SG139.V2 - 1 - 250902

INSTRUCTIONS FOR:

UNDERBODY COATING GUN

Model: SG139.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR

THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURYAND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

pWARNING! Disconnect the gun from the air supply before changing accessories, servicing or performing any maintenance.

3Maintain the gun in good condition. Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may

be dangerous and will invalidate the warranty.

3Keep the gun clean and rinse out nozzle and pipes with paraffin after use.

p

p

WARNING! If gun components become blocked there is a danger of excessive pressure building up in unit causing the canister

to burst.

3Locate the gun in a suitable, well ventilated area. Keep area clean, tidy and free from unrelated materials and ensure there is

adequate lighting.

3Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

3Keep children and unauthorised persons away from the working area.

3Avoid unintentional operation.

3Ensure underbody coating manufacturers instructions are carefully followed.

7DO NOT hold gun or attachments close to your face (especially eyes, ears, etc.) and do not point gun or air hose at other persons

or animals.

7DO NOT carry by the air hose, or yank the hose or the gun from the air supply.

7DO NOT use the gun for any purpose other than for which it is designed and do not fill with any other fluid.

7DO NOT operate the gun if damaged.

3When not in use disconnect from the air supply and store in a safe, dry, childproof area.

2.1. Introduction

2.1.1. The SG139.V2 is used for anti-rust treatment of vehicles and agricultural machines by the application of underbody

coating. Fits a standard body schutz canister.

2.1.2. Check contents against the following list. If any item is damaged or missing contact your supplier immediately.

Gun Gun Nose Suction Tube

2.2. Specification

Air Supply . . . . . . . . . . . . . . . . . . . . .60 - 90psi

Air Consumption . . . . . . . . . . . . . . . . . . .10cfm

Connection . . . . . . . . . . . . . . . . . . . .1/4in BSP

3. PREPARING THE GUN FOR USE

3.1 Air Supply

3.1.1 Ensure the trigger is not depressed before connecting to the air supply.

3.1.2. An air pressure of no more than 90psi and an air volume of 10cfm will be required.

3.1.3. pWARNING! Ensure air supply does not exceed 90psi. Too high a pressure will shorten the product life and may

be dangerous, causing damage and/or personal injury.

