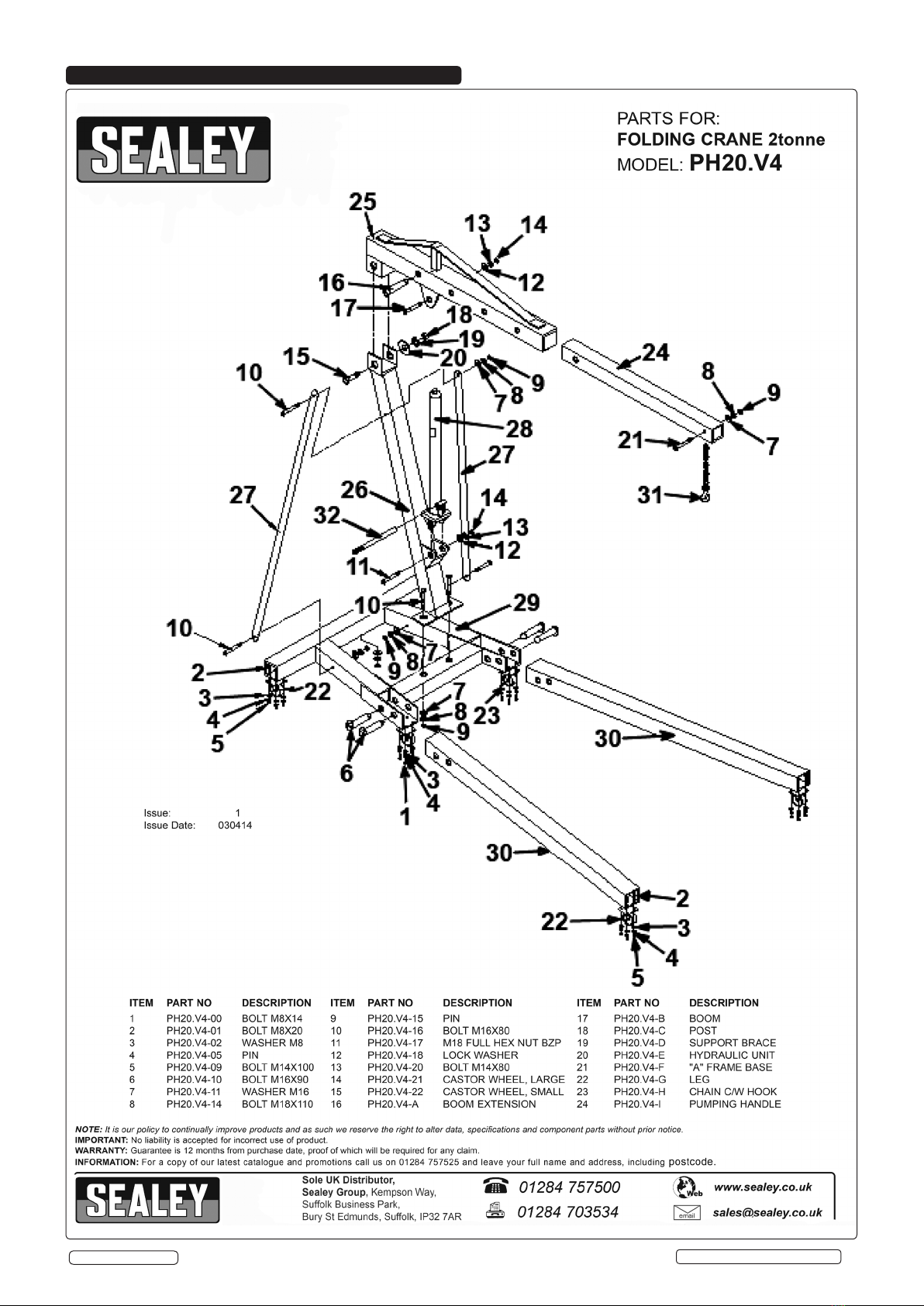

page 2

3. SAFETY/OPERATING INSTRUCTIONS

3.1. SAFETY

3Keep crane, lifting slings, support and beams in good working order and condition. Follow the inspection requirements as

described in Section 4, Maintenance. Take immediate action to repair or replace damaged parts by contacting your supplier.

