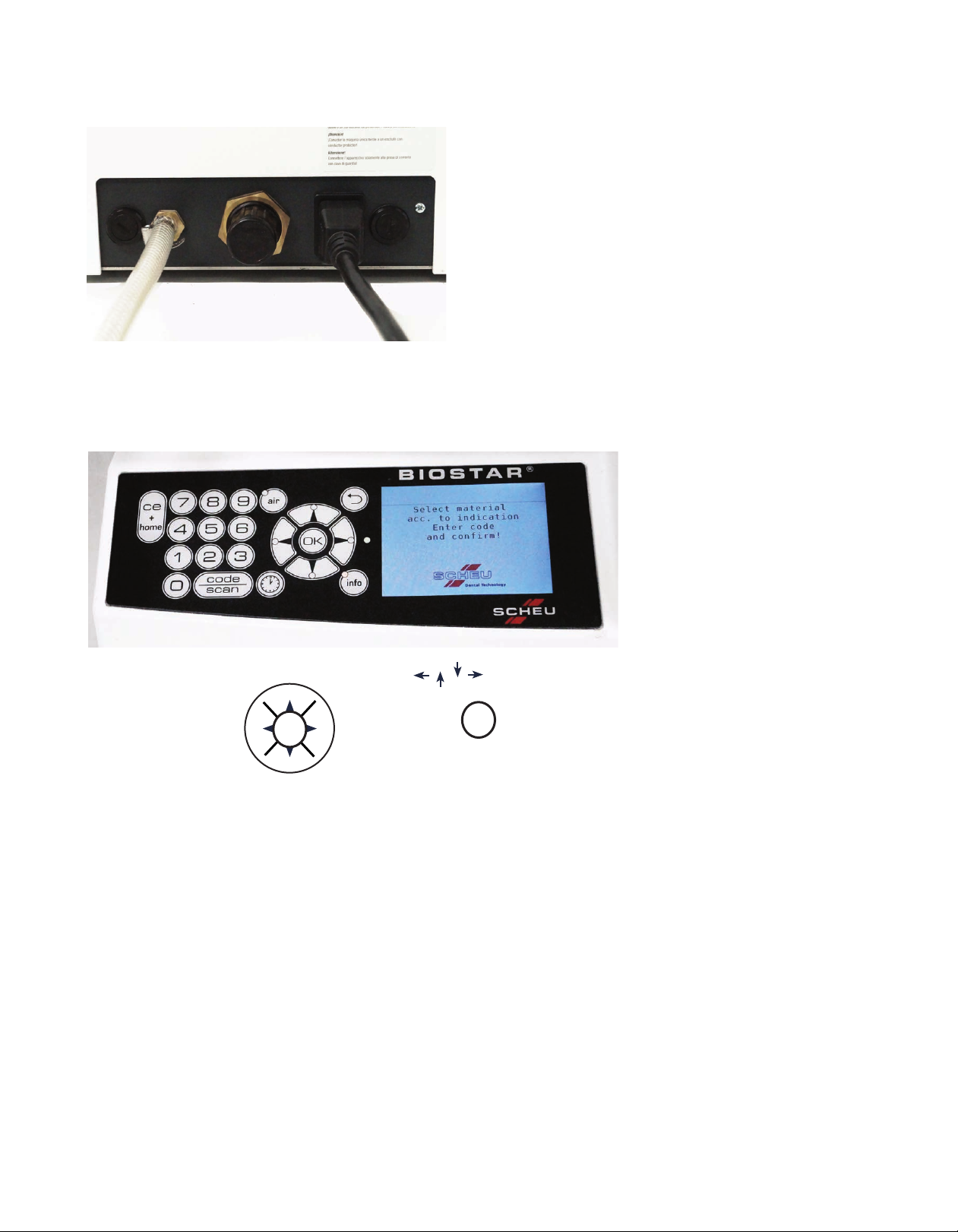

Remove model bubbles and detail the oral anatomy

with a laboratory knife. Fill holes in the model with a

quick-setting stone.

When referencing the model to the platform, make

sure the base of the model is reduced at, parallel

to the occlusal surface. In some cases, the base is

removed creating a at horseshoe model to eliminate

excessive material thinning.

No undercuts under the model base should be

present. This will prevent material from forming

beneath the model base causing potential air leaks

and poor material forming. For some materials, a

liquid separating foil is applied to allow for easy

removal of the formed material.