3.1.4. Drain air supply tank daily. Water in the air line will damage the gun and will invalidate your warranty.

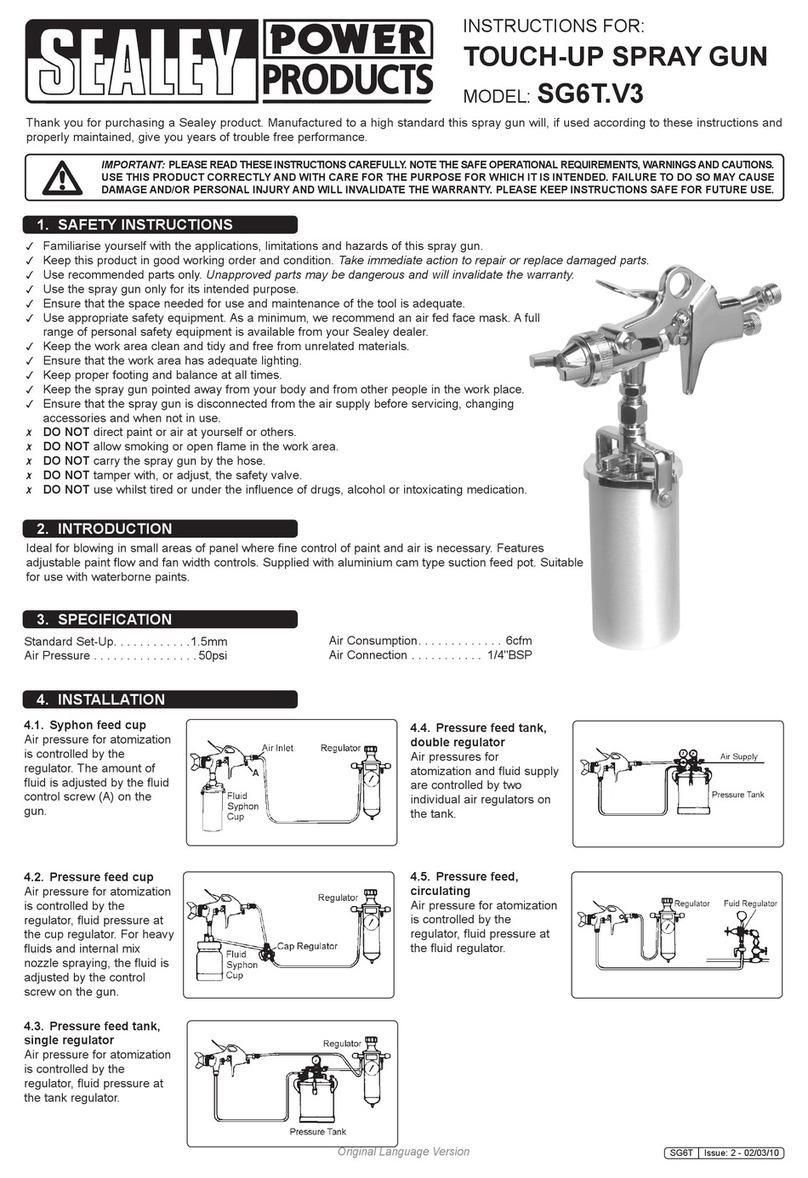

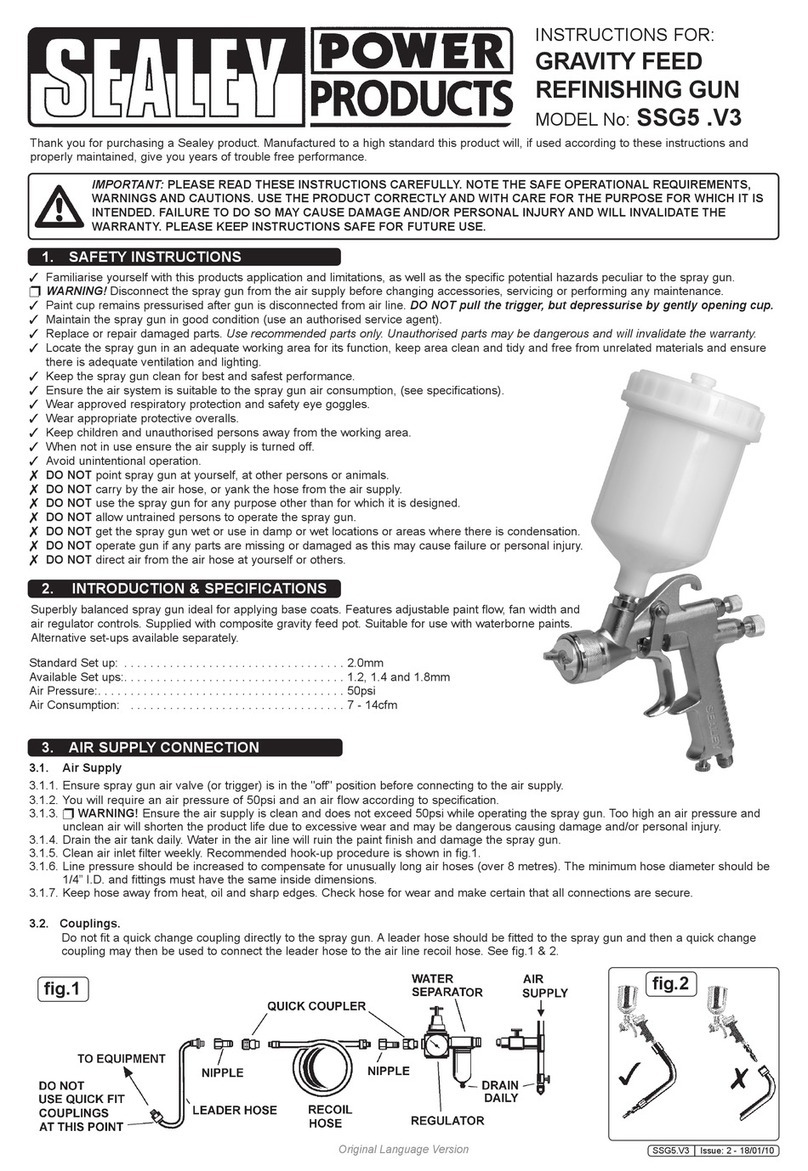

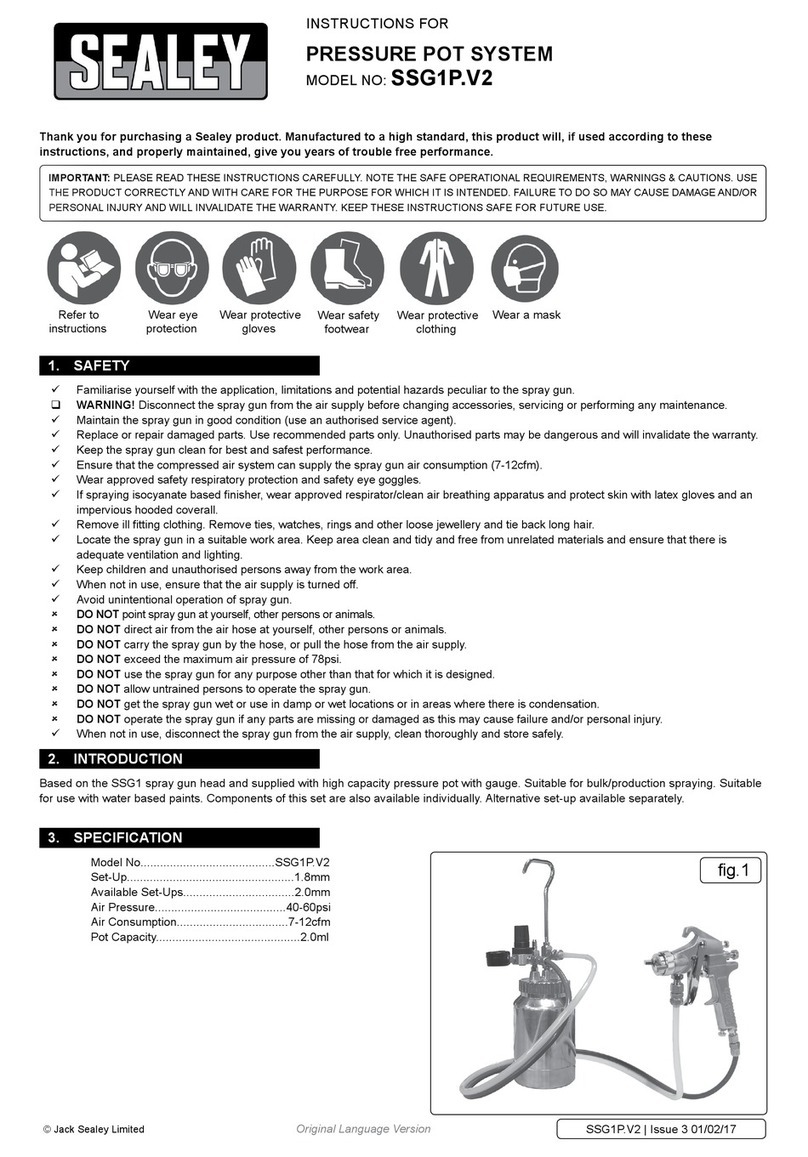

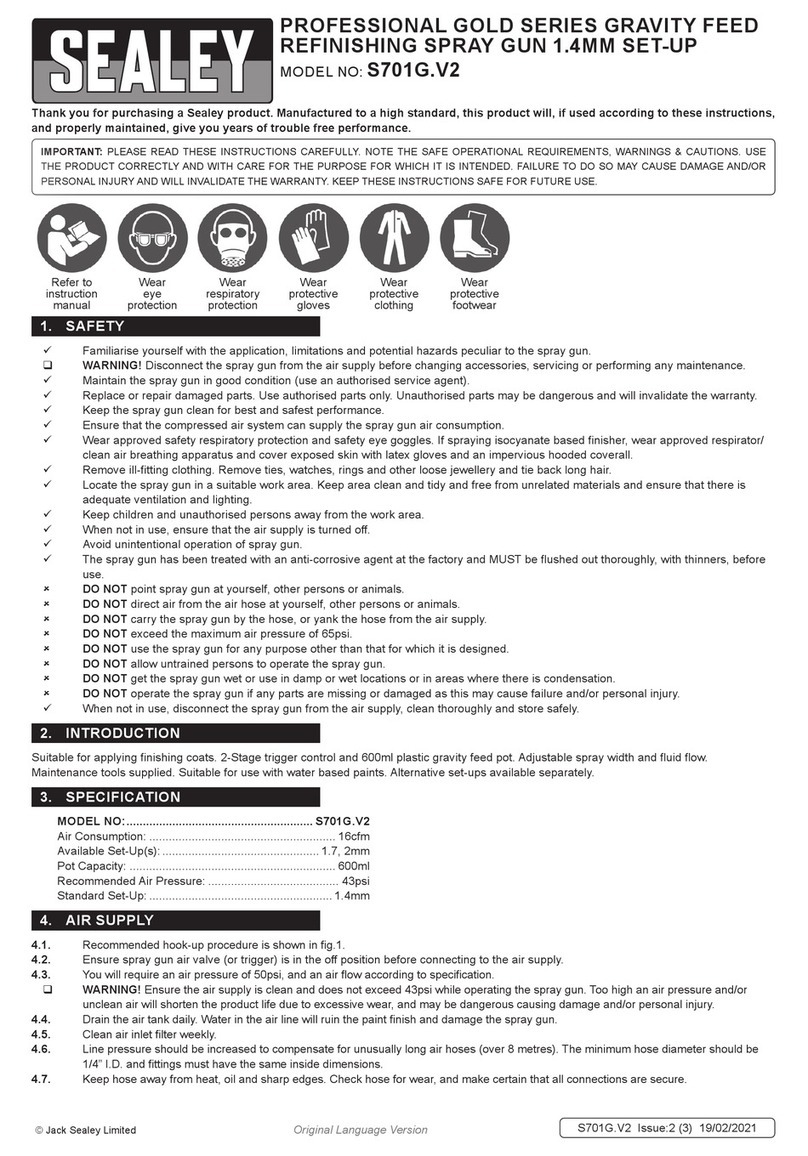

3.1.5. Clean air inlet filter screen weekly. For recommended hook-up, see figs.1& 2.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose and

fittings diameter should be 10mm I.D.

3.1.7. Keep hoses away from heat, oil and sharp edges. Check hoses for wear and make certain that all connections are secure.

3.2. Couplings.

3.2.1. Vibration may cause failure if a quick change coupling is connected directly to the wrench. To overcome this, connect a

leader hose to the wrench. A quick change coupling may then

be used to connect the leader hose to the air line recoil hose. See figs. 1& 2.

2. INTRODUCTION & SPECIFICATION

Fig 1 Fig 2

SG139.V2 - 1 - 250902

INSTRUCTIONS FOR:

UNDERBODY COATING GUN

Model: SG139.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR

THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURYAND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

pWARNING! Disconnect the gun from the air supply before changing accessories, servicing or performing any maintenance.

3Maintain the gun in good condition. Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may

