7

7.7 Processing instruments in the container

1. The SALUS - Hygiene has been designed for use in a steam sterilizer for wrapped loads, eliminating the

need for wrapping instruments. It should be processed in a steam sterilizer. Since sterilizers vary in design

and performance characteristics, users are strongly recommended to verify the cycle parameters for the

specific sterilizer they are using. SALUS - Hygiene has been validated in steam sterilizer cycles shown in

Table 2:

Users may also conduct sterilizer testing to:

• verify successful sterilization has been achieved using biological and chemical indicators

• determine drying times necessary to achieve dryness of particular load

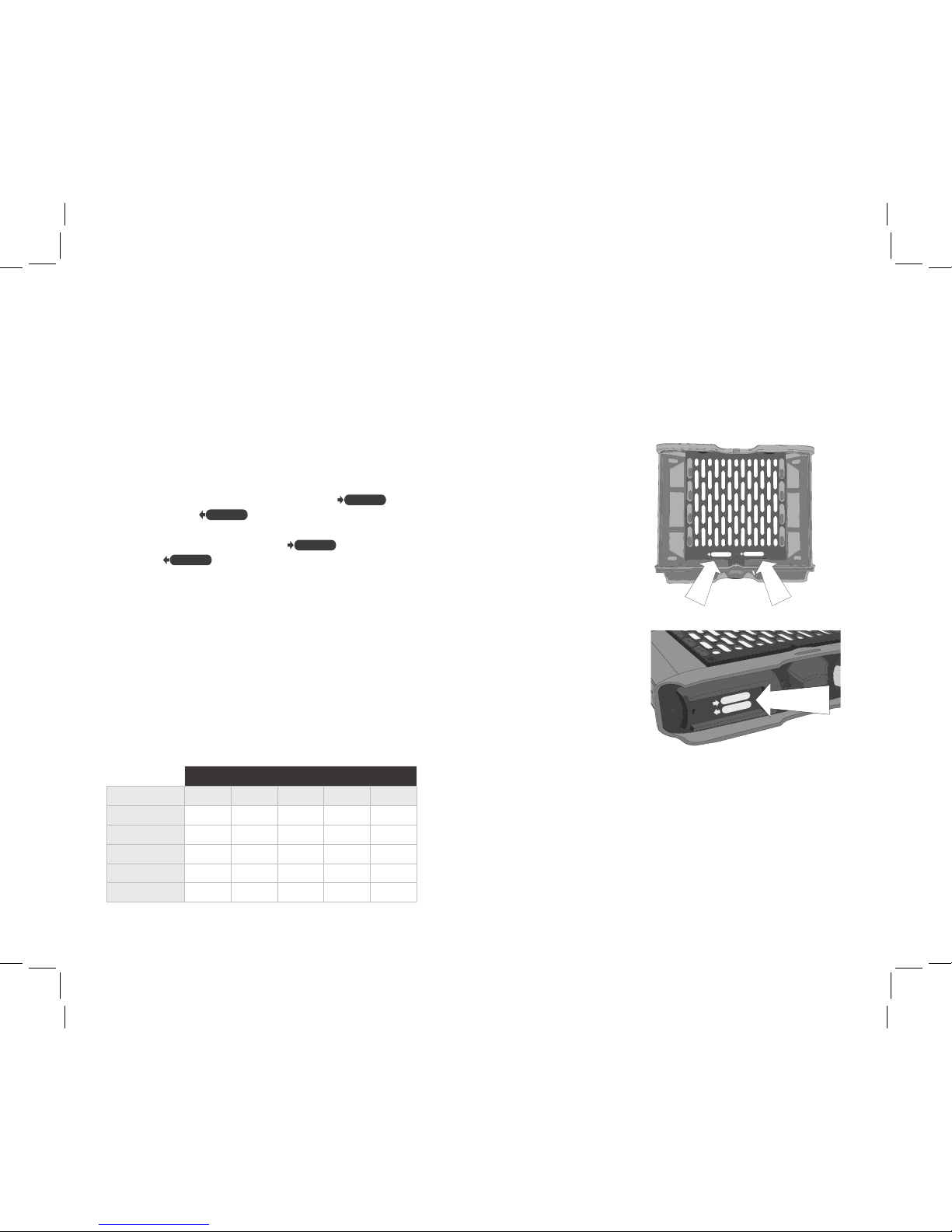

2. Do not stack the SALUS-Hygiene containers for sterilization. Whenever possible, position the SALUS-

Hygiene vertically with the label facing forward to facilitate load drying.

