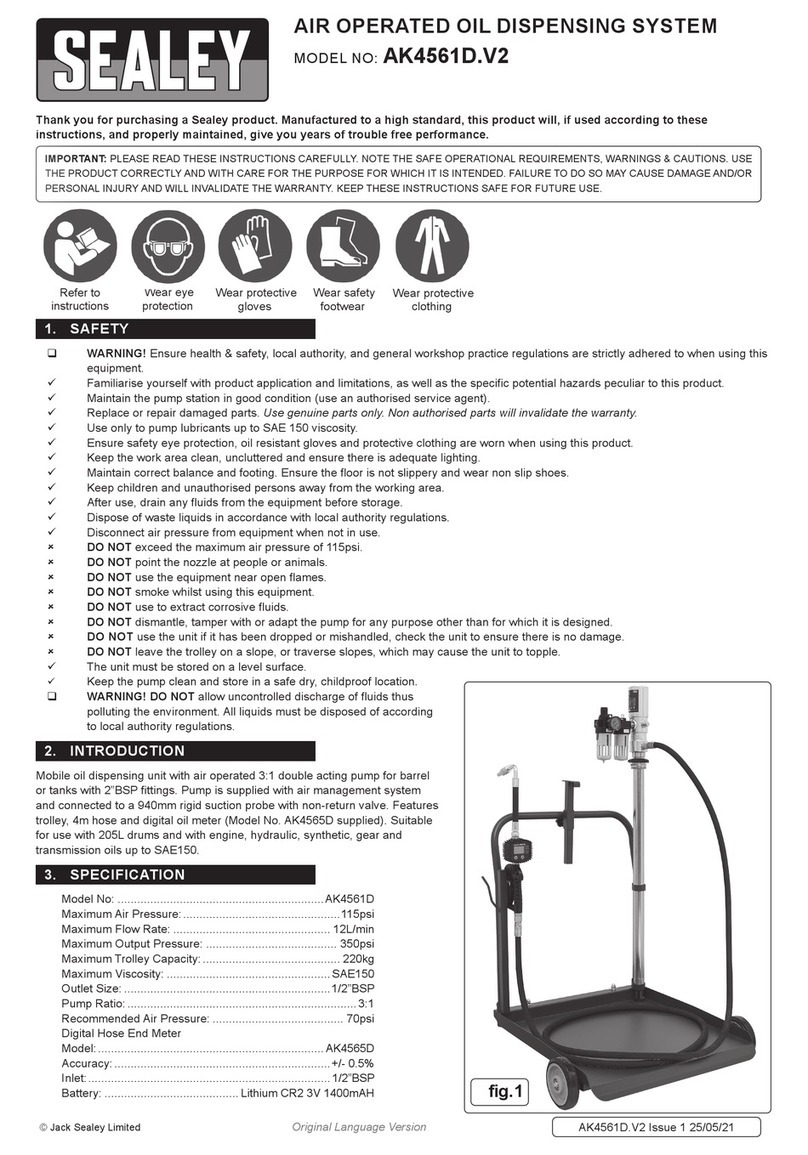

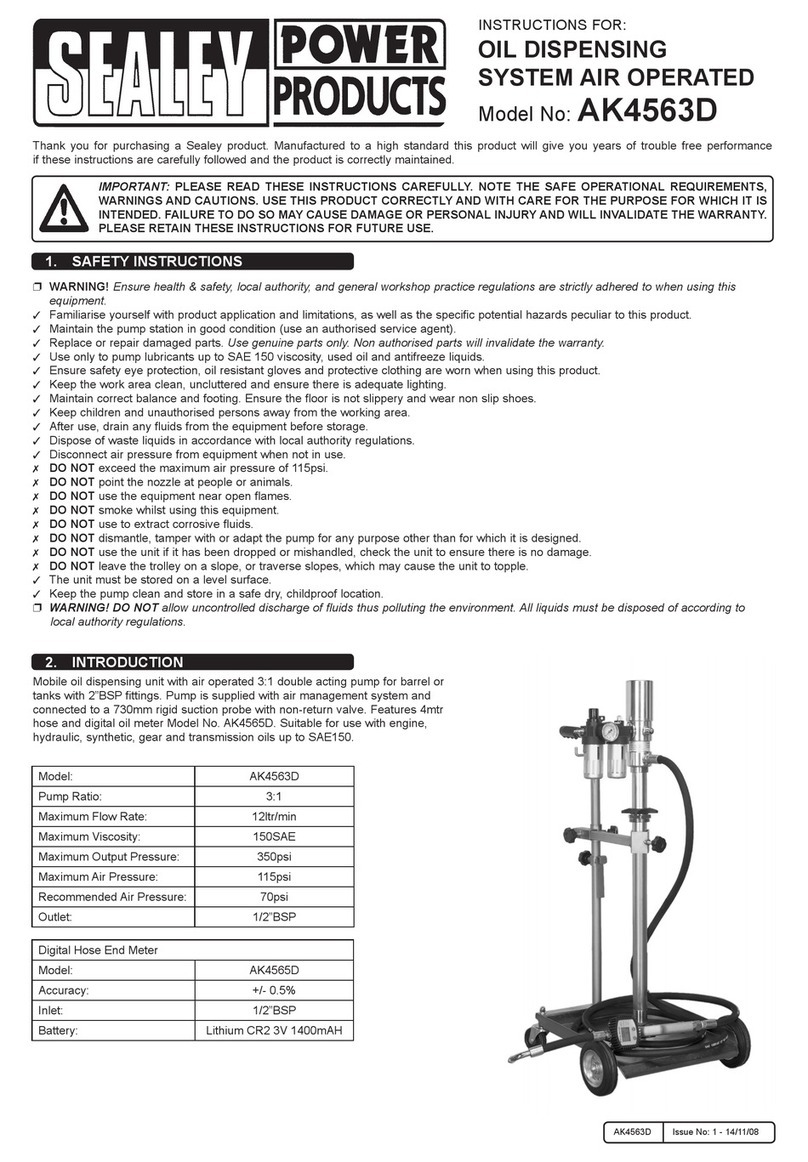

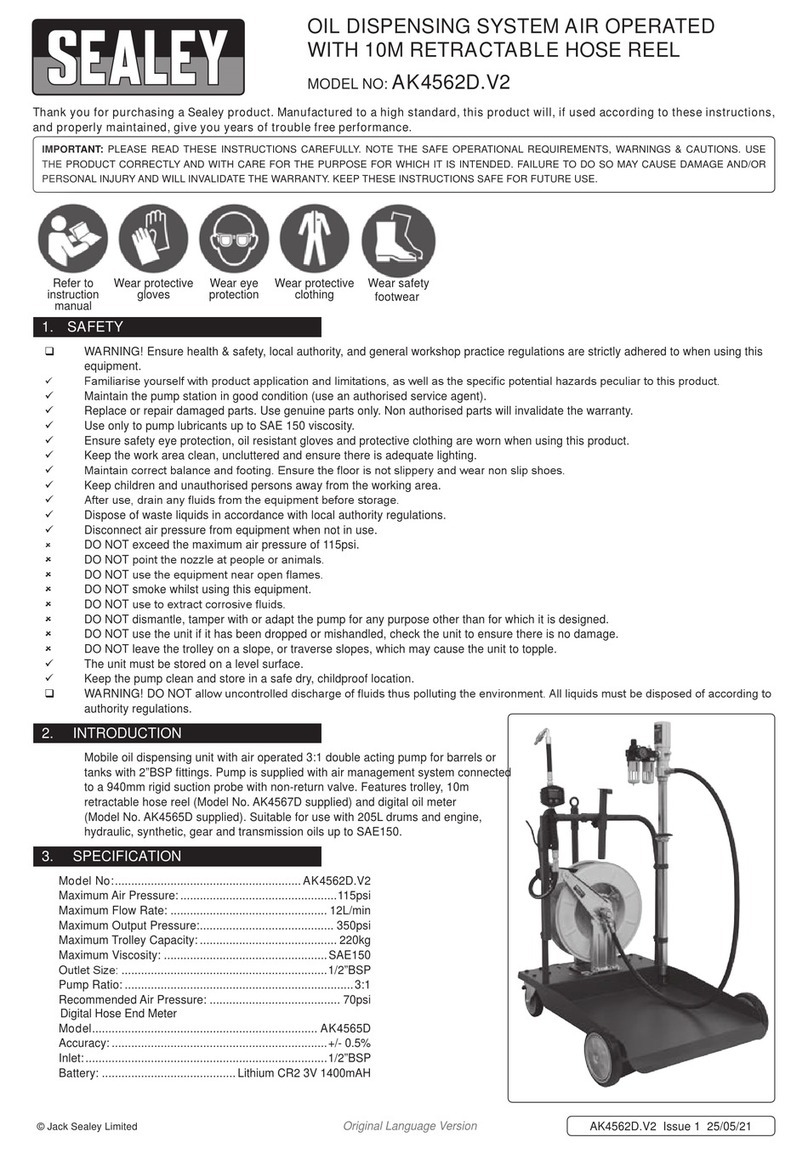

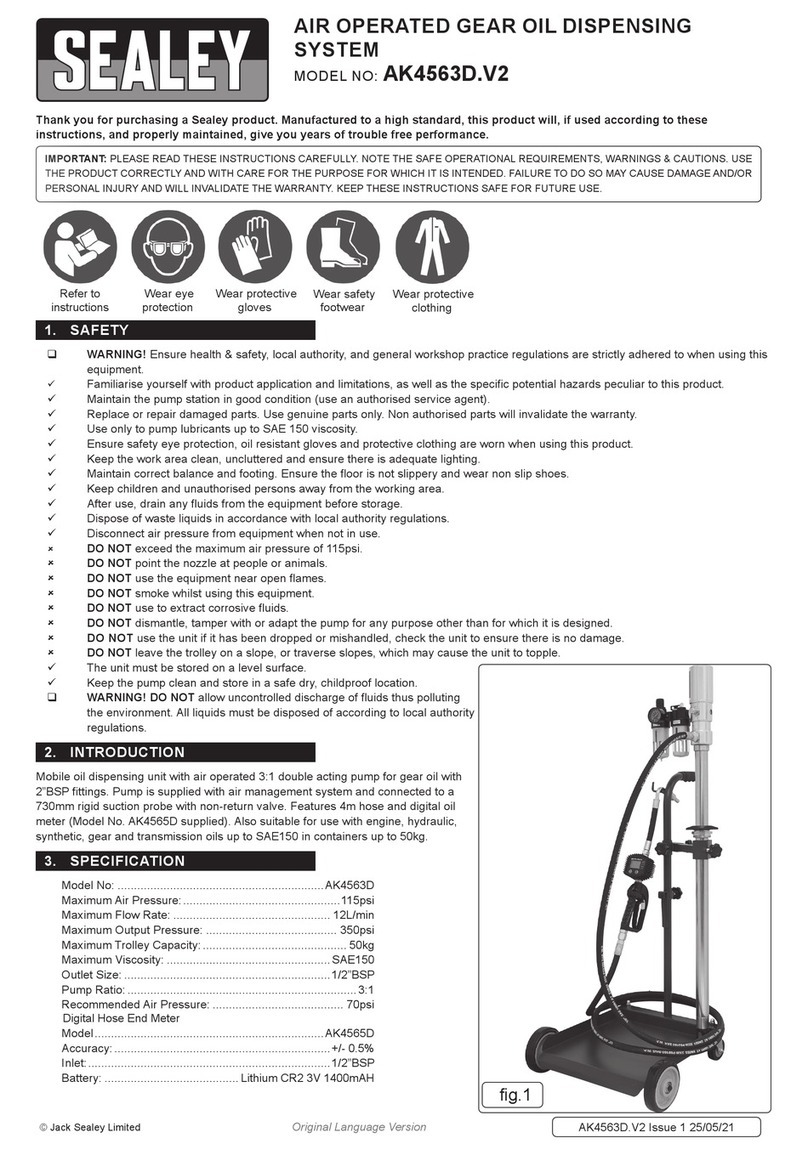

4.1 Place a 205ltr drum onto the trolley, locate the drum using the drum holder

support(g1.2)andsecurewithknob(g.1.1).

4.2 Installing the pump

4.2.1 Remove the bung from the 2"BSP opening of the drum.

4.2.2 Slacken off the locking nut on the pump probe and insert the pump into

the drum until the probe bottoms out, tighten the barrel nut and then

tightenthelockingnuttoxthepumptothedrum.

4.3 Setting up the pump

4.3.1 Ensure that the air regulator valve is fully wound anti-clockwise and then

connect the air supply onto the quick release connector on the air

