INSTRUCTIONS FOR:

AUTOMOTIVE DIAGNOSTIC

OSCILLOSCOPE (4 CHANNEL)

MODEL No: TA4000

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION

3. SPECIFICATION

1.1. GENERAL SAFETY

Use Proper Power Cord. Use only the power cord specified for this

product and certified for the country of use.

Familiarise yourself with the applications, limitations, and potential hazards

of the oscilloscope.

Keep the oscilloscope clean and in good condition.

Connect the probe output to the measurement device before connecting

the probe to the circuit under test. Disconnect the probe input and the

probe reference lead from the circuit under test before disconnecting the

probe from the measurement device.

To avoid fire or shock hazard, observe all ratings and markings on the

product. Consult the product manual for rating information before making

connections to the product.

To avoid fire or shock hazard, observe all ratings and markings on the

product. Consult the product manual for rating information before making

connections to the product. To avoid shock hazard, use a correctly rated

probe for your measurement.

Use adequate ventilation. Refer to the installation instructions for proper

ventilation of the device.

Protect the oscilloscope from electro-magnetic fields, static

electricity and high temperatures.

Remain vigilant when using the oscilloscope on, or near, machinery

where there are rotational parts such as belts, pulleys and fans.

Maintain correct balance and footing. Ensure the floor is not slippery and

wear non-slip shoes.

Remove ill fitting clothing. Remove ties, watches, rings, and other loose

jewellery, and contain and/ or tie back long hair.

Keep Product Surfaces Clean and Dry.

DO NOT use the oscilloscope if damage is suspected. If suspected

damage occurs with the device, have it inspected by qualified service

personnel before further operations.

DO NOT touch exposed connections and components when power is on.

DO NOT connect or disconnect probes or test leads whilst they are

connected to a voltage source.

DO NOT get the oscilloscope wet or use in damp or wet locations or

areas where there is condensation.

DO NOT use the oscilloscope for any purpose other than for which it

is designed.

DO NOT allow untrained persons to operate the oscilloscope.

DO NOT operate the oscilloscoper when you are tired or under the

influence of alcohol, drugs or intoxicating medication.

DO NOToperate in a potentially explosive environment/atmosphere.

WARNING: The warnings, cautions and instructions discussed in this

instruction manual cannot cover all possible conditions and

situations that may occur. It must be understood that common sense

and caution are factors which cannot be built into this product, but

must be applied by the operator.

