RAS3

SPARE PARTS AND

ACCESSORIES

Customer Services provide an efficient,

friendly, customer contact point for ordering

new apparatus, spare parts and accessories.

The team can also provide general information

on Scott Safety products.

WARRANTY

The products manufactured at our factories in

Skelmersdale and Vaasa carry a warranty of

12 months (unless stated otherwise) for parts,

labour and return to site. The warranty period

runs from the date of purchase by the end user.

These products are warranted to be free

from defects in materials and workmanship

at the time of delivery. Scott Safety will

be under no liability for any defect arising

from wilful damage, negligence, abnormal

working conditions, failure to follow the

original manufacturer’s instructions, misuse or

unauthorised alteration or repair.

Evidence of purchase date will need to be

provided for any claims arising during the

warranty period. All warranty claims must be

directed through Customer Services and in

accordance with our sales return procedure.

TECHNICAL

DESCRIPTION

GENERAL

RAS is a positive pressure airline apparatus with

a bandolier and waistbelt harness. The supply

airline hose connects to a CEN connector that

supplies the facemask mounted demand valve

via a length of medium pressure air hose. The

facemask with filter and can be fitted with a

suitable Scott Safety Particulate filter when

entering, or leaving the hazard area with the

airline disconnected. In this mode the facemask

functions as a negative pressure device.

WARNING: RAS must not be used in oxygen

deficient or hazardous atmospheres when

disconnected from the Airline supply.

A NRV in the airline connector prevents

contaminant entering the breathing hose while

the wearer is disconnected from the airline.

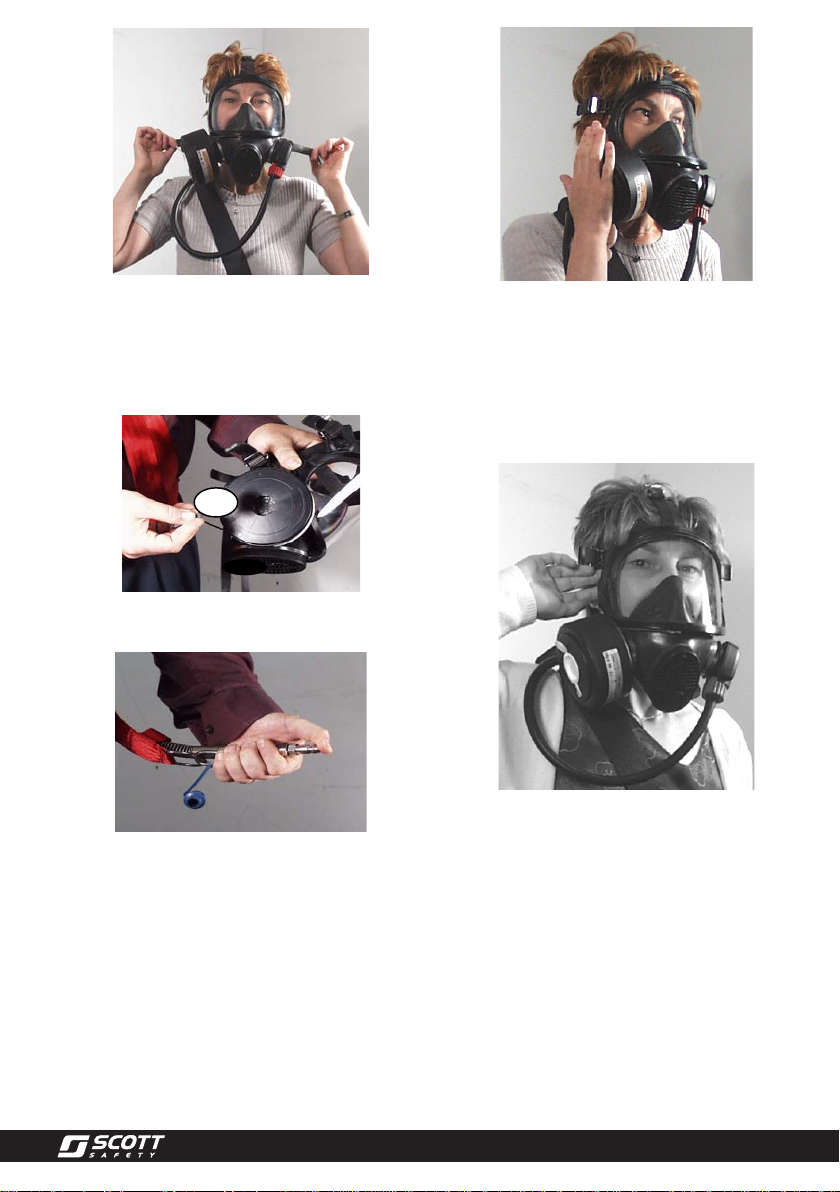

FILTERS

The service life of the filters is dependent on

the environment and the use-by-date marked

on the filter. DO NOT use damaged, wet,

clogged, or time expired filters.

