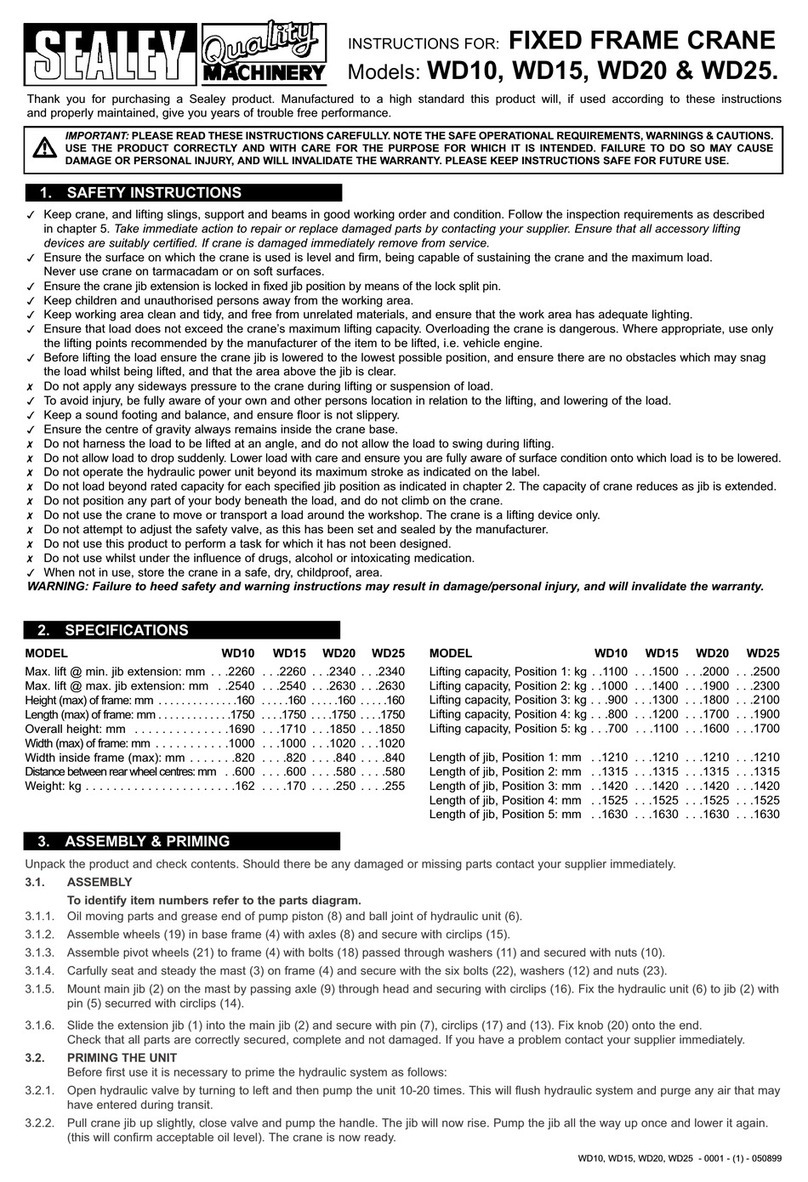

3. SPECIFICATION

Model No:...................................................................SSC750

Height Jib Down:......................................................1530mm

LengthofJibPosition1:.............................................825mm

LengthofJibPosition2:........................................... 1180mm

LiftingCapacityinPosition1:.......................................750kg

LiftingCapacityinPosition2:.......................................250kg

Max.LiftHtatJibPosition1:....................................2060mm

Max.LiftHtatJibPosition2:....................................2350mm

3.1. Foradescriptionofin-serviceandout-of-serviceconditionssee

Section1Safety,Section6Maintenance.

3.2. Thecraneisttedwithabypassvalvethatwillpreventtheramfrom

over extending.

