Part No. SCAZ037886 8.6.00 5 E&OE

Merlin and Magnum HydrostaticOperating Instructions

Table of contents

Title Page

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Health and Safety advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hazard awareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety support props . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The CANbus system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

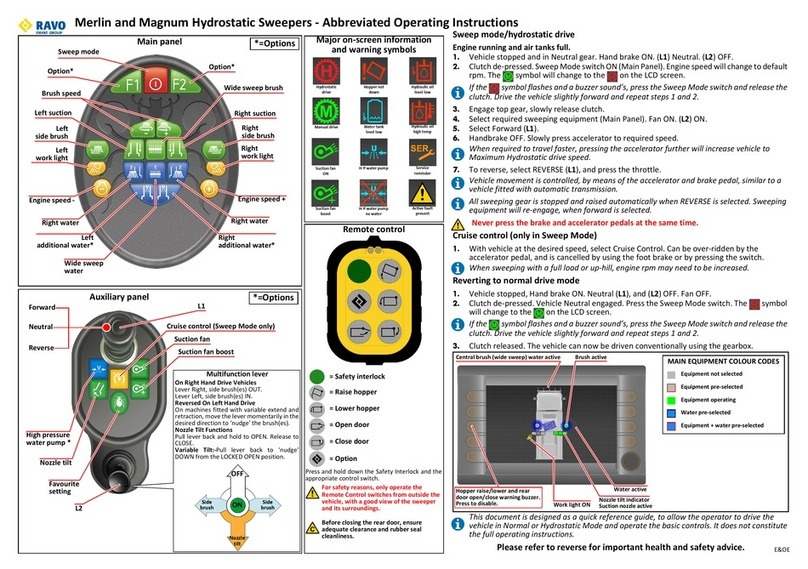

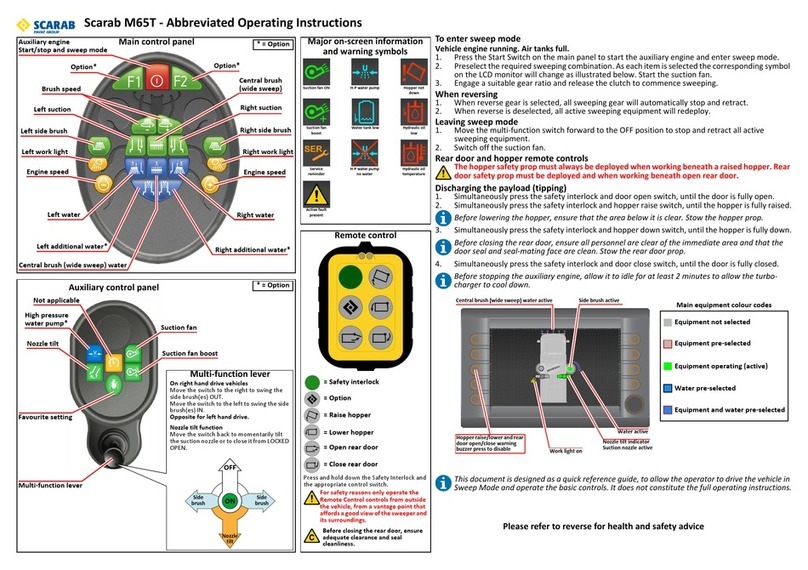

Main control panel switch functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auxiliary control panel switch functions . . . . . . . . . . . . . . . . . . . . . . . . 12

Hopper remote control switch box functions . . . . . . . . . . . . . . . . . . . 13

The LCD monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Additional controls and instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Brush pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Controls for overhead wander boom . . . . . . . . . . . . . . . . . . . . . . . 15

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engaging hydrostatic drive (Manual gearbox trucks) . . . . . . . . . . . . . 16

Sweeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Suction fan boost setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Climbing Gradients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reverting to normal drive mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CNG IVECO with Allison gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Engage hydrostatic drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Disengage hydrostatic drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Discharging the hopper (tipping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the auxiliary hydraulic pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Title Page

Standard wander hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the standard wander hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the rear mounted wander hose . . . . . . . . . . . . . . . . . . . . . . . . . 24

Using the overhead wander boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the Dust Suppression System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filling the water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using the low pressure water system . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using the high pressure water system . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hand lance detergent option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Retractable hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Clearing a blockage in the suction path . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Recommended operator’s routine maintenance . . . . . . . . . . . . . . . . . . . 30

Key maintenance procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the suction fan and screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hydraulic oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Topping-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Suction nozzle clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Side brushes and skirts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removing and cleaning the water filter element(s) . . . . . . . . . . . . . . 34

Manual greasing and lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

LCD monitor - Options screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Button function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Screen menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operator’s notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44