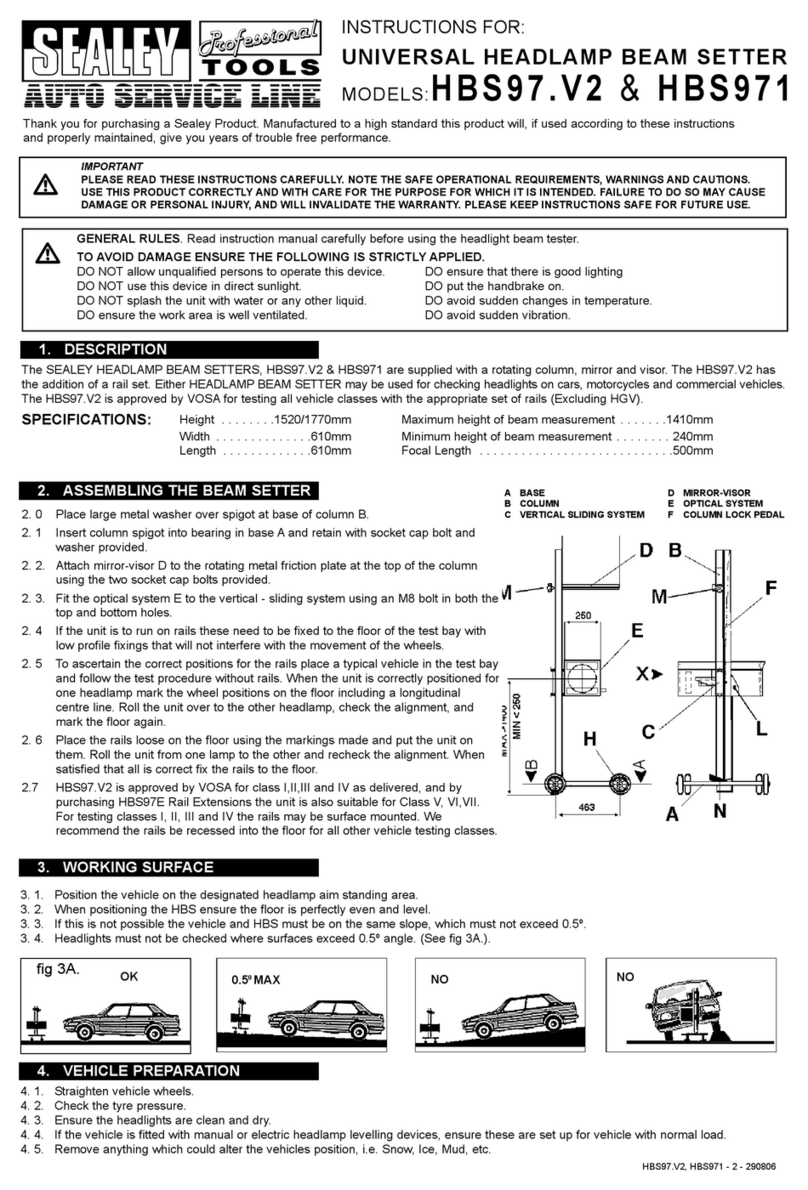

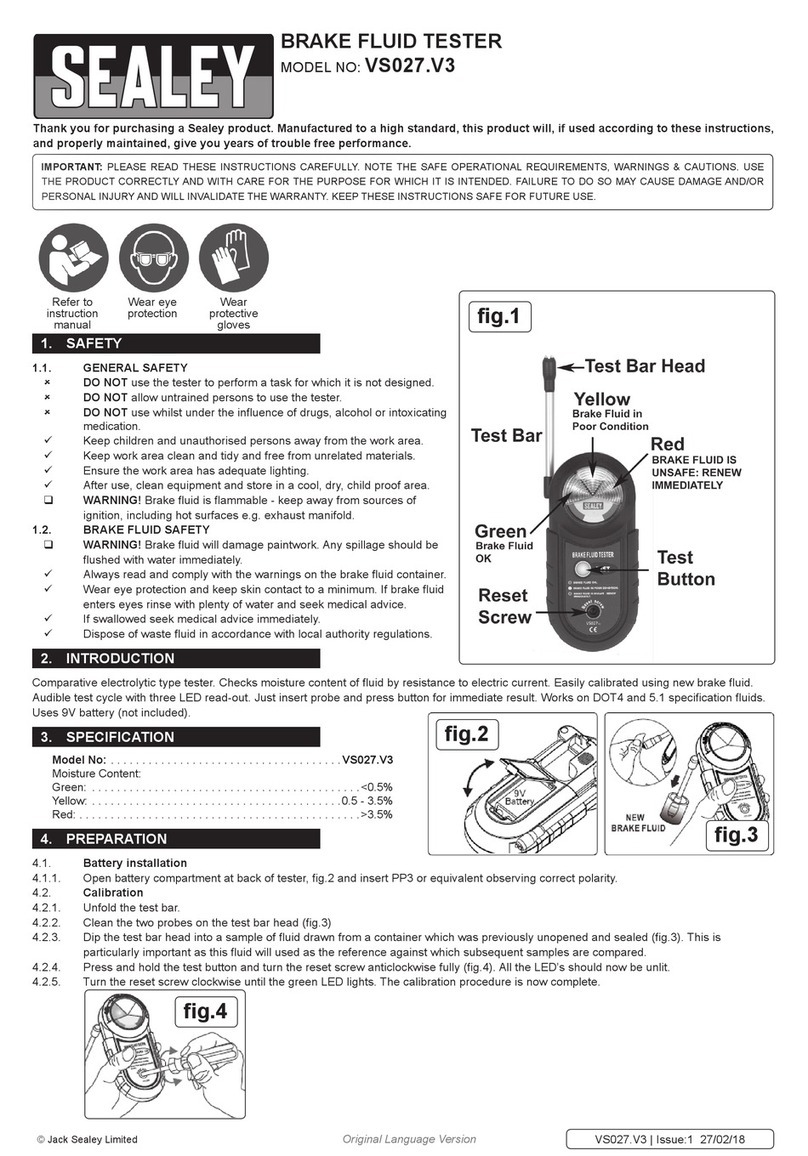