3.3. ForapplicationsseeSection1Safety.

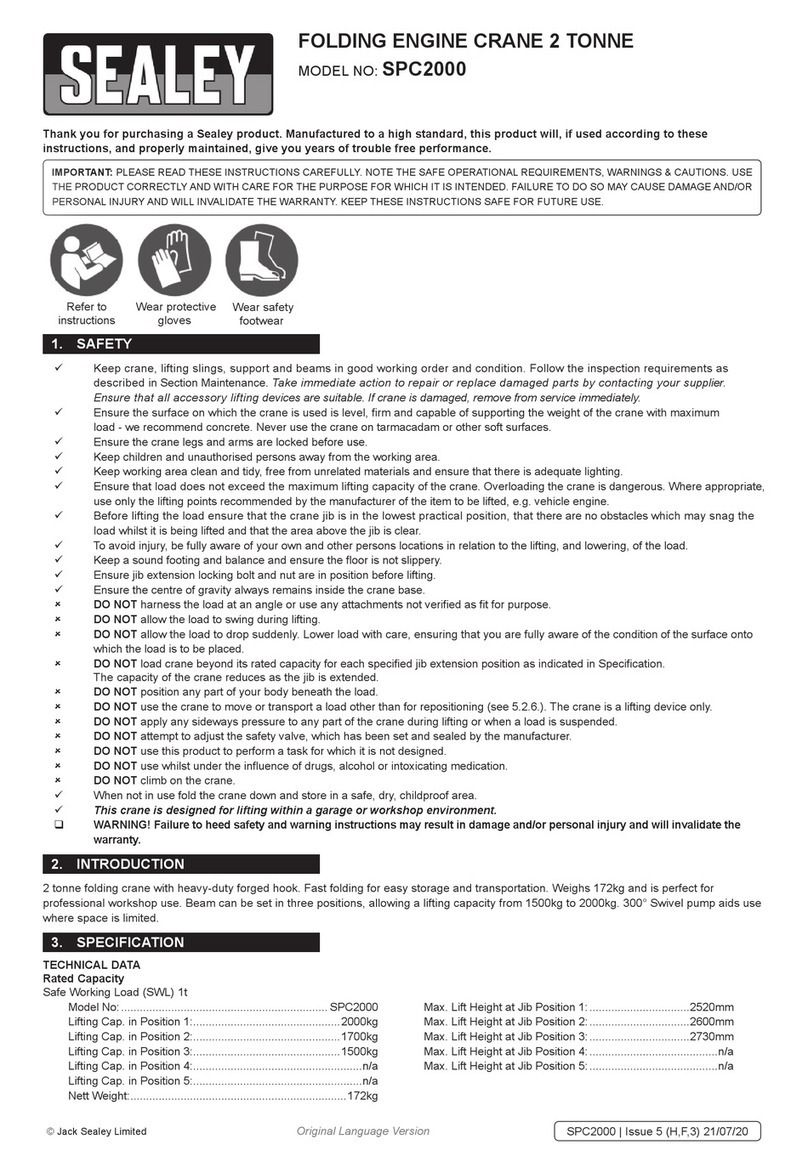

3.4. Forcontrolsystem,seeg.2forreleasevalve,pumpassemblyand

handle.OperationisexplainedinSection5.

3.5. Forgroundconditionrequirements,seeSection1Safety.

3.6. For information on parts and materials requiring specialised repair

techniques see Section 6 Maintenance.

4. ASSEMBLY

WARNING!Thebase(g.1)mustbefastenedsecurelytothesurface or vehicle on which it is to be mounted.

Owing to the design of this crane, the mounting is

subject to substantial leverage.

No liability will be accepted for incorrect mounting or use of this crane.

4.1. Solid Mounting: Use anchor bolts of suitable size and design to secure the base.

If in any doubt, consult a specialist with the relevant knowledge.

4.2. VEHICLE MOUNTING: When mounting on a vehicle, consult the vehicle

manufacturerand/orbody-buildertodetermineasuitablelocationon

whichtomountthecrane.Incorrectmountingcouldaectthestabilityofthe

vehicle when using the crane.

