SCARAB HYDROSTATIC TRUCK-MOUNTED SWEEPERS

Original Issue - 28 November 2006 Operator’s Manual 2

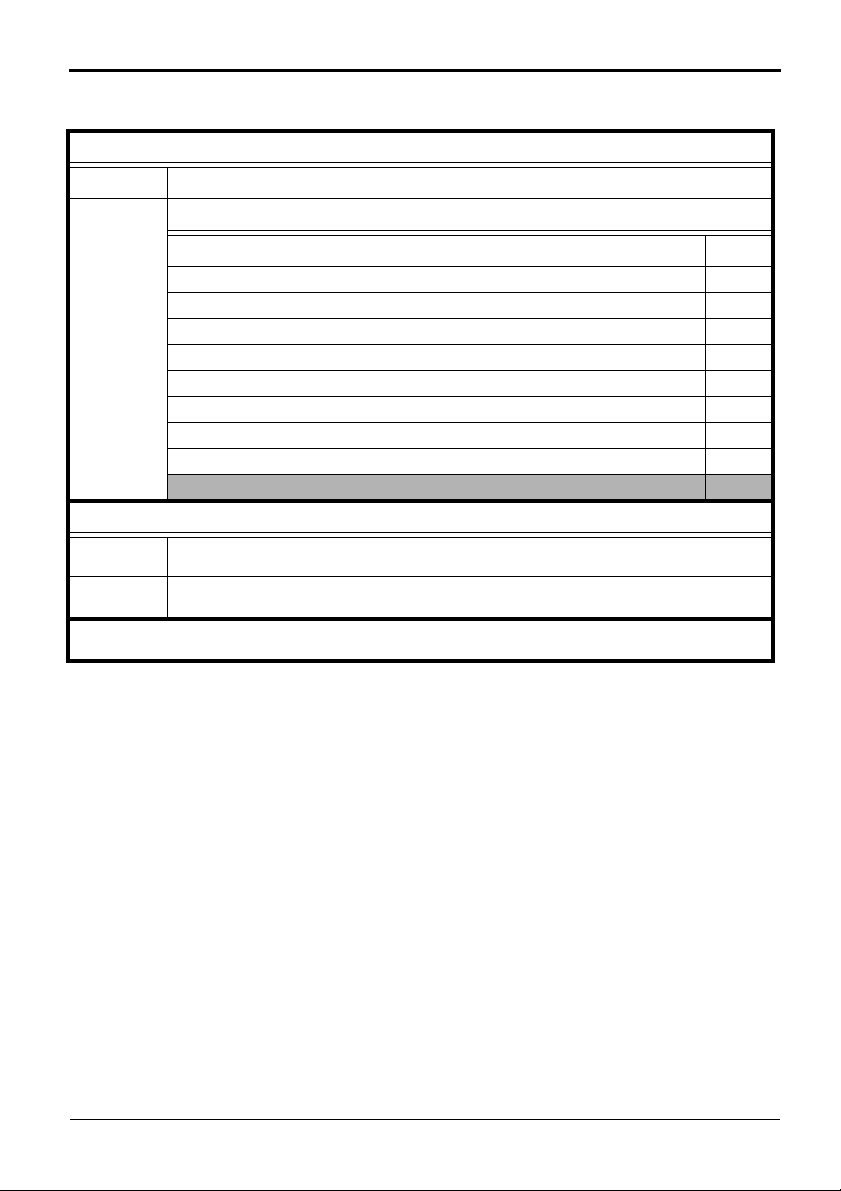

TABLE OF CONTENTS

Para Title Page

GENERAL INFORMATION ................................................................................................. 1

TABLE OF CONTENTS (This Page) .................................................................................... 2

HEALTH AND SAFETY ADVICE .......................................................................................... 3

EXPLANATION OF SWITCH OPERATING SYMBOLS ......................................................... 4

LCD Screeen Information ................................................................................................. 6

OPERATING ADVICE ........................................................................................................ 6

THE CANbus SYSTEM ........................................................................................................ 7

