WARNING! Ensure Health & Safety, local authority

and general workshop practice regulations are

adhered to when using this flywheel puller.

Familiarise yourself with the applications, limitations

and potential hazards of this flywheel puller.

Maintain the flywheel puller in good condition.

Replace or repair damaged parts. Use genuine

parts only. Unauthorised parts may be dangerous

and will invalidate the warranty.

Keep the work area clean, uncluttered and ensure

there is adequate lighting.

WARNING!Wear approved safety eye protection

(standard spectacles are not adequate).

Maintain correct balance and footing. Ensure the

floor is not slippery and wear non-slip shoes.

Remove ill fitting clothes. Remove ties, watches,

rings and other loose jewellery. Contain or tie back

long hair.

Wear appropriate protective clothing.

Ensure that the motorcycle is properly supported

and stable before using the flywheel puller.

Keep children and unauthorised persons away from

the working area.

DO NOT operate flywheel puller if parts are

damaged or missing as this may cause failure and/

or personal injury.

DO NOT use the flywheel puller for a task it was

not designed to perform.

DO NOT operate flywheel puller if you are tired, or

under the influence of alcohol, drugs or intoxicating

medication.

When not in use clean and store the flywheel puller

in a safe, dry, childproof location.

WARNING: The warnings, cautions and

instructions discussed in this instruction

manual cannot cover all possible conditions

and situations that may occur. It must be

understood that common sense and caution are

factors which cannot be built into this product,

but must be applied by the operator.

