3

AZM190

Operating instructions

Solenoid interlock

EN

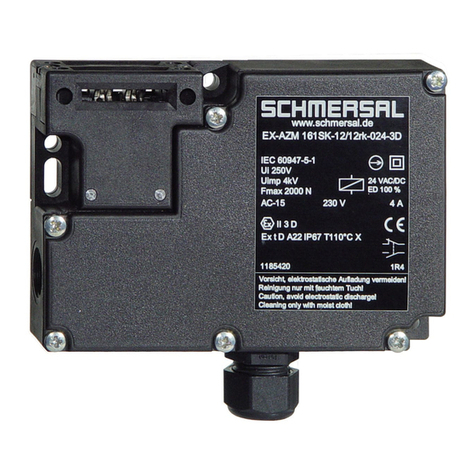

2.4 Technical data

Standards: IEC 60947-5-1, ISO 14119

Enclosure: glass-fibre reinforced thermoplastic

Actuator and locking bolt: galvanised steel / zinc die-cast

Holding force Fmax:2,550 N

Holding force FZh: 1,950 N

Latching force: 20 N

Coding level according to ISO 14119: low

Protection class: IP67

- Ordering suffix N and T: IP65

Contact material: Silver

Contact type: change-over contact with double break, or 2 NC

contacts, with galvanically separated contact bridges

Switching system:

A

IEC 60947-5-1, slow action,

NC contact with positive break

Connection: screw terminals

Cable type: solid and stranded wire

Cable section: 0.5 - 2.5 mm2

(max. 1.5 mm2with wire end ferrules)

Cable entry: 2 x M20

Rated impulse withstand voltage Uimp: 4 kV

- Device with 4 contacts or 3 contacts with LED: 1.5 kV

Rated insulation voltage Ui:250 V

- Device with 4 contacts or 3 contacts with LED: 60 V AC

Thermal test current Ithe:4 A

Utilisation category: AC-15, DC-13

Rated operating current/voltage Ie/Ue: 4 A/230 V AC

4 A/24 V DC

- Devices with 4 contacts: 4 A/24 V AC

4 A/24 V DC

- Devices with LED: 4 A/24 V DC

Max. fuse rating: 4 A gG D-fuse to IEC 60269-1

Required short-circuit current: 1,000 A

Positive break travel (unlocked): 2 × 3.5 mm

Positive break force (unlocked): 20 N

Magnet switch-on time: 100 %

Rated control voltage Us:24 V DC,

24 V AC / 50/60 Hz,

48 V AC / 50/60 Hz,

110 V AC / 50/60 Hz,

230 V AC / 50/60 Hz

Power consumption: max. 8.5 W

Actuating speed: max. 20 m/min

Actuating frequency: max. 1,200/h

Ambient temperature: 0°C … +50°C

Mechanical life: 1 × 106operations

Listed 15 HA - Industrial Control Equipment - Enclosure

Type I. Use copper wire only. Use 60/75° wire only.

Tightening torque 0.8 Nm. The hub shall be connected to

the conduit before it is connected to the enclosure.

( not valid for LED-version -G.)

2.5 Safety classification of the interlocking function

Standards: ISO 13849-1

Envisaged structure:

- Basically: applicable up to cat. 1 / PL c

- With 2-channel usage applicable up to cat. 3 / PL d

and fault exclusion mechanism: with suitable logic unit

B10D NC contact: 2,000,000

B10D NO contact at 10% ohmic contact load: 1,000,000

Mission time: 20 years

TF

D

10Dopop

op

n

(Determined values can vary depending on the application-specific

parameters hop, dop and tcycle as well as the load.)

If multiple safety components are wired in series, the Performance

Level to ISO 13849-1 will be reduced due to the restricted error

detection under certain circumstances.

2.6 Safety classification of the guard locking function

If the device is used as an interlock for personal safety, a safety

classification of the guard locking function is required.

When classifying the interlock function, a distinction must be made

between monitoring of the interlock function (locking function) and

controlling the unlocking function.

The following safety classification of the unlocking function is based on

the application of the principle of safety energy disconnection for the

solenoid supply.

The classification of the release function is only valid for

devices with monitored guard locking function and in the

power to unlock version (see ordering code).

A fault exclusion for the locking device of the solenoid interlock can be

assumed by a safety external energy disconnection.

In this case, the locking device of the solenoid interlock does not have

an effect on the failure probability of the unlock function.

The safety level of the unlock function is determined exclusively by the

external safety power shutdown.

A1

A2

+24 VDC

PL ?

PFHd?

0 VDC

Safety power

shutdown

Solenoid

interlock

Guard locking

function

Fault exclusion with regard to wiring routing must be

observed.

If for a certain application the power to unlock version of

a solenoid interlock cannot be used, for this exception an

interlock with power to lock can be used if additional safety

measure need to be realised that have an equivalent safety

level.