Ensure that all accessory lifting devices are suitably certified. If crane is damaged, remove from service immediately.

3Ensure the surface on which the crane is used is level, firm and capable of supporting the weight of the crane with

maximum load - we recommend concrete. Never use the crane on tarmacadam or other soft surfaces, as the crane may sink in.

3Ensure the crane legs and arms are locked before use.

3Keep children and unauthorised persons away from the working area.

3Keep working area clean and tidy, free from unrelated materials and ensure that there is adequate lighting.

3Ensure that load does not exceed the maximum lifting capacity of the crane. Overloading the crane is dangerous. Where

appropriate, use only the lifting points recommended by the manufacturer of the item to be lifted, e.g. vehicle engine.

3Before lifting the load ensure that the crane jib is in the lowest practical position, that there are no obstacles which may snag

the load whilst it is being lifted and that the area above the jib is clear.

3To avoid injury, be fully aware of your own and other persons locations in relation to the lifting, and lowering, of the load.

3Keep a sound footing and balance, and ensure the floor is not slippery, and wear non-slip footwear.

3Ensure jib extension locking bolt and nut are in position before lifting.

3Ensure the centre of gravity always remains inside the crane base.

7DO NOT harness the load at an angle or use any attachments not verified as fit for purpose.

7DO NOT allow the load to swing during lifting.

7DO NOT allow the load to drop suddenly. Lower load with care, ensuring that you are fully aware of the condition of the surface onto

which the load is to be placed.

7DO NOT load crane beyond its rated capacity for each specified jib extension position as indicated in Section 2 page 1.

The capacity of the crane reduces as the jib is extended.

7DO NOT position any part of your body beneath the load.

7DO NOT use the crane to move or transport a load other than for repositioning (see 3.2.f). The crane is a lifting device only.

7DO NOT apply any sideways pressure to any part of the crane during lifting or when a load is suspended.

7DO NOT attempt to adjust the safety valve, which has been set and sealed by the manufacturer.

7DO NOT use this product to perform a task for which it is not designed.

7DO NOT use whilst under the influence of drugs, alcohol or intoxicating medication.

7DO NOT climb on the crane.

3When not in use fold the crane down and store in a safe, dry, childproof area.

3This crane is designed for lifting within a garage or workshop environment.

WARNING! Failure to heed safety and warning instructions may result in damage and/or personal injury and will invalidate the

warranty.

NOTE: ENSURE YOU HAVE READ AND UNDERSTOOD THE SAFETY INSTRUCTIONS AT THE BEGINNING OF THIS SECTION BEFORE YOU

OPERATE THE CRANE.

