8DO NOT operate the wrench when you are tired or under the inuence of alcohol, drugs or intoxicating medication.

8DO NOT get the wrench or battery charger wet or use in damp or wet locations.

9 Keep wrench and charger in the case and store in a safe, dry, childproof area where the temperature will not exceed 104°F (40°C)

1.3. BATTERY SAFETY

9 Charge the battery pack prior to rst use. The battery pack will have been shipped in a low charge state.

9 Use only the charger provided to charge the battery pack.

8DO NOT charge the battery pack when room temperature is below 50°F (10°C) or above 95°F (35°C).

8DO NOT attempt recharging the pack by means of an engine generator or a DC power source.

8DO NOT short-circuit the battery pack by touching both terminals at the same time with a metal object, or your ngers etc.

8DO NOT store battery pack or tool in locations where the temperature may exceed 104°F (40°C ) e.g. in sheds, above heaters etc.

▲DANGER! DO NOT attempt to dismantle the battery pack. For safety and environmental reasons DO NOT discard in domestic

waste or by burning. ONLY discard or recycle according to local authority regulations.

8WARNING! DO NOT allow a leaking battery to contact your person. In case of contact with battery liquid take the following

immediate action:

a) Skin contact: Wash immediately with cool, clean running water for at least 15 minutes.

b) Eye contact: If acid enters eye, ush eye immediately with cool, clean running water for at least 15 minutes and seek immediate

medical attention.

2. INTRODUCTION

Nut busting torque of up to 1000Nm(738lb.ft). Variable speed trigger for greater control. Three selectable speed settings. Cast aluminium

gearbox. Double injection body with rubber grips for added comfort. Fitted with electronic brake. LED Work light illuminates work area when

trigger is pressed. Supplied in storage case with 4Ah Li-ion battery and 2 hour mains charger.

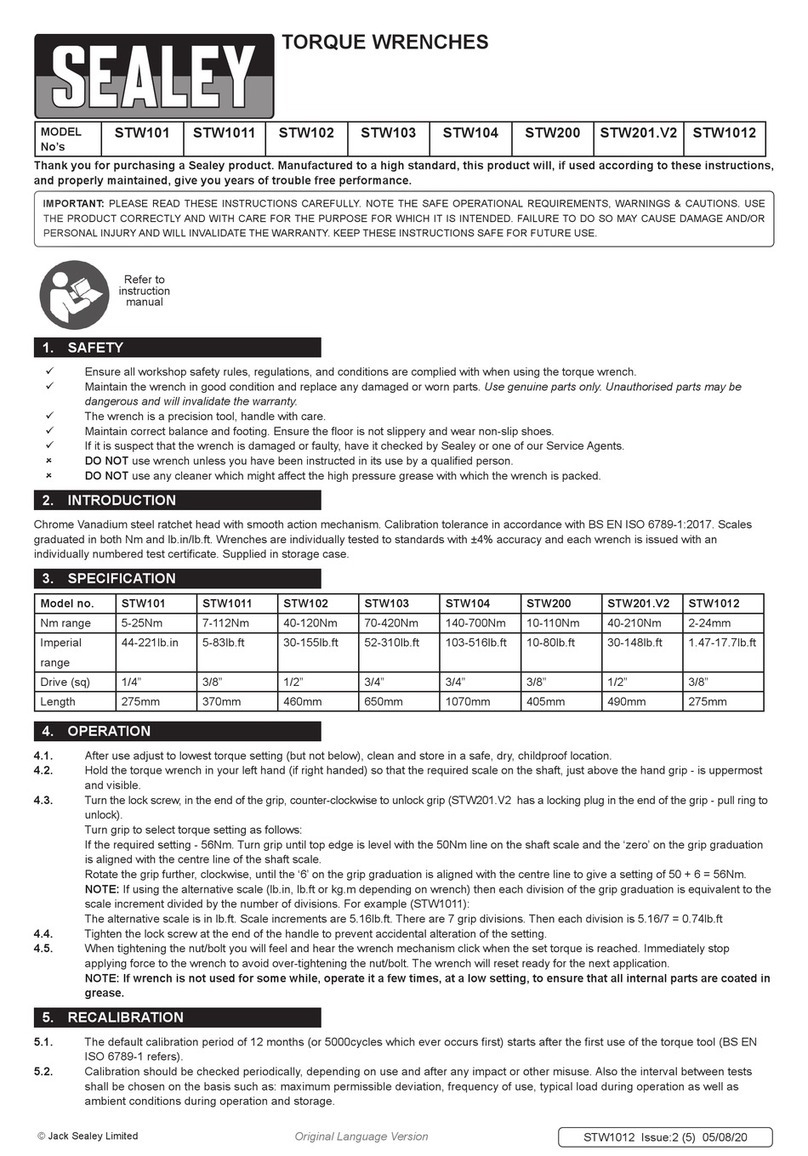

3. SPECIFICATION

Model Number........................................................... CP1812

Replacement Battery.............................................CP1812BP

Battery ............................................................18V 4Ah Li-ion

Drive ........................................................................... 1/2”Sq

No Load Speed ...............................0-900/0-1400/0-1750rpm

Impact Rate.................................. 0-1050/0-1650/0-2050bpm

Maximum Torque........................................1000Nm (738lb.ft)

Noise Power.................................................................. db(A)

Noise Pressure ............................................................. db(A)

Vibration................................................................... 15.3m/s2

Uncertainty................................................................. 1.5m/s2

4. OPERATION

IMPORTANT WARRANTY INFORMATION:

The battery pack tted to this cordless tool is considered to be a

consumable item and its ability to accept charge will reduce over time.