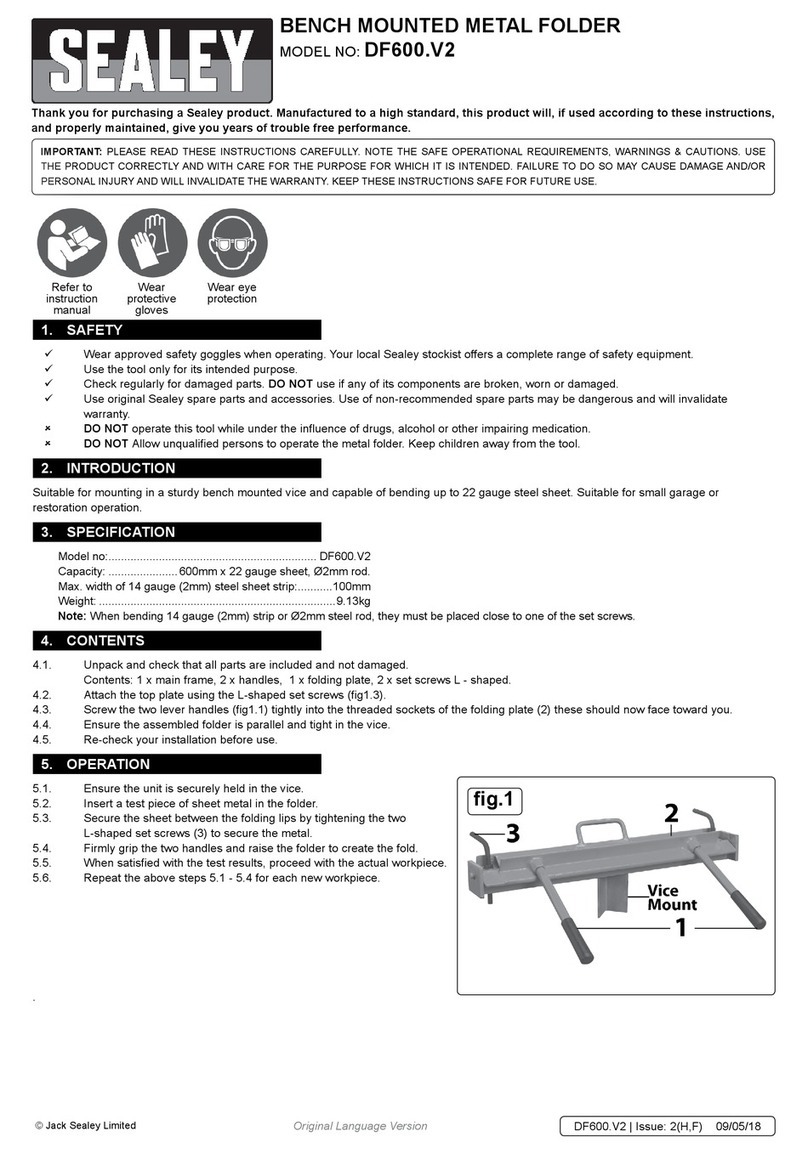

4.3. CRANE ASSEMBLY:(Partnumbersrefertothepartsdrawing).

4.3.1. Ifrequired,boltwheelhub(part2)ontopost(part9)usingbolts(part3),

securing with washers and nuts.

4.3.2. Attachboom(part12)topostusingbolt(part10),securingwithwashersand

nut.

4.3.3. Attachlowerendofjack(part8)topostusingbolt(part6),washersandnut.

4.3.4. Similarly,attachupperendofjacktoboomusingbolt(part11),washersandnut.

4.3.5. Slideboomextensionintoboomandsecurewithpin(part13).

4.3.6. Attachhookandchain(part16)usingbolt(part15),washersandnut.

4.4. Beforeuse,purgethehydraulicsystembyopeningthereleasevalve(g2.B)

slightlyandoperatingthepumpforabout20strokes.Closethereleasevalve

andcheckoillevelasinsection6.1.B.

5. OPERATION

5.1. OPERATION(RefertoSection6.2regardinginspectionbeforeeach

andeveryuse).

