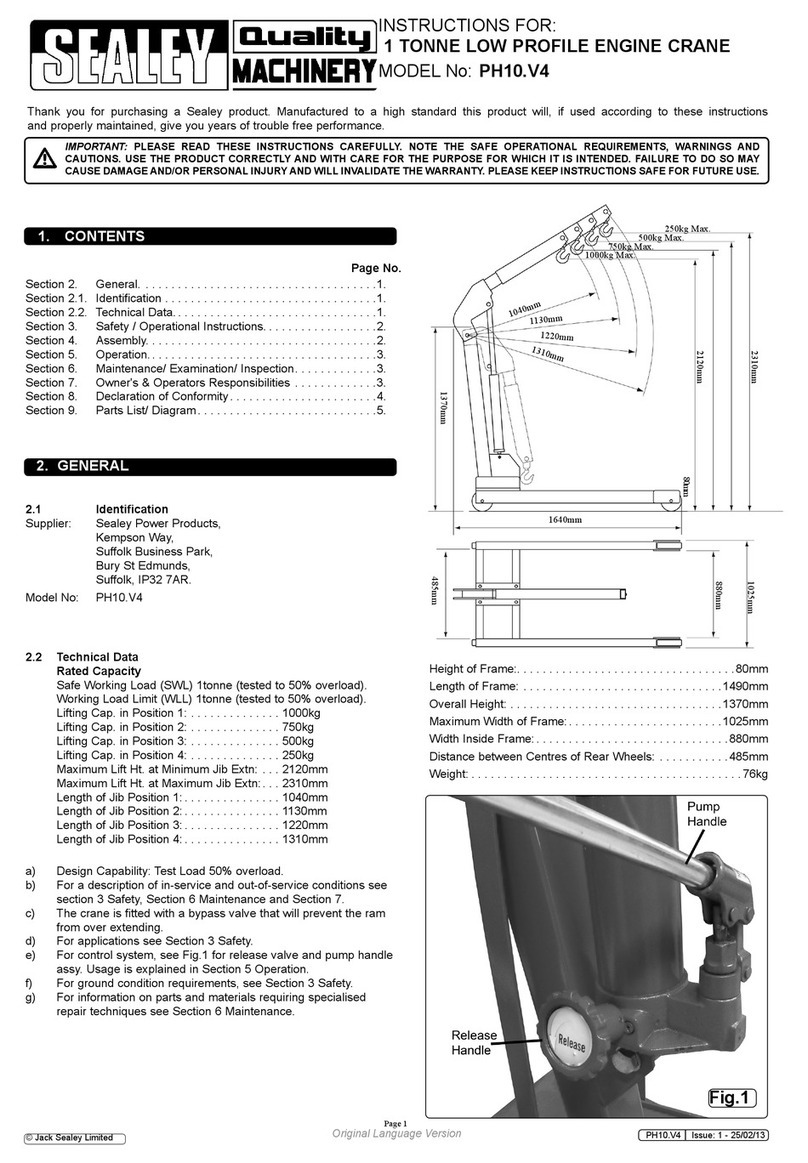

3. SPECIFICATION

TECHNICAL DATA

Model No:....................................................................... PH5

Height folded down: ................................................ 1330mm

Height of frame .......................................................... 100mm

Rated Capacity

Safe Working Load (SWL) 0.5t (tested to 50% overload).