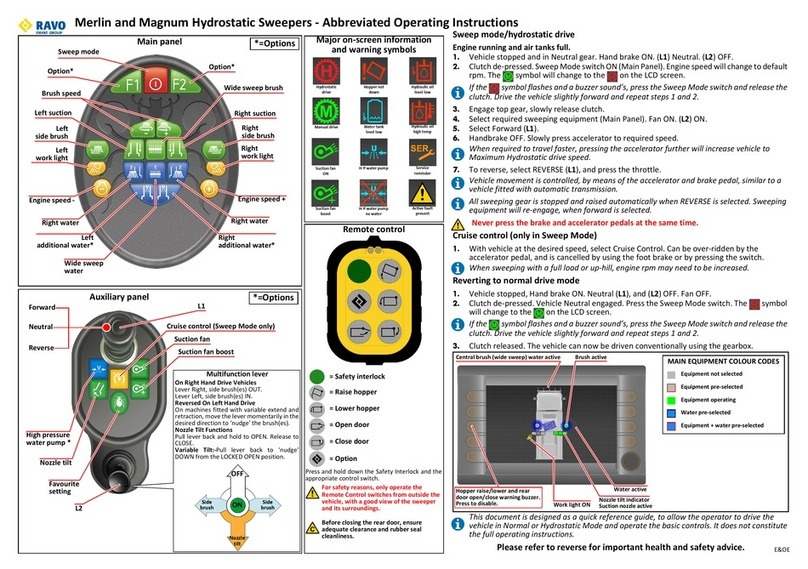

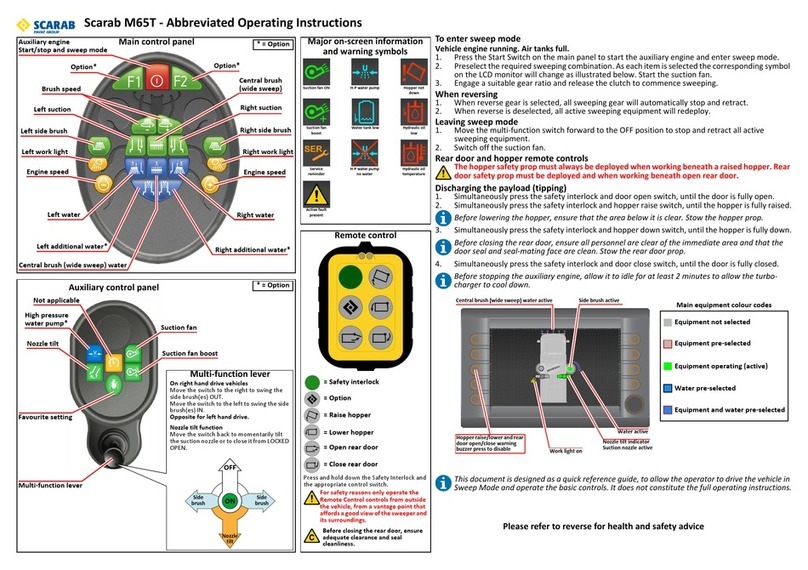

DESCRIPTION OF MAIN CONTROL PANEL ...................................................................... 8

DESCRIPTION OF AUXILIARY CONTROL PANEL ............................................................ 13

Rear-mounted Nozzle Option ........................................................................................ 15

Additional Controls and Instruments ............................................................................. 16

OPERATING MODES ....................................................................................................... 17

Engaging Hydrostatic Drive............................................................................................ 17

Suction Fan Boost-setting................................................................................................ 18

Climbing Gradients ......................................................................................................... 18

Selecting Normal-Drive Mode........................................................................................ 19

Reducing Noise Levels and Fuel Consumption............................................................ 19

DISCHARGING THE HOPPER (TIPPING) ......................................................................... 20

Operating the Rear Door................................................................................................ 20

Operating the Hopper .................................................................................................... 21

In-cab Controls...................................................................................................... 21

External Controls ................................................................................................... 22

USING THE AUXILIARY HYDRAULIC PUMP..................................................................... 23

Rear Door ......................................................................................................................... 23

Hopper.............................................................................................................................. 24

WANDER HOSE & WANDER BOOM................................................................................ 25

USING THE LOW-PRESSURE WATER PUMP...................................................................... 27

Draining............................................................................................................................. 27

USING THE OPTIONAL HIGH-PRESSURE WATER PUMP .................................................. 28

Oil Level / Draining / Priming .......................................................................................... 29

OPTIONAL SUCTION FAN WASH-ASSIST SYSTEM.......................................................... 29

RECOMMENDED OPERATOR’S ROUTINE MAINTENANCE............................................. 31

KEY MAINTENANCE PROCEDURES ................................................................................ 33

Cleaning the Suction Fan ............................................................................................... 33

Suction Nozzle Clearances............................................................................................. 34

Side Brushes & Skirts ......................................................................................................... 34

Draining & Cleaning the Water Strainers ...................................................................... 35

Manual Greasing............................................................................................................. 36

Recommended Lubricants & Consumables................................................................ 38

Fluid Levels........................................................................................................................ 38

SCARAB PARTS & SERVICE PROVIDERS......................................................................... 39

LEGIONELLA STATEMENT ................................................................................................ 40

ENGINE SPEED-CONTROLLER INSTRUCTIONS .....................................Inside Rear Cover