We will warranty it against mechanical and electrical defect for a period

of one year - this does not cover fair wear and tear. If the battery is

not properly charged before rst use, or regularly conditioned, its

capacity will diminish. Under these circumstances we will not replace

the battery pack even if it is less than one year old.

Remove battery pack from case and charge as below:

4.1. REMOVING/INSTALLING BATTERY PACK

WARNING! DO NOT touch metal terminals.

4.1.1. To remove the battery from the wrench, press the release button on the front of battery pack.

WARNING! DO NOT use force when inserting the battery pack. If it does not slide in easily then it is not being inserted correctly.

WARNING! Ensure you read, understand and apply safety instructions before use.

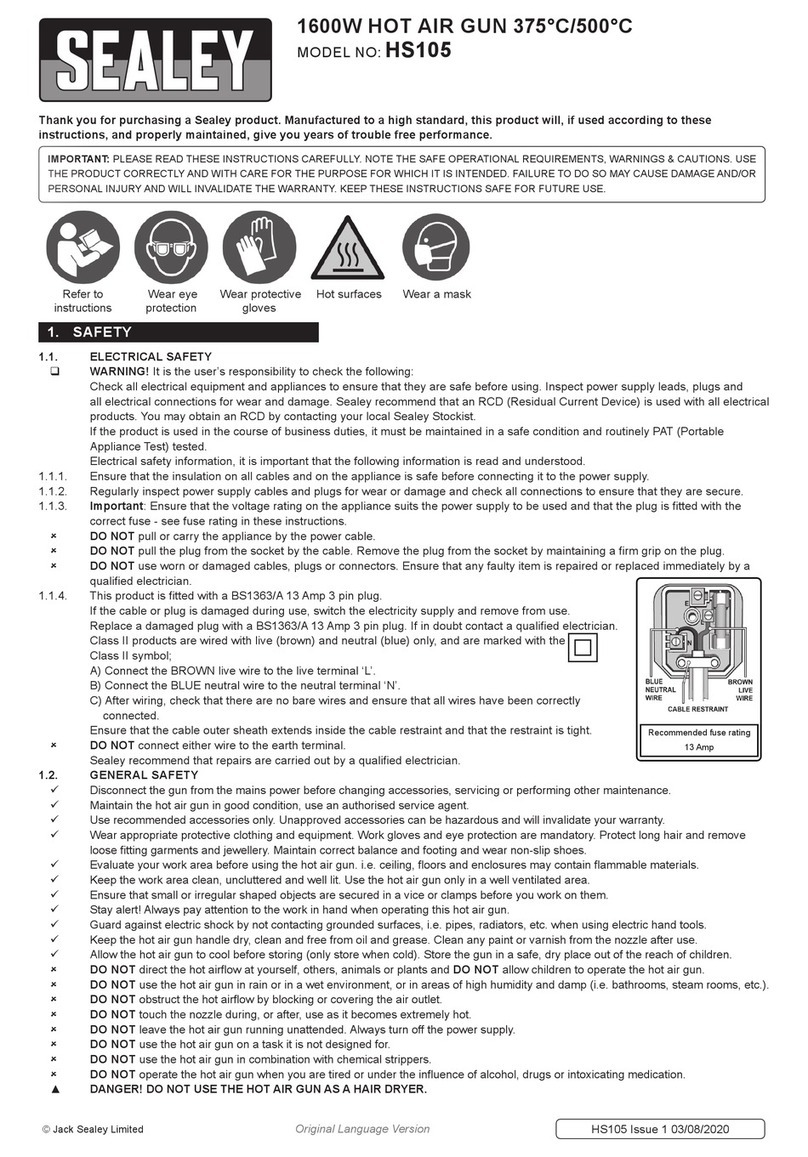

4.2. CHARGING THE BATTERY PACK

4.2.1. Slide the battery pack into the charger.

4.2.2. Plug the charger into the mains supply. A steady red light will show.

4.2.3. The red charging light will come on. The red light goes out and the green one comes on when charged.

4.2.4. After charging, unplug the charger from the power source.

4.3. BATTERY CHARGE LEVEL INDICATORS

4.3.1. Press the button on the battery to display the charge level, red low charge, amber through to green, charged.

4.4. USING THE WRENCH

4.4.1. Use only impact sockets which are specically designed for use with an impact wrench. The use of normal chrome vanadium

sockets is dangerous since these are more brittle and are liable to shatter.

4.4.2. Fit the socket to the wrench by snapping it on.

4.4.3. Fit the battery pack to the wrench.

4.4.4. Select the required direction of rotation. To change direction, push Forward/Reverse Selector (g.1) to the left or right. Familiarise

yourself with this operation before use. DO NOT attempt to change the direction of rotation whilst trigger is depressed.

4.5. FORWARD SPEED SELECTION

4.5.1. The speed is changed by selecting clockwise direction. Then scroll through the 3 forward speeds using the button. Green lights

show speed selected, g.1.

4.5.2. When tightening, release the trigger as soon as the impact sound is heard. Take care not to over-torque small xings.

NOTE! For critical xings such as wheel nuts always use a calibrated torque wrench according to the vehicle manufacturer’s, or

product, guidelines.

4.5.3. When the wrench is not in use, lock the trigger off by placing the forward/reverse switch in the middle position.

Original Language Version

© Jack Sealey Limited

g.1

CP1812 | Issue 2 (3) 09/01/20