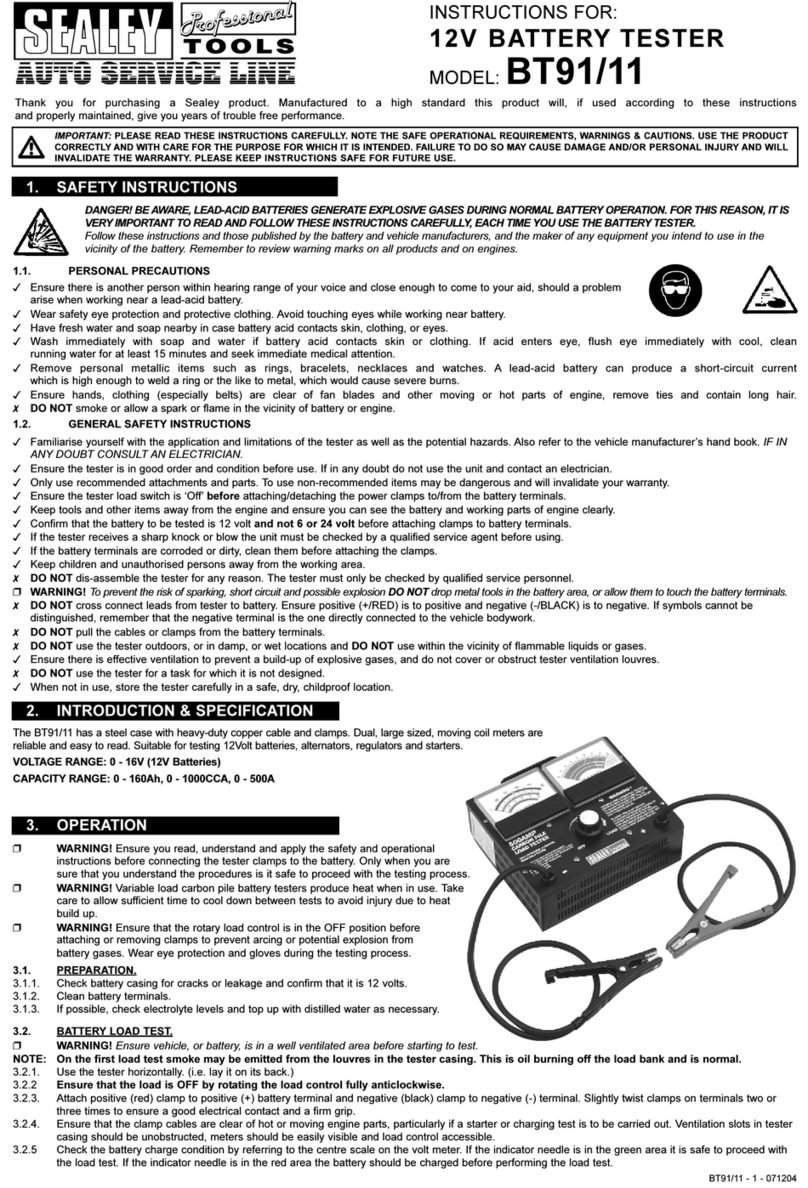

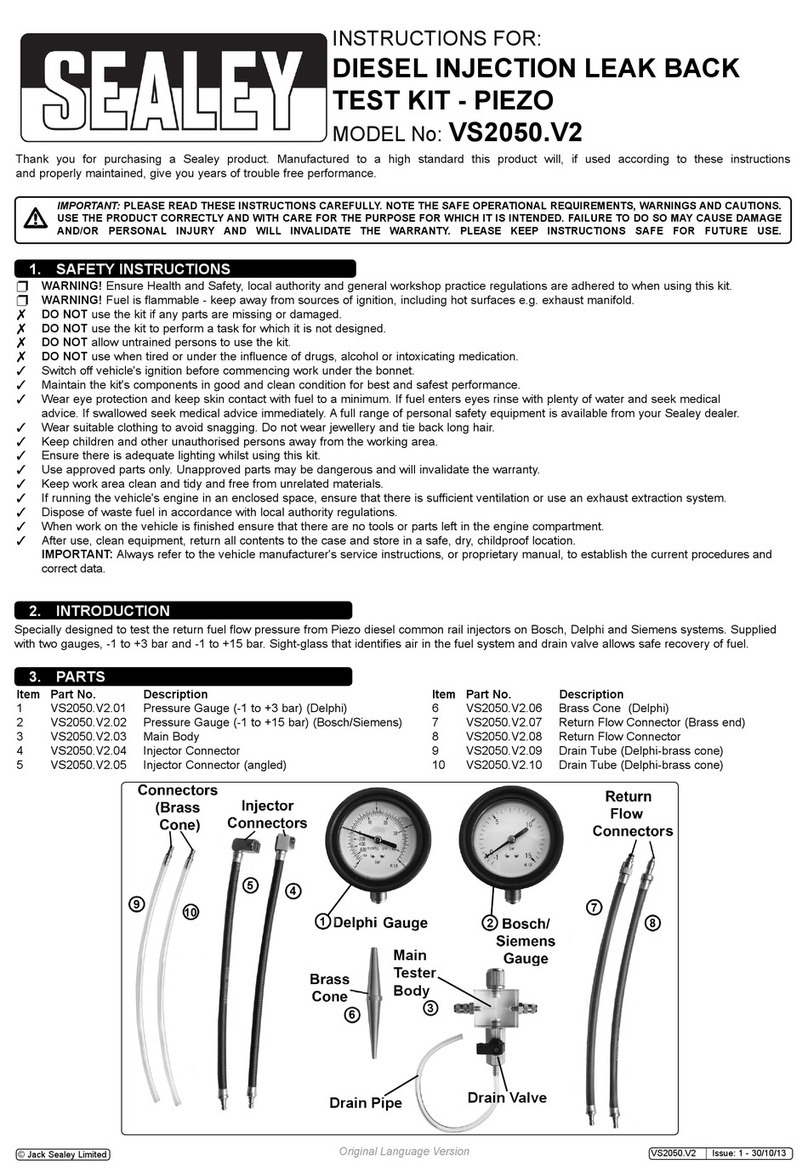

One of the most competitively priced, PC-based ‘scopes around and suitable

for professional applications. High sample rate, multiple memory function

and 4-channel display make this unit ideal for in-depth analysis of a variety

of automotive sensors and components and can be used with any

compatible lap-top or PC. The ‘scope also features a comprehensive

collection of standard automotive diagnostic procedures turning an otherwise

complex process into a click of a button. The system is loaded with

specimen wave-forms allowing the operator to compare actual results with

those expected. The 4-channel function allows multiple components to be

compared simultaneously. The TA4000 can be connected using a LAN cable

(supplied) to any PC running the appropriate software version. The scope is

supplied with a wide selection of automotive type test leads, connectors and

probes. Supplied in carry case.

INPUT

Max. sample rate 200MS/s (Single Channel)

100MS/s (Dual Channel)

Channels 4 Channels

Bandwidth 60MHz (-3dB)

Vertical Resolution 8 bits/channel

Gain range

10mV ~ 5V/div @ x1 probe (10mv, 20mv, 50mv,

100mv, 200mv, 500mv, 1V, 2V, 5V/div 1,2,5 sequence)

100mV ~ 50V/div @ x 10 probe

1V ~ 500V/div @ x 100 probe

10V ~ 5KV/div @ x 100 probe

Range 8 divisions

Offset level +/-4 divisions

Coupling AC, DC, GND

Offset increments 0.02 div

Impedance 1M ohm

DC accuracy +/- 3%

Input protection 35Vpk (DC + peak AC < 10kHz, without external attenuation

Display Mode Y-T, X-Y

TIMEBASE

Timebase range 5ns/div ~ 1000s/div (1-2-5 sequence)

Acquisition mode Timebase range

Range Realtime sampling: 5ms/div ~ 200ms/div

Roll mode: 500ms/div ~ 1000s/div

Buffer Size 10K ~ 16M points (Single Channel)

TRIGGER

Type Edge trigger, Pulse Trigger

Mode Auto, normal and signal

Autoset Yes

Range 10 divisions

Trigger level +/-4 divisions

Settabillity 0.02 div increments

MATH

Measurements

Vpp, Vmax, Vmin, Vmean, Vrms, Vamp, Vtop, Vbase,

Vmid, positive overshoot, negative overshoot, cycle

mean, cycle RMS, period, frequency, positive pulse

width, negative pulse width, rise time (10%~90%), fall

time (10%~90%), positive duty cycle, negative duty cycle

Math Addition, Subtraction, Multiplication, FFT

FFT Rectangular, Hanning, Hamming, Blackman Window

PHYSICAL

Interface USB2.0 (USB1.1 compatible)

Power External power source required. (8.5v dc)

Dimensions 224 x 168 x 37mm

Original Language Version TA4000 Issue: 1 - 06/09/11