Table of Contents

01.00 | CMS | Assembly and operating manual | en | 1553577 3

Table of Contents

1 General ............................................................................................. 5

1.1 About this manual............................................................................... 5

1.1.1 Presentation of Warning Labels ..................................................... 5

1.1.2 Applicable documents ................................................................. 6

1.1.3 Sizes........................................................................................ 6

1.1.4 Variants ................................................................................... 6

1.2 Warranty ........................................................................................... 7

1.3 Accessories ........................................................................................ 7

1.4 Scope of delivery................................................................................. 7

2 Basic safety notes ................................................................................ 8

2.1 Intended use...................................................................................... 8

2.2 Not intended use ................................................................................ 8

2.3 Constructional changes......................................................................... 9

2.4 Spare parts ........................................................................................ 9

2.5 Ambient conditions and operating conditions ........................................... 9

2.6 Personnel qualification ........................................................................ 9

2.7 Personal protective equipment .............................................................. 10

2.8 Notes on safe operation........................................................................ 11

2.9 Transport........................................................................................... 11

2.10 Malfunctions ...................................................................................... 11

2.11 Disposal ............................................................................................ 12

2.12 Fundamental dangers .......................................................................... 12

2.12.1 Protection during handling and assembly ....................................... 12

2.12.2 Protection during commissioning and operation ............................... 13

2.13 Notes on particular risks ....................................................................... 14

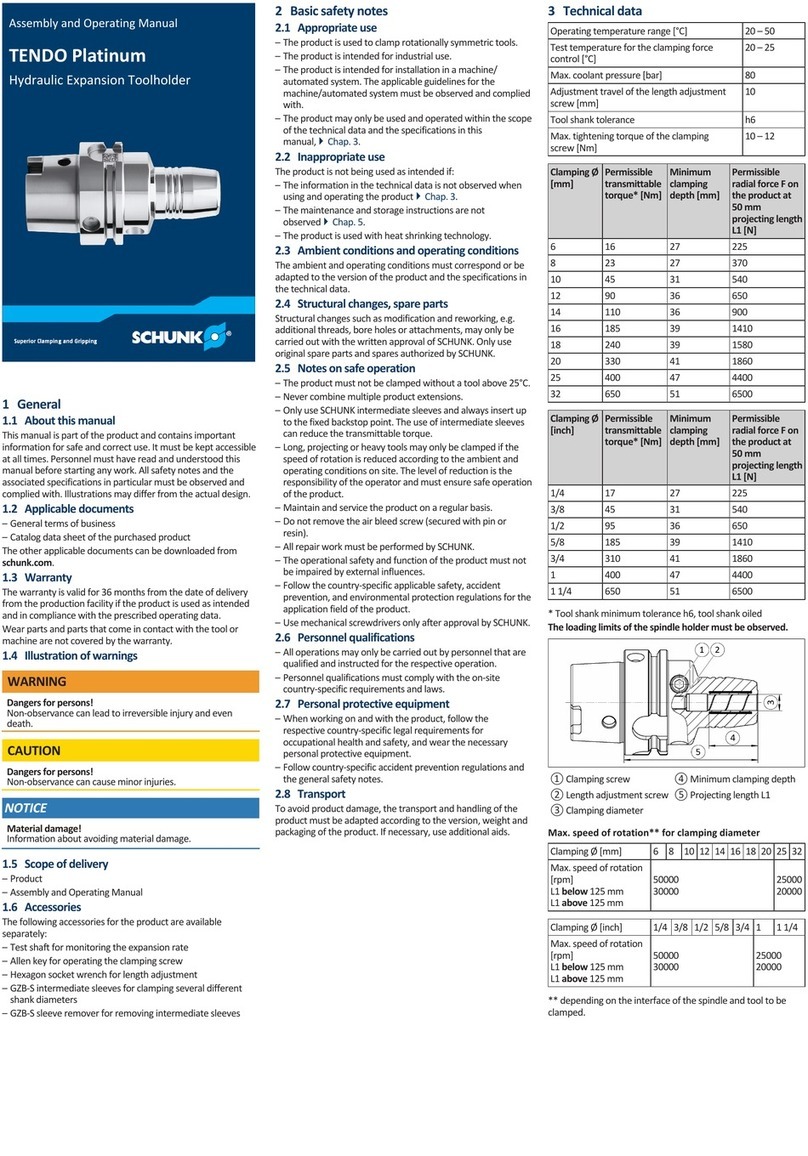

3 Technical data ..................................................................................... 15

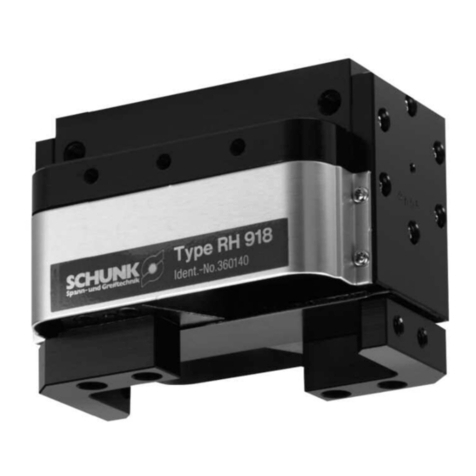

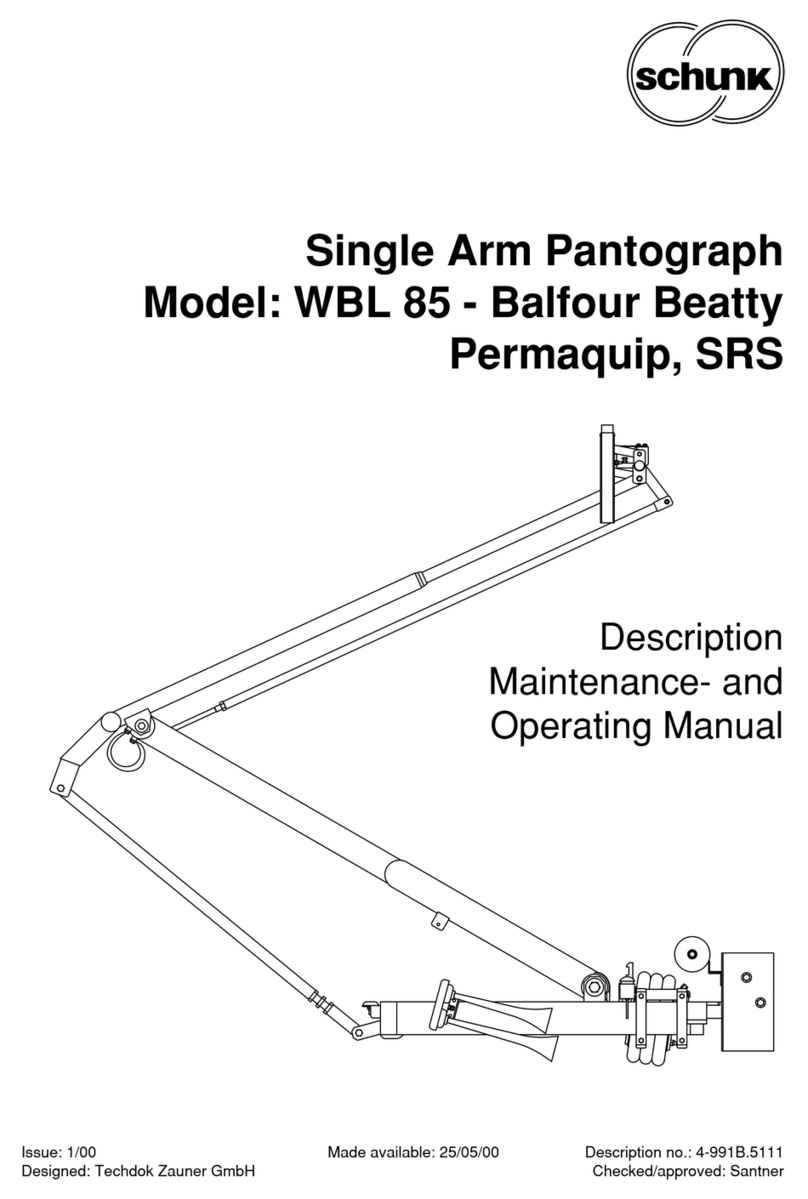

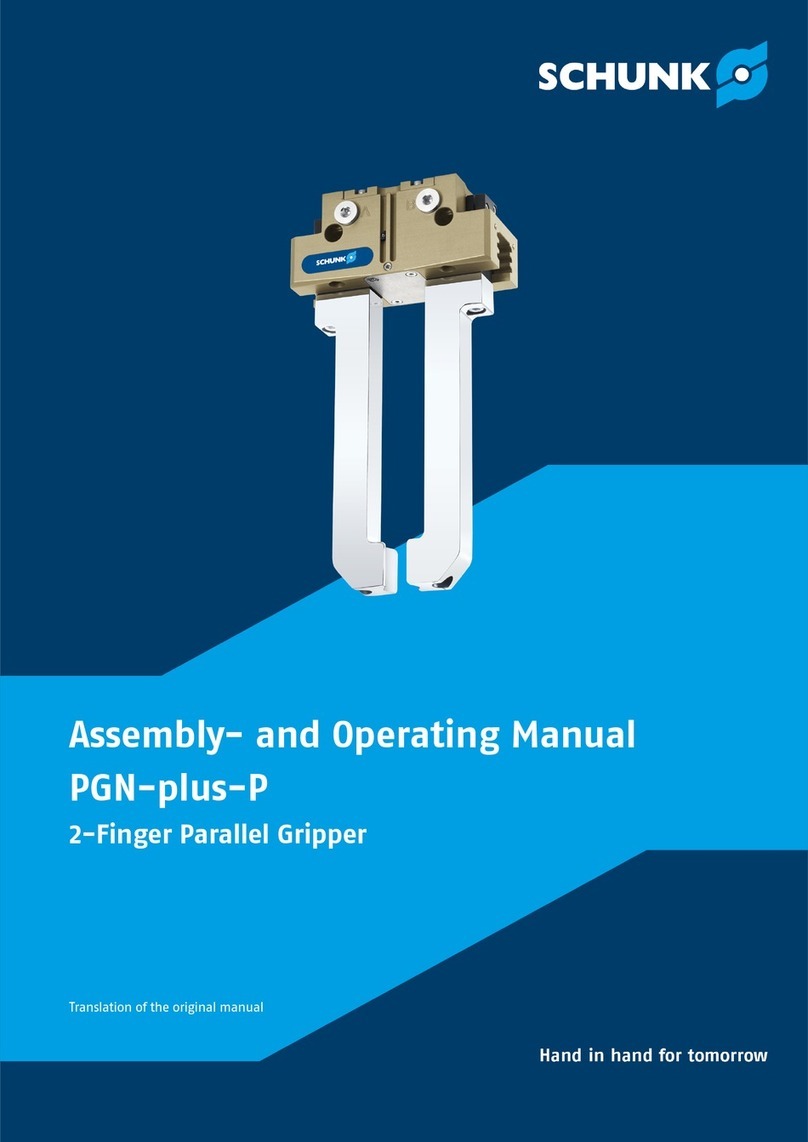

4 Design and description .......................................................................... 16

4.1 Design .............................................................................................. 16

4.2 Description ........................................................................................ 16

5 Assembly............................................................................................ 17

5.1 Installing and connecting ..................................................................... 17

5.2 Mechanical connection......................................................................... 18

5.3 Mounting inductive proximity switch IN 30K-S-M8 ..................................... 20

5.4 Attachment options for optional modules................................................. 21