Original Language Version

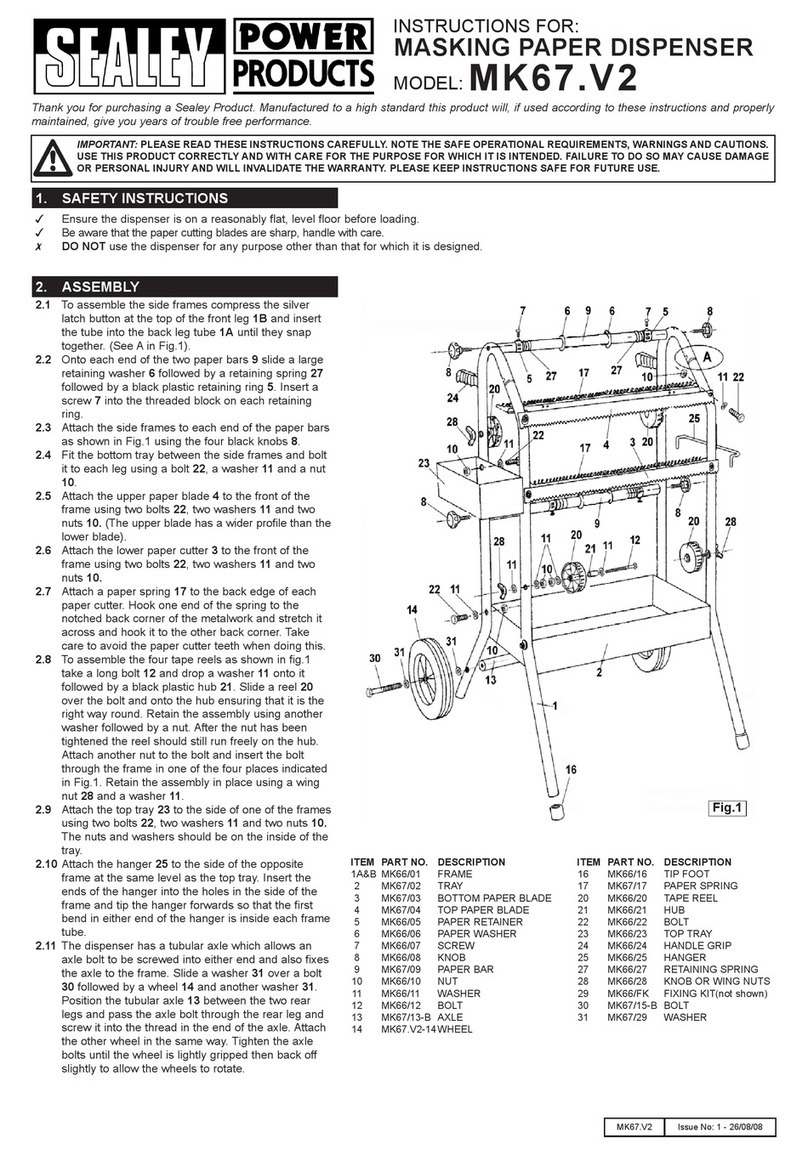

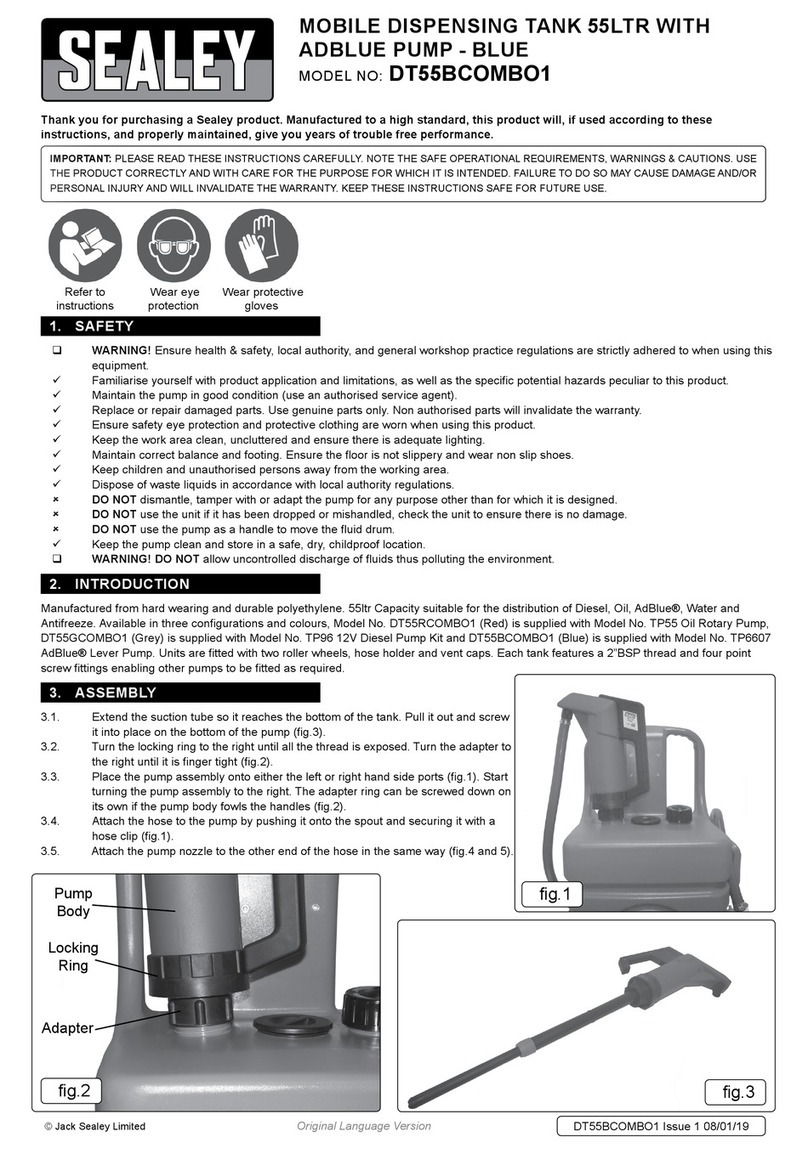

Numbers in BOLD refer to the diagram in Fig.1

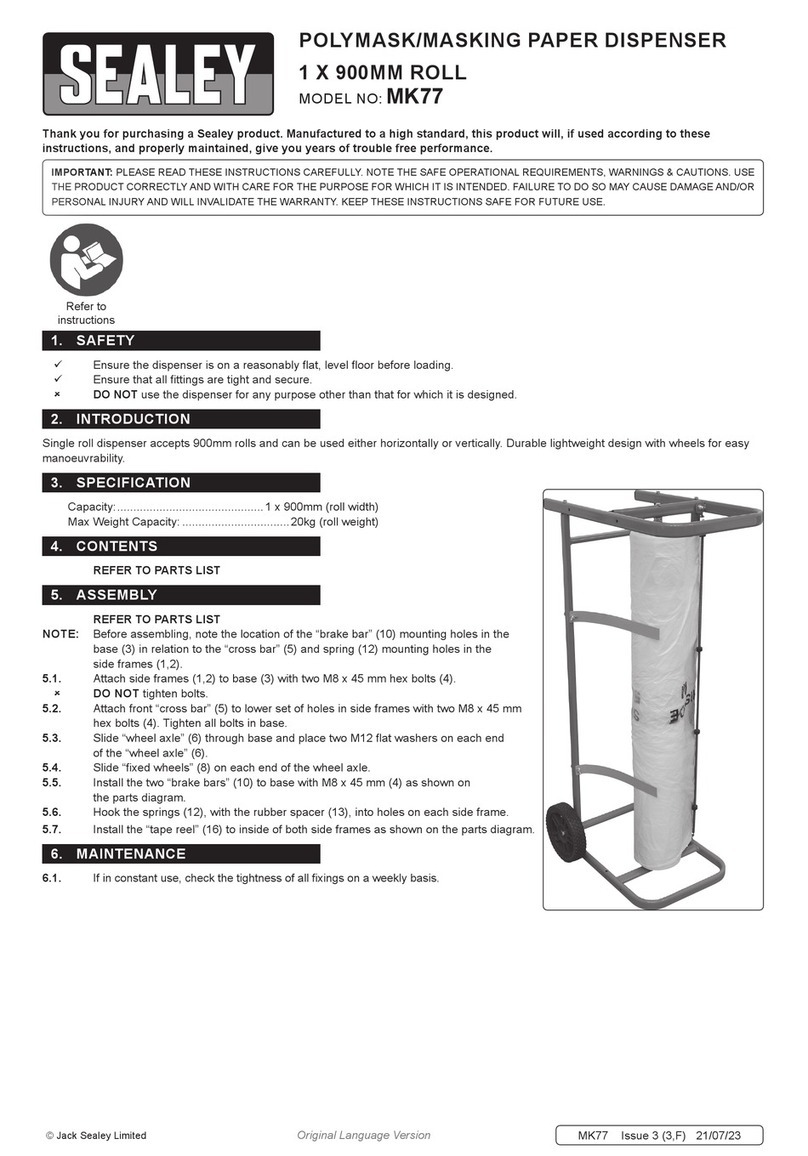

2.1 To assemble the side frames compress the silver latch

button at the top of the front frame 1and insert the tube

into the back frame tube 1A until they snap together.

2.2 Onto each end of the two paper bars 20 slide a paper

holding ring 5followed by a washer 16, holding spring

17 and another washer 16, followed by a paper holding

ring 5. Insert a screw 12 into the threaded block on each

holding ring.

2.3 Attach the side frames to each end of the paper bars as

shown in the main drawing using the four wing bolts 13.

2.4 Fit the bottom tool tray between the side frames and bolt

it to each leg using bolt 10, nut 22 and washer 23.

2.5 Attach the upper paper blade 7to the front of the frame