be dangerous and will invalidate the warranty.

3Keep the gun clean and rinse out nozzle and pipes with paraffin after use.

p

p

WARNING! If gun components become blocked there is a danger of excessive pressure building up in unit causing the canister

to burst.

3Locate the gun in a suitable, well ventilated area. Keep area clean, tidy and free from unrelated materials and ensure there is

adequate lighting.

3Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

3Keep children and unauthorised persons away from the working area.

3Avoid unintentional operation.

3Ensure underbody coating manufacturers instructions are carefully followed.

7DO NOT hold gun or attachments close to your face (especially eyes, ears, etc.) and do not point gun or air hose at other persons

or animals.

7DO NOT carry by the air hose, or yank the hose or the gun from the air supply.

7DO NOT use the gun for any purpose other than for which it is designed and do not fill with any other fluid.

7DO NOT operate the gun if damaged.

3When not in use disconnect from the air supply and store in a safe, dry, childproof area.

2.1. Introduction

2.1.1. The SG139.V2 is used for anti-rust treatment of vehicles and agricultural machines by the application of underbody

coating. Fits a standard body schutz canister.

2.1.2. Check contents against the following list. If any item is damaged or missing contact your supplier immediately.

Gun Gun Nose Suction Tube

2.2. Specification

Air Supply . . . . . . . . . . . . . . . . . . . . .60 - 90psi

Air Consumption . . . . . . . . . . . . . . . . . . .10cfm

Connection . . . . . . . . . . . . . . . . . . . .1/4in BSP

3. PREPARING THE GUN FOR USE

3.1 Air Supply

3.1.1 Ensure the trigger is not depressed before connecting to the air supply.

3.1.2. An air pressure of no more than 90psi and an air volume of 10cfm will be required.

3.1.3. pWARNING! Ensure air supply does not exceed 90psi. Too high a pressure will shorten the product life and may

be dangerous, causing damage and/or personal injury.

3.1.4. Drain air supply tank daily. Water in the air line will damage the gun and will invalidate your warranty.

3.1.5. Clean air inlet filter screen weekly. For recommended hook-up, see figs.1& 2.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose and

fittings diameter should be 10mm I.D.

3.1.7. Keep hoses away from heat, oil and sharp edges. Check hoses for wear and make certain that all connections are secure.

3.2. Couplings.

3.2.1. Vibration may cause failure if a quick change coupling is connected directly to the wrench. To overcome this, connect a

leader hose to the wrench. A quick change coupling may then

be used to connect the leader hose to the air line recoil hose. See figs. 1& 2.

2. INTRODUCTION & SPECIFICATION

Fig 1 Fig 2