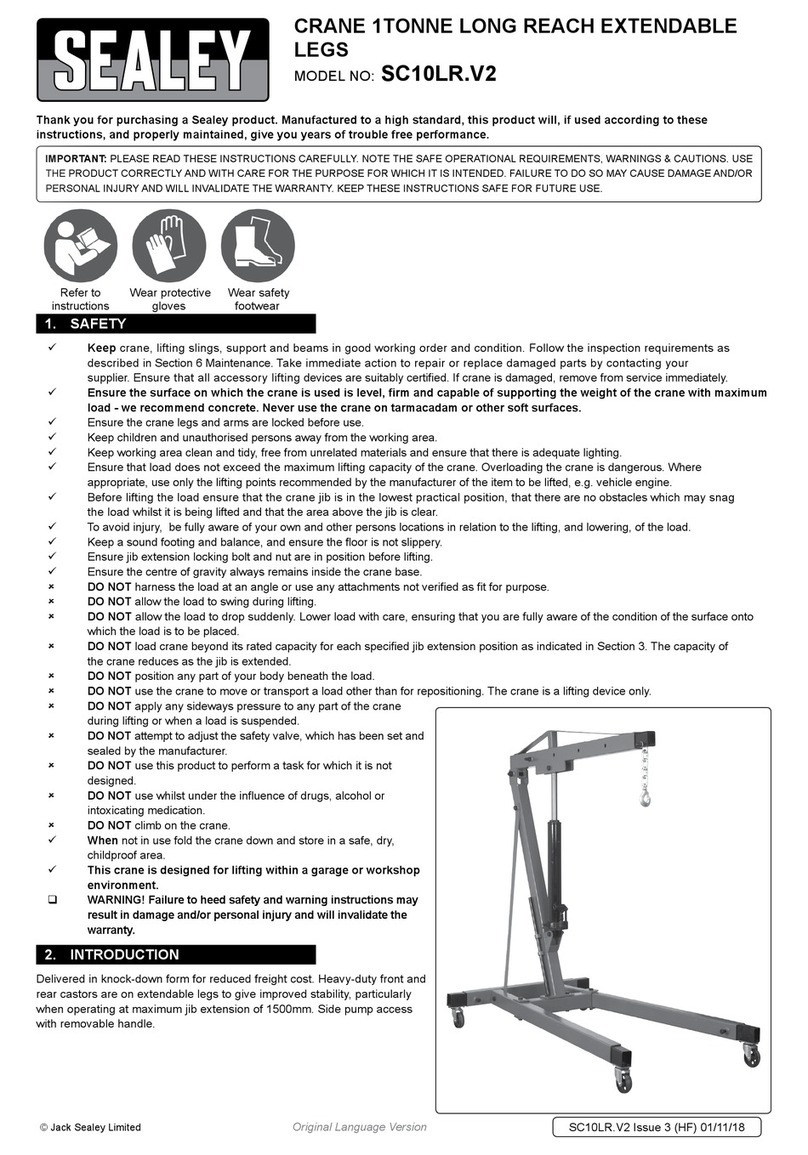

Lifting Capacity in Position 1: ....................................... 500kg

Lifting Capacity in Position 2: ....................................... 400kg

Lifting Capacity in Position 3: ....................................... 300kg

Lifting Capacity in Position 4: ....................................... 200kg

Lifting Capacity in Position 5: ............................................ n/a

Length of jib in Position 1: .......................................... 750mm

Length of jib in Position 2: .......................................... 860mm

Length of jib in Position 3: .......................................... 980mm

Length of jib in Position 4: ........................................ 1100mm

Length of jib in Position 5: ................................................. n/a

Max. Lift Ht at Jib Position1:..................................... 1950mm

Max. Lift Ht at Jib Position2:..................................... 2050mm

Max. Lift Ht at Jib Position3:..................................... 2150mm

Max. Lift Ht at Jib Position4:..................................... 2250mm

Max. Lift Ht at Jib Position5:.............................................. n/a

3.1.1. Design Capability: 500kg. Test Load 50% overload.

For a description of in-service and out-of-service conditions see Section 1 Safety, Section 6 Maintenance.

