6. ADDITIONAL VACUUM SYSTEMS

6.1. Testing One-Way Valves

6.1.1. Many vacuum operated circuits use in-line one-way valves to apply vacuum in

one

direction only.

6.1.2.

To

test the function

of

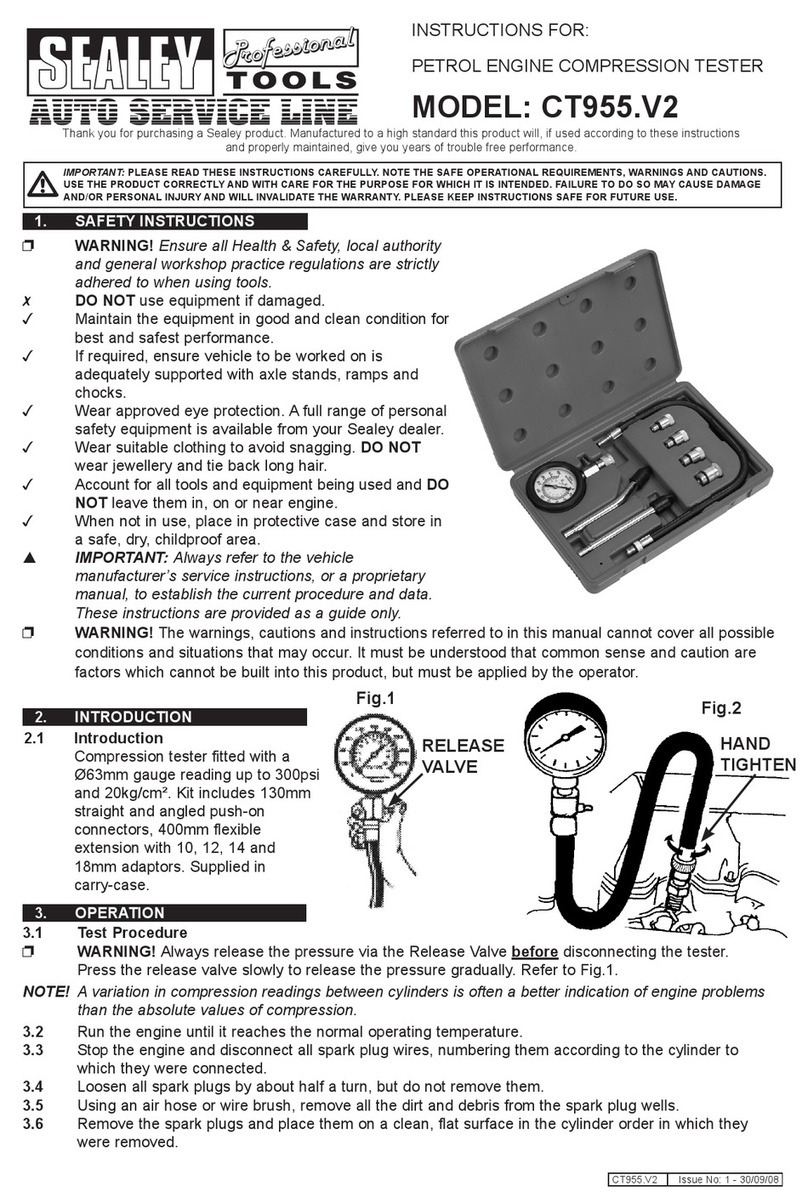

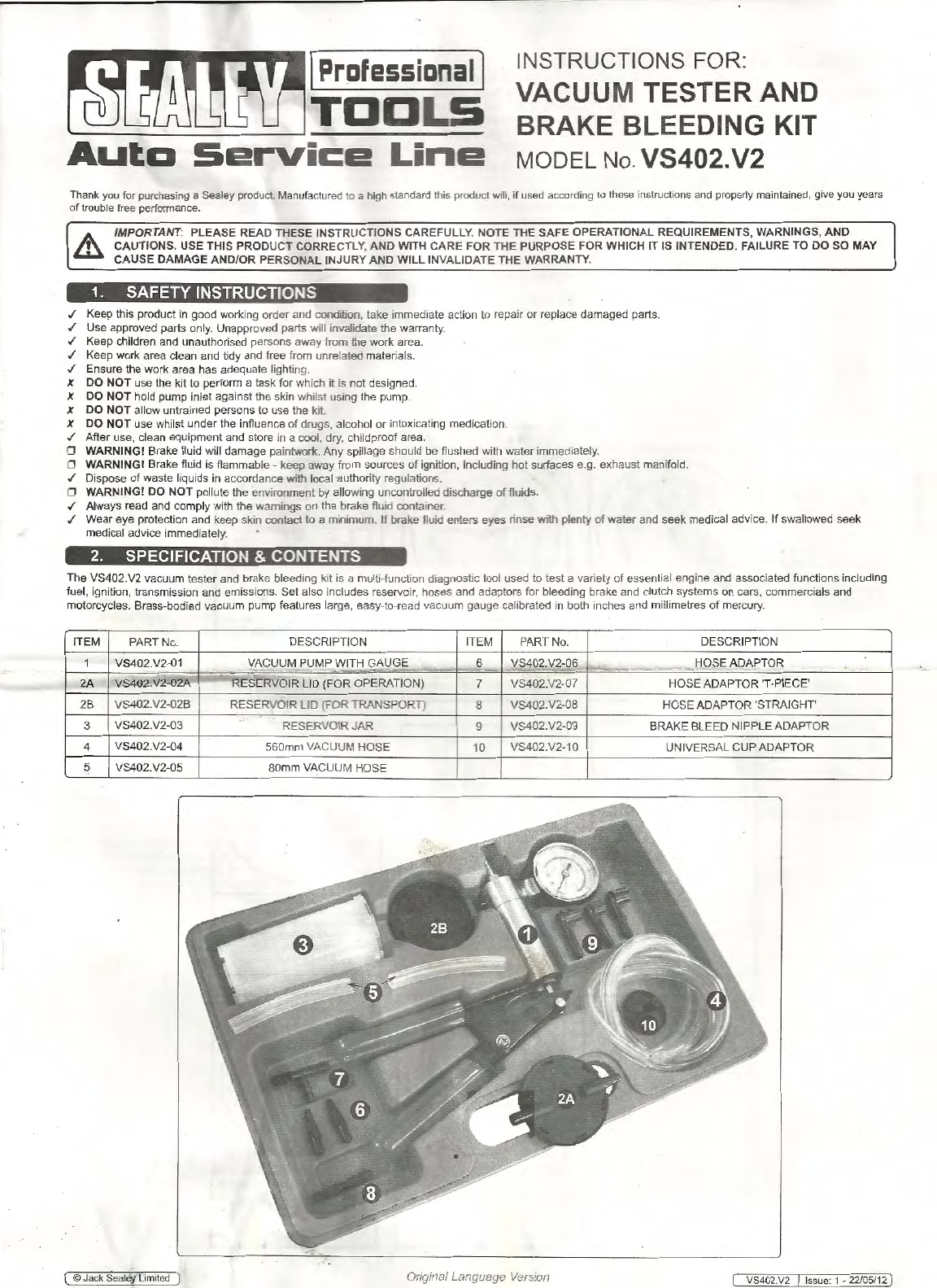

the valve remove it from the circuit. Attach the VS402.V2 vacuum tester (fig.7) and operate pump to apply vacuum. In one direction

the valve shou

ld

hold vacuum and in the opposite d

ir

ection it should not.

6.2.

Testing

Electrically

Operated

Vacuum

Solenoids

6.2.1. Electrically operated vacuum solenoids are commonly used in control c

ir

cuits

for

airconditioning/ventilation systems, emission control syste

ms

, idle step

up

systems etc. and testing the function

of

these when using

the

VS402.V2

is

extremely simple.

