5. OPERATION

5.1. CONNECTING LEADS

5.1.1. On MΩ Range:ConnecttheredtestleadintotheVΩterminalandtheblackterminalintotheCOMterminal.

5.1.2. On 200Ω and ACV Range:Connecttheredtestleadintothe“VΩ”terminalandtheblackleadintoterminal“COM”.

5.2. TEST LEADS CHECK

5.2.1. Settherangeselectswitchtothe200Ωrange.Withthetipandalligatorclipofthetestleadsconnected,theindicatorshouldread

00.0Ω.Whentheleadsarenotconnectedthedisplaywillreadinnityindicatedby“1”.Thiswillensurethattestleadareunder

working condition.

5.3. BATTERY CHECK AND REPLACEMENT

5.3.1. IfbatterypowerisinsufcienttheLCDwilldisplay.6x1.5VAAbatteriesarerequired.

5.3.2. Removethefourscrewswhichholdthebatterycovertotbatteries.

5.4. INSULATION RESISTANCE MEASUREMENT

5.4.1. Measurements at 200mΩ/250V

5.4.2. Thisisthevoltageusedforthemajorityofinsulationresistancetestsonnormalinstallations.

5.4.2.1. To measure insulation resistance, press the test button to power on the tester. The LCD will display the insulation resistance.

Section VII indicated that subdivision of large installations might be necessary because of the large number of parallel insulation

resistance. In such a case, an installation may be divided into sections, each being separately tested. Each section must have not

less than fifty outlets, an outlet being a switch, socket, lighting point etc. A switched socket counts as one outlet. The minimum

acceptableinsulationresistanceis1MΩ.Foralargeinstallation,thecapacitanceoftheinsulationwillbehigh,anditwilltake

longer for it to become charged by the direct testing voltage. Care must be taken not to take a reading until there is a steady

reading, indicating that the charging process is complete.

NOTE: The charge stored in the insulation will be discharged automatically when the test button is released. Be careful not to turn

the range switch knob whilst the test button is pressed, or the instrument will be damaged.

5.4.3. Measurements at 2000mΩ/1000V

5.4.3.1. Somespecicationsrequiretestingat1000V.Thisvoltagemustalsobeselectedwherethesupplyvoltageoftheinstallationis

between 500V and 1000V. First, set the range switch to 1000V and then proceed as indicated above for 500V testing. The above

note also applies to testing at 1000V. In addition the following applies.

NOTE: Make sure that the circuit under does not include components which will be damaged by the 1000V applied. Many normal

components of an installation are likely to be damaged if tested at 1000V. Examples are power factor correction capacitors, low

voltagemineralinsulatedcables,electroniclightdimmers,electronicballastsandstartersforuorescentlampsetc.

5.5. LOCK POWER ON FEATURE

5.5.3.1. For hands free operation a lock power on feature is incorporated on the press to test button. Set LOCK button to lock test voltage,

pressing it again will turn the tester off.