using two screws 10, two nuts 22 and two washers 23.

2.6 Attach the lower cutting blade 7to the front of the frame

using two screws 10, two nuts 22 and two washers 23.

2.7 Attach a paper spring 7A to the back edge of each

cutting blade. Hook one end of the spring to the notched

back corner of the metalwork and stretch it across and

hook it to the other back corner. Take care to avoid the

cutting blade teeth when doing this.

2.8 To assemble the four tape reels as shown in Fig.2 take a

long bolt 14 and screw on to it a wing nut 6 then drop a

washer 23 onto it followed by a metal bush 21. Slide a

reel 8over the bolt and onto the bush ensuring that it is

the right way round. Retain the assembly using another

washer followed by a wing nut 6. After the nut has been

tightened the reel should still run freely on the bush.

Attach another nut to the bolt and insert the bolt through

the frame in one of the four places indicated on the main

drawing. Retain the assembly in place using a nut 22

and a washer 23.

2.9 Attach the small tool tray 15 to the side of one of the

frames using two screws 10, two nuts 22 and two

washers 23. The nuts and washers should be on the

inside of the tray.

2.10 Attach the hanger 9to the side of the opposite frame

at the same level as the top tray. Insert the ends of the

hanger into the holes in the side of the frame, tip the

hanger forwards so that the first bend in either end of

the hanger is inside each frame tube.

2.11 The MK66.V4 has a solid rod axle 4with holes at either

end to accept cotter pins 11. Slide the axle through the

holes near the bottom of each rear leg.

2.12 Slide a wheel 3onto each end of the axle and retain it

with a cotter pin 11 through the axle. Secure by bending

the pin back onto itself.

2.13.Push a plastic tube cover 19 over each front leg.

