTINE MAINTENANCE........................................... 21

KEY MAINTENANCE PROCEDURES ............................................................................... 23

Auxiliary Engine ........................................................................................................ 23

Cleaning the Suction Fan & Screens ..................................................................... 24

Suction Nozzle Clearances..................................................................................... 25

Side Brushes & Skirts ................................................................................................. 25

Manual Greasing ..................................................................................................... 26

Recommended Lubricants & Consumables ........................................................ 27

Other Fluid Levels..................................................................................................... 27

ABOUT THE M6 HYDRAULIC DRIVE SYSTEM .................................................................. 28

LEGIONELLA STATEMENT................................................................................................ 29