When Installing Interceptor Inside

If your dishwashing sink(s)

discharges into a floor

drain/sink (drain), you must

regulate the flow into the

drain to avoid an overflow

of water onto the kitchen

floor. This can be done by

installing a valve or flow

restriction cap on the sink

piping that discharges into

the drain. See drawing

for guidance. For detailed

guidance on indirect connections, go to:

webtools.schierproducts.com/Technical_Data/Indirect_Connections.pdf

Fernco or similar rubber

flow restriction end cap

SPECIAL PRECAUTIONS

For Schier Grease Interceptor Installations - Failure to follow this guidance voids your warranty

High Water Table Installations

Interceptors and risers are not designed to

withstand water table height in excess of the top

of the unit when buried (see figure). If it is

possible for this to occur, install the interceptor

and risers in a water-tight concrete vault or

backfill with concrete or flowable fill (wet

concrete and flowable backfill should be poured

in stages to avoid crushing the interceptor). At

risk areas include but are not limited to tidal

surge areas, floodplains and areas that receive

storm water. Great Basin™models that are direct

buried in high water table scenarios must be

installed with an anchor kit. Models GB-50,

GB-75, and GB-250 use model AK1 anchor kit.

Model GB-500 uses model AK2 anchor kit for

use with deadmen anchors.

Fully Support Base of Unit

Install unit on solid, level surface in

contact with the entire footprint of unit

base; for suspended installations design

trapeze to support the wet weight of the

unit. Do not partially support unit or

suspend unit using metal U-channel to

create a trapeze

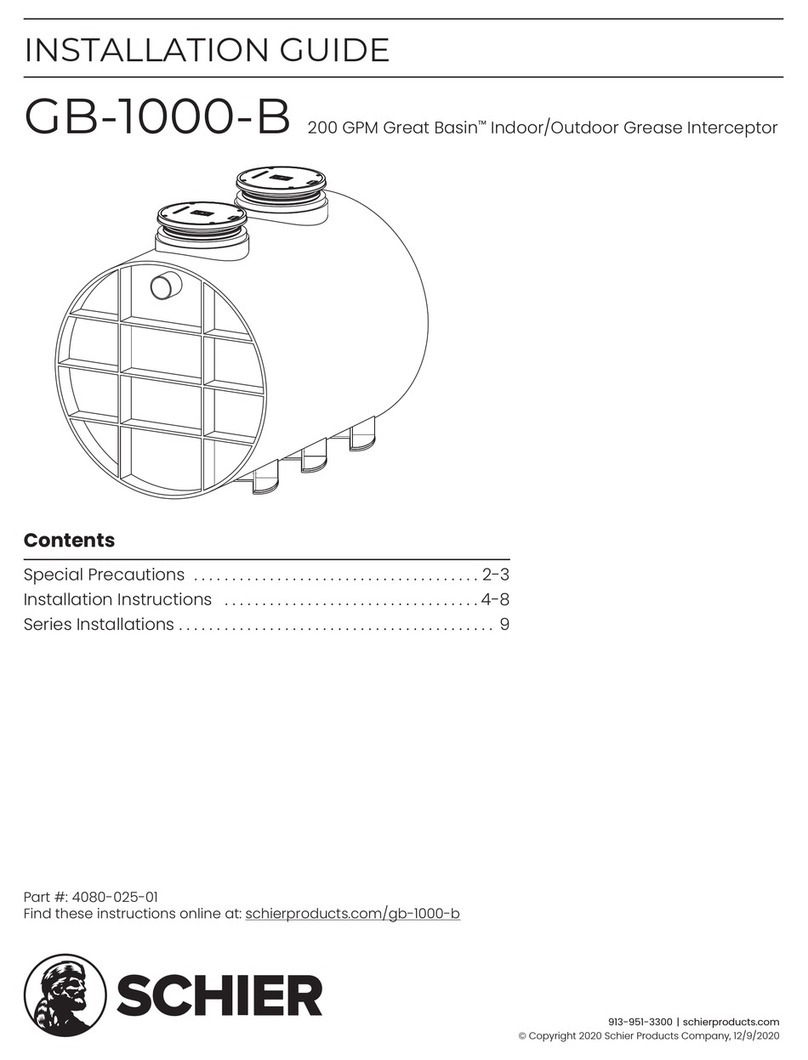

Installation Instructions

Installation instructions and additional

components are included with the interceptor.

Read all instructions prior to installation. This

interceptor is intended to be installed by a

licensed plumber in conformance with all local

codes.

Hydrostatic Slabs

(or Pressure Slabs)

When installed under a

hydrostatic slab (slab

designed to withstand

upward lift, usually caused by

hydrostatic pressure)

interceptor must be enclosed

in a watertight concrete vault.

Support Inlet and Outlet Piping

For above grade installations ensure heavy

inlet and outlet piping (such as cast iron or

long runs) is properly supported or suspended

during the entire installation process to

prevent connection failure or damage to

bulkhead fittings.

High Temperature Kitchen Water

If water is entering the interceptor at excessive temperature (over

150º F), a drain water tempering valve (DTV) and approved backflow prevention

assembly must be installed. Most state and local plumbing codes prohibit water

above 150º F being discharged into the sanitary sewer. Water above 150º F will

weaken or deform PVC Schedule 40 pipe, poly drainage fixtures like interceptors

and erode the coating of cast iron (leading to eventual failure).

pipe supports

InterceptorInterceptor

concrete slab subject to hydrostatic pressure

watertight

concrete

vault

InterceptorInterceptor

concrete floor

suspended installation

InterceptorInterceptor

max water table height for

direct burial

deadman anchor

nylon strap

turnbuckle

InterceptorInterceptor

Do not install this unit in any manner

except as described in these instructions.

Doing so may result in property damage, personal injury or death.

installation

instructions

AGS2

Above Grade Installation Support

(for Model GB-500 Only)

The wet weight of the interceptor combined with

high temperature kitchen water creates the

potential for tank deformation when installed

above grade. Model GB-500 installed above grade

must be installed with Above Grade Support Kit

model AGS2 to maintain structural integrity

DO NOT

COMPACT

BACKFILL

DO NOT AIR TEST UNIT OR RISER SYSTEM!

Schier | GB-500-250HF Installation Guide

page 2 of 11