5.6. LOW RESISTANCE (CONTINUITY MEASUREMENTS)

5.6.1. Settherangeswitchto200Ωposition.

5.6.2. ConnecttheredtestleadtotheVΩterminalandblacktotheCOMterminal.

5.6.3. Connectthetipsofthetestleadstobothendsofthecircuitundertest.ReadresistanceinΩontheLCD.

5.6.4. Whentheimpedanceoncircuitisbelowapproximately40Ω.Itwillindicatebyacontinuousbeeper.

5.7. AC/DC VOLTAGE MEASUREMENTS

5.7.1. Set the range switch to acV or dcV position.

5.7.2. Connectredtestleadto“VΩ”terminalandblacktestleadtoterminal“COM”.

5.7.3. Connect test prods of test leads IN PARALLEL to the circuit being measured.

5.7.4. Read the voltage value on LCD.

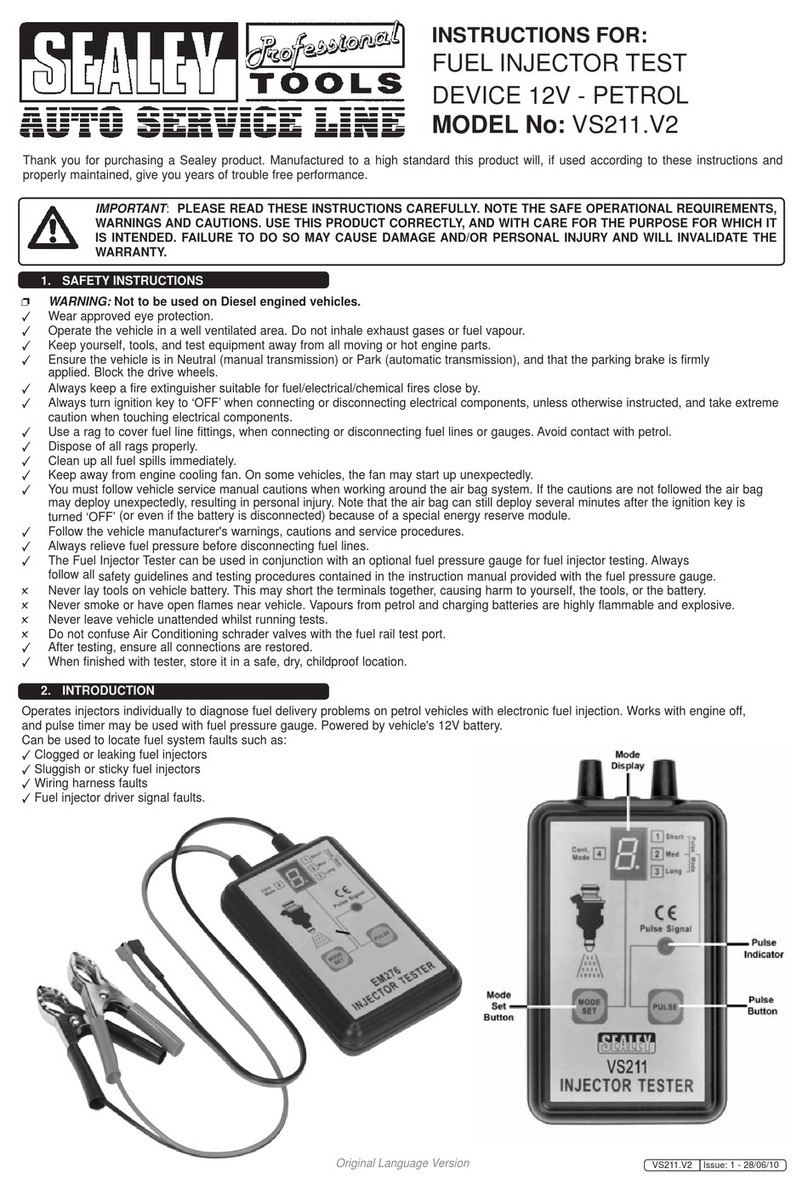

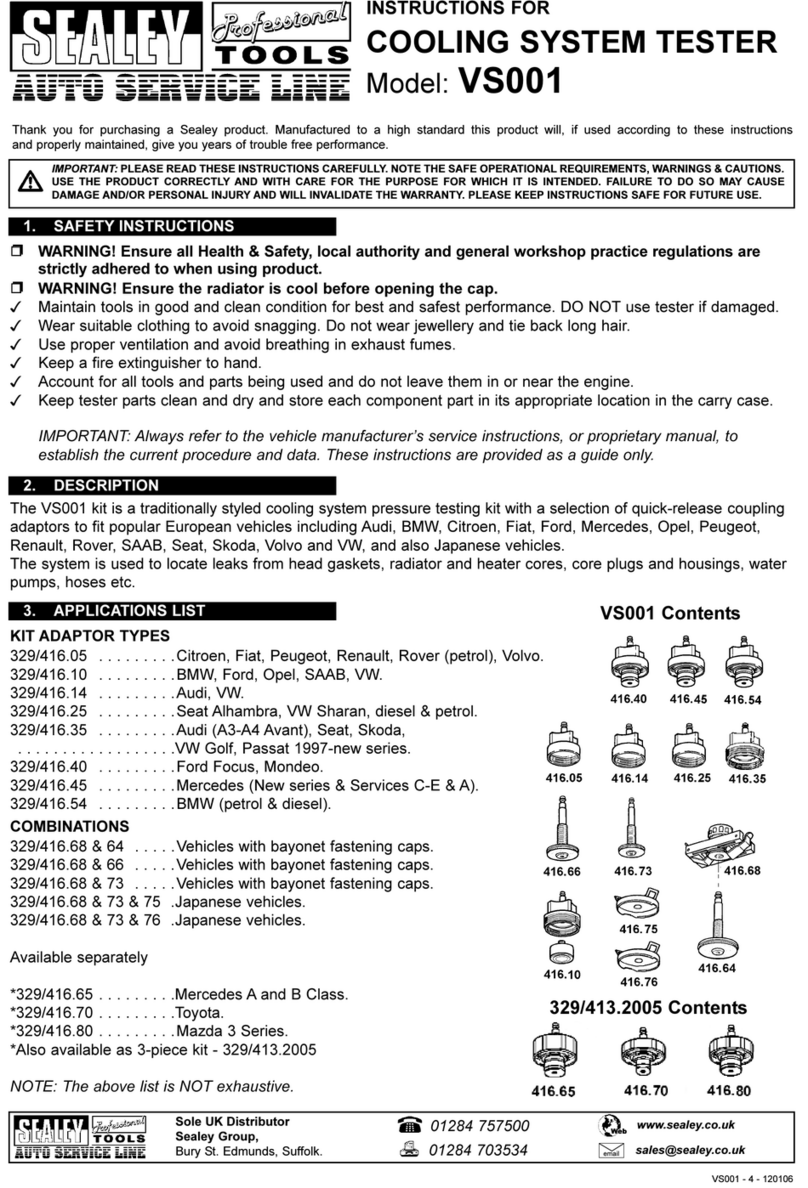

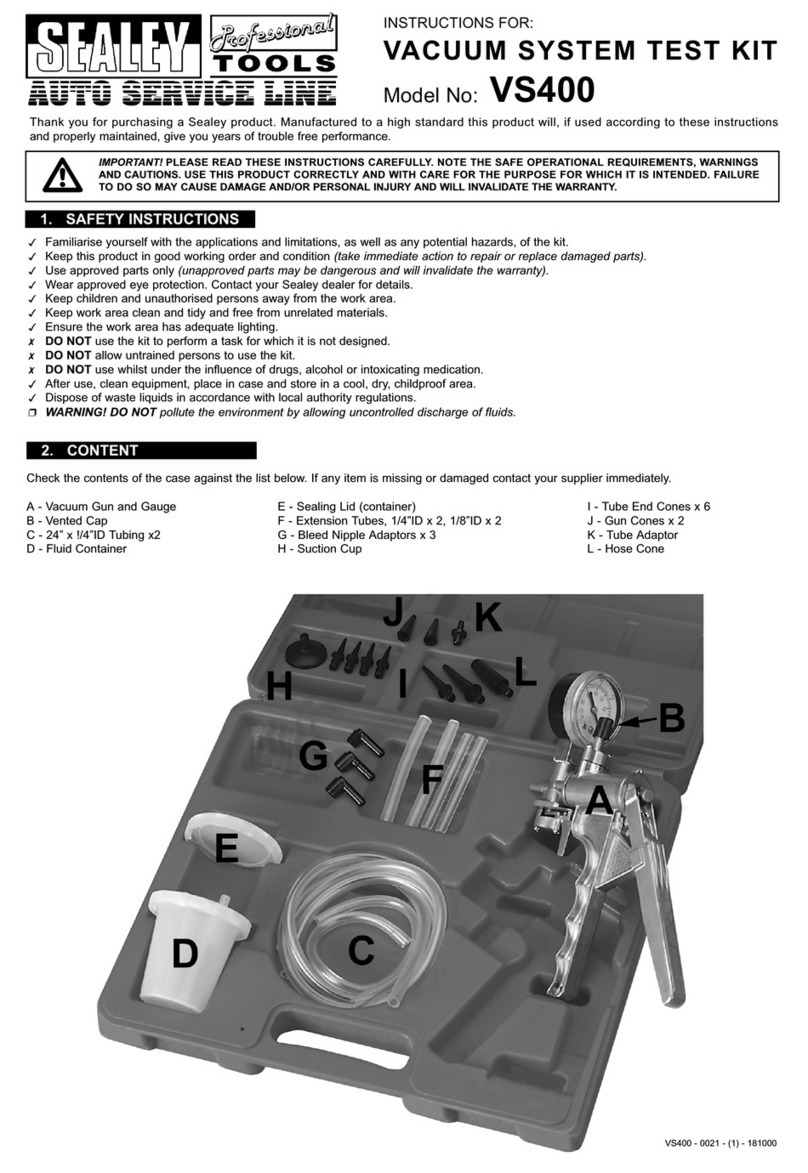

5.8. POWER TOOLS AND SMALL APPLIANCES See (g.1)

5.8.1. This test would also apply to other similar equipment that has a power cable. For double insulated power tools, the megohmmeter

lead shown connected to the housing would be connected to some metal part of the tool (e.g chuck or blade).

NOTE: Theswitchofthedevicemustbeinthe“ON”positionandthemainspowershouldbedisconnected.

5.9. AC MOTORS Refer to (g.1)

5.9.1. Disconnect the motor from the line by disconnecting

the wires at the motor terminals or by opening the

main switch. If the main switch is used and the

motor also has a starter then the starter must be held,

bysomemeans,inthe“ON”position.Inthelatter

case, the measured resistance will include the

resistance of the motor, wire and all other components

between the motor and the main switch. If a weakness

is indicated, the motor and other components should

be checked individually. If the motor is disconnected

at the motor terminals, connect one megohmmeter

lead to the grounded motor housing and the other

lead to one of the motor leads.

5.10. DC MOTORS Refer to (g.1)

5.10.1. Disconnect the motor from the line. To test the brush

rigging,eldcoilsandarmatureconnectone

megohmmeter lead to the grounded motor housing and

the other lead to the brush on the commutator. If the

resistance measurement indicates a weakness, raise

the brushes off the commutator and separately test the

armature,eldcoilsandbrushriggingbyconnecting

one megohmmeter lead to each of them individually,

leaving the other connected to the grounded motor

housing. The above also applies to dc generators.

Original Language Version

© Jack Sealey Limited

g.1

TA319.V2 Issue 1 11/3/21