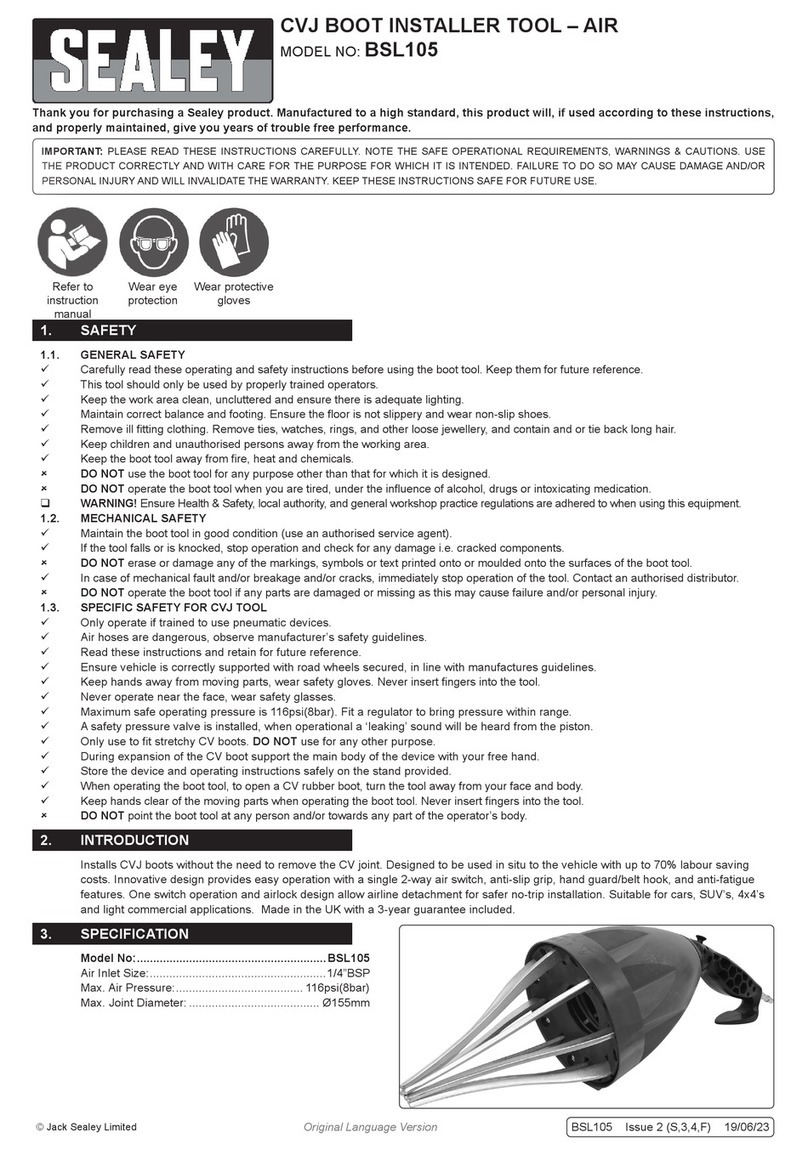

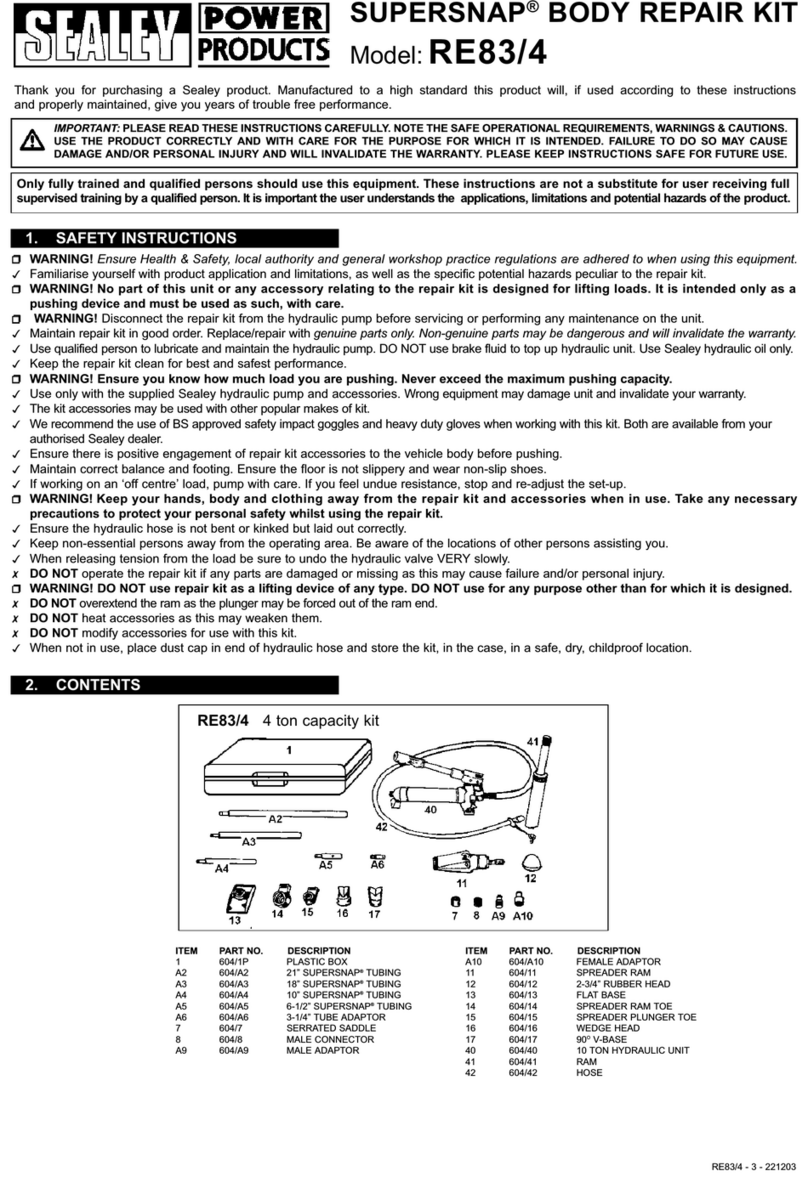

Designed with 6 different sized threaded adaptors for

flywheel rings on motorcycles. Models with tapered lock

type rings cannot be removed without the use of this

specialized tool. Suitable for most types of motorcycle.