regulator.

4.3.2 Lift the knob on the regulator and slowly turn clockwise until the

recommended operating pressure of 70psi is reached, push down on the

regulator knob to lock the position.

Note: Check the system for leaks, should an air leak be discovered, release the

pressure, disconnect the air line and repair the joint or seal before

continuing.

4.4 Operating the gun

❐ WARNING! Ensure that the trigger is not depressed before opening the

nozzle valve.

4.4.1 Press the Reset button for 1 sec to zero the display.

4.4.2 With the nozzle pointing into the receiving container, open the nozzle valve

asshowning.4.

4.4.3 Depress the trigger and dispense the liquid the amount dispensed is

shownonthedisplay(g.5.4).

4.4.4 Release trigger and close the nozzle valve.

4.5 Determining the Correction Factor

4.5.1 Dispense at least 1 litre of liquid into a calibrated container.

4.5.2 Record the quantity of liquid in the container and record the quantity of

liquid dispensed as indicated on the meter display. Press the Move +

Resetbuttons(g.5.1andg.5.2)simultaneouslytodisplaythecurrent

correction factor.

Qty Dispensed

Qty Indicated x Current Correction Factor = New Correction Factor.

4.6 Programming the Correction Factor

4.6.1 Remove the rubber protective cover from the meter and unscrew the four

phillipsscrews(g.6)holdingthedigitalmeter,removefromthegun.

