INSTRUCTIONS FOR:

BUSH REMOVAL TOOL

(RENAULT LAGUNA)

MODEL:VSE4777

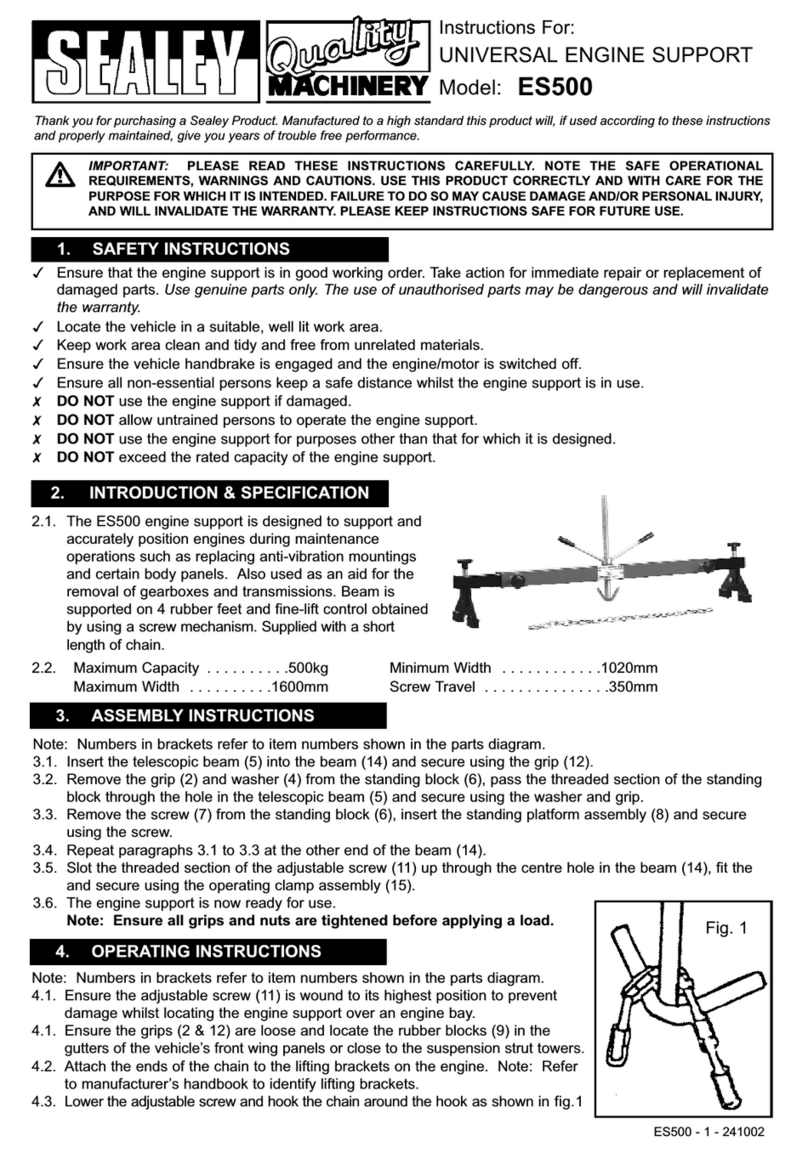

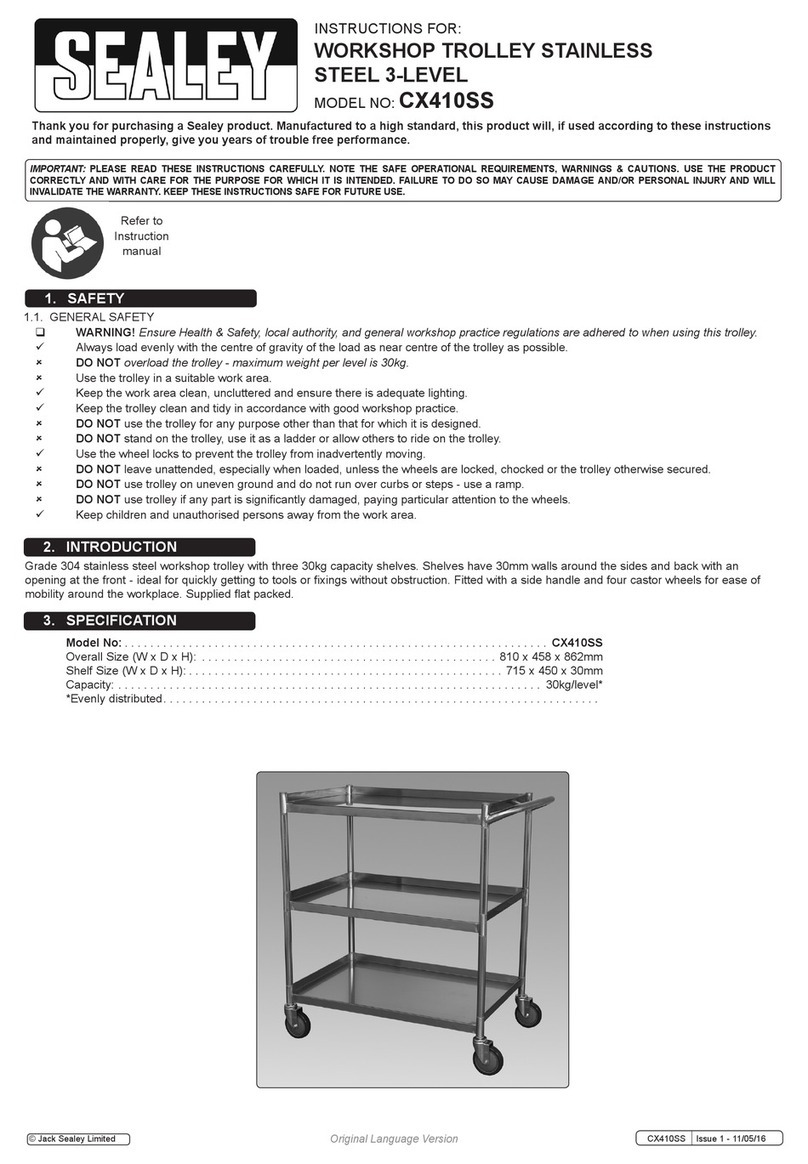

2. INTRODUCTION & APPLICATION

3. OPERATION

2.1 Introduction: Remove/Install front mounting bushes in Laguna

rear sub-frame. Can be used in situ – no need to remove

subframe from vehicle.

Applications: Renault Laguna, 2001 onwards.

vehicle it will be necessary to lower it to gain access to both sides

of the bush housing.

3.3 Remove the rear wheels, the brake pipe retaining plate, the left- and

right-hand bush retaining brackets and the lower shock absorber

bolts. For a detailed and up to date breakdown of this procedure

refer to the vehicle manufacturer’s service instructions, or a

proprietary manual.

