WARNING! These jacking beams weigh 94kg and 102kg respectively. Seek

assistance before attempting to locate jacking beam on ramp or inspection pit

runners.

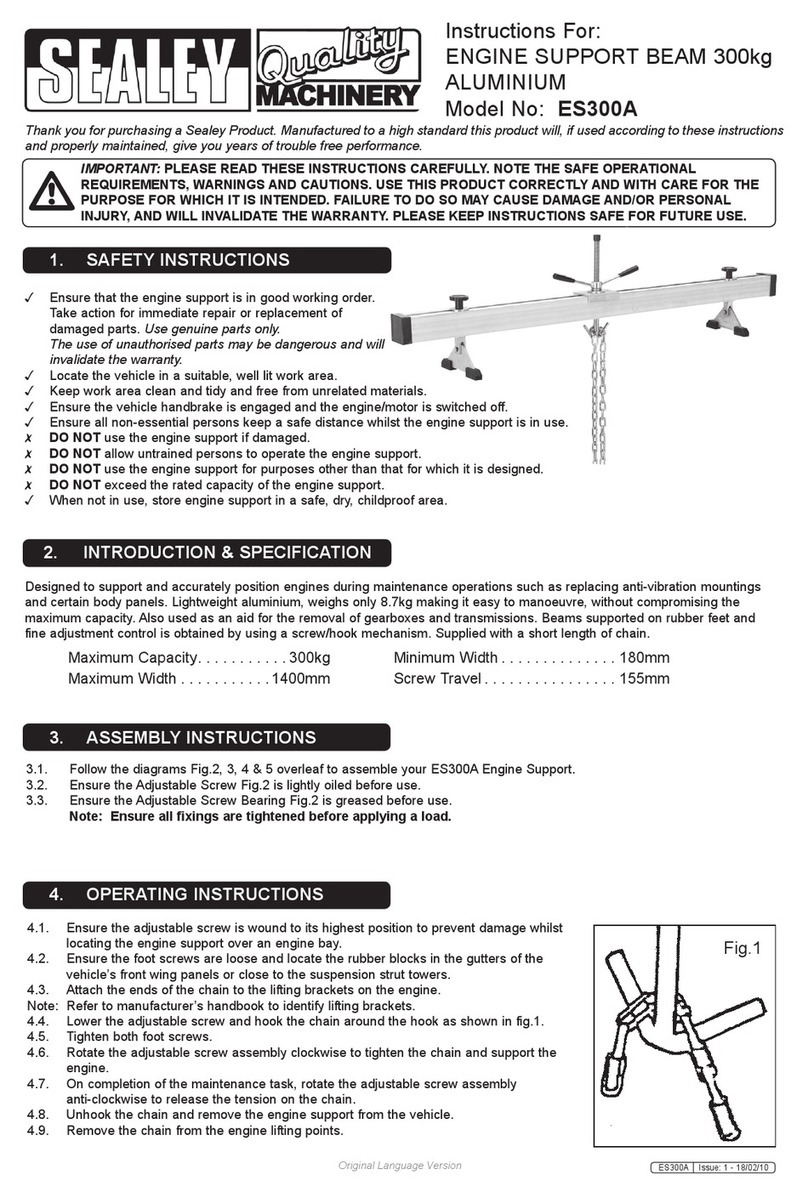

3.1. Locating jacking beam.

3.1.1. Extend the roller arms to the correct width for ramp or pit runners. See fig.3 overleaf.

3.1.2. With the beam central on the ramp/pit and the rollers located on the runners, tighten

the roller arms set bolts. (Fig.2)

3.1.3 Adjust the spring tension on all four rollers (see fig.3 overleaf) so that the rollers

will just support the weight of the jacking beam on its own and allow it to travel

freely over the ramp/pit. Note that too much spring tension will cause the rollers to

jam against the side arms. When the jacking beam is in use the weight of the vehicle

will overcome the spring tension, pushing the rollers upwards and allowing the

jacking beam to settle onto the two roller arms.

3.1.4. Before use you must remove the transportation plug and fit the supplied vent valve

in its place. (Fig.1)

INSTRUCTIONS FOR:

JACKING BEAMS

MODELS: SJBEX200.V2 & SJBEX300

Your new jack is produced and manufactured to a high standard of dependability and will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS JACK CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

1. SAFETY PRECAUTIONS

2. SPECIFICATIONS

Fully certified and approved to comply with VOSA requirements. Features two stage

mechanical safety lock and telescopic finger guards to prevent accidental injury. Supplied with

two pairs of aluminium support blocks. Beam has spring loaded flat arms with roller bearings

when unloaded, these support the weight of the beam, allowing the entire unit to run smoothly

along the pit or ramp, but when loaded locate the unit firmly. Wide lift configuration meets

VOSA recommendation for lifting on jacking point.

Ensure the beam is in sound condition and good working order. Take action for immediate repair or replacement of damaged parts.

Use genuine parts only. The use of improper parts may be dangerous and will invalidate the warranty.

Inspect the beam before each use. DO NOT use the beam if it is damaged, altered, modified, in poor condition, leaking hydraulic fluid, or

unstable due to missing parts.

DO NOT alter or modify this beam in any way.

DO NOT load the beam beyond its rated capacity.

DO NOT operate the beam if damaged.

DO NOT allow untrained persons to operate the beam.

DO NOT use the beam for purposes other than that for which it is intended.

DO NOT use the centre saddle if the work to be performed can cause

the load to move.

DO NOT top up hydraulic system with brake fluid. Use hydraulic

jack oil only.

Use the beam only for its intended purpose.

Consult the vehicle manufacturer for the correct lifting locations.

Make sure the vehicle is in park and the handbrake is on before attempting to raise the vehicle.

Only use the saddles provided with the jacking beam.

Be sure setup is stable and secure before lifting. Be careful of pinch points.

This is a lifting device only. Make sure the load is centered on saddles before lifting.

The beam can only be used to lift one end of the vehicle.

Ensure that there are no persons or obstructions beneath the vehicle before lowering.

Always lower load slowly and carefully.

When not in use store beam fully lowered.

Ensure all non-essential persons keep a safe distance whilst the beam is in use.

Use a qualified person to maintain or repair the beam’s hydraulic system.

WARNING! Failure to heed these precautions may result in loss of load, damage to beam and/or personal injury.

3. PREPARATION

Model .....................SJBEX200.V2............SJBEX300

Capacity:...................2ton ...................3ton

Support Arm Reach: ..........780 - 1075mm ...........780 - 1075mm

Beam Lift: ..................95 - 300mm .............95 - 300mm

Load Arm Reach: ............850 - 1600mm ...........850 - 1600mm

Net Weight:.................94kg ...................102kg

Fig.1

Fig.2

TRANSPORTATION PLUG

REMOVE AND REPLACE WITH VENT

VALVE BEFORE USE.

Original Language Version SJBEX200.V2, SJBEX300 Issue: 4 - 16/10/09