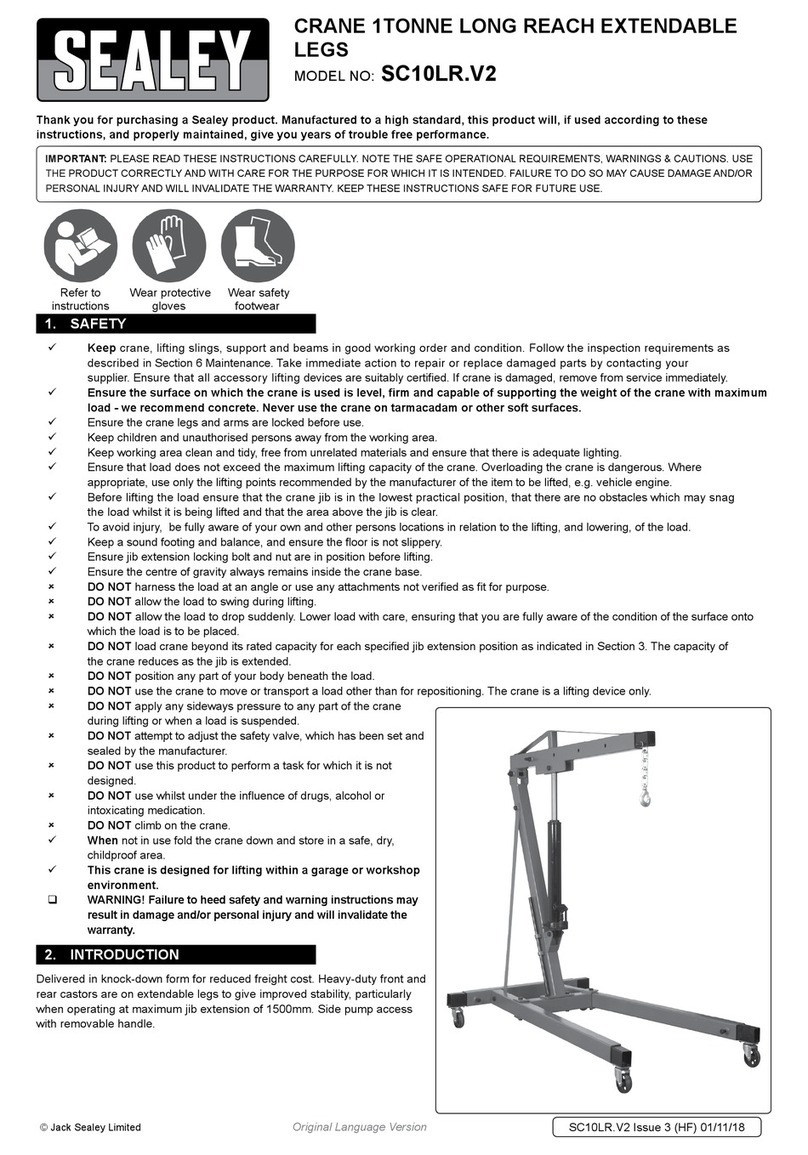

5.1.1. Loosenlockingarm(g.3)allowingmasttorotate.

5.1.2. Placepumpinghandle(gs.2.E&4)intopumpsocket(g.2.A)and

pump, the boom will raise. Continue to pump until the boom reaches

the height at which the load can be secured.

5.1.3. Connect the crane hook to the load using a suitable sling or support

beam. Ensure you are aware of the load weight, and check that it is

withinthecapacityofthecrane(attheboomextensionyouareusing)

and the sling or support beam.

5.1.4. Lift only from directly above the load. WARNING! DO NOT lift the

load at an angle!

5.1.5. Toslewthecraneanditsload,placetheslewinghandle(g.4)into

the socket and use as a lever, taking care not to place yourself or

any other person in the path of the load. If vehicle mounted, monitor the attitude of the vehicle and stop lifting if any sign of

instability becomes apparent.

5.1.6. Tolowerload,placethenotchesintheendofthepumphandleoverthelugsonthereleasevalve(g.2.B)andturnWARNING!

DO NOT allow the load to drop suddenly.

5.1.7. When load has been secured, remove lifting sling, support beam etc. Secure the crane with boom fully lowered and the locking arm

tightened.

6. MAINTENANCE/INSPECTION

NOTE: The crane MUST be kept clean and dry and must be maintained in accordance with these instructions.

6.1. LUBRICATION

A) Oilallworkingpartsmonthly.

250mm

++

105mm

ø17mm

g.1

g.2

g.3

Original Language Version

© Jack Sealey Limited SSC750Issue109/03/23

g.2