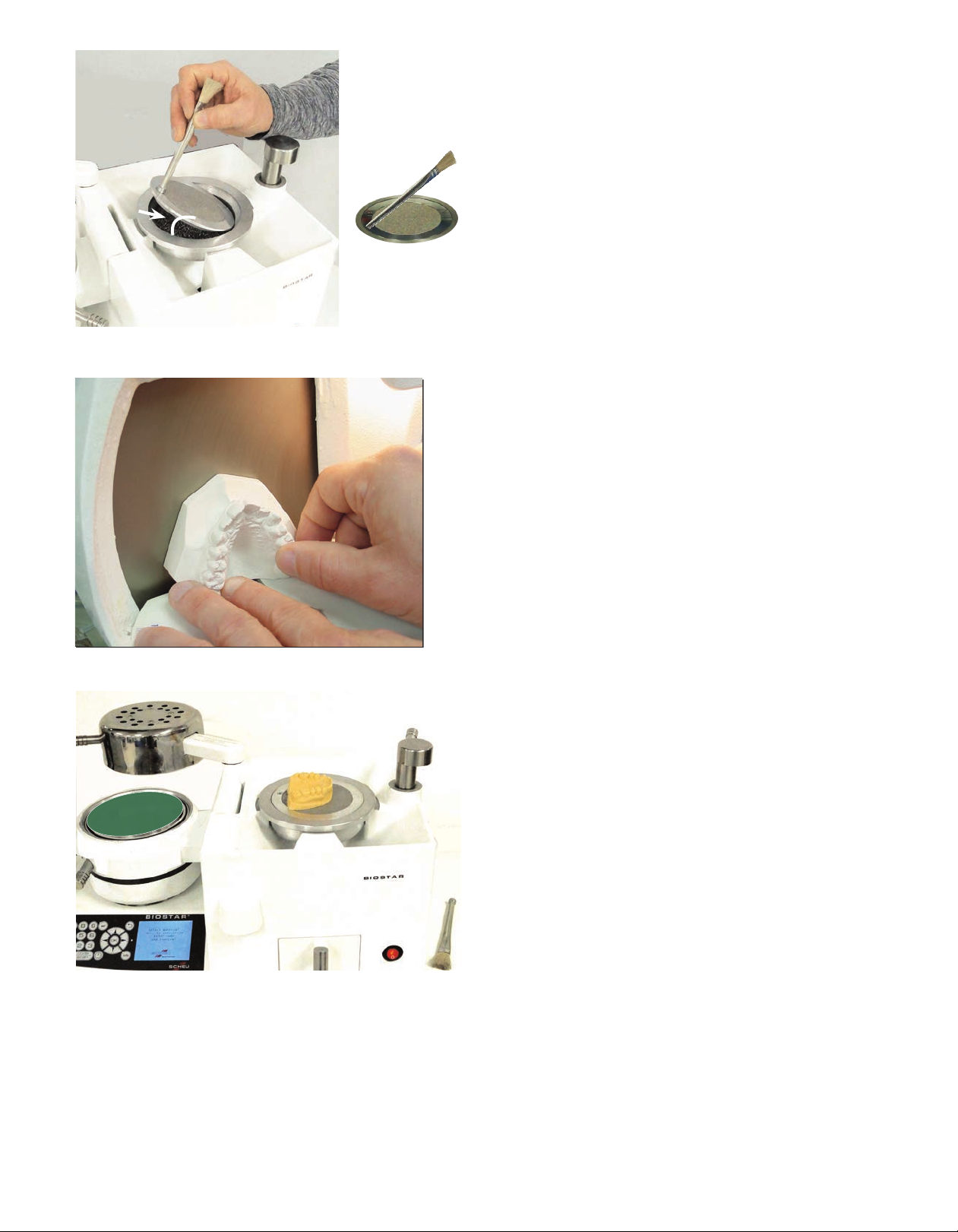

Position the model on the platform, referencing the

heel toward the material in the pressure chamber,

and incisor segment near the center area of the

platform. Placing the model to the left side of the

platform provides better material forming along

the incisor region.

Apply a liquid model-separating medium, such

as Great Lakes Separator (175-034) or Bioplast

Insulator (175-068) to the dental casts before the

material is formed.

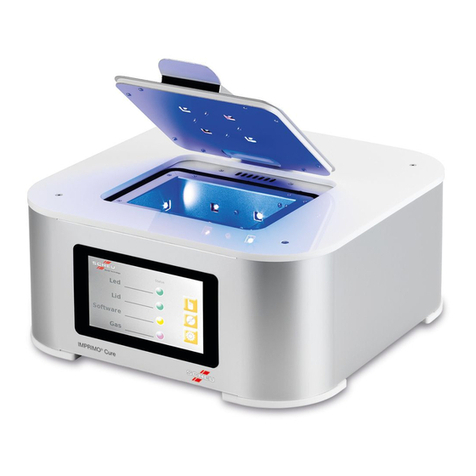

Empty cup or reduce the pellet line to the half-way

level (white arrow). Make sure the inner lip of the

cup is clean. Place the outer ring of the platform

on the inner lip of the pellet cup with the at

platform surface on top (curved white line).

To remove the platform, use the Biostar Brush with

Magnet (016-021).

Engage the tip and lift up.

Pellet Use

A 2.5 pound container of zinc pellets (010-125) is supplied with each Biostar. Pellets are used to

prevent the thermal-plastic materials from stretching over areas of the model that are not part of the

appliance design. Stainless steel pellets (010-099) are also available. The pellets will prevent sealing

the chamber to the cup, and inhibit the pressure-molding process if left on the pellet cup rim.

Note: The use of pellets other than what the manufacturer recommends may result in

machine malfunction and could void the warranty.