Operation

Mains switch

To activate the electric press mains switch (4) “ON”. The switch itself becomes

shining. Now all electrical functions are controllable. To switch the unit off press

mains switch (4) “OFF” again.

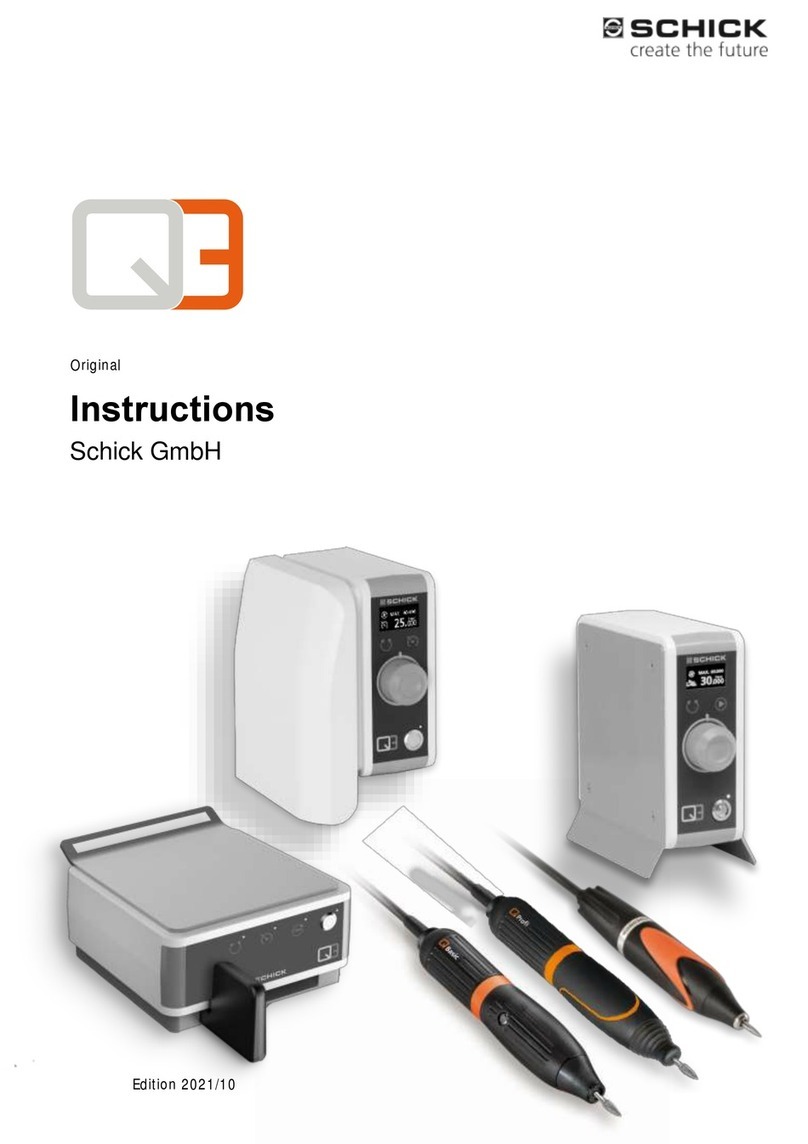

7.1 3D - Milling arm

Jointed arm

Fastening and loosening of the arm by the electro-magnetic

couplings is done with the foot switch (6). An additional, third

articulation is loosened by turning the thumb screw (15) slightly

to the left.

Then the milling arm can be adjusted and locked again in any desired

position. When work is finished the milling arm can be put into a

“parking position” - also when the jointed arm is not in use for

longer time (pict. 2). Before activating the mains switch put milling

arm into this position (left side stop).

A permanent magnet locks the arm. This is to avoid un unintended

swing out of the milling arm when the unit is switched off.

The magnetic couplings are inactive after the unit is switched off.

Vertical saddle

The vertical saddle (38) is to be fixed with a knurdel srew (8) in any

position. On the top of this saddle there is the grip sleeve to adjust

the depth stop (9).

The tension of the spring (10) in the vertical saddle can individually

be adjusted at the bottom of the milling arm (40) (see point 7.5;

page 12) using the supplied hexagon head socket wrench w.a.f. 4.

The spindle for depth stop (9) shows a radial graduation

of 50 x 0,01 mm and an axial graduation of 0,5 mm.

One complete rotation of this spindle is a travel of 0,5 mm.

The vertical way of the saddle is 24 mm.

The drill-lever (11) can be screwed out if required.

Milling spindle

To remove the milling spindle detach light equipment and loosen

knurled nut (13) (pull spindle out upwards). To detach the light

equipment loosen knurled screw (16) (pict.. 1) and pull light

equipment carefully down.

Put light equipment on again in reverse order.

When putting on the light equipment please take care that the

connections click into place !

pict. 1

pict. 2

pict. 3

16

13

12

9

10

11

15

8

31

38

7. Operation

Attention:: when the unit is switched off the magnetic couplings are no

longer activated ! Put the milling arm into the resting position

9