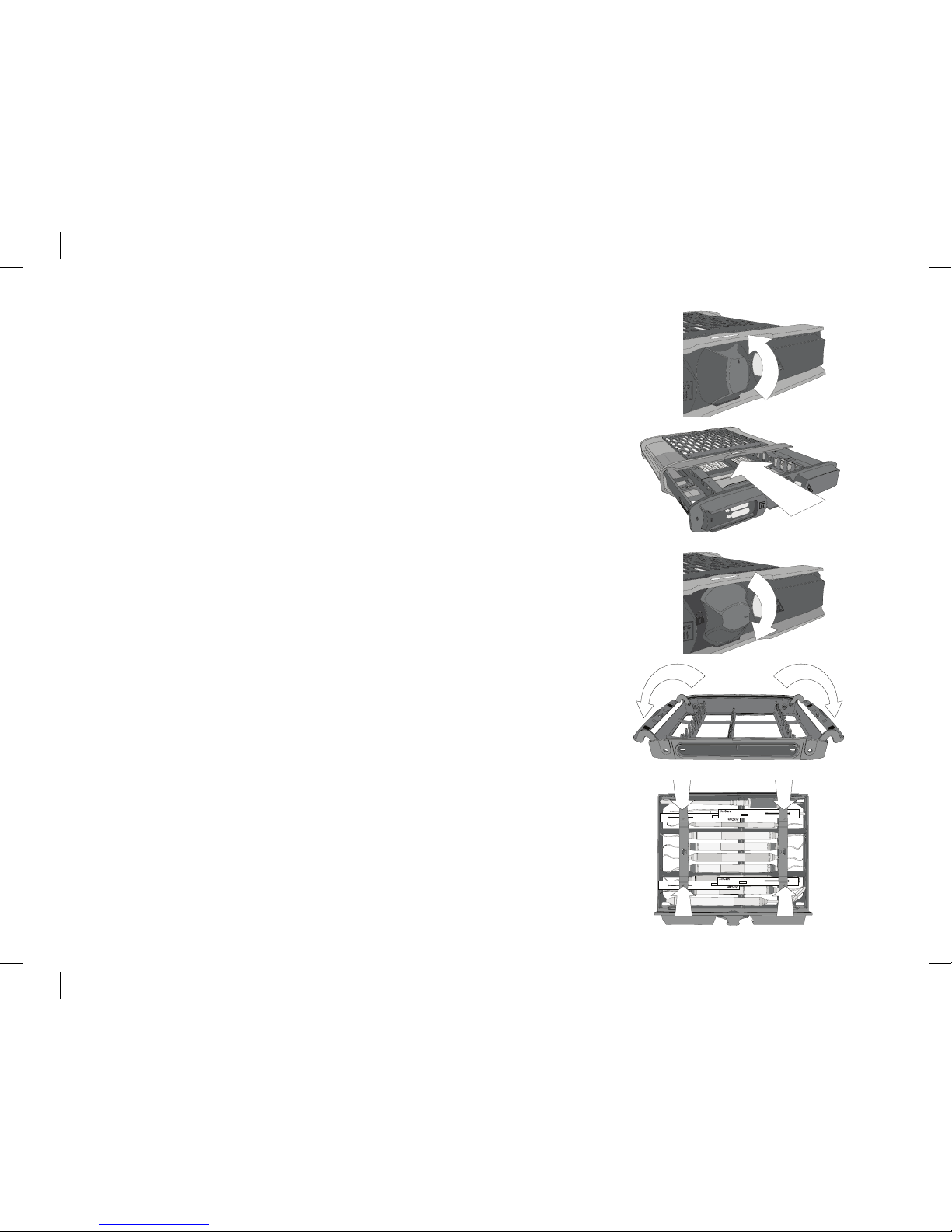

3. When sterilization is complete and successful, remove the SALUS-Hygiene from the sterilizer.

CAUTION: Burns from hot surfaces. When removing the SALUS-Hygiene after a sterilization cycle, exercise