6.2.2. Locate the solenoid to be tested and remove the line that goes to the component being tested. Connect the VS402.V2 to the solenoid port (fig.8) and start

the engine. With the system turned offthere should·be a zero gauge reading. Nowturn the system to the 'on' position and a gauge reading equal

to

the

manifold vacuum should be observed,

if

no

reading exists remove the vacuum supply line and test

for

manifold vacuum

at

this point. If the vacuum does

exist this indicates that the solenoid is faulty

or

it

is

no

t receiving a 'switch on' voltage (use a multimeter to test this). If no vacuum exists trace the supply

line backto the vacuum source checking

for

kinks and breaks.

6.3.

Testing

Thermal

Vacuum

Sw

itc

hes

6.3.1. There are

many

vacuum controlled circuits that must only operate when the en

gi

ne reaches nonnal operating temperature. This is done usi

ng

thennal

switches that remain in an

'off

position until a given temperature

is

reached.

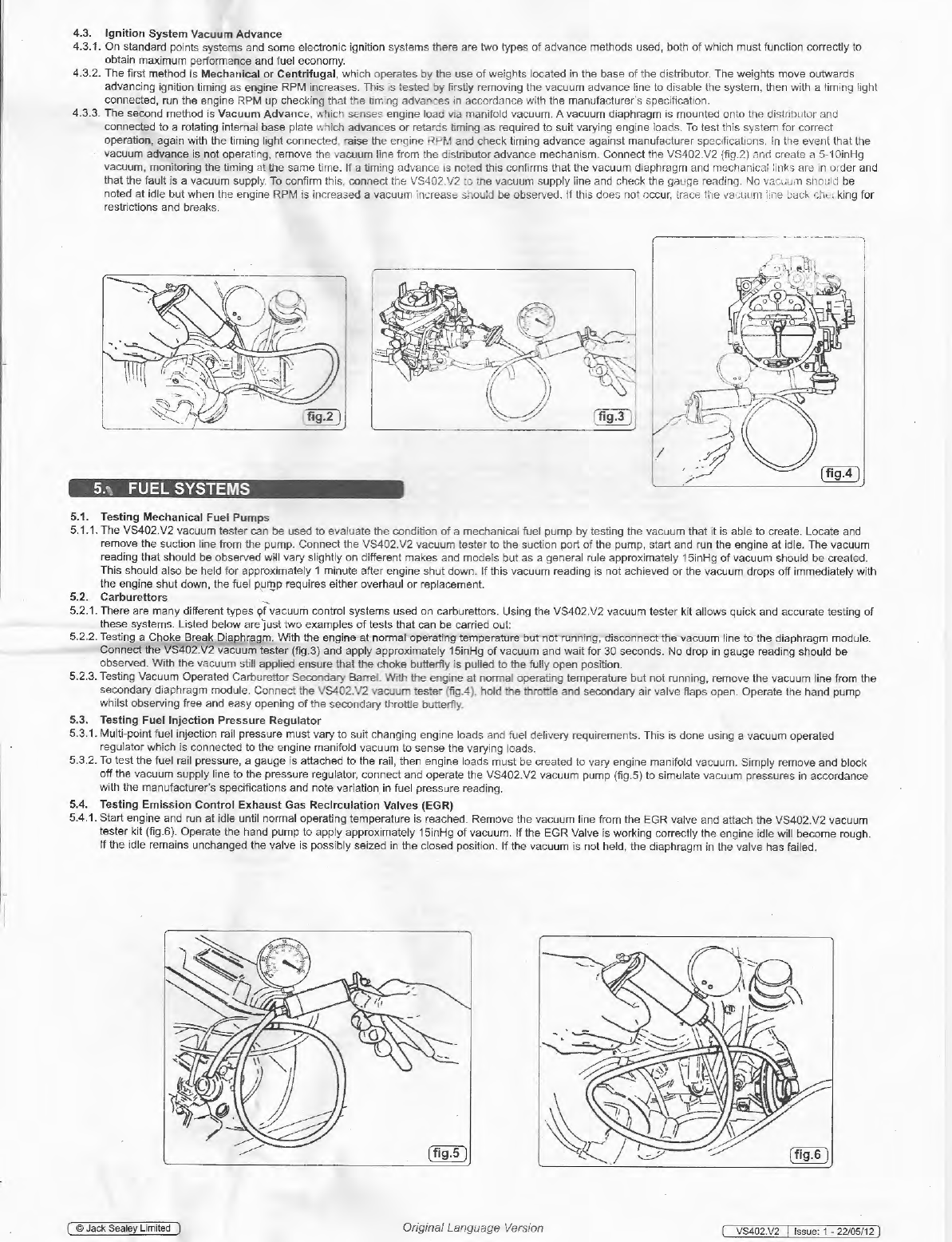

6.3.2. To test this type of switch, remove the vacuum supply line co

mi

ng

from the manifold to t

he

switch and test for manifold vacuu

m.