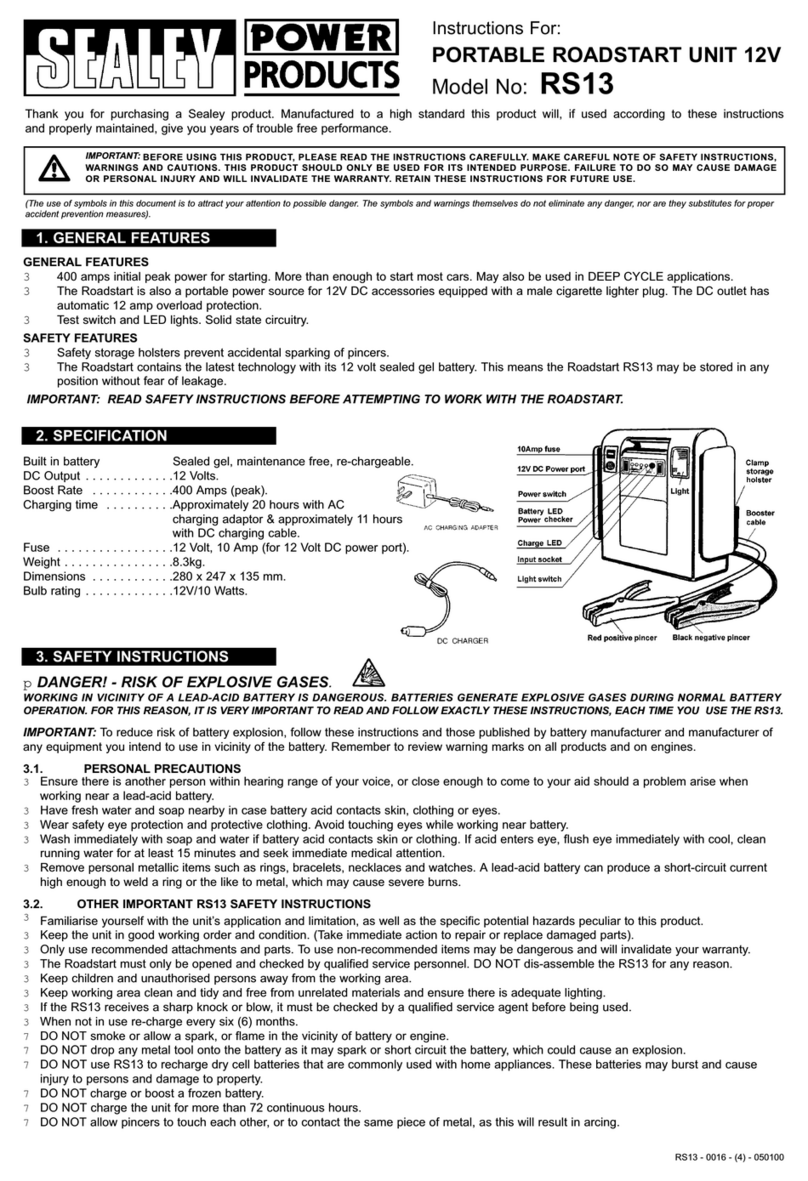

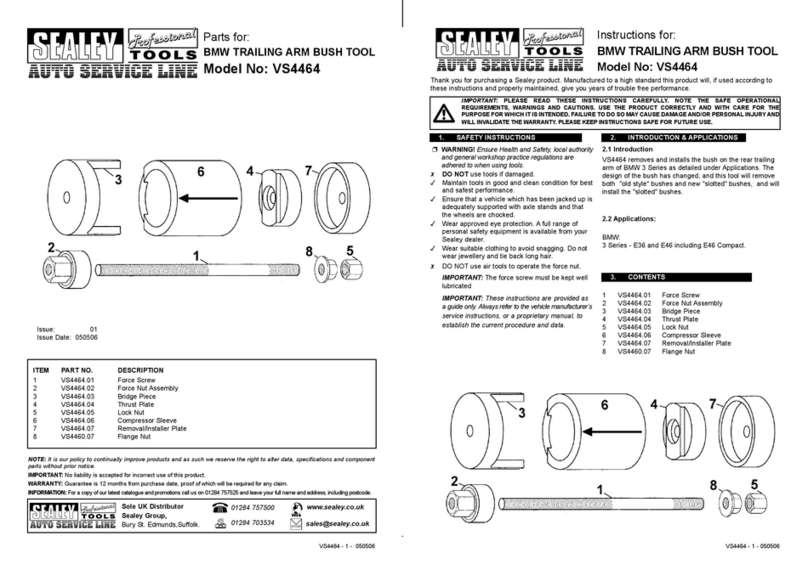

3.4 To remove the old bush assemble the tool onto the bush and sub-

frame as shown in Fig.2. Ensure that the threaded rod 3is well

lubricated prior to assembly. Hold the flange nut 1with a 24mm ring

spanner. Using a ratchet wrench with a 24mm deep socket turn the

nut on the force nut assembly 5 clockwise to drive the bush out of

its housing. The bush will come out more easily if penetrating oil has

been applied to the bush housing prior to removal.