The filter screws into the facemask’s screw

connector. A filter cover is provided to

preserve the filter when an airline is in use. A

blank-plug is provided to seal the mask when

a filter is not fitted. Filters must conform

to EN14387:2004+A1:2008 or EN143 with

an EN148-1 standard thread and must be

appropriate for the known work place hazards.

RAS apparatus may be used with up to 90

metres (297 feet) of medium pressure airline

hose, with a burst pressure in excess of 80 bar.

When likely to come into contact with corrosive

fluids or materials, it is recommended that only

anti-static hoses are used.

DEMAND VALVE HOSE

The hose has a working pressure of 16 bar and

a burst pressure in excess of 80 bar.

The airline manifold assemblies have an integral

particle filter to remove contaminant from the

air supply.

The RAS airline manifold assemblies incorporate

a NRV.

DEMAND VALVE (DV)

The DV operates in conjunction with the exhale

valve in the facemask to maintain a positive

pressure within the facemask.

The DV has a reset button that enables wearers

to close the airflow through the DV, allowing

the facemask to be removed without loss of

cylinder air.

When the apparatus is donned the DV is

normally ‘reset’ (closed), and is opened

(activated) when the wearer takes a first breath.

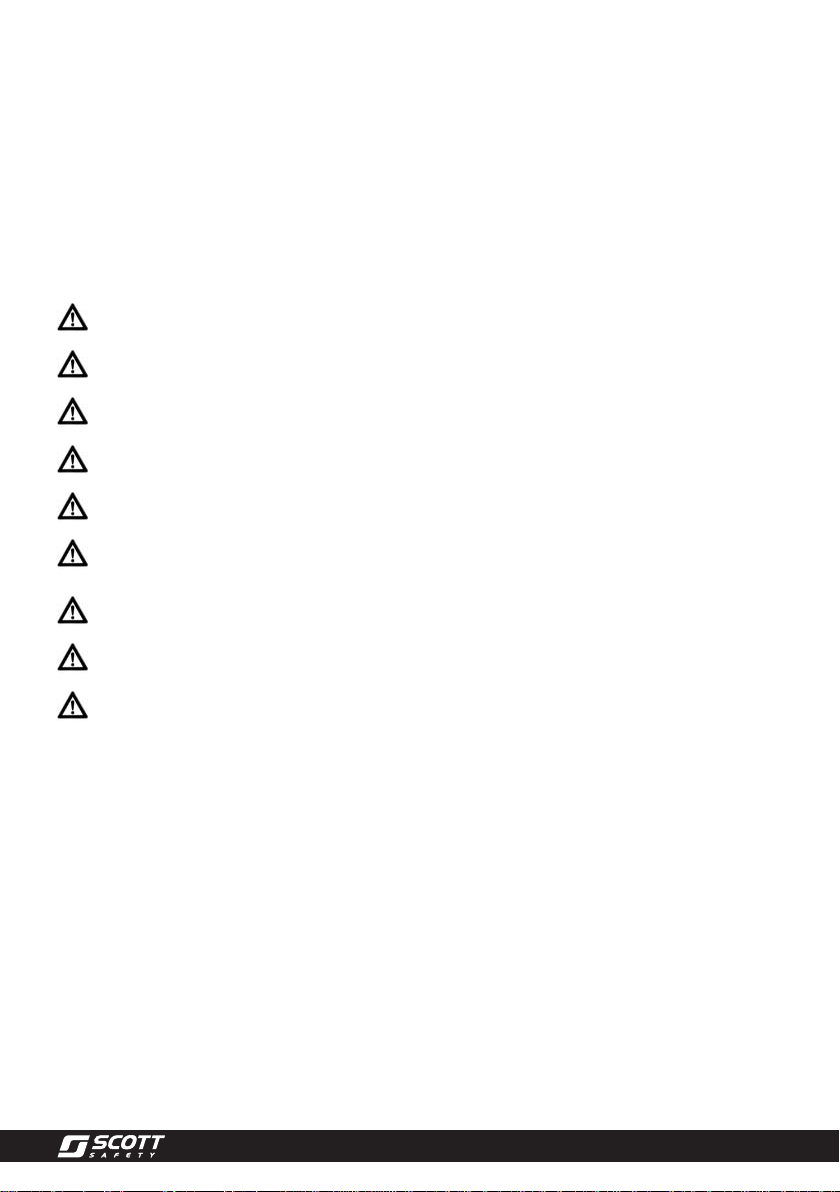

PANASEAL / VISION 3 /

PROMASK FACEMASK

The Panaseal, Vision 3 and Promask facemasks

are available, manufactured in non-dermatitic

Neoprene or Silicone and have a 5-point

head harness. A neckstrap is provided. The

polycarbonate visor is impact resistant.

An inner mask minimises CO2 dead space and

visor misting. A speech diaphragm is fitted.