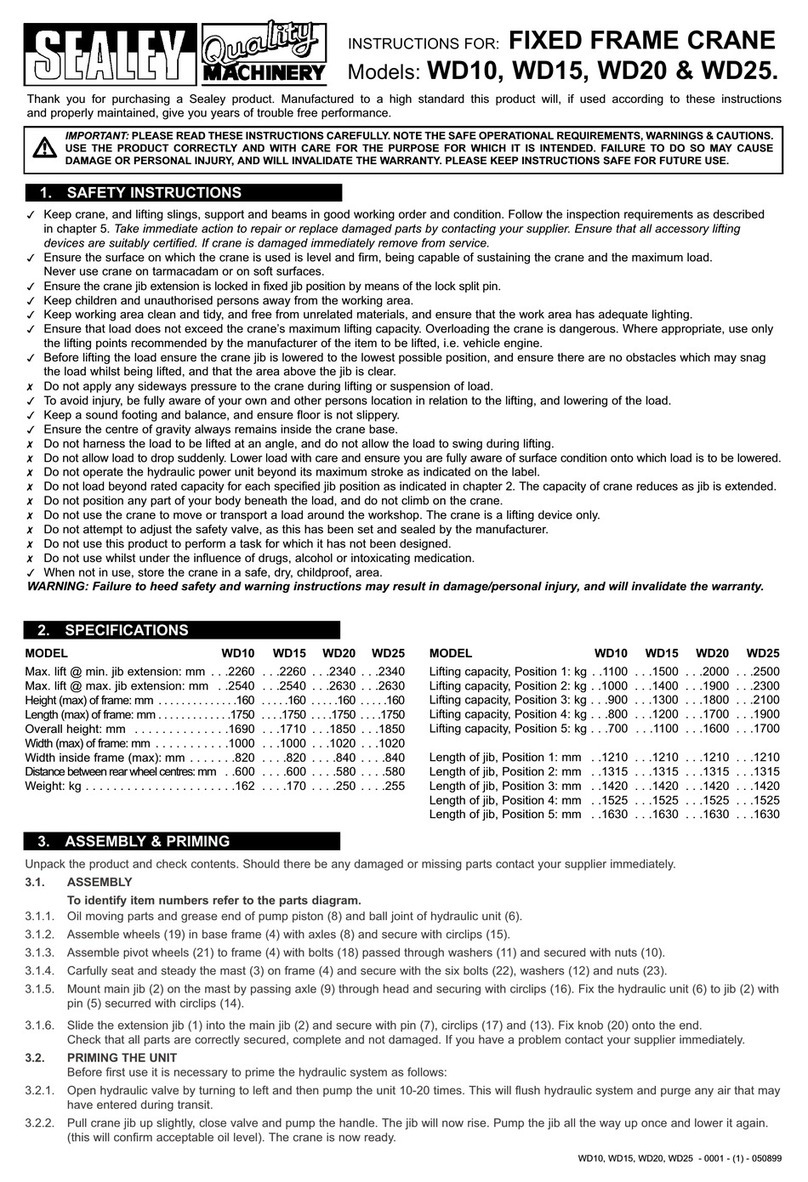

3.2. OPERATION. (Refer to Section 4.2 regarding inspection before each and every use).

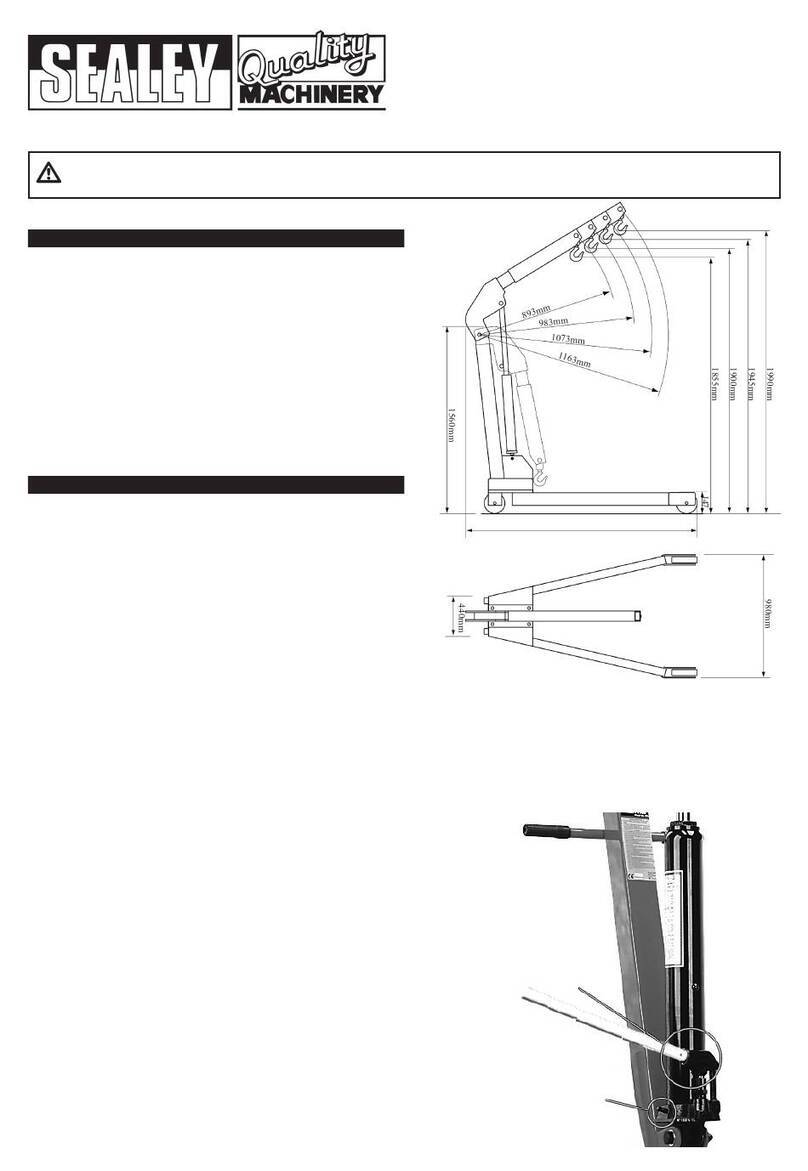

a) Use the pump handle recess to tighten the release valve, turning firmly clockwise.

b) Place handle into pump socket and pump, the jib will raise. Continue to pump until the jib reaches the height at which the load can be secured.

c) Connect the crane hook to the load using a suitable sling or support beam. Be aware of the load weight, and check that it is

within the capacity of the crane (at the jib extension you are using) and the sling or support beam. When removing engines ensure the

weight to be lifted is known. Use only the lifting points recommended by the vehicle manufacturer.

d) Lift only from directly above the load. WARNING! DO NOT LIFT THE LOAD AT AN ANGLE!

e) To lower load, position handle on release valve at base of ram and turn VERY SLOWLY anti-clockwise avoiding any sudden movement.

WARNING! DO NOT allow the load to drop suddenly.

f) The crane is not a transportation device but may be used to reposition the load being worked on. To do so, lower load and jib

with care, to the lowest possible point before attempting to move. DO NOT try to move crane in a sideways direction. The crane is

not designed to support the load indefinitely. When the load has been repositioned, lower the load onto a secure and

appropriate working base, being fully aware of your own and other persons locations in relation to the lowering load.

g) When load has been secured, remove lifting sling, support beam etc. and place crane in a safe location with lifting beam fully lowered.

NOTE: The crane MUST be kept clean and dry and must be maintained in accordance with these instructions.

4.1. LUBRICATION.

a) Oil all working parts monthly.