3.1.2. For applications see Section 1 Safety.

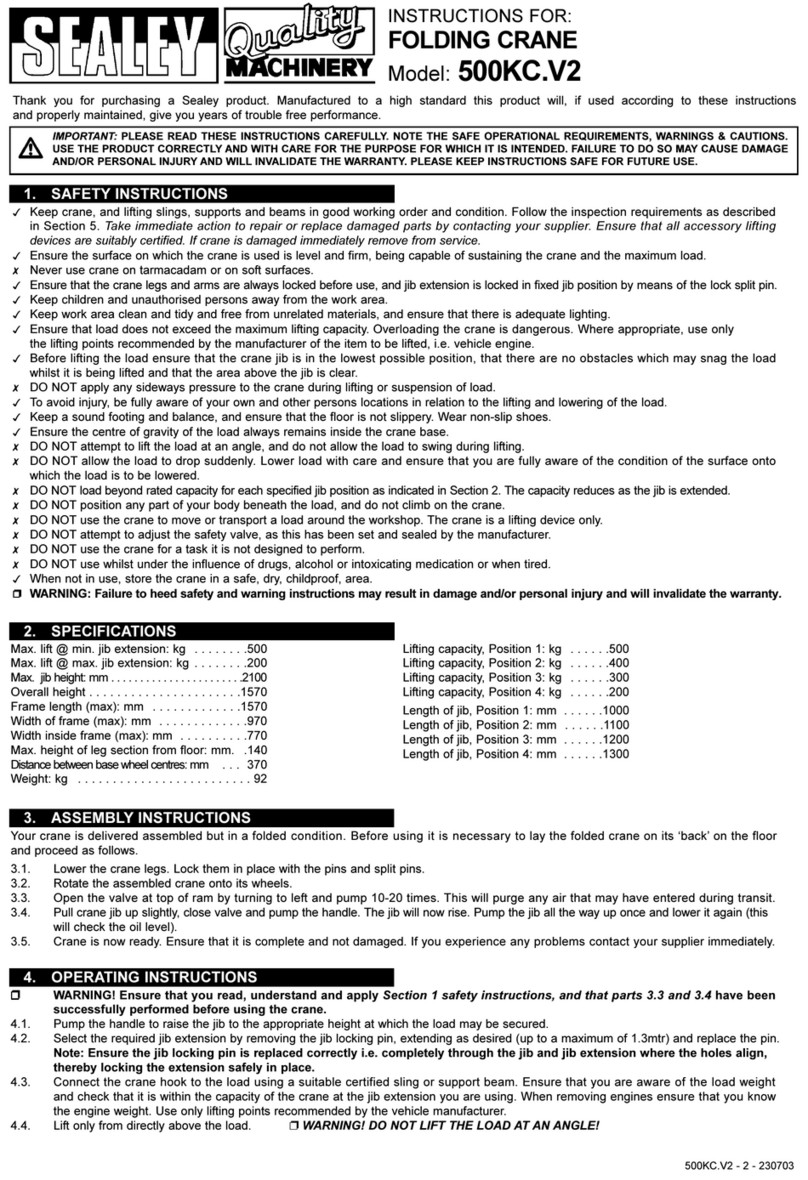

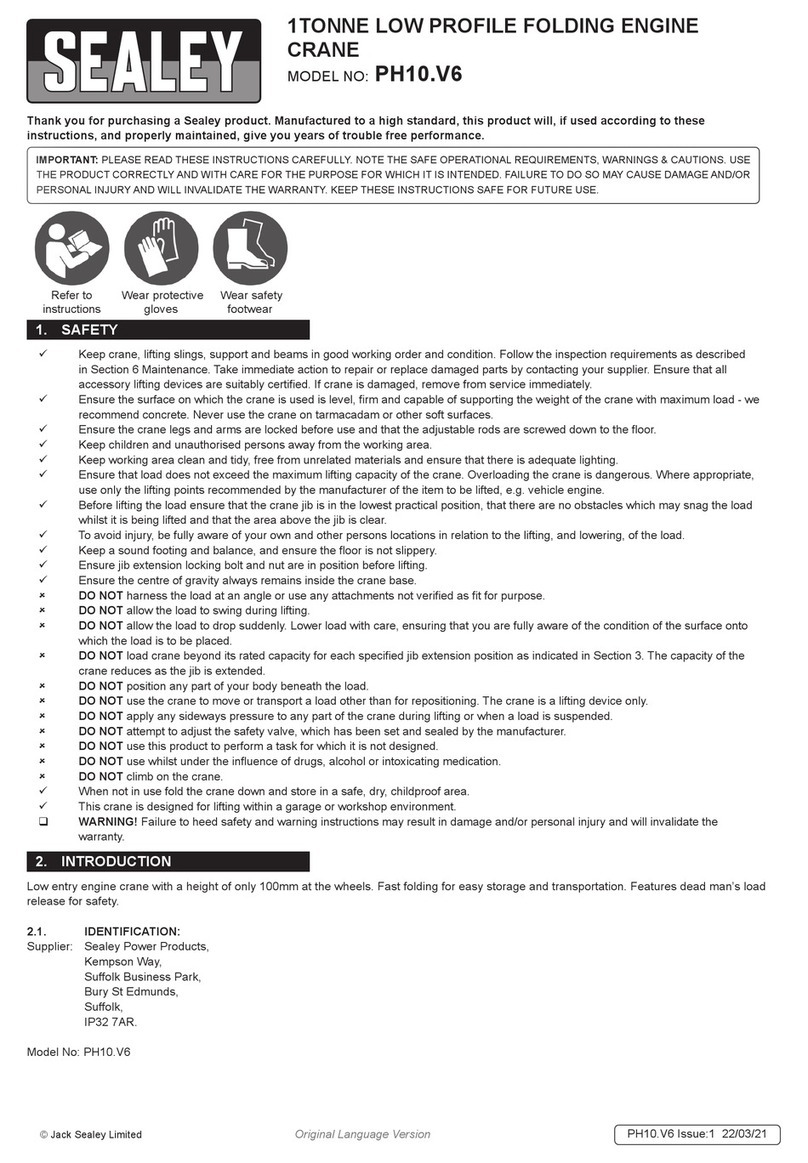

3.1.3. Forcontrolsystem,seeg.1forreliefvalve,andpumparrangement.OperationisexplainedinSection5.

3.1.4. For ground condition requirements, see Section 1 Safety.

For information on parts and materials requiring specialised repair techniques see Section 6 Maintenance.