caution to avoid skin burns as the container surfaces may still be hot. Allow SALUS-Hygiene to cool

sufficiently before handling or wear Personal Protective Equipment.

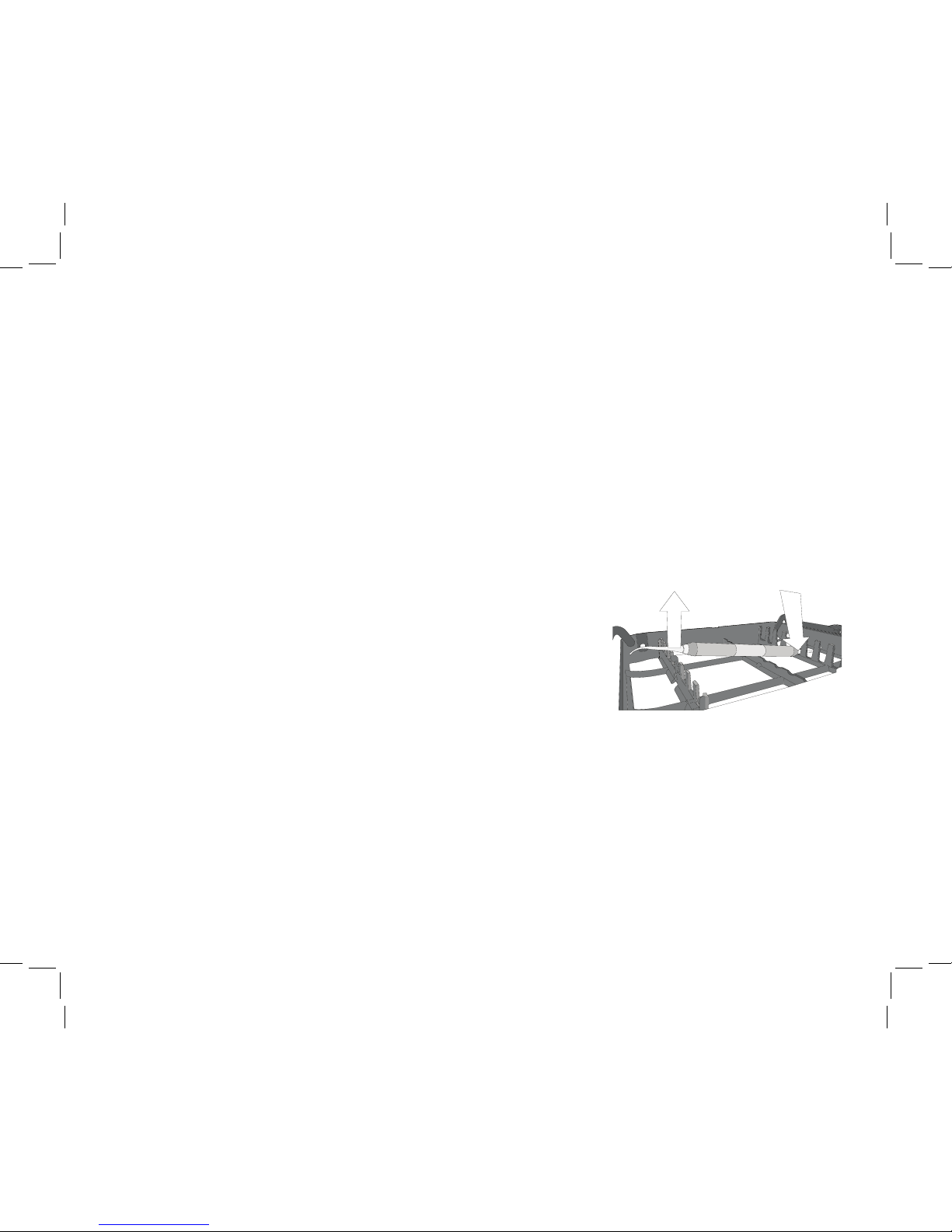

4. Check the tamper-evident latch to ensure it is extended to indicate the SALUS - Hygiene has been

processed [See Fig. 8].

5. Check the chemical indicator to ensure it has reached recommended sterilization conditions.

6. If using the instruments immediately, transport the container to chairside for immediate use.

7. If the container is to be stored, inspect the container and its contents for dryness. If moisture is present,

