SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9111 Page 4 of 7 © 2021 DESCO INDUSTRIES, INC.

Employee Owned

Performing a Measurement

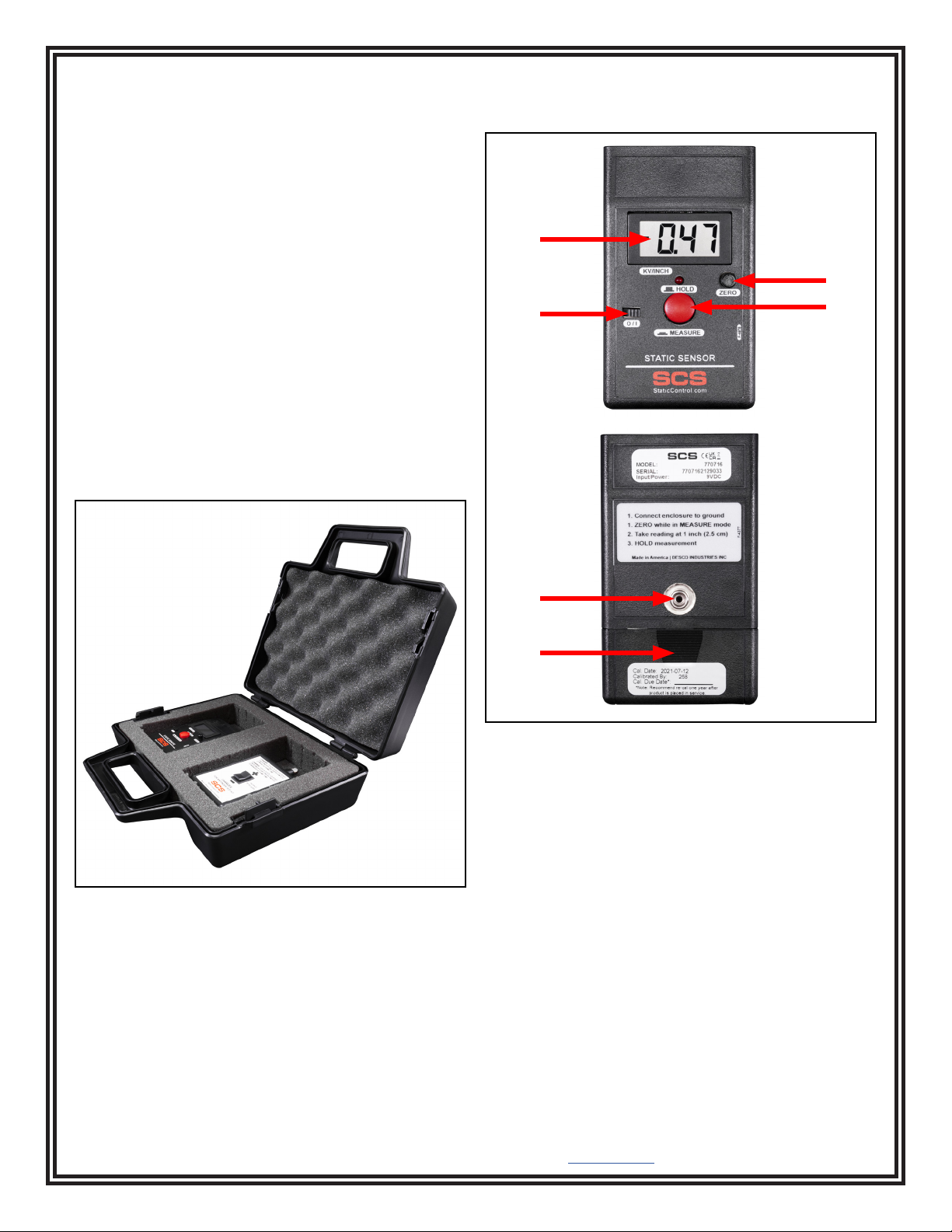

Use the LED range indicator to position the top of the

Static Sensor 1 inch (2.5 cm) from the object to be

measured. The Static Sensor will display a reading (from

0 to ±19.99) of the electrostatic eld in kilovolts per inch.

NOTE: The display will indicate “1” or “-1” when the

Static Sensor is over-ranged. Change the range of the

unit if necessary. If the measurement exceeds 20 kV,

move the Static Sensor farther away from the object and

multiply the reading by the distance (in inches) away

from the object being measured. The measurement

accuracy is dependent on a stable ground reference

and the 1 inch measuring distance. It is also dependent

on the “aspect ratio”, relating the size of the object to be

measured to the measurement distance.

NOTE: This aspect ratio should be at least 3 for best

accuracy. In other words, the object should be at

least a 3 inch square when measuring at a 1 inch

distance. Accurate measurements may be made at

other measurement distances by scaling the Static

Sensor range and observing the proper aspect ratio.