4. ASSEMBLY

WARNING! It takes two people to build the crane. Leave all nuts loose until assembly is complete.

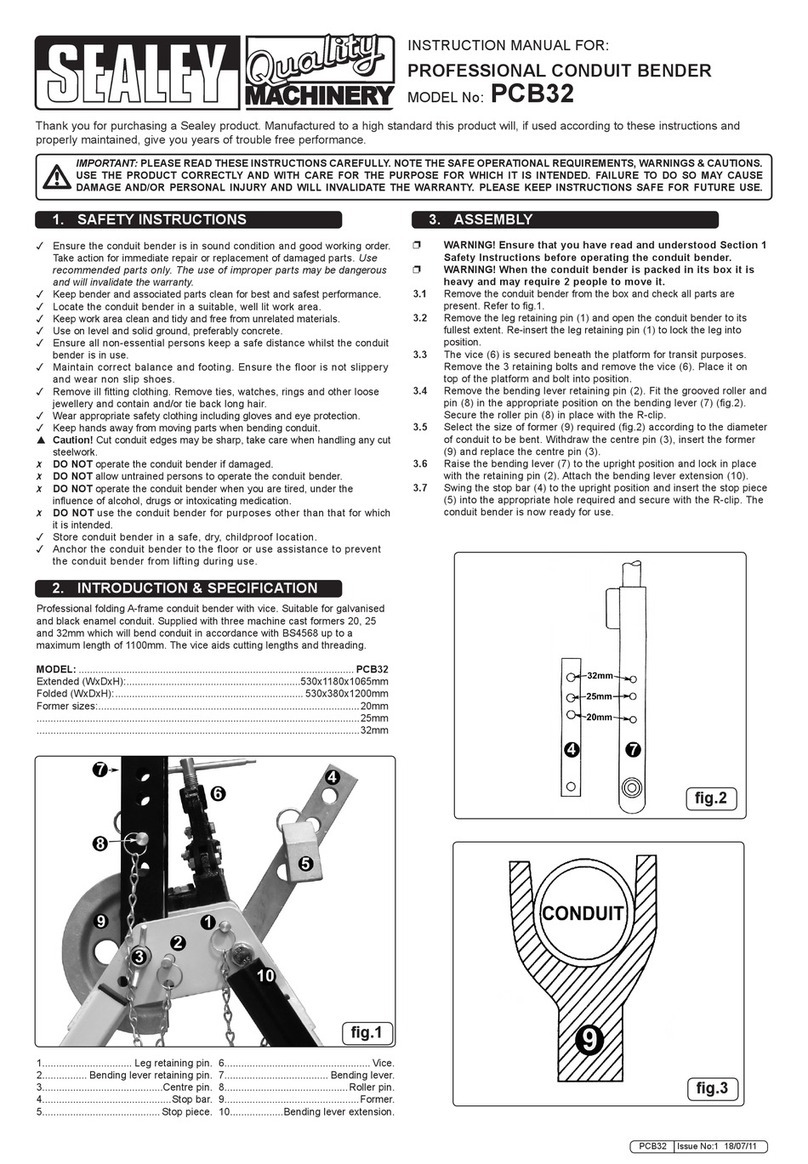

NOTE: Item numbers refer to attached parts diagram. Unpack and check against parts lists.

4.1. Assemblebaseelements(1,2,3,4,5,11and12)usingxingsshown.

4.2. Assemble upright (6) to base frame front base member (4).

4.3. Assembleboomandboomextension(7,8)toupright(6)usingxingsshown.

4.4. Fithydraulicunit(10)startingatthelowermountingpointusingxingsshown.

4.5. Hanghookandchainassembly(9)usingxingshown.

4.6. Tighten all nuts and bolts.

4.7. BLEED HYDRAULIC SYSTEM: Place the pump handle into the pump socket, ensure the relief valve is in the open position

(g.1)andpumpthehandle10-15times,throughthefullstroke,thusbleedingfromthehydraulicsystemanyairwhichmayhave

entered the system during transit.