reprocess and re-sterilize the load with a longer drying time. Before storing the container, write the expiry

date (30 days from the date it is processed) on the external label.

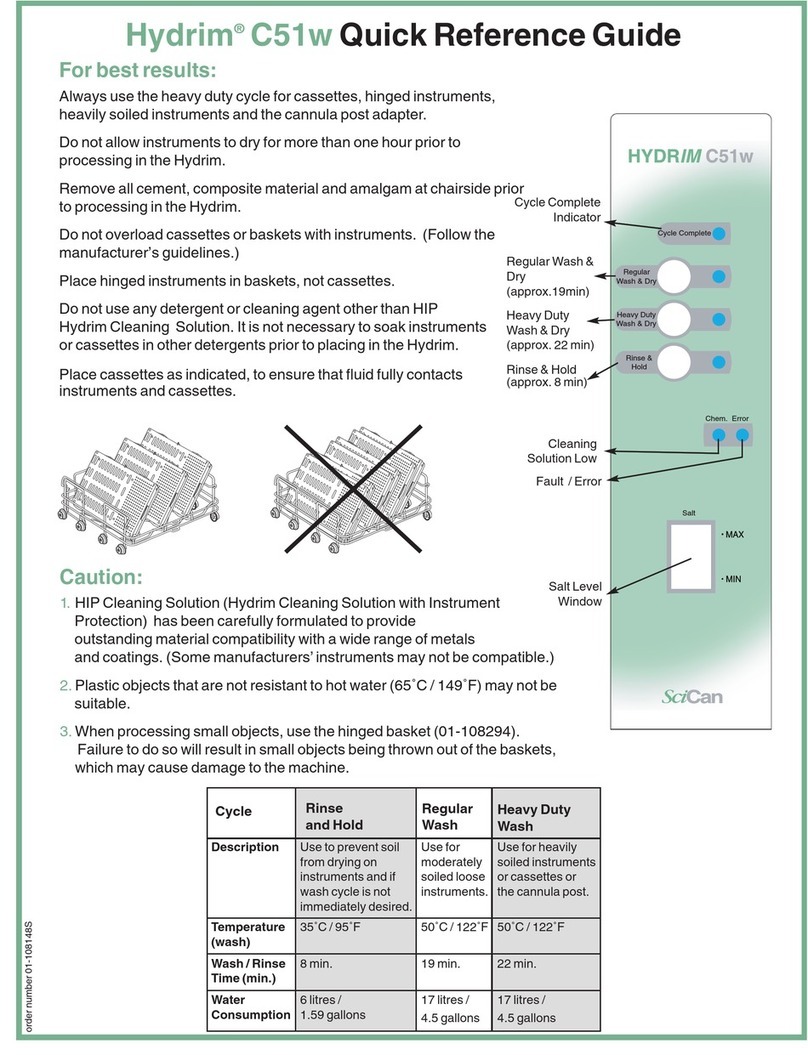

INSTRUCTIONS FOR USE IN CASSETTE AUTOCLAVES

After cleaning the cassette chamber, spray a liberal amount of STAT-DRI Plus on all interior surfaces of the

cassette chamber. Wipe with a paper towel and allow a coating to remain. When processing with the SALUS -

Hygiene containers, reapply STAT-DRI Plus to the interior surfaces of the cassette chamber before every cycle

to ensure complete dryness. Follow the Operator’s Manual of the cassette autoclave for instructions for the

frequency of cleaning the cassette chamber.