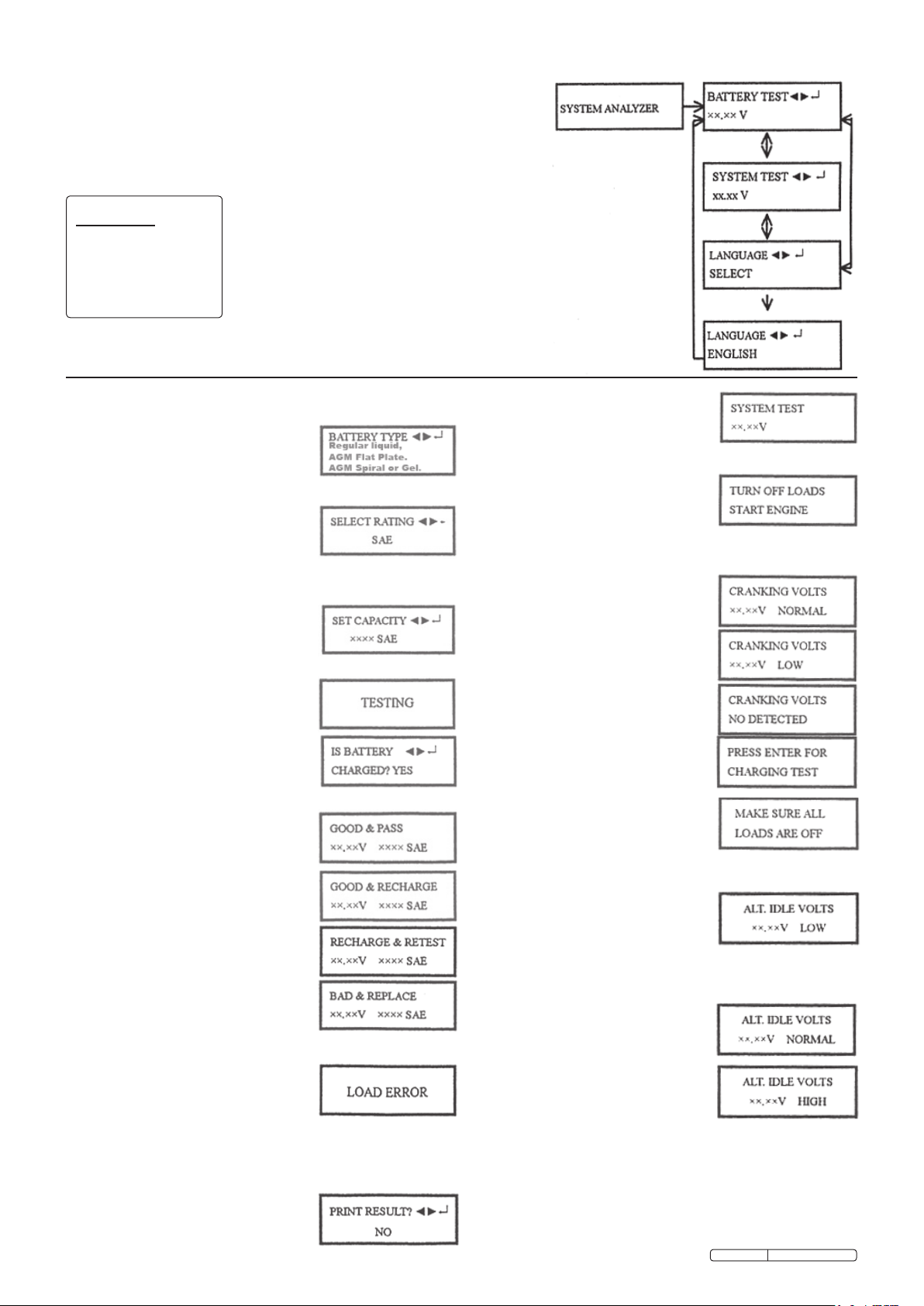

Fig.1

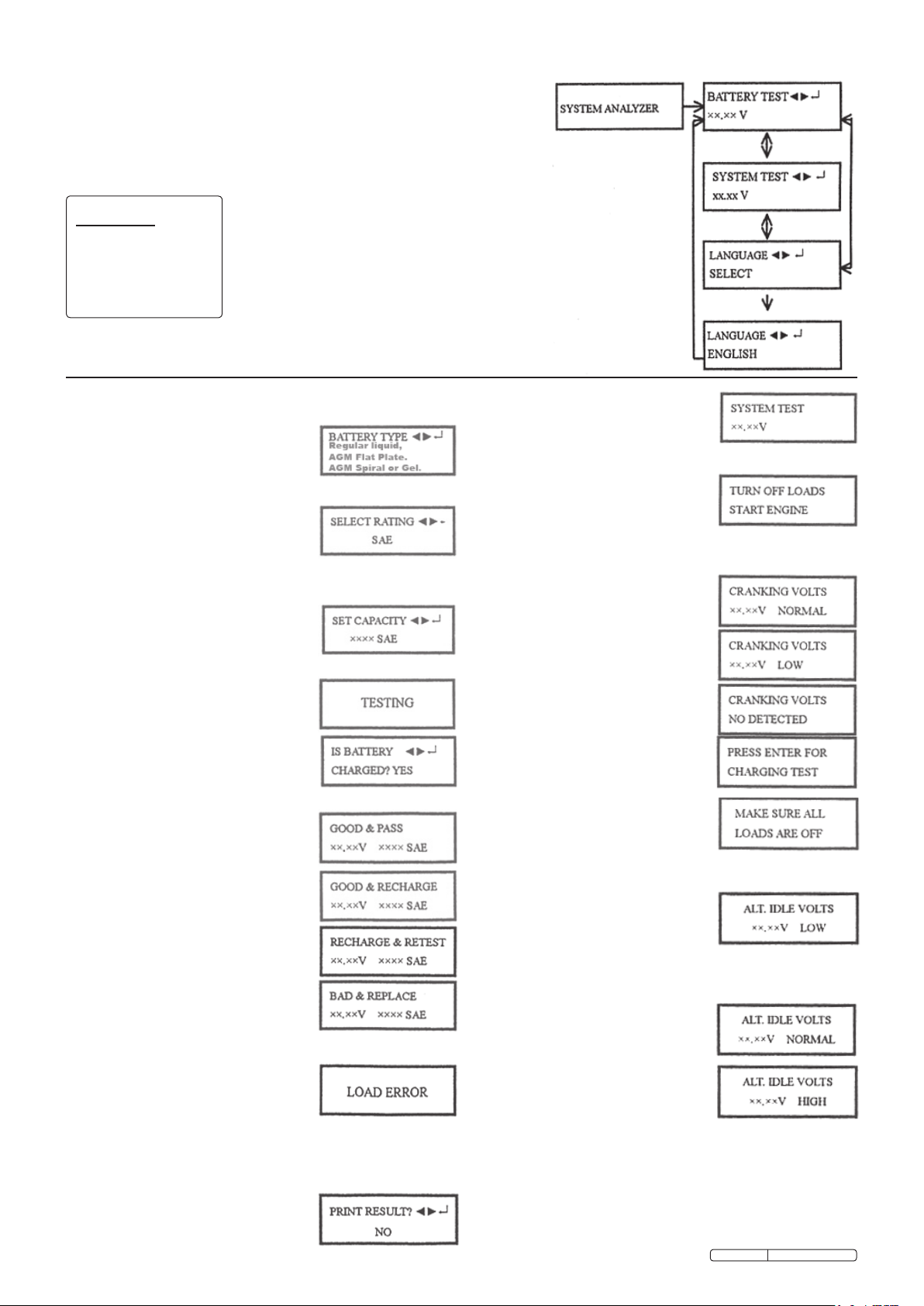

3.3 BATTERY TEST

3.3.1 With battery test screen displayed

press ENTER.