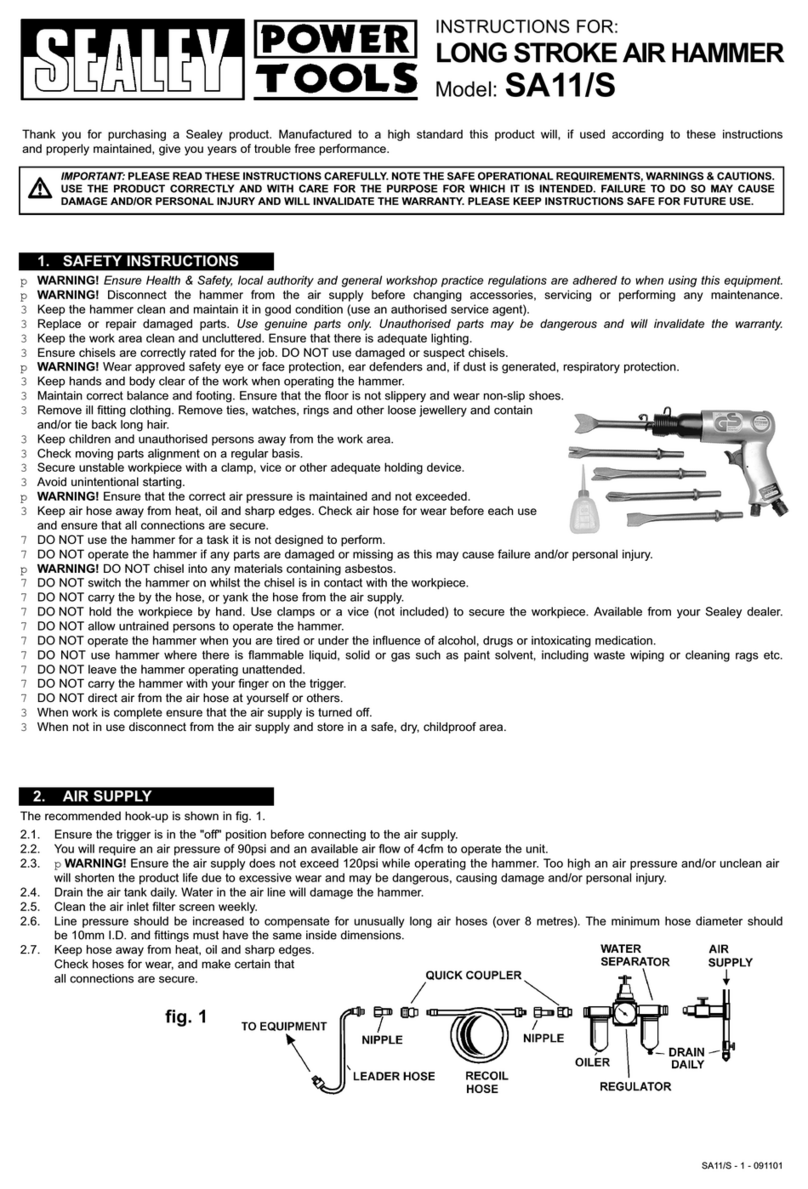

3.5 To insert the new bush, assemble the tool and bush onto the

sub-frame as shown in Fig.3. Ensure that the threaded rod 3is well

lubricated prior to assembly. Hold the hex nut 1with a 24mm ring

spanner. Using a ratchet wrench with a 24mm deep socket turn

the nut on the force nut assembly 5clockwise to drive the bush into

the compression sleeve 4.

WARNING! Ensure Health and Safety, local authority and general

workshop practice regulations are adhered to when using tools.

DO NOT use tools if damaged.

Maintain tools in good and clean condition for best and safest

performance.

Ensure that the vehicle which has been jacked up is adequately

supported with axle stands.

Wear approved eye protection. A full range of personal safety

equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery

and tie back long hair.

Account for all tools, locking bolts, pins and parts being used and

do not leave them in or near the engine.