For example, at a measurement distance of 3 inches,

multiply the Static Sensor reading by 3 to give a range

of 0 to 60 kilovolts. For accuracy, the object being

measured at this distance should be at least a 9 inch

square.

Holding the Last Reading

With the Static Sensor positioned 1 inch (2.5 cm) from

the object being measured, press the red pushbutton

switch into the HOLD position. This will freeze the

measurement on the display and illuminate the red LED

located above the pushbutton switch. This feature allows

the operator to move the Static Sensor where it may be

more easily read or saved for later reference.

NOTE: The LED range indicator will disable while the

Static Sensor is in HOLD mode. Use the HOLD feature

between measurements to prolong the battery’s life.

Air Ionizer Test Kit

Performing Oset Voltage (Balance) Measurements

The Air Ionizer Test Kit has been designed to match the

compact size and hand held convenience of the Static

Sensor. Use the following procedure to verify the

oset voltage (balance) of air ionization equipment.

This quick and easy procedure will help determine if

the piece of ionization equipment is working within the

manufacturer’s specications or user requirements. It is

extremely important that ionizers be checked regularly

for oset voltage (balance) and discharge times.

An ionizer operating in an out-of-balance state can

place a charge on sensitive electronic components or

assemblies.

NOTE: The Static Sensor’s enclosure is conductive. The

instrument senses the dierence in potential between

the enclosure and the tested surface. The meter must

be grounded by either the hand of a grounded operator

or the included coiled ground cord to achieve accurate

measurements.

Installing the Conductive Plate

The Static Sensor’s case has two slots along its sides.

The top slot is closest to the face of the instrument. Slide

down the tabs of the Conductive Plate plate into the top

slot of the Static Sensor’s case as far as they go.

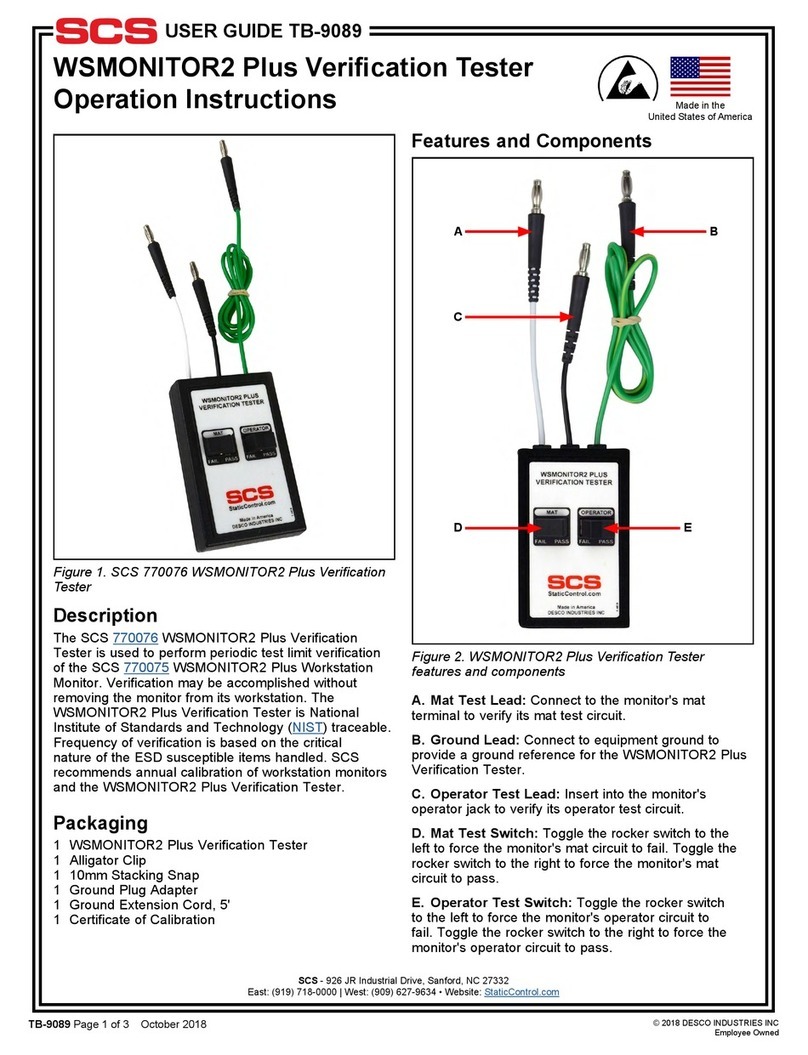

Figure 7. Aligning the two bullseyes emitted by the LED

range indicator