3.3.2 Use the <(forward) and >(backward)

buttons to select the battery type:

Regular Liquid, AGM Flat Plate, AGM

Spiral, Gel.

Press ENTER to confirm choice.

3.3.3 Use the <(forward) and >(backward)

buttons to select the battery rating: SAE,

EN, IEC, DIN or JIS.

Press ENTER to confirm.

3.3.4 Use the <(forward) and >(backward)

buttons to input the battery capacity.

CCA:

DIN: 25 - 1300

EN: 40-2100

IEC: 30 - 1500

JIS: By battery type

SAE: 40 - 2000

Press ENTER to begin test.

3.3.5 Test Battery for 1 second.

3.3.6 Press <(forward) or >(backward) buttons

to select battery fully charged: Yes or No.

Press ENTER to confirm choice.

3.3.7 When the test is complete, the LCD

shows the actual volts and CCA.

One of the following results will be

displayed.

3.3.8 GOOD & PASS: Battery is capable of

holding a charge.

3.3.9 GOOD & RECHARGE: The battery is

good but needs to be recharged.

3.3.10 RECHARGE & RETEST: Battery is

discharged, the battery condition cannot

be determined until it is fully charged.

Recharge and retest.

3.3.11 BAD & REPLACE: The battery will not

hold its charge. Replace.

3.3.12 LOAD ERROR: The tested battery is

larger than 2000CCA or 200Ah. Or the

clamps are not connected properly.

Please fully charge the battery and retest

after excluding both previous reasons. If

reading is the same, the battery should

be replaced immediately.

NOTE! The operator is asked if any accessories

are left on as a possible cause. If

accessories are left on, the operator is

instructed to charge and retest the battery.

If accessories are not left on, the operator

is instructed to replace the battery since

the charging system is working and a good

battery should have accepted a charge.

3.3.13 Press <(forward) or >(backward) buttons

to select result printing: Yes or No. Press

3.2 DISPLAY GENERAL

By pressing the < (forward) and > (backward) buttons the display will cycle through

the options. Press ENTER button when the option you require is displayed.

3.2.1 System Analyser will display initially and then automatically switch to Battery Test.

3.2.2 Use the <(forward) and >(backward) buttons to cycle between System Test,

Language Select, and Battery Test. (Fig. 1)

ENTER to confirm choice.

3.3.14 Remove the clamps from the battery after

completion of testing.

3.4 SYSTEM TEST

3.4.1 Press "ENTER" button, you will view the

following screen.

3.4.2 Turn off all vehicle accessory loads such

as light, air conditioning, radio, etc.

before starting the engine.

3.4.3 When the engine is started, one of the

three results will be displayed along with

the actual reading measured.

3.4.4 CRANKING VOLTS NORMAL: The

system is showing normal draw. Press

ENTER to perform the charging

system test.

3.4.5 cranking volts low: The cranking

voltage is below normal limits,

troubleshoot the starter with

manufacturer’s recommended procedure

3.4.6 CRANKING VOLTS NO DETECTED:

The cranking voltage is not detected.

3.4.7 If the cranking voltage is normal, press

ENTER to begin charging system test.

3.4.8 Press the ENTER key, you will view the

following screen.

3.4.9 Press the ENTER key, one of the three

following results will be displayed along

with the actual reading measured.

LOW CHARGING VOLTS WHEN TESTED AT

IDLE: The alternator is not providing sufficient

current to the battery. Check the belt to ensure the

alternator is rotating with engine running. If the belt

is slipping or broken, replace and retest. Check the

connections from the alternator to the battery. If

the connection is loose or heavily corroded, clean

or replace the cable and retest. If the belt and

connections are in good condition, replace the

alternator.

CHARGING SYSTEM NORMAL WHEN TESTED

AT IDLE: The system is showing normal output

from the alternator. No problem is detected.

HIGH CHARGING VOLTS WHEN TESTED AT

IDLE: The voltage output from the alternator to the

battery exceeds the normal limits of a functioning

regulator. Check to ensure there are no loose

connections and the ground connection is good. If

there are no connection problems, replace the

regulator. Since most alternators have the

regulator built-in, this will require you to replace the

alternator. The normal limit of a typical automotive

regulator is 14.6 volts. Check manufacturer’s

specifications for the correct limit, as it will vary by

vehicle type and manufacturer.

Battery Type:

Regular liquid.

AGM Flat Plate.

AGM Spiral.

Gel.

Original Language Version BT2003.V4 Issue: 1 - 08/10/10