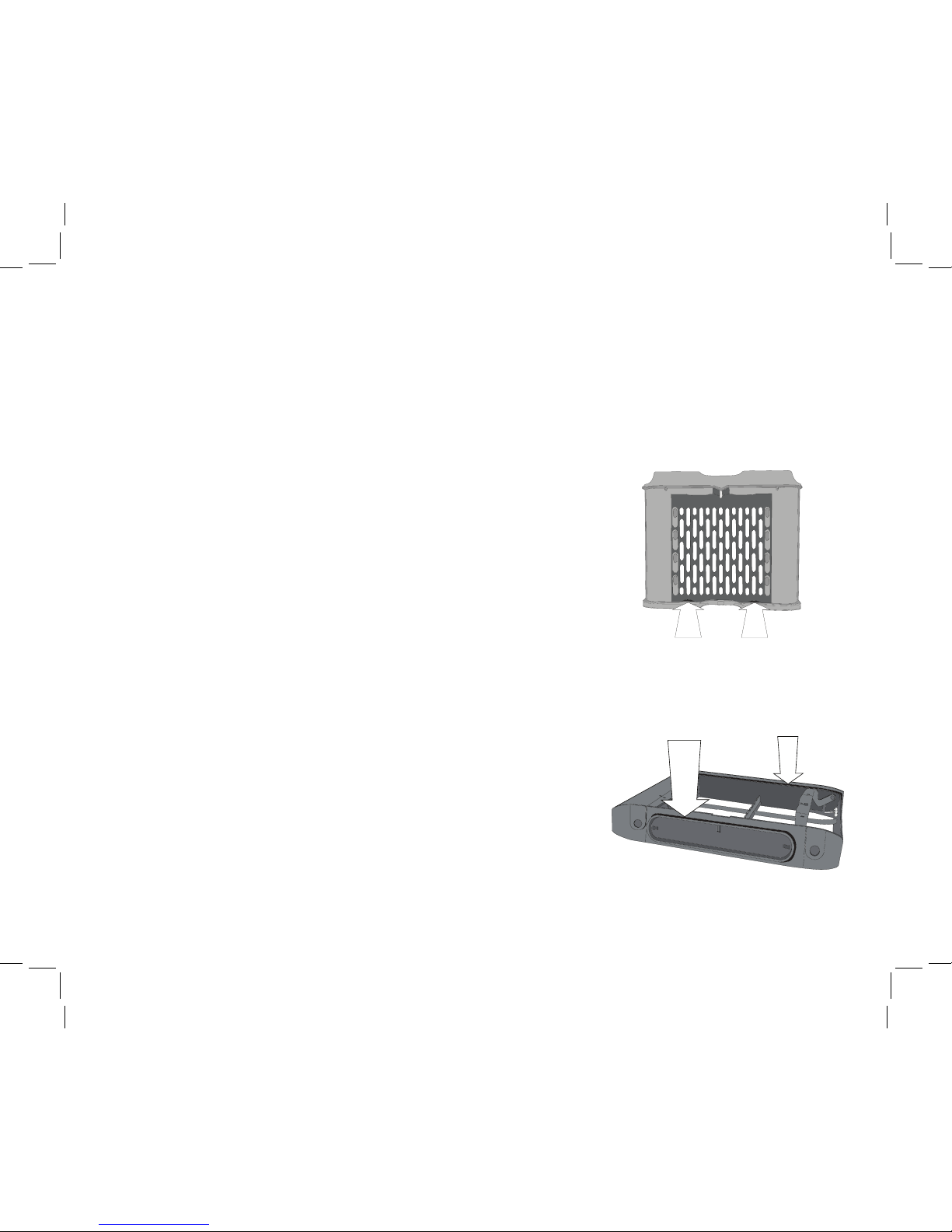

Fig. 7

Fig. 8

8.

