INSTRUCTIONS FOR:

DIESEL & FLUID FLOW METER

MODEL No: TP91300.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLYAND ONLY FOR ITS INTENDED PURPOSE. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY

AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

Maintain the meter in good condition (use an authorised service agent).

Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Keep the meter clean for the safest and best performance.

Ensure that a fuel filter is securely attached to any pick up pipe so that unfiltered fuel is not taken through the meter.

Wear safety goggles, gloves and protective clothing when working around fuel. A full range of personal safety equipment is available from your

local Sealey dealer.

Use the meter in a suitable work area. Keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the work area.

DO NOT use the meter and any associated pump where explosive or flammable vapours may be present.

WARNING! DO NOT pump the following fluids through the flow meter: Petrol, flammable liquids with Flashpoint <55°C, water, liquids with

viscosity >20 cSt, corrosive chemicals and solvents.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION AND SPECIFICATION

3. INSTALLATION

Introduction:

Volumetric nutating disc meter with three digit resettable display and six

digit total display. Unique filter and flange assembly allows meter to be

positioned in four configurations. Suitable for use with all Sealey brand

diesel & fluid transfer pumps.

Specification:

Working pressure: ...................................................................0.1 - 3.5 Bar

Operating Temp:......................................................................-10 to +50ºC

Precision:.......................................................................................... +/- 1%

Flow Rate: .............................................................................20 - 80 ltr/min

Partial Indicator:.........................................................................max 999 ltr

Total indicator: .....................................................................max 999999 ltr

Resolution:..........................................................................................0.1 ltr

Weight: ...............................................................................................1.5kg

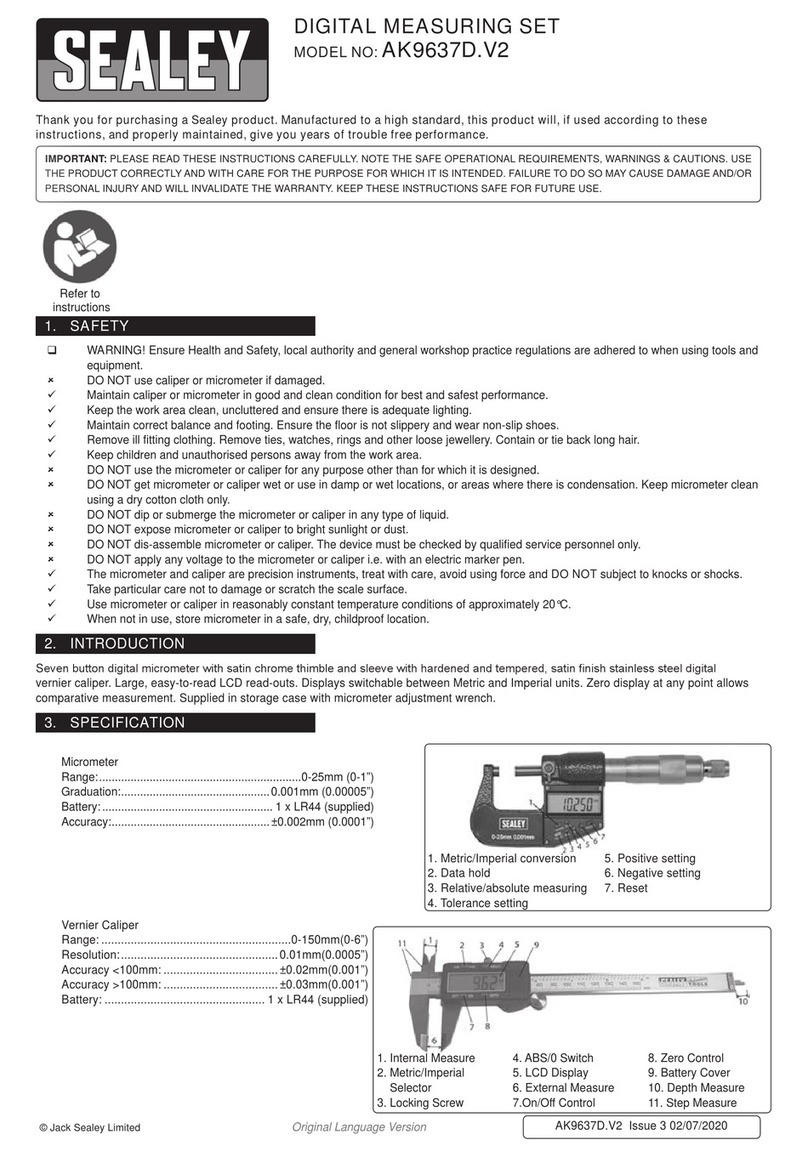

Accessories:

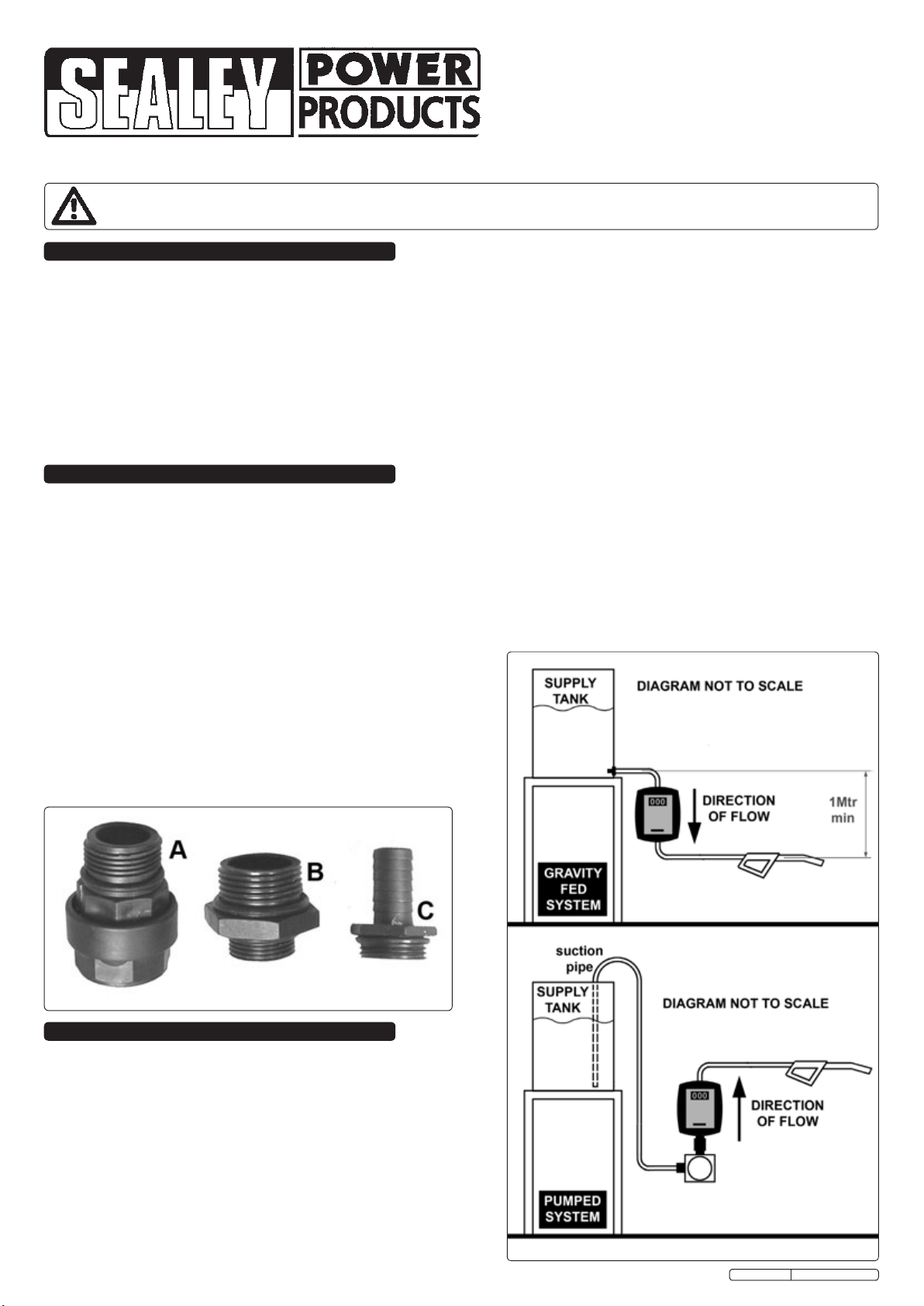

A- Swivel adaptor B- Pump connector

C- Outlet connector

TP91300.V2 Issue: 1 - 18/07/11

Original Language Version

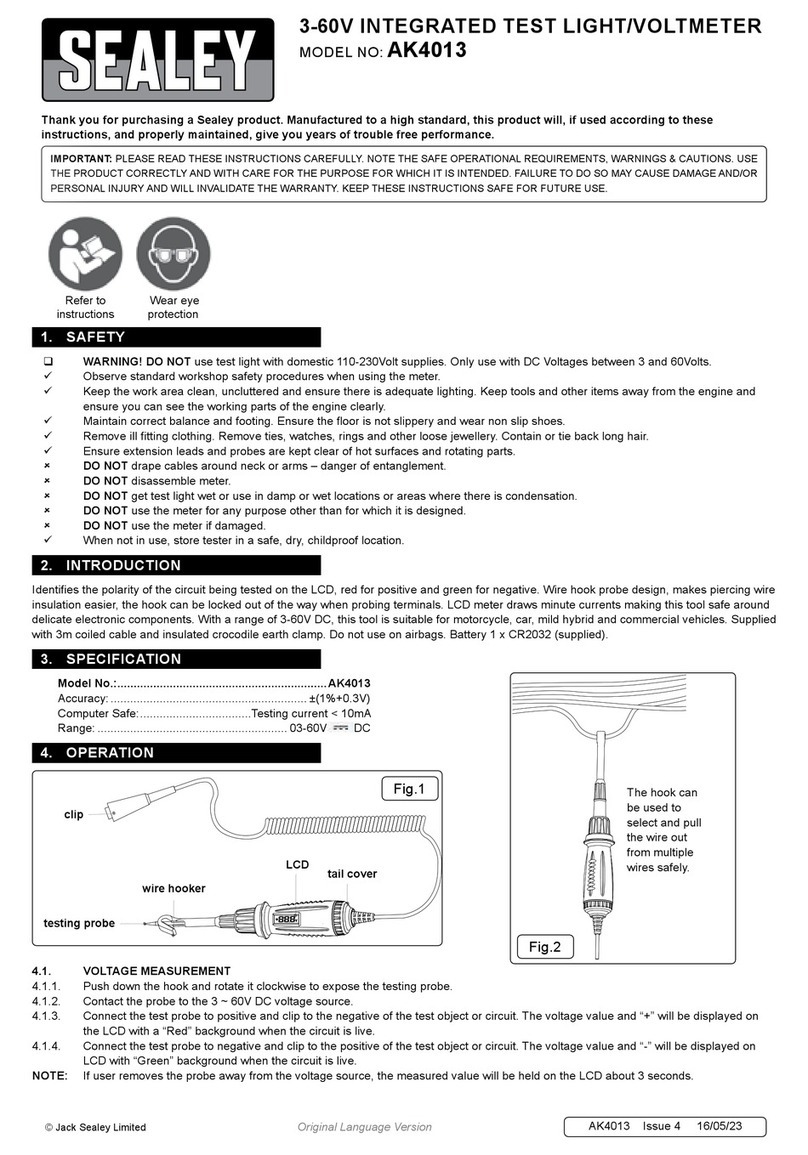

3.2.4 Following installation and setting, (see section.3.3) the meter is

ready for use. To reset the partial counter to zero, rotate the reset

knob clockwise.

3.2.5 Constructed for operation at a maximum pressure of 3.5 bar (50

PSI), the meter must be mounted in a such way that no unfiltered

liquid or air is pumped through it. In the case of gravitational

systems (without pumps), there must be a difference in height of at

least 1 metre between the outlet of the tank and the delivery gun

to ensure optimum operation.

fig.1

fig.2

fig.3

3.1 Installation options.

The TP91300.V2 flow meter can be used in both gravity fed

systems (see fig.2) and circuits with motor pumps (see fig.3) or

manual circuits equipped with a by-pass (not illustrated). In any

particular installation, attention must be paid to the direction of flow

through the meter as indicated by the moulded in arrows on the

back of the unit. If the required installation will result in the meter

readout being upside down it is possible to turn the face through

180º to correct this situation as described below.

3.2 Slide the reset knob from its shaft.

3.2.1 Undo both small crosshead screws at the sides of the plastic body.

3.2.2 Undo the four allen headed bolts at the back of the meter (fig.4)

and prise off the back of the meter and rotate through 180°

3.2.3 Reassemble in the reverse order of the above.