5. OPERATION

5.1. OPERATION. (Refer to Section 6.2 (a) regarding inspection before each and every use).

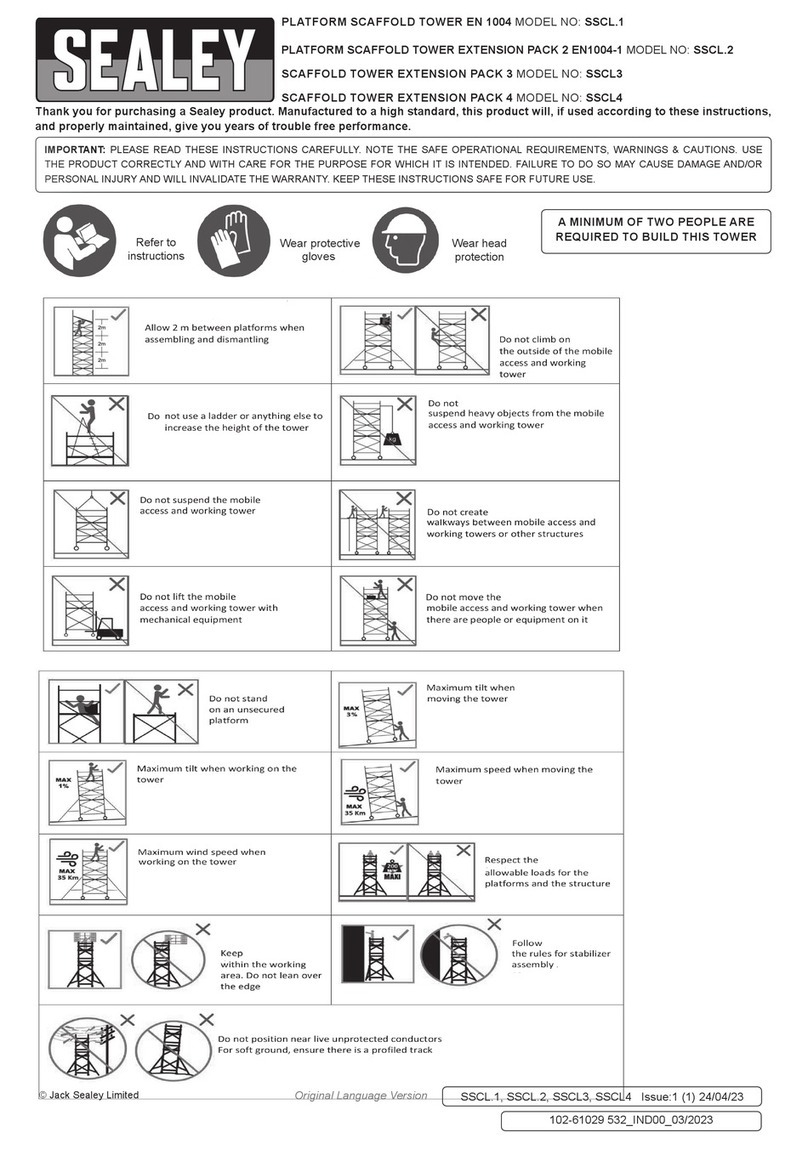

a) Ensure the relief valve is in the closed position (fig.1).

b) Place handle into pump socket and pump, the jib will raise. Continue to pump until the jib reaches the height at which the load can be secured.

c) Connect the crane hook to the load using a suitable certified sling or support beam. Ensure you are aware of the load weight,

and check that it is within the capacity of the crane (at the jib extension you are using) and the sling or support beam. When removing

engines ensure you know the weight to be lifted. Use only the lifting points recommended by the vehicle manufacturer.

d) Lift only from directly above the load. WARNING! DO NOT LIFT THE LOAD AT AN ANGLE!

e) To lower load, turn relief valve VERY SLOWLY anti-clockwise avoiding any sudden movement.

WARNING! DO NOT allow the load to drop suddenly.

f) The crane is not a transportation device but may be used to reposition the load being worked on. To do so, lower load and jib

with care, to the lowest possible point before attempting to move. DO NOT try to move crane in a sideways direction. The crane is

not designed to support the load indefinitely. When you have repositioned the load, lower the load onto a secure and

appropriate working base, being fully aware of your own and other persons locations in relation to the lowering load.

g) When load has been secured, remove lifting sling, support beam etc. and place crane in a safe location with lifting beam fully lowered.

6. MAINTENANCE/INSPECTION

NOTE: The crane MUST be kept clean and dry and must be maintained in accordance with these instructions.

6.1. LUBRICATION.

a) Oil all working parts monthly.

b) The ram is filled with oil and should only require occasional topping up. For the occasional top up DO NOT use brake fluid, as this will

damage the hydraulic seals. Proceed as follows:

1) Use only good quality hydraulic jack oil available from your Sealey stockist.

2) DO NOT OVERFILL as this will cause failure.

Original Language Version

© Jack Sealey Limited PH5 Issue 1 04/12/19

g.1