DO NOT use an impact wrench with this tool.

IMPORTANT: Refer to the vehicle manufacturer’s service

instructions, or a proprietary manual, to establish the current

procedure and data.

1. SAFETY INSTRUCTIONS

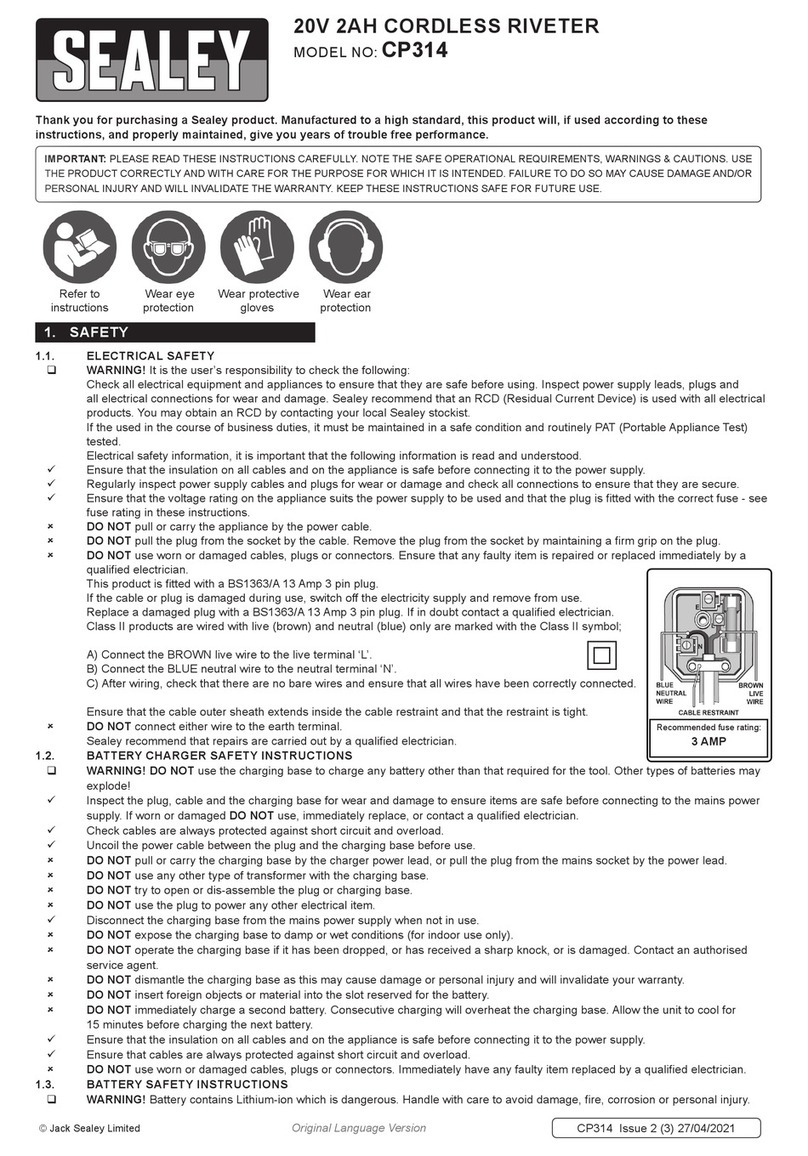

ITEM PART NO: DESCRIPTION

1 VSE4777.01 FLANGE NUT

2 VSE4777.02 BRIDGE PIECE

3 VSE4777.03 FORCE SCREW

4 VSE4777.04 COMPRESSOR SLEEVE

5 VSE4777.05 FORCE NUT ASSEMBLY

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Fig.1

Fig.2

Fig.3

DO NOT USE AN IMPACT WRENCH WITH THIS TOOL.

3.1 Ensure that the vehicle is adequately supported on axle stands

before working under the vehicle.

3.2 Although there is no need to remove the subframe from the

Original Language Version VSE4777 Issue: 2 - 23/08/11