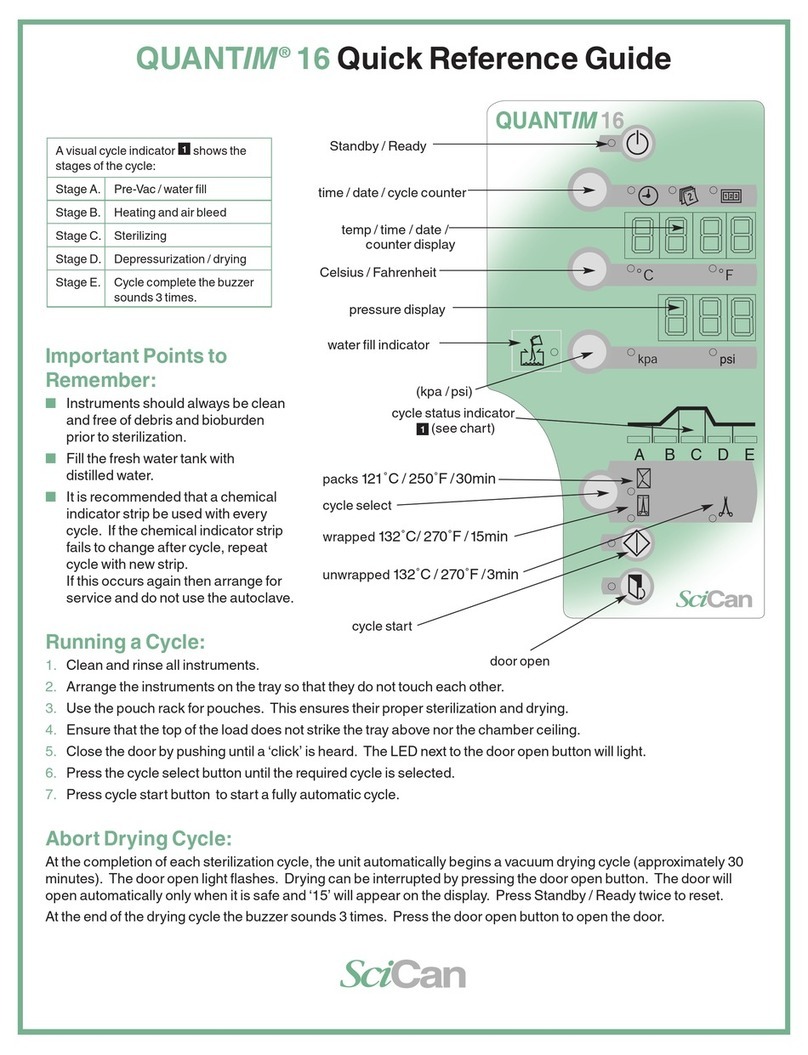

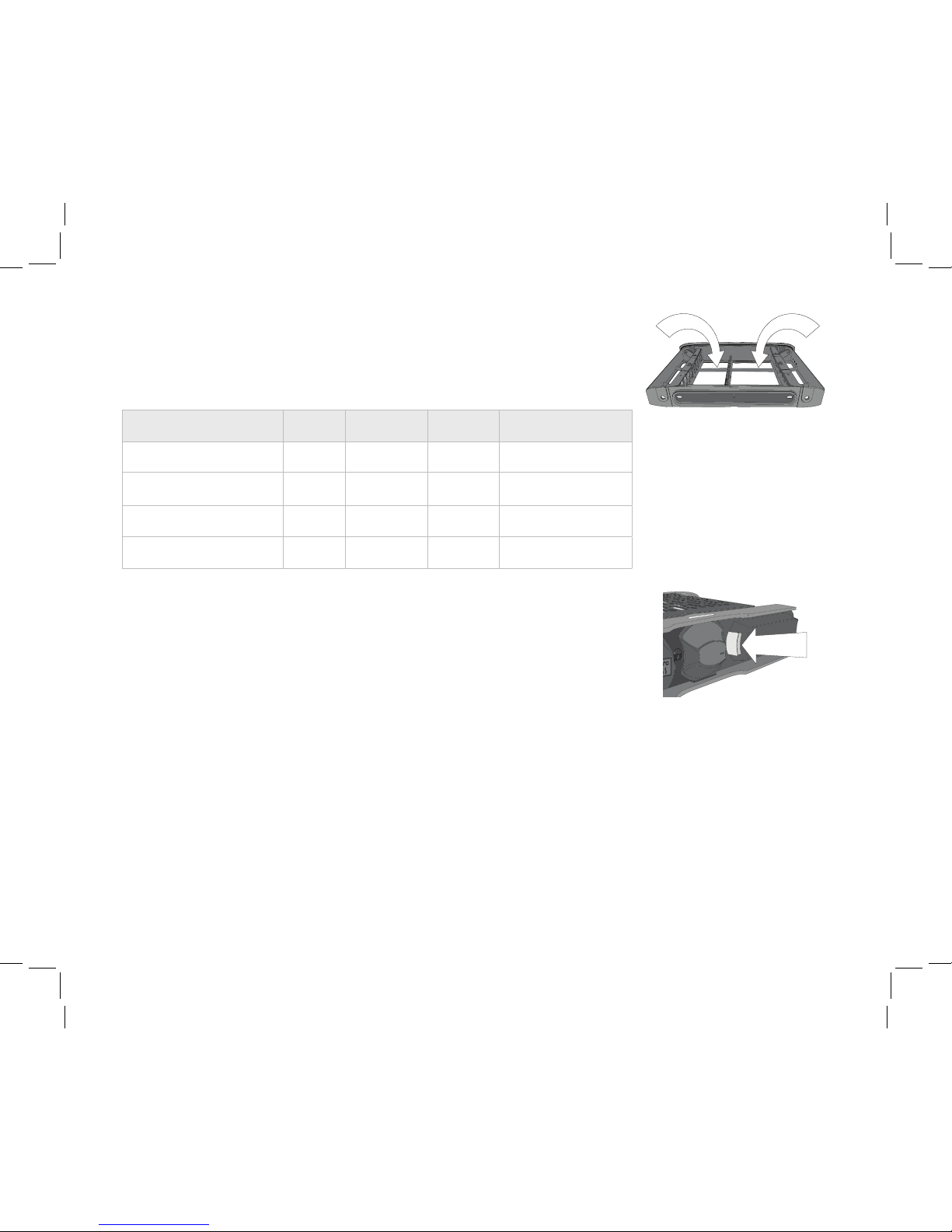

Table 2: Steam sterilizer cycles validated with SALUS - Hygiene.

* No visible condensation or pooling on the external surface of the container and the contents are free of visible condensation

[ANSI/AAMI ST77:2013 Sections 4.4.2 & 5.7]

Steam Sterilizer Type Cycle Sterilization

Temperature Exposure

Time

Recommended Drying

Time*

Dynamic-air-removal

(pre-vacuum)

Wrapped 134°C (273°F) 4 minutes 30 minutes

Dynamic-air-removal (steam-flush,

pressure-pulse, SFPP)

Wrapped 132°C (270°F) 5 minutes

6 minutes

30 minutes

30 minutes

Dynamic-air-removal (steam-flush,

pressure-pulse)

Wrapped 134°C (273°F) 3.5 minutes 30 minutes

Dynamic-air-removal (steam-flush,

pressure-pulse)

Wrapped 134°C (273°F) 6 minutes 30 minutes (STATIM 5000

NA wrapped cycle)

95-114369 CA EN FR R3_SALUS_OpsMan.indd 7 2016-11-10 8:44 AM