4.6.2 Pressbutton"2"ontherearofthemeter(g.7.2)for1sectoenterthe

Correction Factor mode.

4.6.3 Press the Move button to select the digit to be changed, each press of the

Move button will select the next digit.

4.6.4 Press the Reset button to add 1 on the digit, press as many times as

required until the correct number is reached.

4.6.5 Press "2" for 1 sec to quit the Correction Factor mode.

4.6.6 Press the Move + Reset buttons simultaneously to display the new

correction factor.

4.7 Changing the Units

Note: The meter is pre-set to display litres.

4.7.1 Press button "2" on the rear of the meter for 1 sec to enter the Correction

Factor mode.

4.7.2 PresstheMovebuttonvetimestoselecttheunits(g.5.3).

4.7.3 Press the Reset button to scroll through the Units (L/Gal/PT/QT), select

the Unit required.

4.7.4 Press "2" for 1 sec to quit the Correction Factor mode.

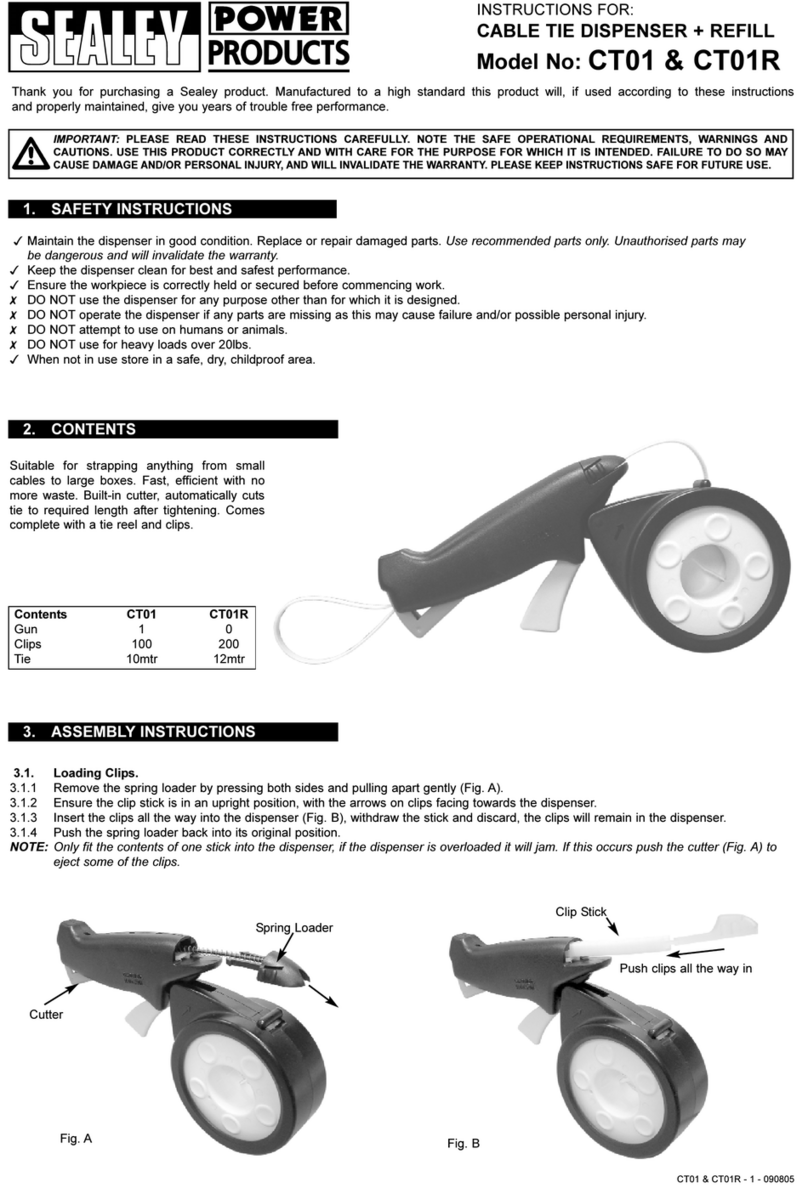

4. OPERATION

AK4561D Issue No: 1 - 14/11/08

g.5

3

4

12

g.7

2

1

g.4

g.6

Meter

Screws

Battery Cover

3.3 Pre-Operation

3.3.1 Liftuptheknob(g.2A)ontheairregulatorandensurethattheknobis

wound fully anti-clockwise.

3.3.2 Removethellerplug(g.2B)fromthelubricatorandllthelubricatorwith

aqualityairtooloil(SealeyATO1000S),retthellerplug.

3.3.3 The lubricator feed is set when the unit is running, adjust the feed knob

(g.2C)thedripratecanbeseenthroughthesightglassofthedome.The

rate of oil feed will automatically increase or decrease inline with the air

ow.