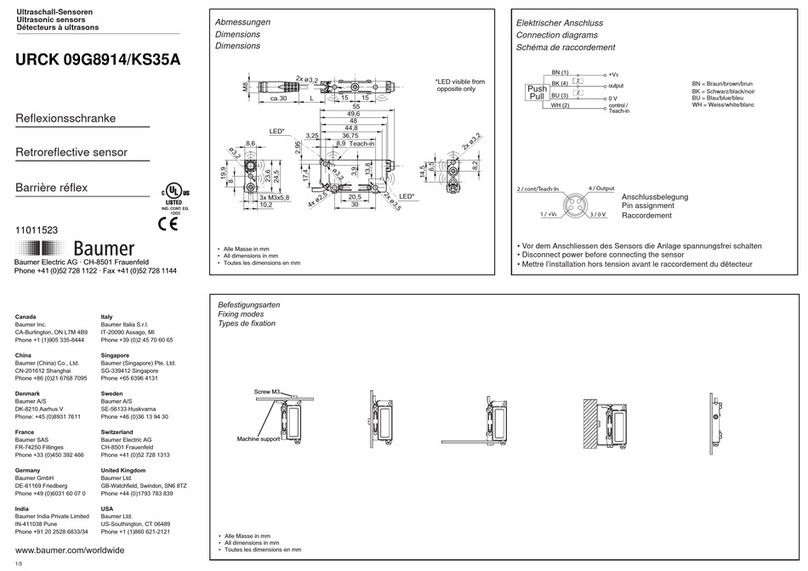

2The electrical connection may only be carried out by authorised personnel in a de-energised condition.

The safety outputs can be integrated into the safety circuit of the control system. For applications of PL e / category

4 to EN ISO 13849-1, the safety outputs of the safety sensor or of the sensor chain must be wired to a safety

monitoring-module of the same category.

The required electrical cable fuse protection must be integrated in the installation.

Protection is not required when pilot wires are laid. The cables however must be separated from the supply and

energy cables. The max. fuse rate for a sensor chain depends on the section of the connecting cable of the sensor.

Requirements for the connected safety-monitoring module:

dual-channel safety input, suitable for p-type sensors with NO function

FInformation for the selection of suitable safety-monitoring modules can be found in the Schmersal catalogues or in the

online catalogue on the Internet: products.schmersal.com.

As an alternative to a safety-monitoring module, the safety sensors of the CSS 34F0 or CSS 34F1 series can also be

used as first sensor of a series-wired chain for the direct control and monitoring of safety contactors (refer to

operating manual of CSS 34F0 / CSS 34F1).

If the safety sensor is wired to relays or to non-safety relevant control components, a new risk analysis must be

carried out.

The sensors cyclically switch off the safety output to test them. The safety-monitoring module therefore does not

need to be equipped with a cross-wire short detection. The switch-off times must be tolerated by the safety-

monitoring module. The switch -off time of the safety sensor is additionally extended depending on the cable length

and the capacity of the cable used. Typically, a switch-off time of 250 μs is reached with a 30-m connecting cable.

FConfiguration of the safety-monitoring module

If the safety sensor is connected to electronic safety-monitoring modules, we recommend that you set a discrepancy time

of min. 100 ms. The safety inputs of the safety-monitoring module must be able blanking a test impulse of approx. 1 ms.

The safety-monitoring module does not need to have a cross-wire short monitoring function, if necessary, the cross-wire

short monitoring function must be disabled.

5.2 Serial diagnostic -SD

Cable design

The wiring capacitance of the connecting cable of the safety sensor must not exceed 50 nF.

Depending on the strand structure, normal unshielded 200 m long control cables LIYY 0.25 mm² to 1.5 mm² have a

wiring capacitance of approx. 20 … 50 nF

FOn wiring SD devices, please pay attention to the voltage drop on the cables and the current carrying capacity of the

individual components.

FAccessories for the series-wiring

For convenient wiring and series-wiring of SD components, the SD junction boxes PFB-SD-4M12-SD (variant for the field)

and PDM-SD-4CC-SD (variant for control cabinet on carrier rail) are available along with additional comprehensive

accessories. Detailed information is available on the Internet, products.schmersal.com.