Part No. SCAZ038022 2.4.1 E&OE

Operating Instructions - Unidrive Truckmounted Road Sweeper

GENERAL INFORMATION

WARNING - VOLTAGE SENSITIVE COMPONENTS.

DO NOT USE A BOOST STARTER / SUPER START, A BOOSTED START WILL BURN OUT THE VEHICLES ELECTRONIC CONTROL NODES, IF BATTERIES

ARE NOT CHARGED ALWAYS USE A FRESH SET.

TYPICAL WEIGHTS, DIMENSIONS AND CAPACITIES

GROSS VEHICLE WEIGHT (GVW)*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 to 18 tonne

GROSS VEHICLE WEIGHT (GVW)* MAGNUM . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 18 tonne

OVERALL HEIGHT (hopper lowered)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 to 3500mm

OVERALL LENGTH* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5640 to 7500mm

OVERALL WIDTH (brushes stowed)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2500mm

HOPPER GROSS VOLUME* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5³ to 8.2³ Gross

TANK CAPACITY*

Fuel Tank* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Typically 100 to 150 litres

Hydraulic Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 litres

Water Tank* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900 litres to 4500 litres

NOISE LEVELS

In cab . . . . . . . . . . . . . . . . . . . . . . . . . . Between 70 - 84 dB(A) dependent on operating speed

External . . . . . . . . . . . .Maximum LWA of 114 dB(A) in accordance with directive 2000/14/EC

VIBRATION

Description . . . All dynamic prime moving components are resiliently mounted to minimise

vibrations.In accordance with 2006/42/EC as amended.

Whole body . . . . . . . . . . . . . . . . . . . . . Equipment does not exceed 0.5 m/s² (RMS, weighted)

Hand & Arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Equipment does not exceed 2.5 m/s² (VTV)

* Dependent upon model

In view of the fact that many variables such as chassis and machine specification

affect the weight and dimensions of the finished machine, it is not possible to quote

these precise details. If this type of information is required, please contact our

Technical Sales staff giving your sweeper’s Serial Number.

TOWING

SERIOUS DAMAGE TO THE TRANSMISSION WILL RESULT IF THE VEHICLE IS TOWED WHILE

THE GEARBOX IS ENGAGED.

If towing is necessary, it is imperative that the prop shaft is disengaged from the differential

or that the rear wheels are clear of the ground before making any attempt to tow the vehicle.

IDENTIFICATION PLATES

The SERIAL NUMBER PLATE is located on the rear face of the left hand suction nozzle spigot.

The Serial Number will comprise four numerical digits only (for example 5843).

For the location of the vehicle’s VIN PLATE and CHASSIS NUMBER, refer to the chassis

manufacturers’ documentation.

LIMITATIONS OF USE

The Scarab Merlin, Merlin XP and Magnum are classified as truck-mounted heavy-duty

suction road sweepers and, as such, are intended only for operation in the sweeping and

associated roles for which they have been expressly designed.

The sweeper bodywork is integrated to the truck/carrier vehicle, and is therefore not

demountable.

APPLICABILITY

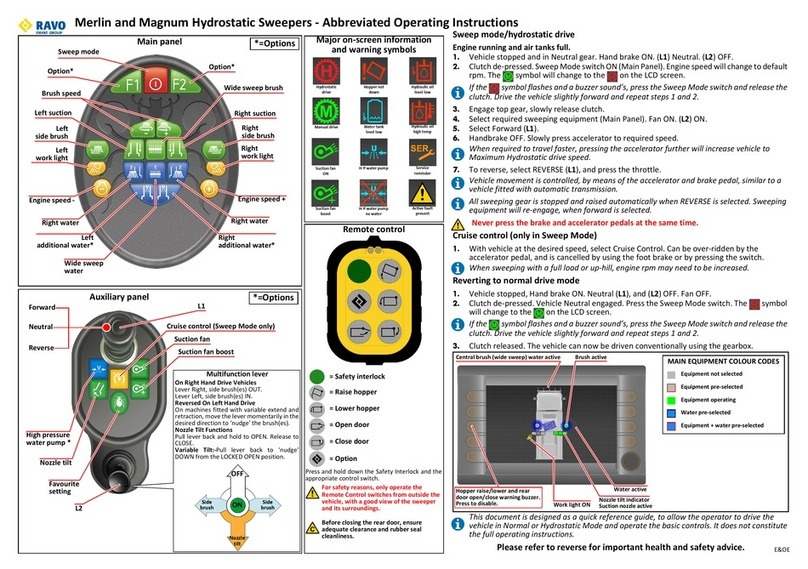

This manual covers the operating requirements of the Scarab Merlin, Merlin XP and

Magnum Hydrostatic sweepers with the CANbus 3 system.

CB Radios and other electrical equipment used in the sweeper should be

properly suppressed (EMC) to prevent the possibility of interference in the

sweeper electronic system

Warning