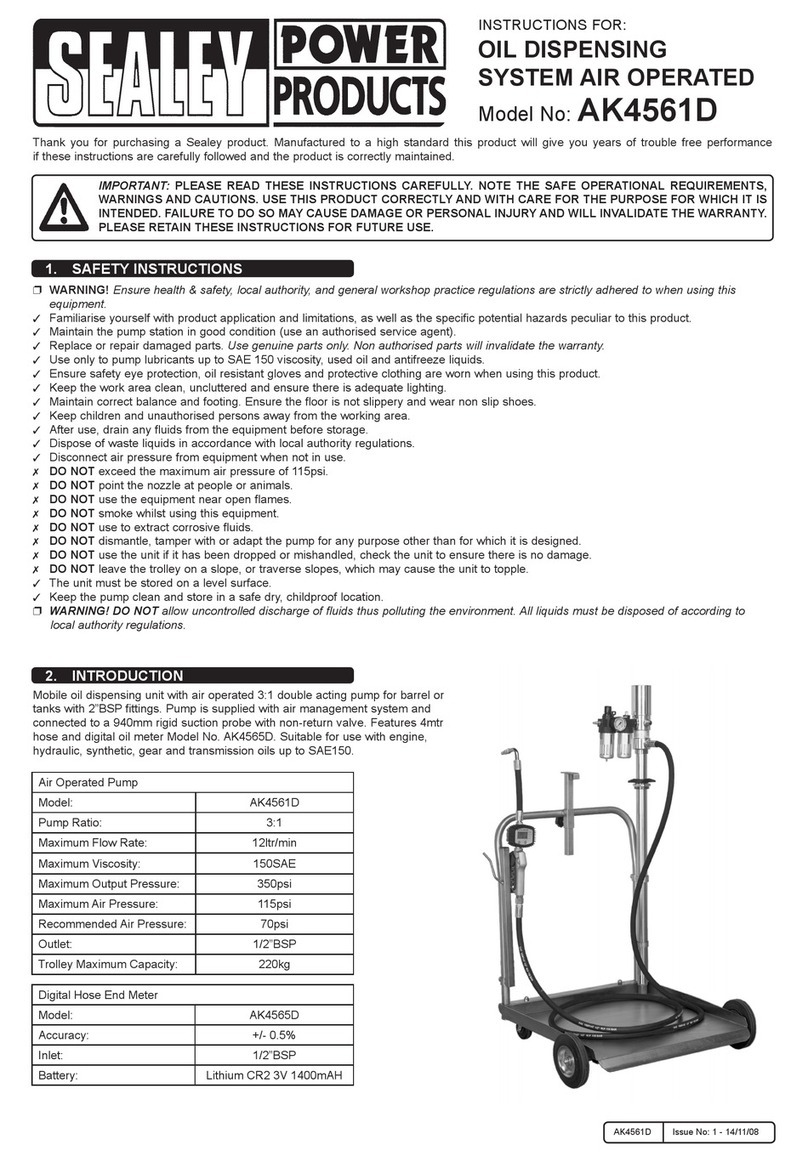

INSTRUCTIONS FOR:

MASKING PAPER DISPENSER

MODEL No: MK66.V4

1 FRONT FRAME

1A REAR FRAME

2 TOOL TRAY (LARGE)

3 WHEEL

4 AXLE

5 PAPER HOLDING RING

6 WING NUT

7 CUTTING BLADE

7A CUTTING BLADE SPRING

8 TAPE REEL

9 HANGER BAR

10 BOLT

11 COTTER PIN

Ensure the dispenser is on a reasonably flat, level floor before loading.

Ensure that all fittings are tight and secure.

Be aware that the paper cutting blades are sharp, handle with care.

DO NOT use the dispenser for any purpose other than that for which it is designed.

12 WING BOLT M5 x 15

13 WING BOLT

14 LONG BOLT

15 SMALL TOOL TRAY

16 PAPER HOLDING WASHER

17 PAPER HOLDING SPRING

18 HANDLE GRIP

19 PLASTIC TUBE COVER

20 PAPER BAR

21 BUSHING FOR TAPE REEL

22 NUT M6

23 WASHER M6

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions and maintained properly, give you years of trouble free performance.

Refer to Instruction

Manual

1. SAFETY

2. ASSEMBLY

© Jack Sealey Limited MK66.V4 Issue: 1 - 24/06/16

Fig.1