b) The ram is filled with oil and should only require occasional topping up. For the occasional top up DO NOT use brake fluid, as this will

damage the hydraulic seals. Proceed as follows:

1) Use only good quality hydraulic jack oil available from your Sealey supplier.

2) DO NOT OVERFILL as this will cause failure.

3) After filling with hydraulic oil, pump the crane up to its full height and pour off any excess oil.

4.2. INSPECTION AND EXAMINATION OF CRANE BEFORE USE.

a) Before each use of the crane, perform an inspection for leaks, damage, loose or missing parts.

b) The workshop crane must be examined immediately if it has been subject to an abnormal load or shock. It is recommended that such

an examination is made by an authorised service agent.

c) The owner and/or operator must be aware that repair of this equipment will require specialised knowledge and facilities.

It is recommended that an annual examination of the workshop crane is made by an authorised service agent.

d) Unauthorised parts may be dangerous and will invalidate the warranty.

Note! See the Definition of ‘Inspection’ and ‘Examination’ below.

INSPECTION:

Inspect the crane for defects and check the operation of controls, limiting and indicating devices without loading the crane.

This check does not normally require any part of the crane to be dismantled other than removal or opening of covers or housings.

EXAMINATION:

Verification that the crane can safely continue in service including a functional test of all safety devices i.e. limiting, indicating

equipment, brakes, clutches, safety valves etc to verify that they operate within the required tolerances. An examination is more

thorough than an inspection.

4. MAINTENANCE / EXAMINATION / INSPECTION

Original Language Version PH20.V4 Issue: 4 - 26/06/17

© Jack Sealey Limited