Thread sizes: ............ M10 x 1.25R, M14 x 1.5R,

M16 x 1.5R, M18 x 1.25R, M24 x 1.0R, M27 x 1.0L

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

MOTORCYCLE FLYWHEEL PULLER

MODEL No: MS034

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

2. DESCRIPTION & SPECIFICATION

MS034 Issue No: 1 - 11/10/10

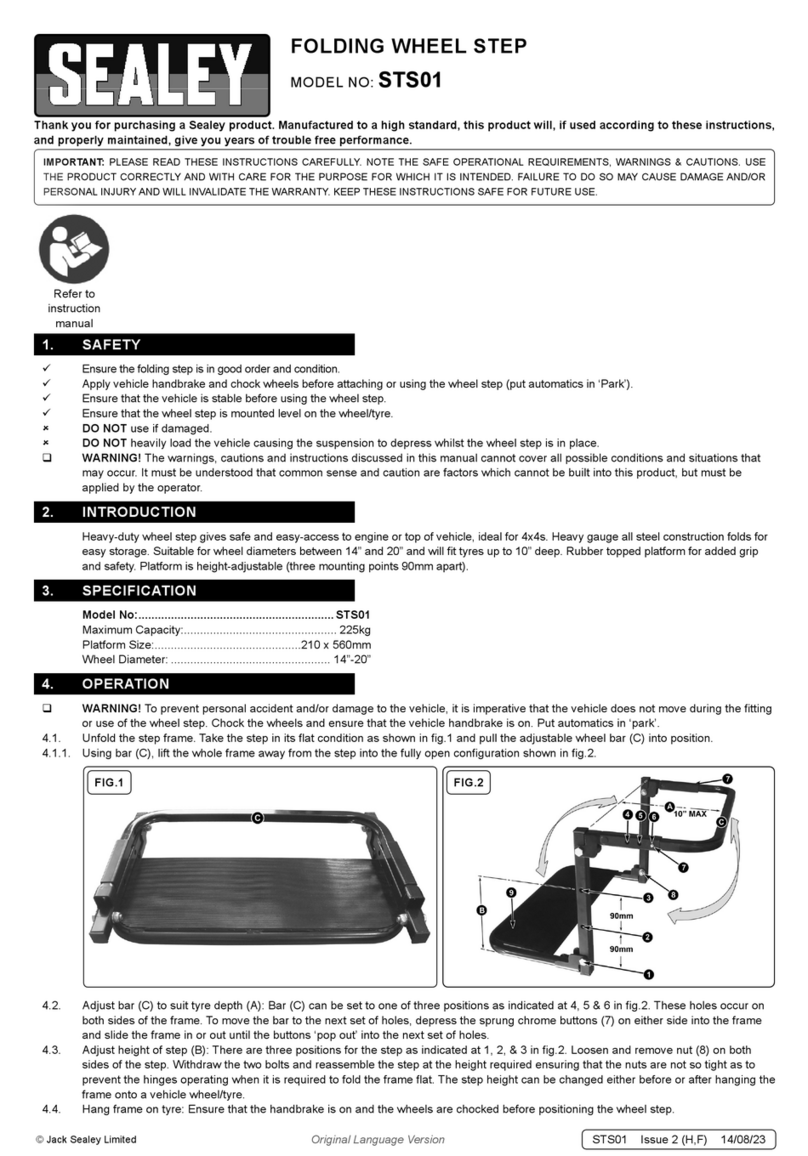

Before commencing work ensure that the

motorcycle is properly supported and stable before

using the flywheel puller.

3.1. Referring to the manufacturer's service manual

remove the engine side cover to reveal the

flywheel.

3.2. Prevent the flywheel from rotating using a

suitable proprietary tool to hold it steady. Loosen

and remove the flywheel retaining nut as

indicated in fig.2. Apply some penetrating oil to

the exposed end of the tapered crankshaft.

3.3. Inside the recess which accommodated the

retaining nut will normally be a left handed

female thread intended to accept a puller. Take

the double ended puller body and identify the

correct thread to use and carefully screw it into

position as indicated in fig.3.

3.4. Take the multi-threaded cross piece and screw

the smallest (M10) thread through the centre of

the puller body until it makes contact with the

end of the crankshaft as shown in fig.4.

3.5 . Place a 21mm spanner onto the flats on the

puller body to prevent the puller and flywheel

from rotating. Continue to screw the cross piece

into the puller body until the flywheel is released

from the tapered end of the crankshaft.

3. INSTRUCTIONS

Original Language Version

fig.1