If

this vacuum is correct refit

the supply line to the thermal switch and remove the opposing line from the switch. Attach the VS402.V2 vacuum tester to the

po

rt (fig.9) and start the

engine. With a cold engine

no

reading shou

ld

be noted. When the engine reaches nonnal operating temperature a manifo

ld

vac

uum reading should be

noted.

6.4.

Testing

Vacuum

Operated

Heater

Taps

6.4.1. Climate control ventilation systems are becoming very common on newervehicles and most of

the

systems use vacuum operated taps to control the heating

modes.

On

the majority

of

makes and models, the system uses vacuum to tum the heat

er

tap 'on'.

6.4.2. To test these remove the supply line from the tap vacuum m

od

ule and connect the VS402.V2 vacuum tester (fig.10). With the engine

at

nonnal operating

temperature locate and feel

the

heater return hose. With the heatertap in the '

otr

position, this hose should be cold. Now operate the vacu

um

pump to open

the tap.The gauge read

in

g must hold. If

the

tap is in working order. the retum hose will begin to heat.

If

the

ho

se does not begin to heat, this indicates that

the tap is faulty.

6.5.

Testing

Vacuum

Operated

Remote

Central

Locking

Systems

6.5.1. Some makes and models use vacuum operated bellows mounted in each

door

to centrally lock and

un

lock the

veh

icles doors. These systems use either

manifold vacuum stored in a reservoir

for

use when the engine

is

not

running

or

an electrically driven vacuum pump which operates

wh

en the doors are

locked

or

unlocked.

6.5.2. In either system, the VS402.V2 vacuum tester

is

ideal for testing each individu

al

door bellows. To do this. removA the door trims as required. Remove the

vacuum supply lines from the bellows and attach the VS402.V2 vacuum tester (fig.11 ) and operate to apply vacuum to the bellows. Wait

for

30 seconds,

no

drop on the gauge should be noted.

If

the bellows are found to be

in

order attach the vacuum supply line to the VS402.V2 vacuum tester and operate

system to test for vacuum supply.

If

the vacuum supply does not exist

or

is low trace back down the lines to the vacuum supply looking for kinks, restrictions

or

cracked lines. Repair as required and retest.

6.6.

Testing

Automati

c

Transmission

Vacuum

Operated

Modulator

Valves

6.6.1. Automatic transmissions are nonnally equipped with a vacuum operated modulator valve in order for the automatic transmission to detect engine loads and

adj

ust

shift points to suit. ·

6.6.2. The VS402.V2 vacu

um

tester can be used to test both that the modulation valve diaphragm

is

serviceable and

al

so to simulate varying engine loads so

modulator pressure readings can be recorded.

To

test the modulator valve diaphragm remove

the

vacuum supply line from the valve and attach the

VS402.V2 vacuum tester. Operate t

he

vac

uum pu

mp

until approximately 15in

Hg

is achieved

and

monitor

the

gauge

reading

for

approximately 30 seconds.

No

vacuum drop should be noted.

6.6.3.

To

ctle

ck modulator pressure readings attach a pressure gauge to the appropriate port

on

the transmission. RerllOYe the

vaaMTI

supply

line from the

modu

la

tor and attach the VS402.

V2

vacuum tester (fig.

12

). Start and run the engi

ne

and apply

vac

uum pressures.

Monitor

readings and confinn that

these

are in conformance with manufacturer specifications.

(

C>

J

ac

k Sealey Umited

l

To

Manifold

) Vawum

Original Language Version ( VS402.V2 I Issue: 1 •

2210

51

12

)